Friction stir welding apparatus

a technology of friction stir and welding apparatus, which is applied in welding apparatus, metal-working apparatus, manufacturing tools, etc., can solve the problems of not knowing the size of the probe to be used, not knowing the cleaning method with respect to the rotatable probe, etc., and achieves the effect of reliable detection, simple configuration and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]A friction stir welding apparatus according to an embodiment of the present invention is explained in detail below with reference to the accompanying drawings. In the drawings, an x-axis, a y-axis, and a z-axis constitute a three-axis orthogonal coordinate system. A plane defined by the x-axis and the y-axis is parallel to a horizontal plane, and a normal direction of the z-axis is an upward direction.

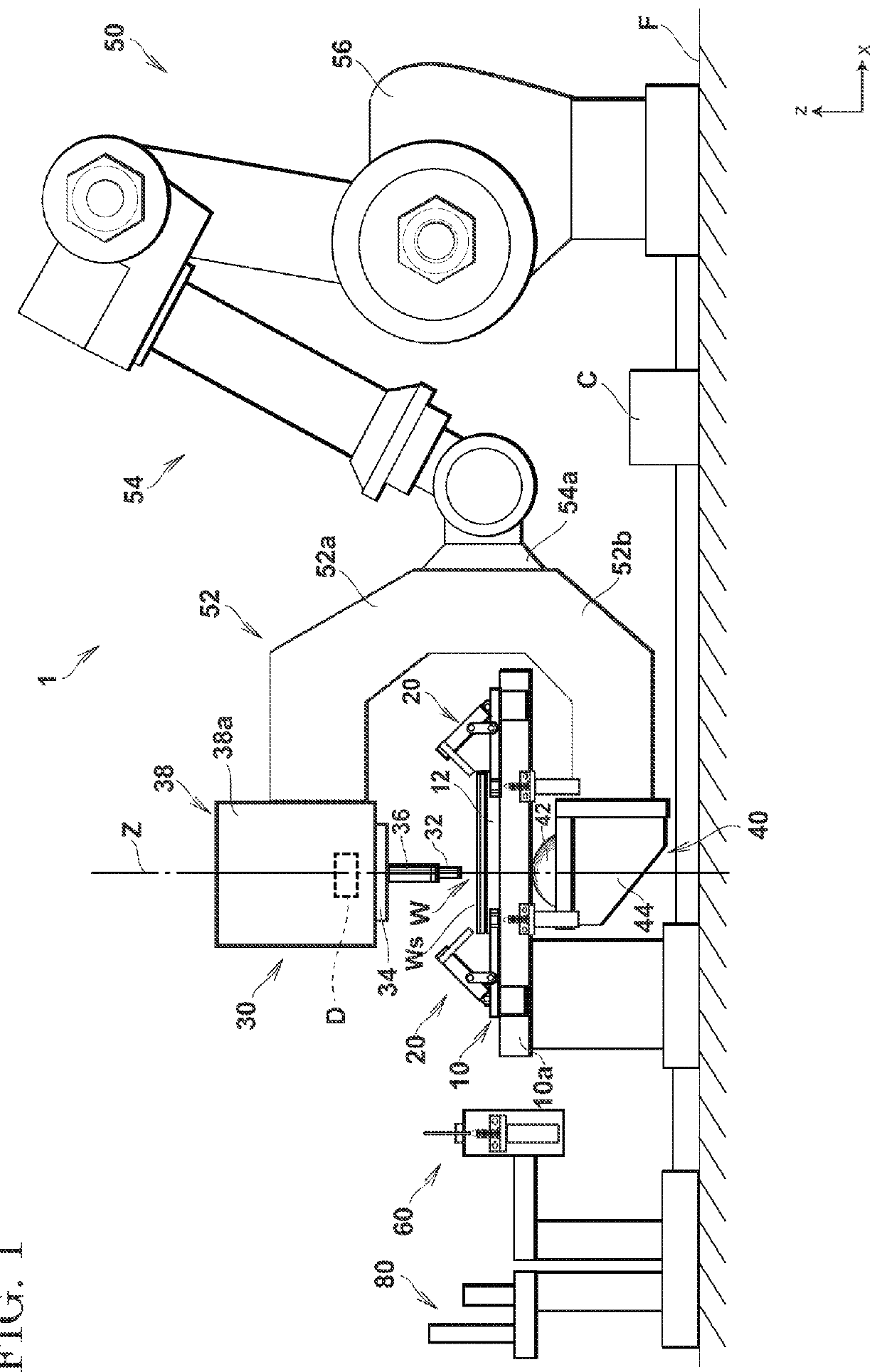

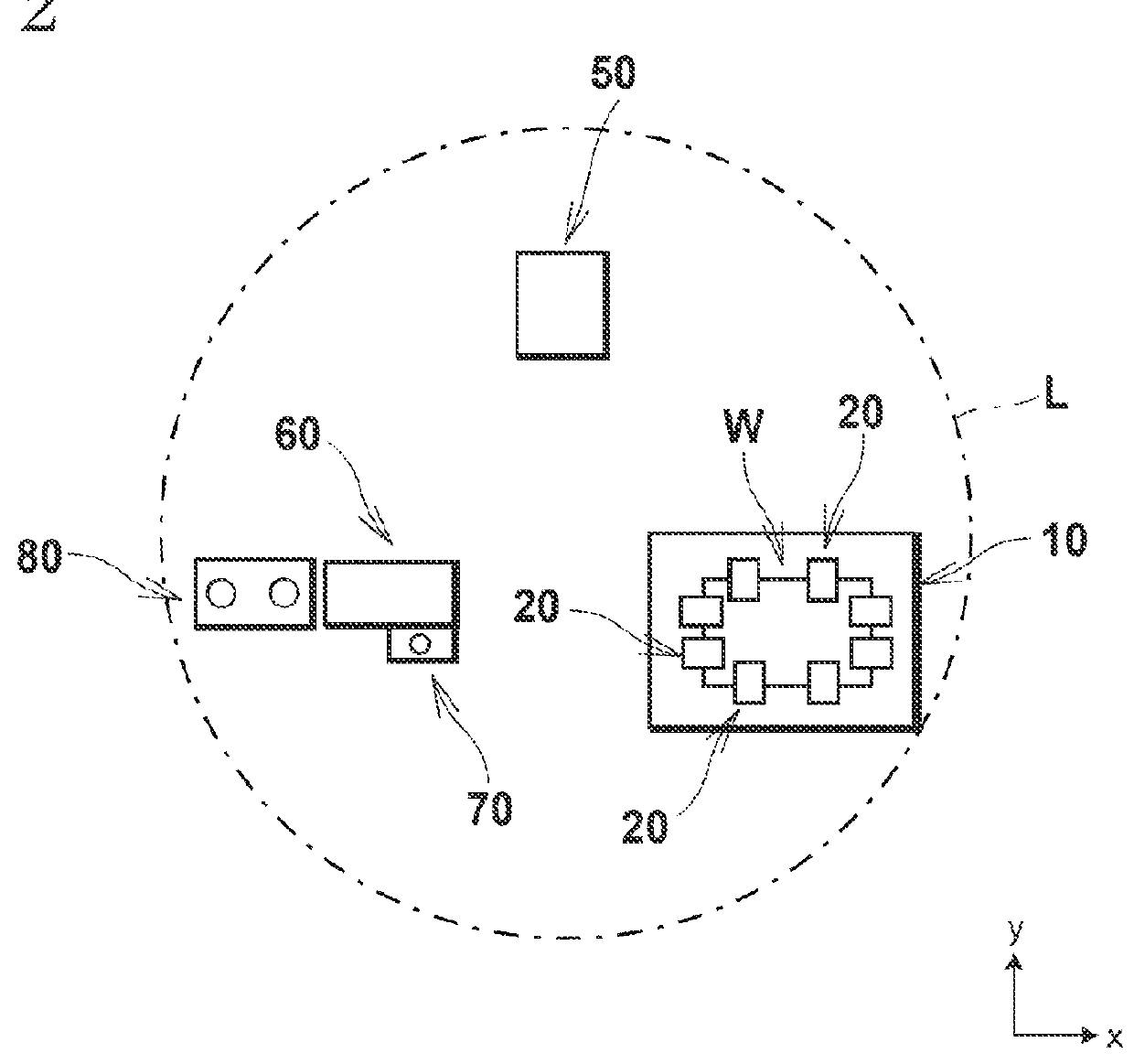

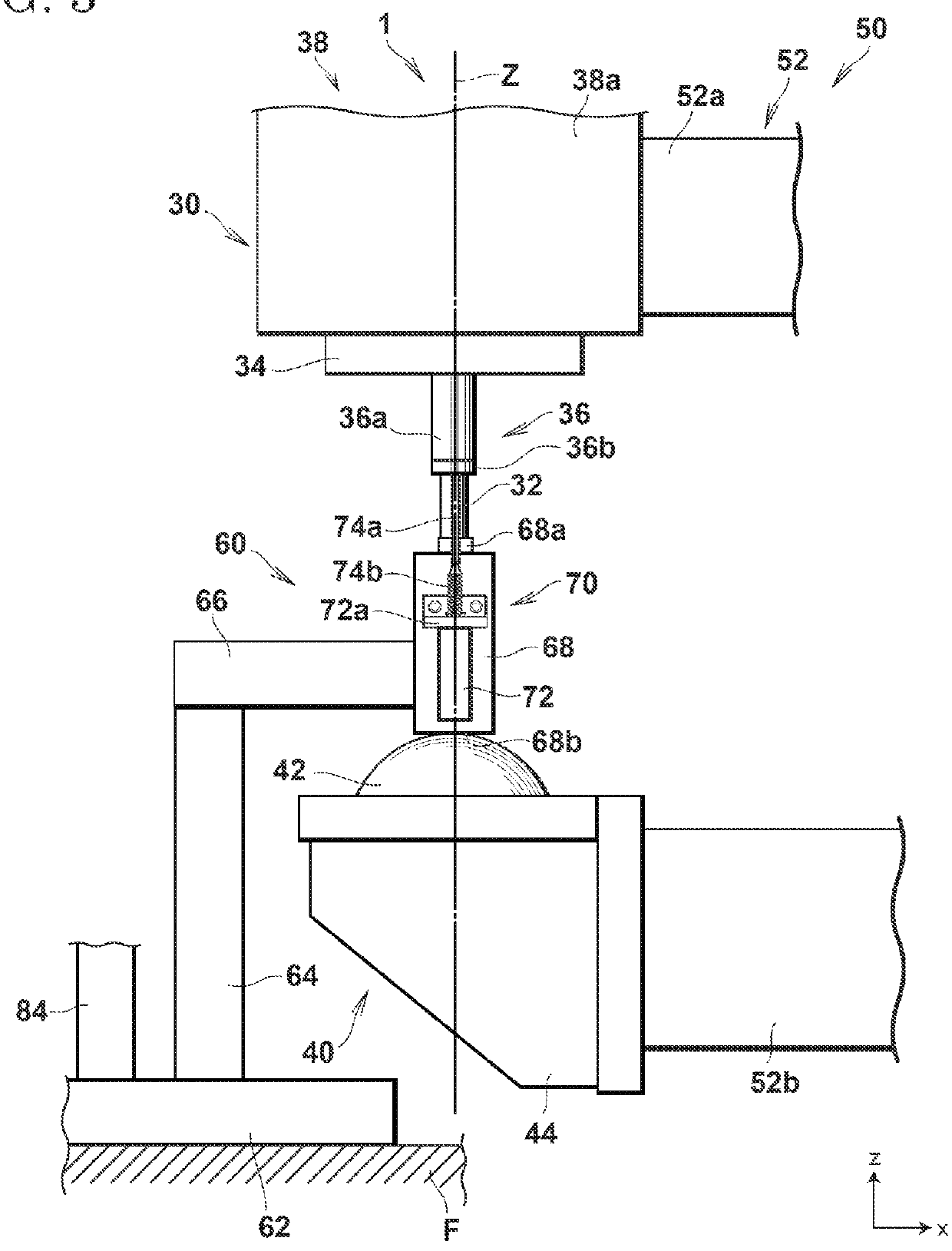

[0042]A configuration of the friction stir welding apparatus according to the present embodiment is explained in detail with reference to FIGS. 1 to 7.

[0043]FIG. 1 is a side view showing an overall configuration of the friction stir welding apparatus according to the present embodiment. FIG. 2 is a schematic top view showing an arrangement range of respective constituent elements of the friction stir welding apparatus according to the present embodiment. FIG. 3 is a partial enlarged side view showing a probe detection mechanism of the friction stir welding apparatus according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com