Pivoting shelf

a shelf and rotating technology, applied in the field of shelves, can solve the problems of insufficient number of carts, high price of carts, and difficulty in making use of hand sanitizers by hospital staff, and achieve the effect of facilitating repair and maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]In this specification and in the claims, the use of the article “a”, “an”, or “the” in reference to an item is not intended to exclude the possibility of including a plurality of the item in some embodiments of the invention. It will be apparent to one skilled in the art in at least some instances in this specification and the attached claims that it would be possible to include a plurality of the item in at least some embodiments of the invention.

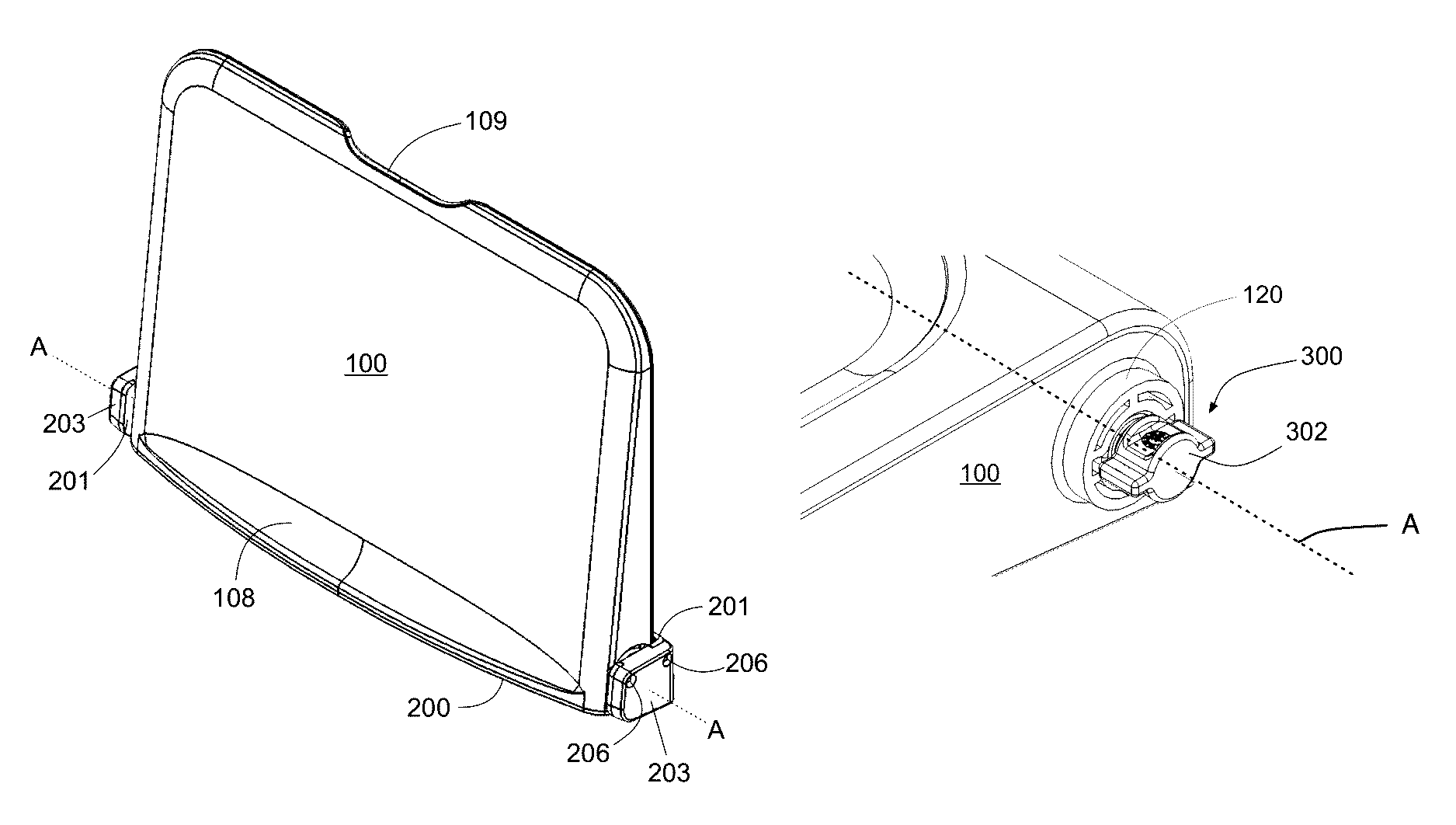

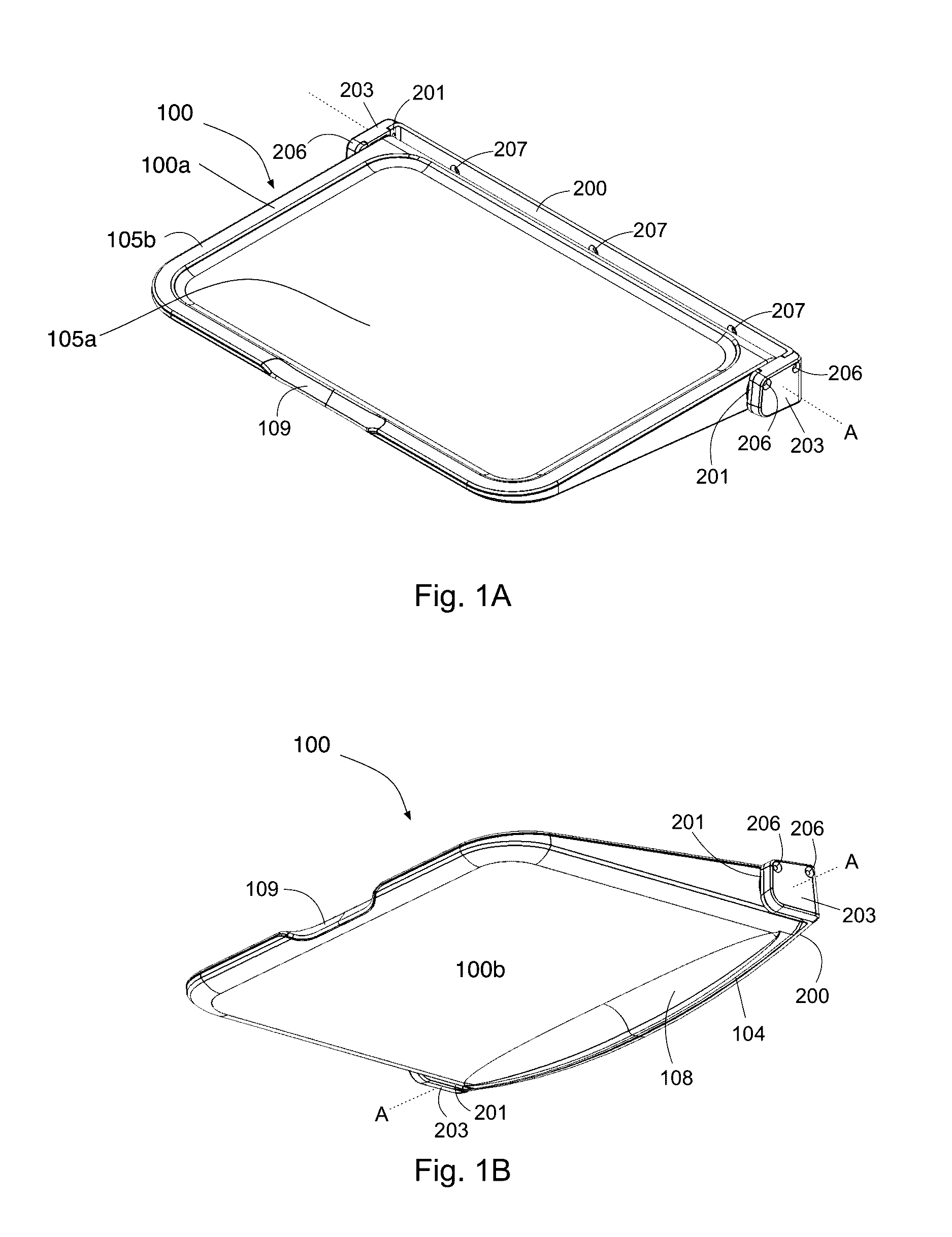

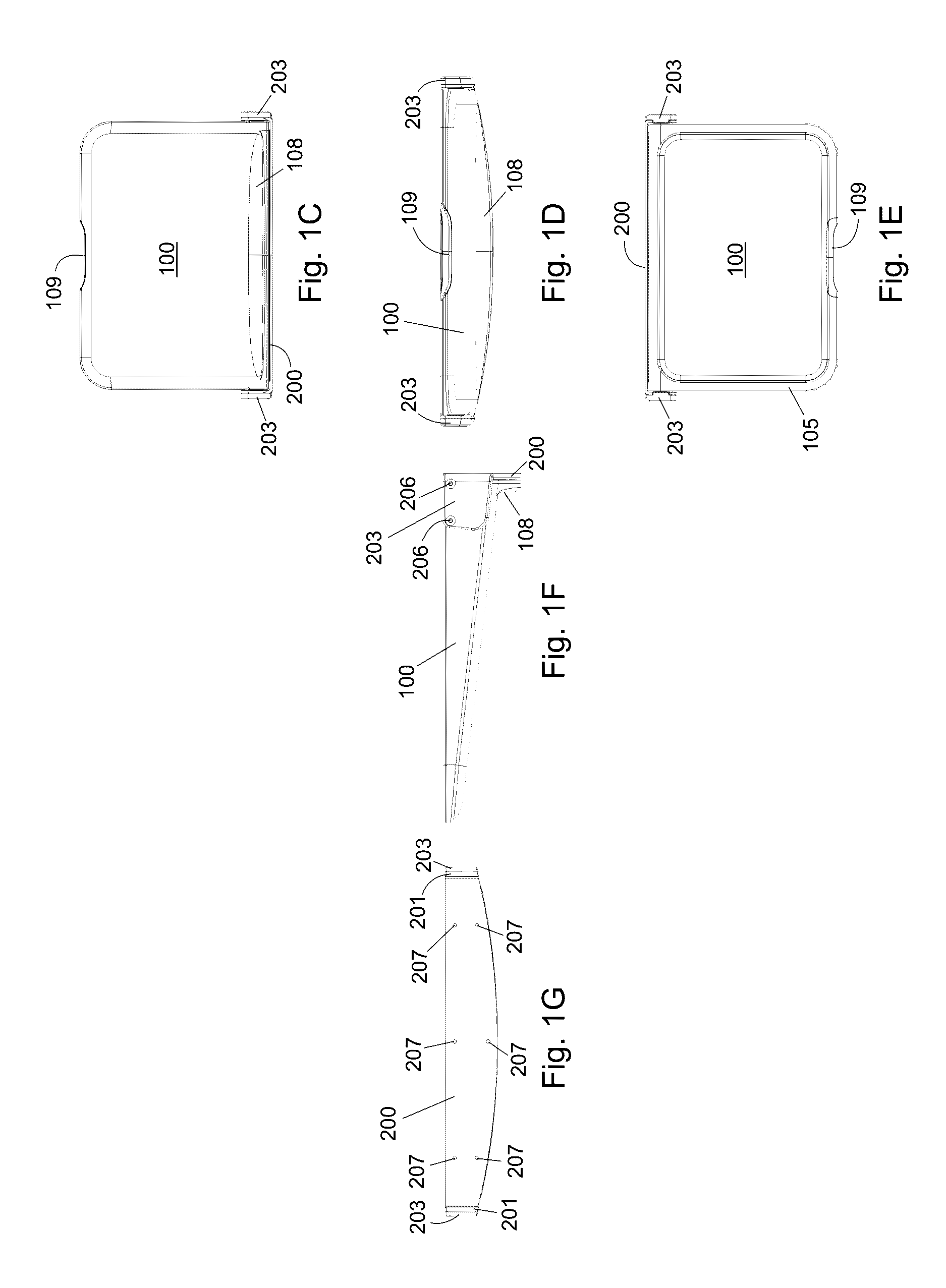

[0059]A pivoting shelf assembly in accordance with an embodiment of the present invention is depicted in an open horizontal position in FIGS. 1A-1G and FIG. 3A and in a closed upwardly vertical position in FIGS. 2A-2G and FIG. 3B. The shelf assembly comprises a shelf 100 supported between bracket ears 201 of a mounting bracket 200. The shelf 100 comprises spaced-apart upper and lower surfaces, a front end, a rear end and two opposed side edges. The upper surface is shown at 105 of the shelf 100 and comprises a central depression 105a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com