Vacuum storage container

a vacuum storage container and vacuum technology, applied in the field of vacuum storage containers, can solve the problem that conventional mechanical vacuum storage containers cannot automatically pump out air, and achieve the effects of high rotational conversion efficiency, fast vacuum creation, and superior performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

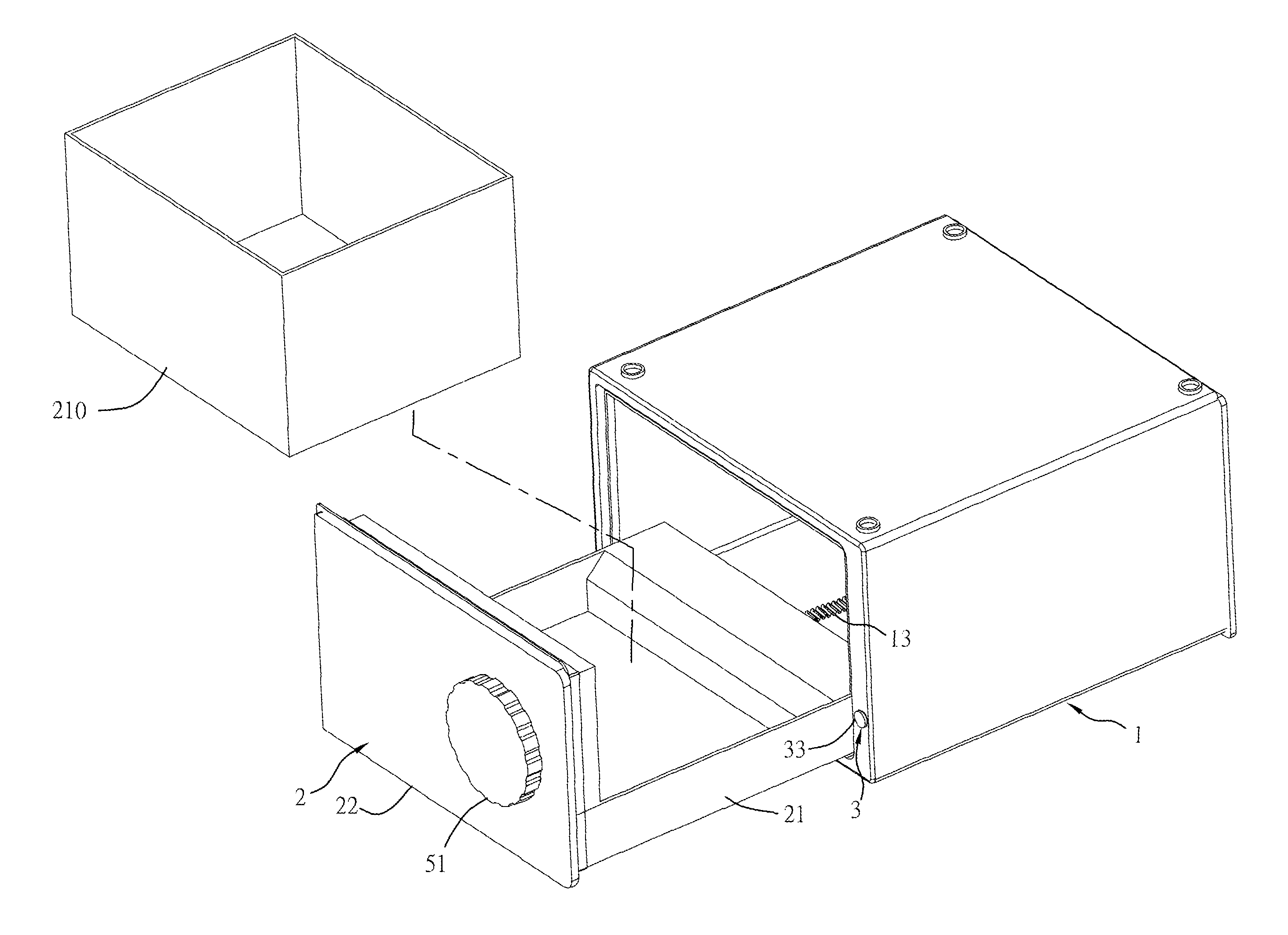

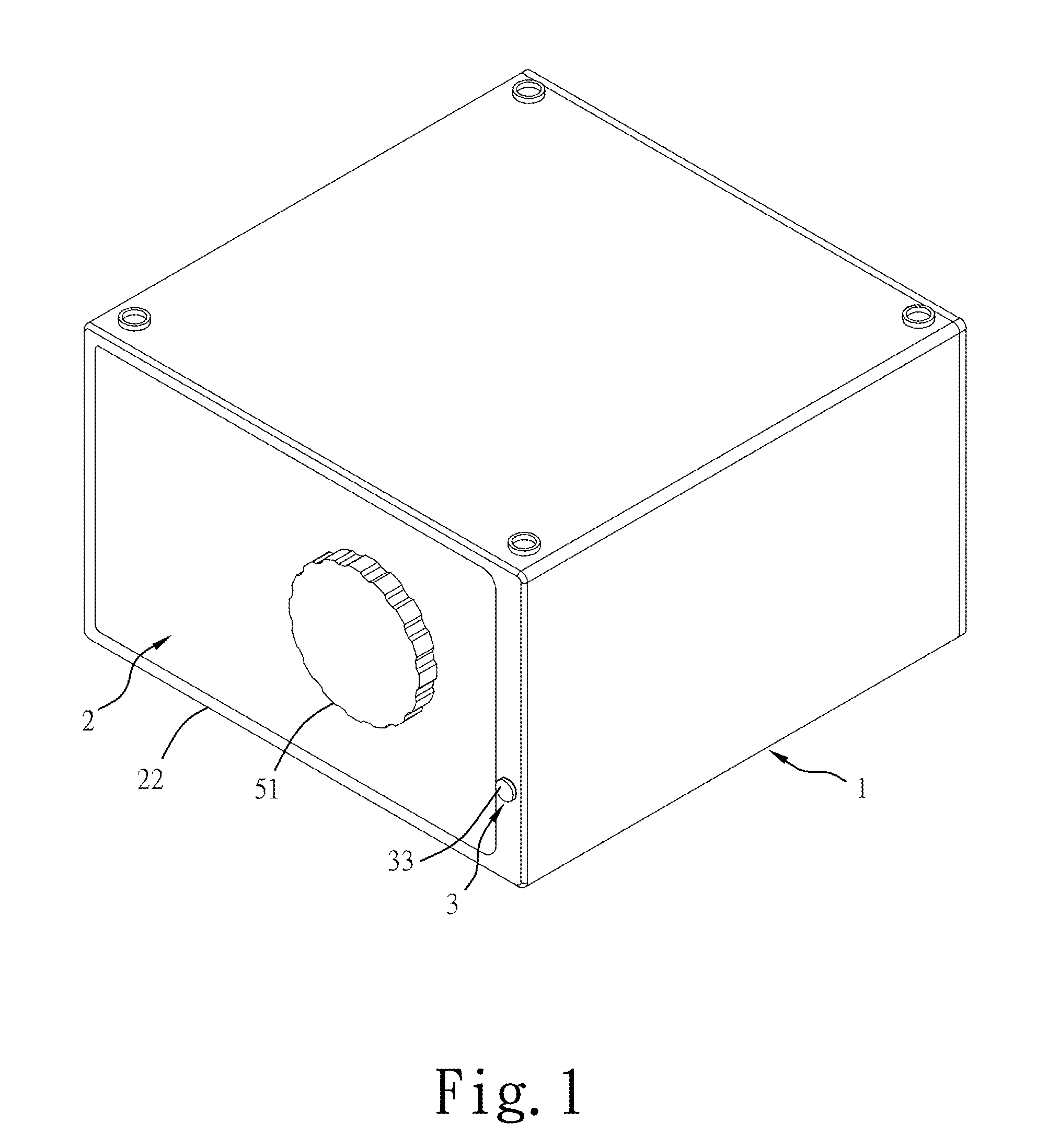

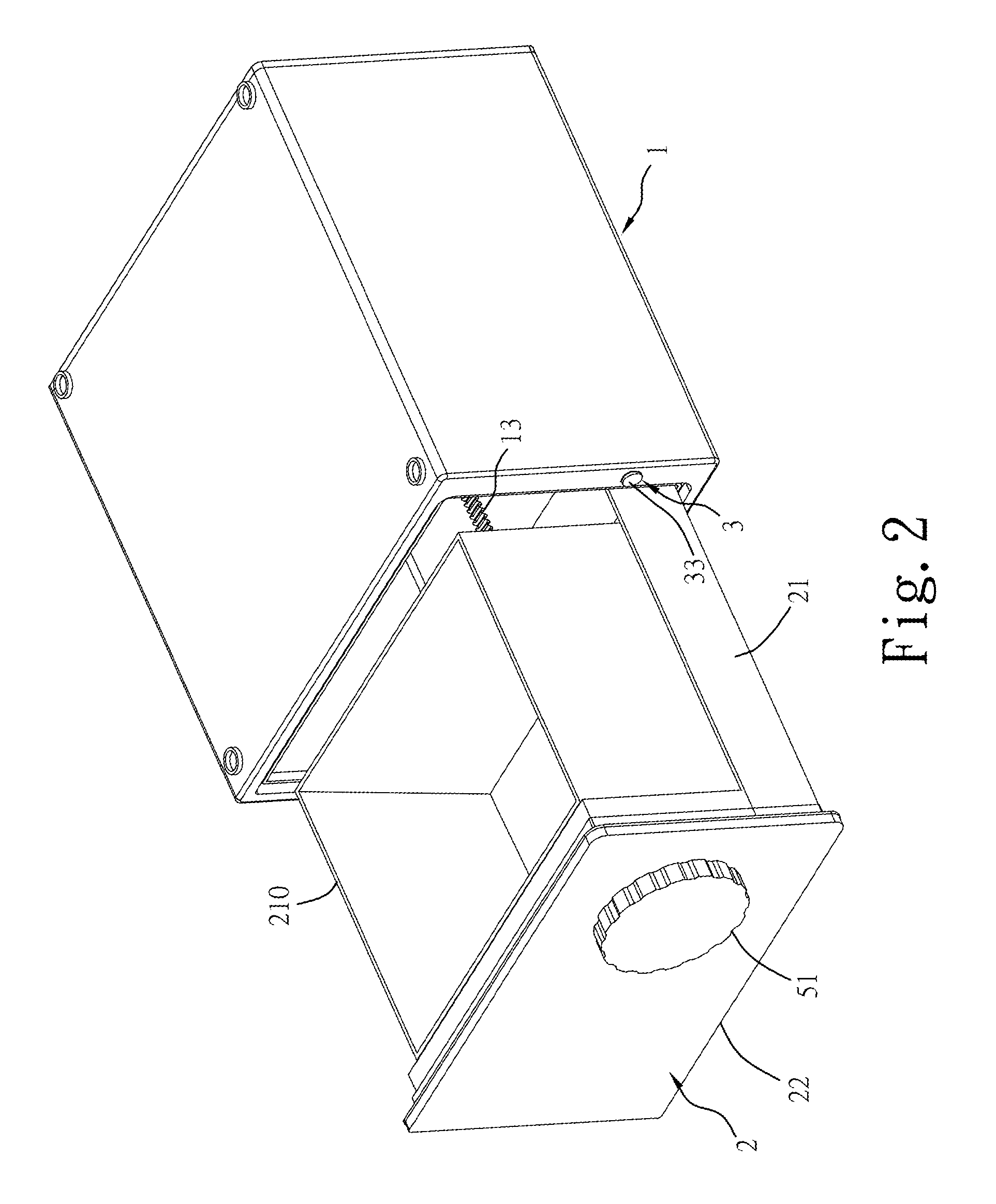

[0030]Referring to FIGS. 1-15, a vacuum storage container in accordance with the present invention is shown. The vacuum storage container comprises a container housing 1 and a drawer 2.

[0031]The container housing 1 is configured for accommodating a drawer 2, enabling the accommodated drawer 2 to be moved in and out between a closed position and an open position. The container housing 1 comprises an operating member control mechanism 3 for locking the drawer 2, for enabling the drawer 2 to be automatically ejected out from the closed position to the open position by an ejection mechanism A (see FIGS. 6-9 and FIGS. 11-14).

[0032]The drawer 2 comprises a drawer body 21 slidably inserted into the container housing 1 (see FIG. 2 and FIG. 3), a door cover 22 located at a front side of the drawer body 21, a rotary knob 51 pivotally mounted in an outer side of the door cover 22 and having a center shaft 511(see FIG. 4) inserted through the door cover 22, a clockwork 52 (see FIG. 4 and FIG. 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com