Adjustable footwear sole construction

a technology of sole construction and adjustable sole, which is applied in the direction of bootlegs, uppers, heels, etc., can solve the problems of increasing the cost of manufacture and assembly, complicated design and manufacture of footwear, and tendency to pronate, and achieves simple and effective construction, facilitates cushion insert adjustment, and is easy to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

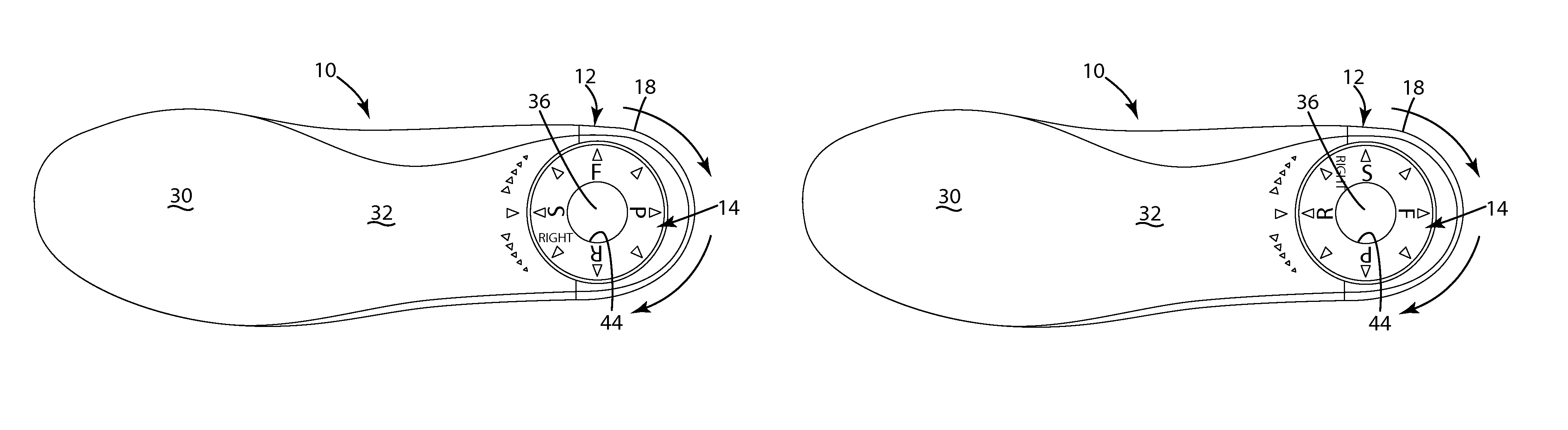

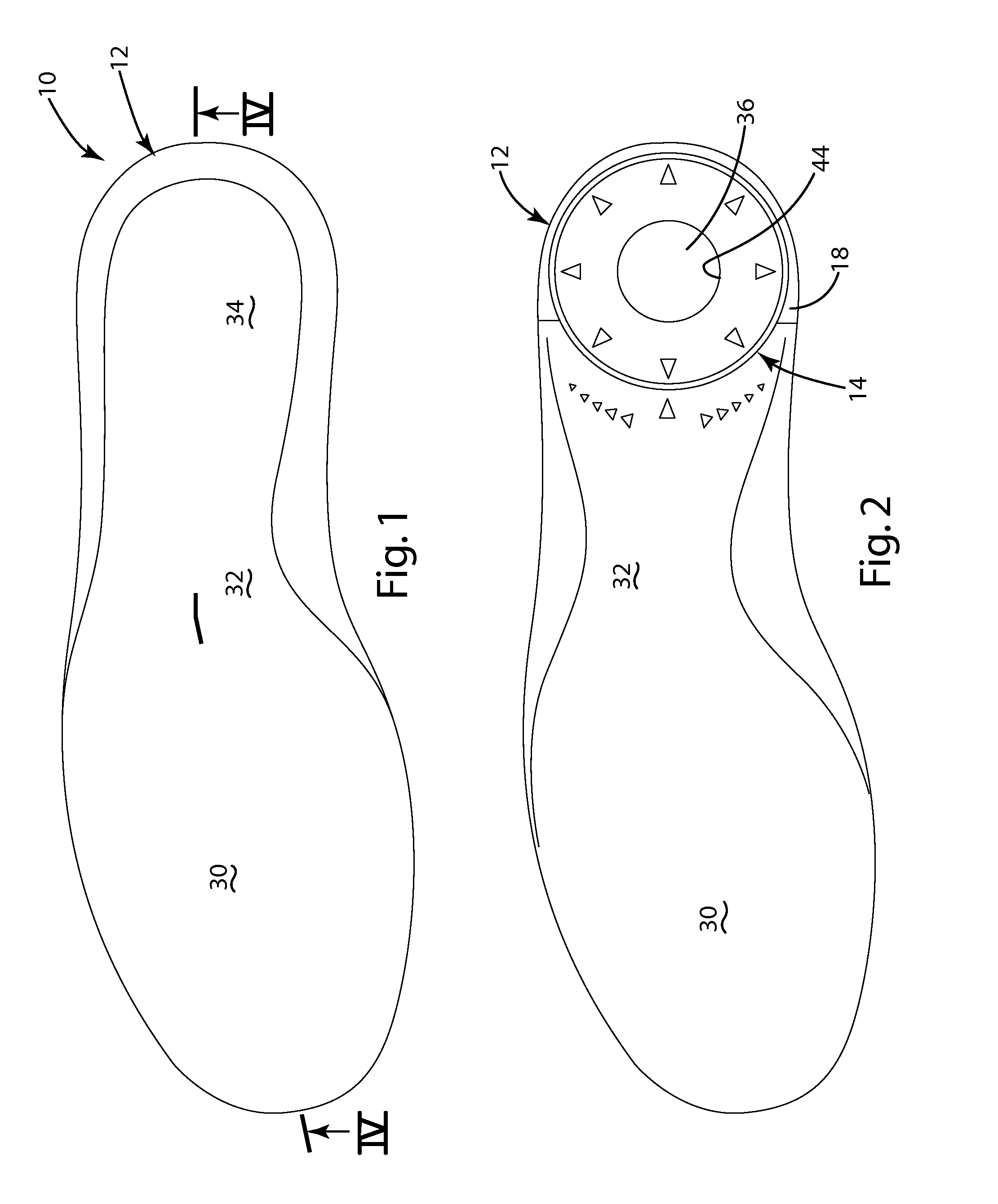

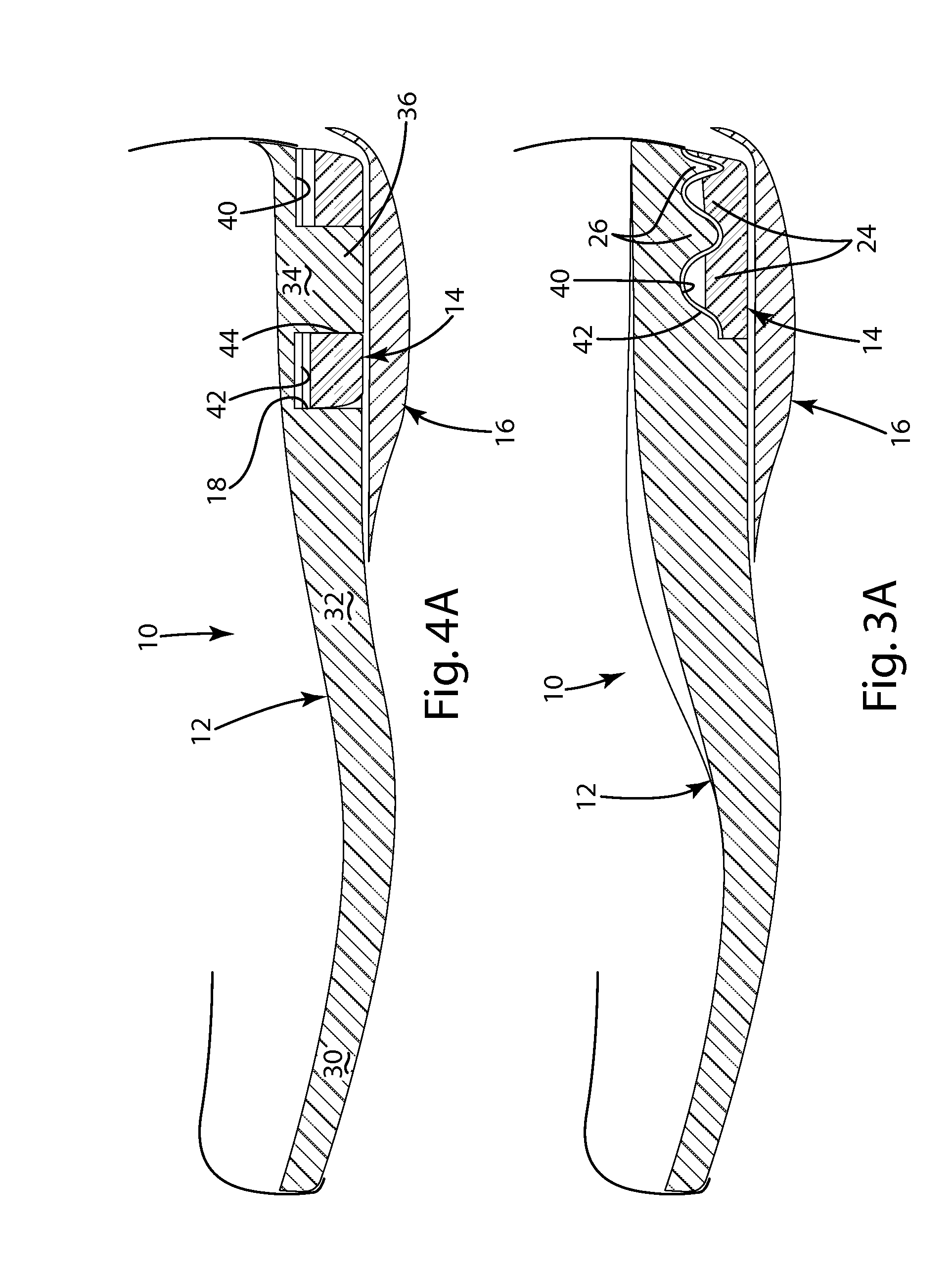

[0087]A sole construction in accordance with an embodiment of the present invention is shown in FIGS. 1-11 and generally designated 10. The illustrated embodiment generally includes a midsole 12, a cushion insert 14 and a heel wedge 16. The midsole 12 defines a receptacle 18 adapted to receive the cushion insert 14. The heel wedge 16 is positioned below the midsole 12 / cushion insert 14 combination. The top surface 20 of the cushion insert 14 includes a plurality of lobes 24 and the bottom surface 22 of the receptacle 18 includes a plurality of lobes 26. The lobes 24 and 26 may be of different shapes so that they provide different support / cushioning characteristics. The lobes 24 and 26 are interfitted when the cushion insert 14 is installed in the receptacle 18. The components may be seated within essentially any article of footwear. For purposes of disclosure, the present invention is described in connection with a midsole construction. The present invention may, however, be integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com