Microstructure manufacturing method

a manufacturing method and microstructure technology, applied in the direction of liquid/solution decomposition chemical coating, instruments, imaging devices, etc., can solve the problems of difficult to obtain a desirable phase image, difficult to obtain an image of soft material or soft tissue using these techniques, and more places of sticking of periodic structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first example

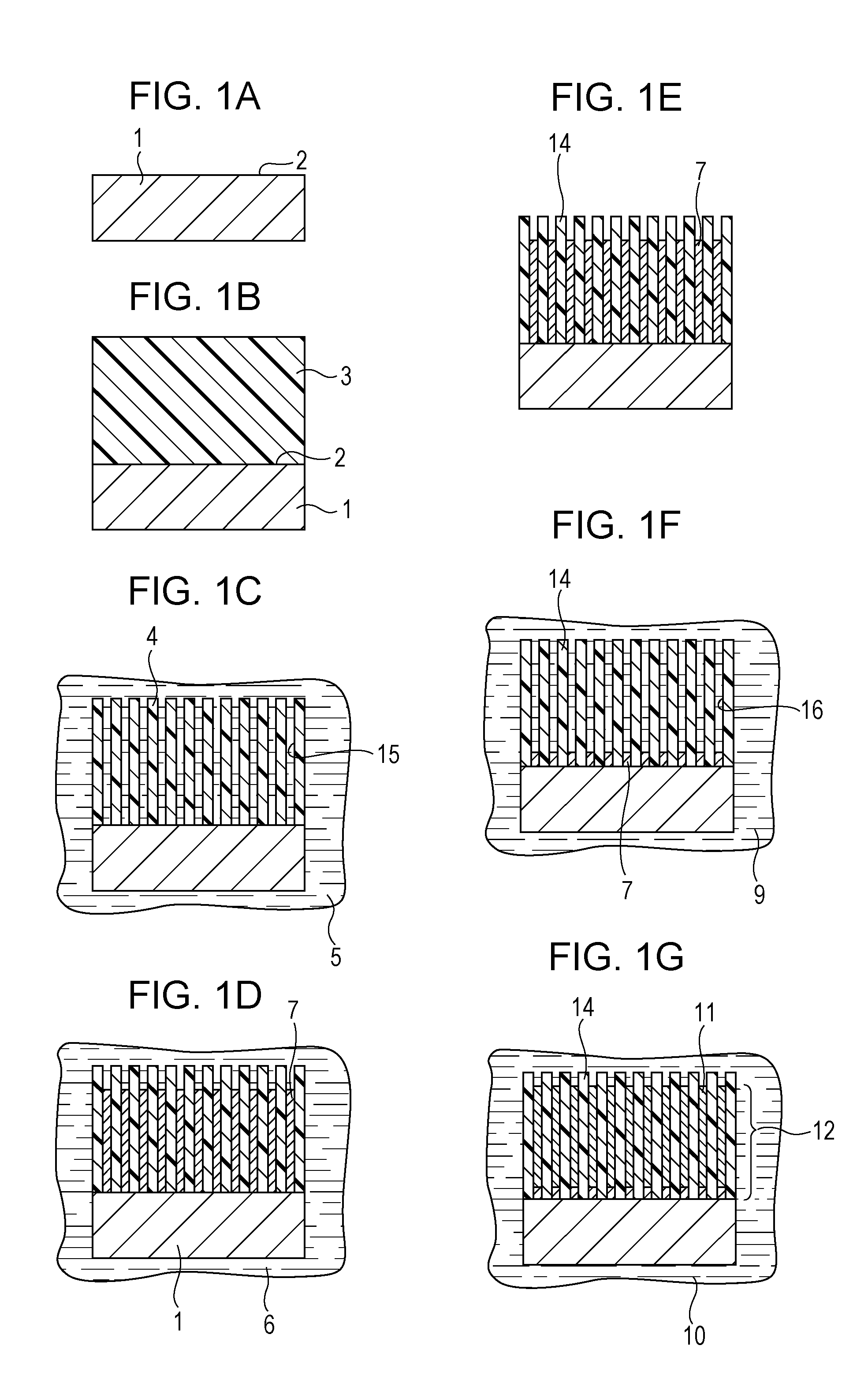

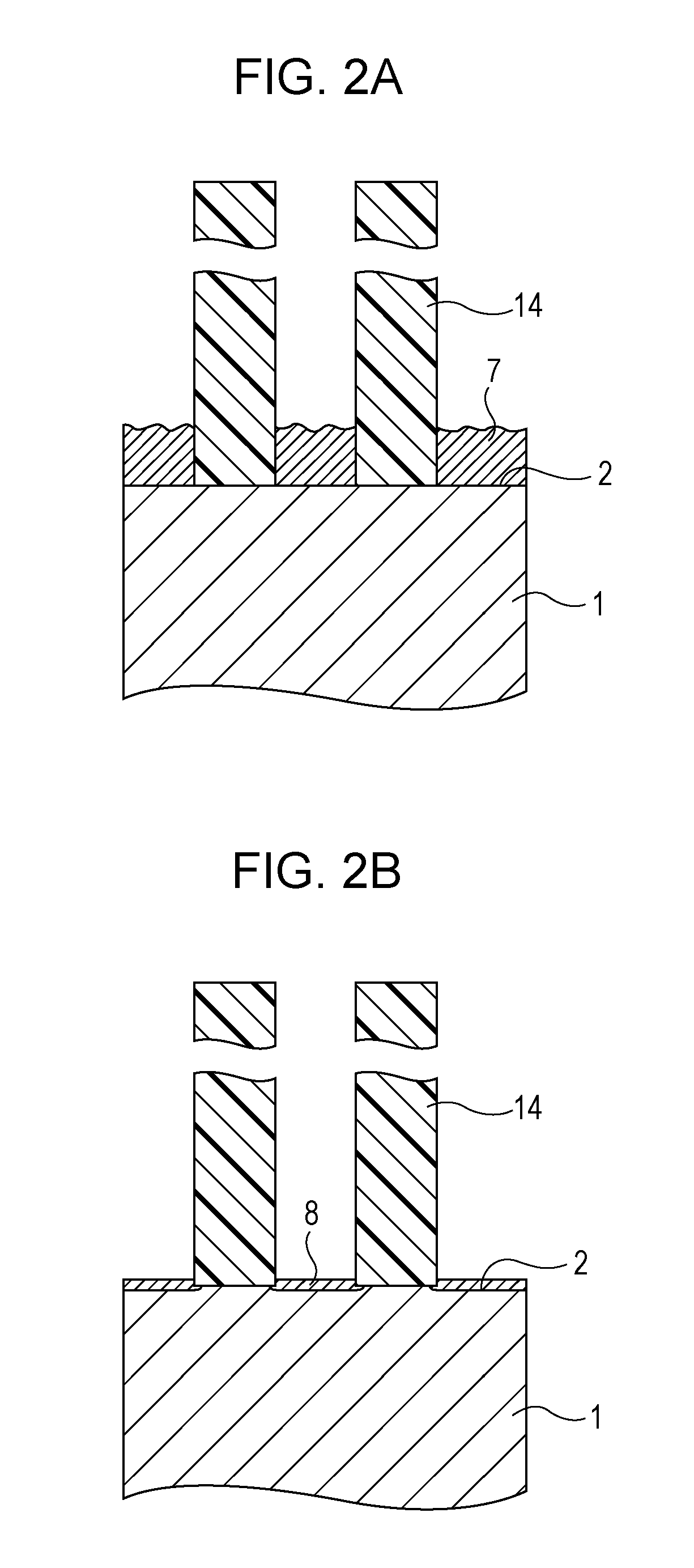

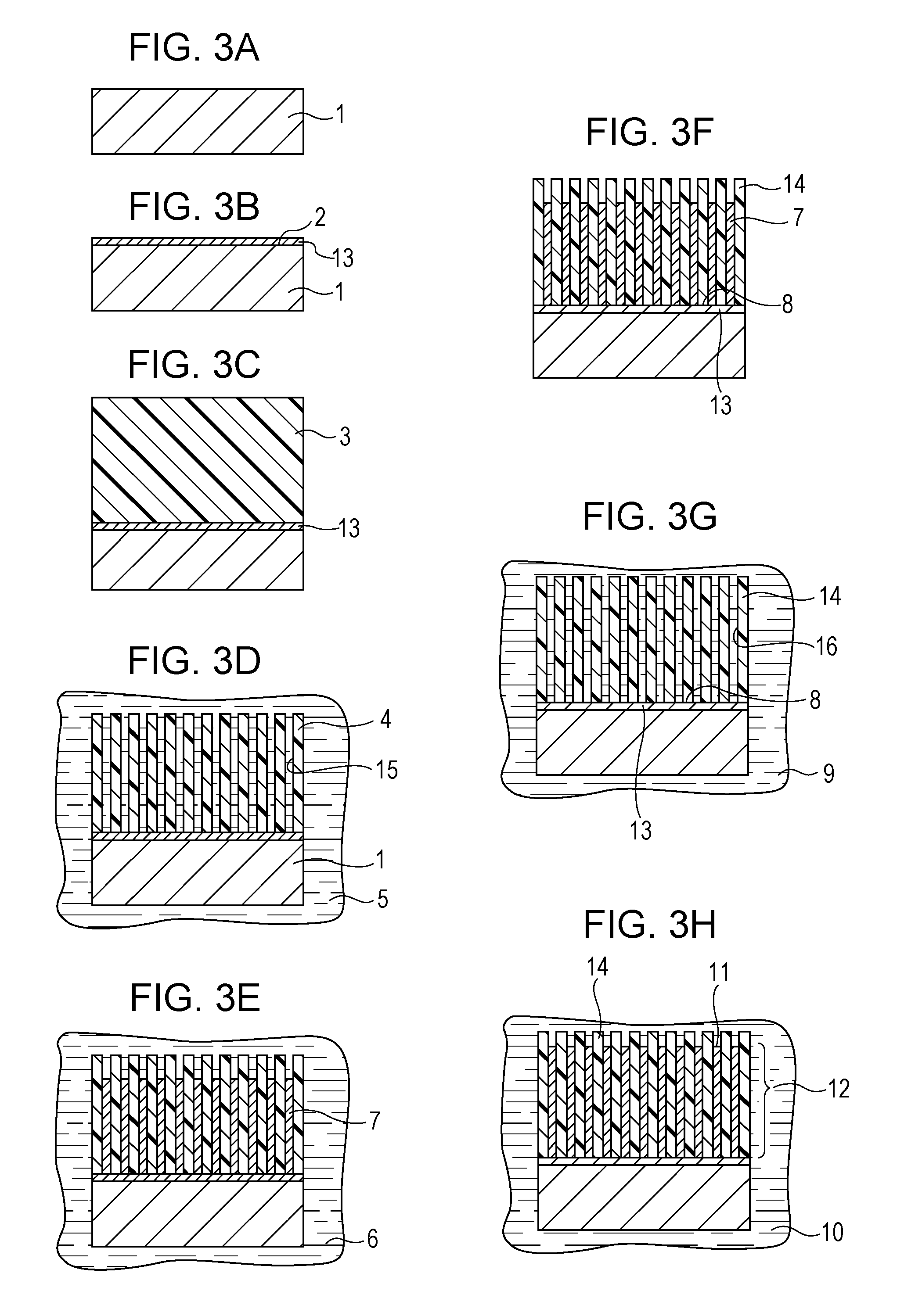

[0050]FIGS. 3A to 3h illustrate a first example according to the microstructure manufacturing method of the present invention.

[0051]In the present example, a silicon wafer is used as the substrate 1 (FIG. 3A). The wafer is double sided, and its diameter is 4 inches and its thickness is 525 μm. A titanium film with a thickness of 5 nm and a gold film with a thickness of 100 nm are formed sequentially in this order on the substrate 1 as the electrically conductive layer 13 by an electron beam deposition apparatus (FIG. 3B).

[0052]The negative resist of SU-8 (manufactured by KAYAKU Micro Chemical Co., Ltd) is used as the photosensitive resin. The SU-8 is applied on the electrically conductive layer 13, and a photosensitive resin layer 3 with a thickness of 40 μm is formed, the photosensitive resin layer 3 is soft-baked at 95° C. for ten minutes (FIG. 3C). Next, the photosensitive resin layer 3 is exposed to ultraviolet light by MPA600 (manufactured by Canon), and the exposed photosensit...

second example

[0060]FIGS. 4A to 4H illustrate a second example according to the microstructure manufacturing method of the present invention.

[0061]In the present example, a silicon wafer is used as the substrate 1 (FIG. 4A). The wafer is double sided, and its diameter is 4 inches and its thickness is 525 μm. A chromium film with a thickness of 5 nm and a platinum film with a thickness of 100 nm are formed sequentially in this order on the substrate 1 as the electrically conductive layer 13 by a vacuum sputtering apparatus (FIG. 4B).

[0062]The negative resist of SU-8 (manufactured by KAYAKU Micro Chemical Co., Ltd) is used as the photosensitive resin. The SU-8 is applied on the electrically conductive layer 13, and a photosensitive resin layer 3 with a thickness of 60 μm is formed, the photosensitive resin layer 3 is soft-baked at 95° C. for ten minutes (FIG. 4C). Next, the photosensitive resin layer 3 is exposed to synchrotron radiation light by X-ray exposure apparatus, and the exposed photosensi...

third example

[0068]FIGS. 5A to 5g illustrate a third example according to the microstructure manufacturing method of the present invention.

[0069]In the present example, a stainless plate is used as the substrate 1 (FIG. 5A). The substrate 1 includes the substrate surface 2 which has electrical conductivity. The negative resist of SU-8 (manufactured by KAYAKU Micro Chemical Co., Ltd) is used as the photosensitive resin. The SU-8 is applied on the stainless plate, and a photosensitive resin layer 3 with a thickness of 60 μm is formed, the photosensitive resin layer 3 is soft-baked at 95° C. for ten minutes (FIG. 5B). Next, the photosensitive resin layer 3 is exposed to synchrotron radiation light by X-ray exposure apparatus, and the exposed photosensitive resin layer 3 is baked at 65° C. for five minutes. A latent image is formed in the photosensitive resin layer 3 in such a manner that a square pole pattern 2 μm on a side is two-dimensionally arranged at the 4 μm pitch. The latent image is develo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com