Method of manufacturing disposable underpants by applying annular adhesive zones to the backsheet and top sheet for retaining elastic for leg holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

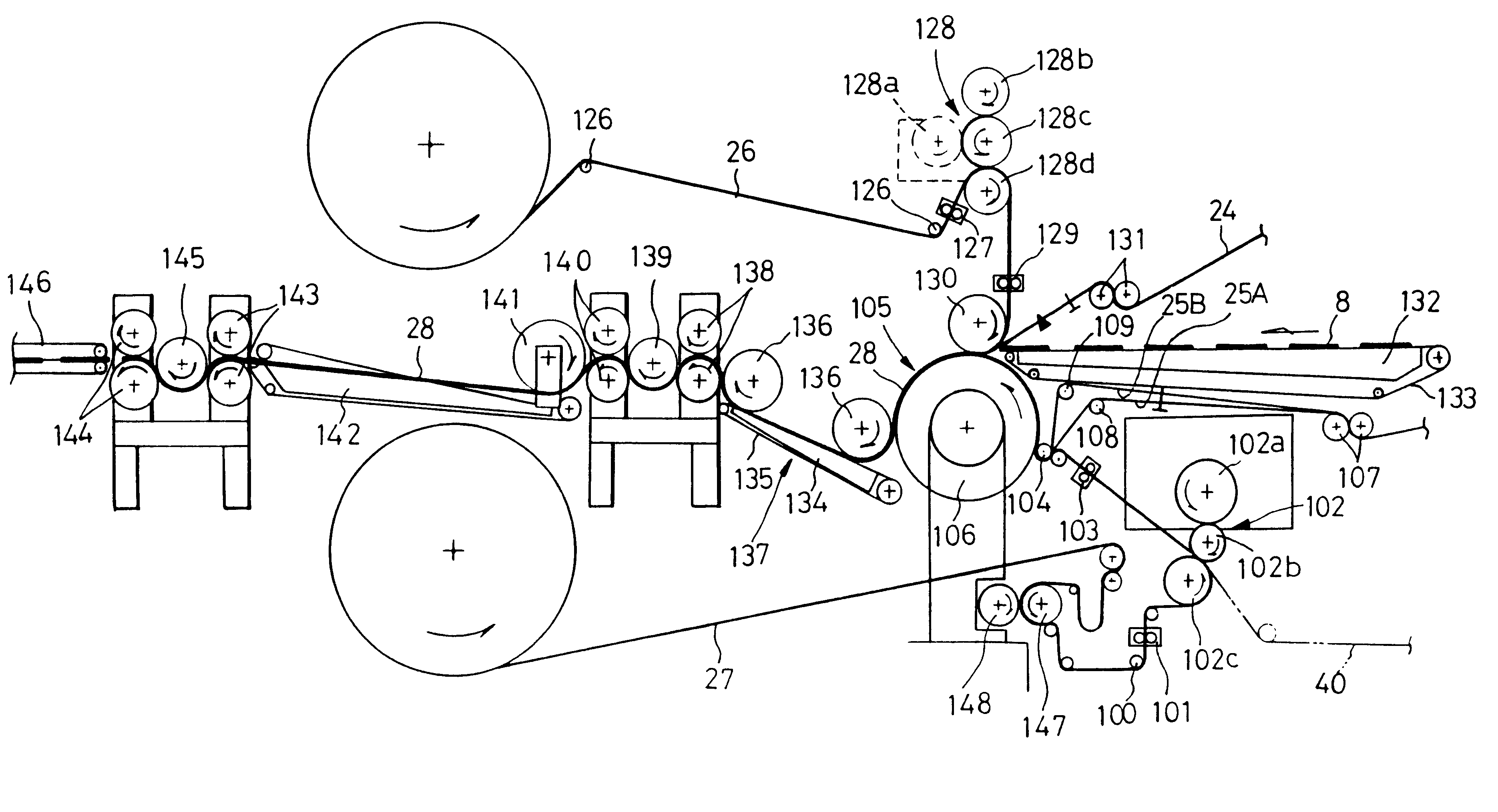

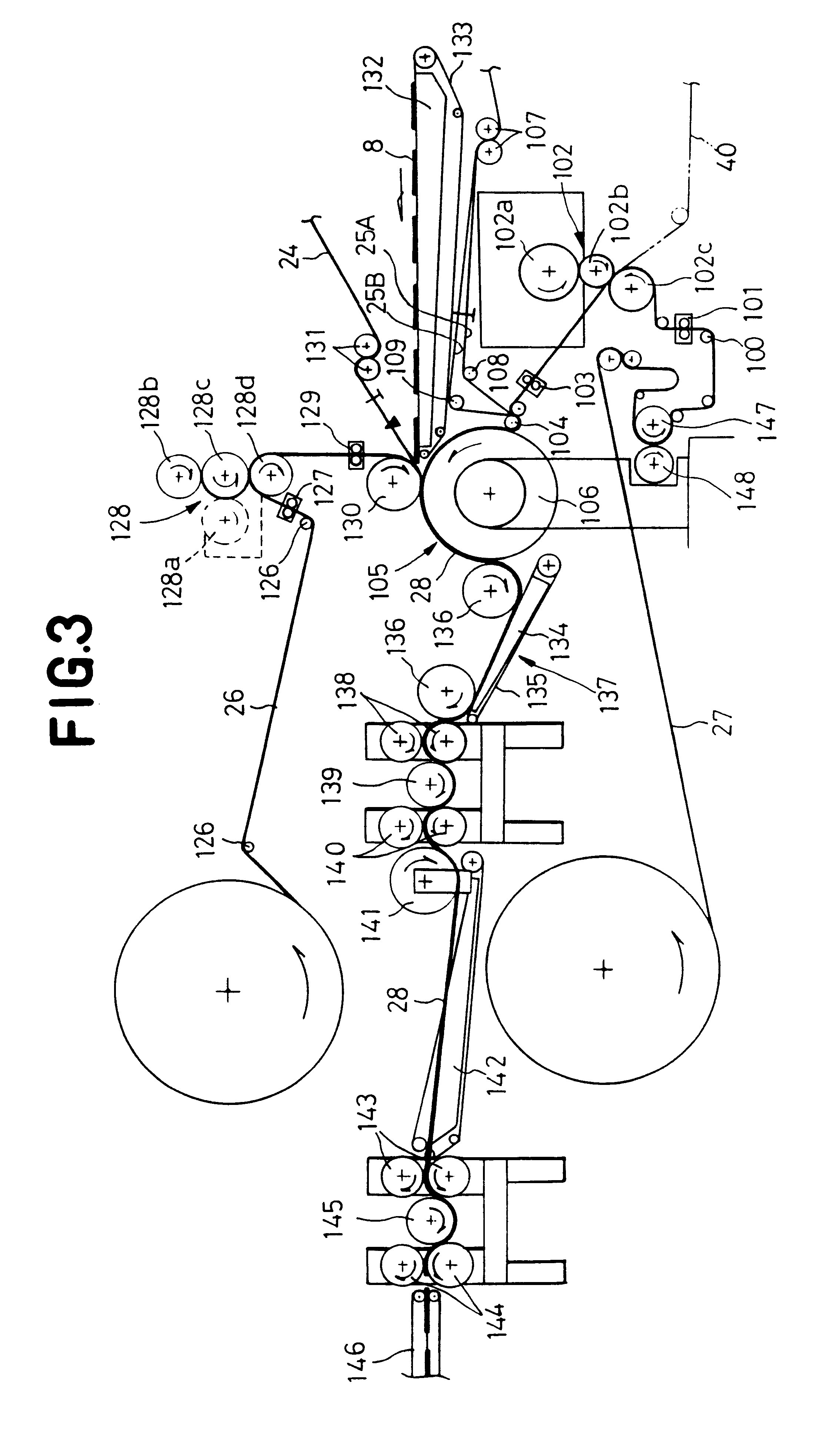

An embodiment of the invention will be described in greater detail in reference with the accompanying drawings.

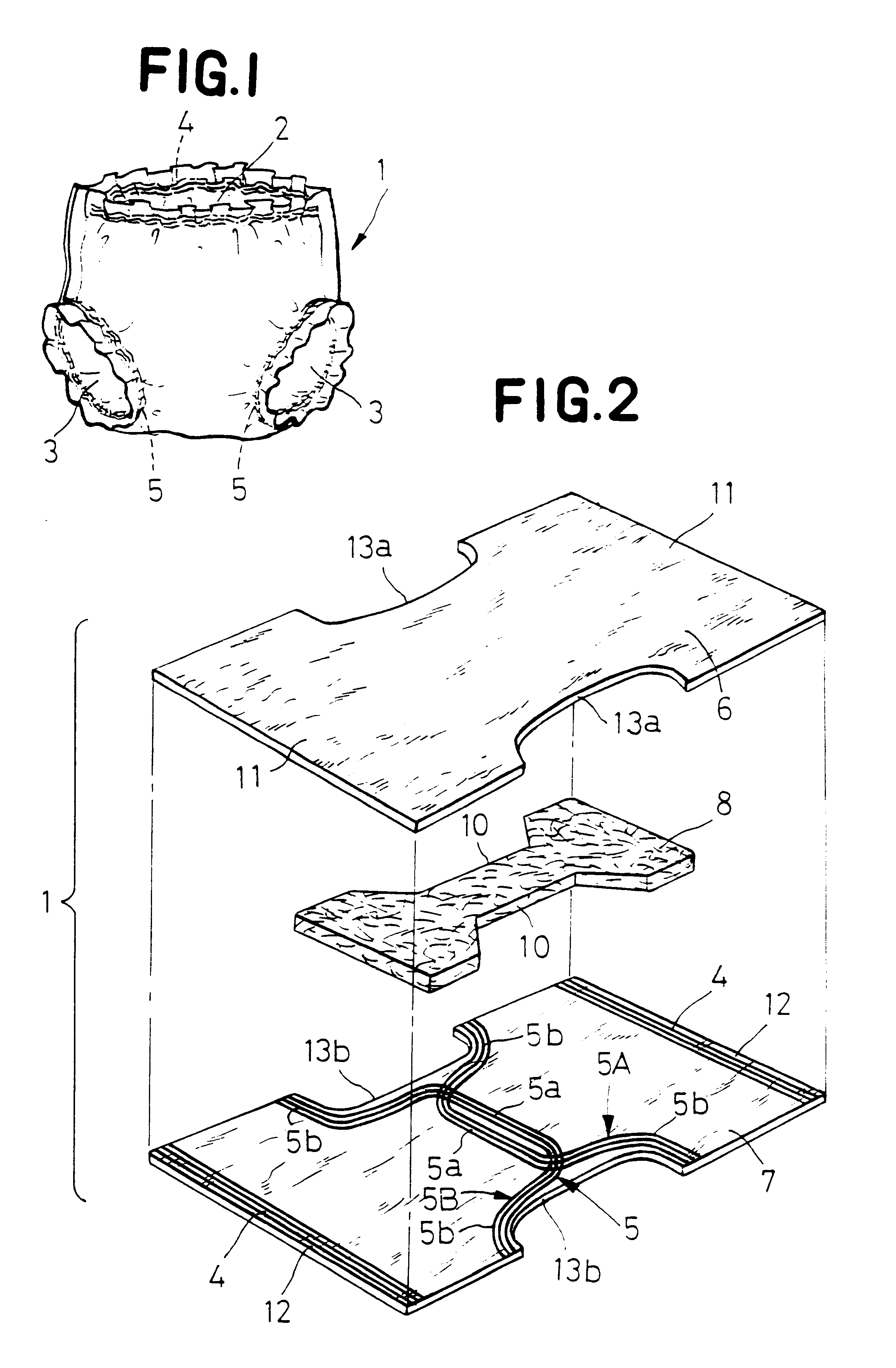

FIG. 1 is a perspective view showing disposable underpants to be manufactured by the method of the invention as has been completely assembled. The underpants 1 include a waist-hole 2, a pair of leg-holes 3 and elastic members 4, 5 adhesively attached to the underpants 1 around these holes so as to form elastic gathers therearound.

FIG. 2 is an exploded perspective view of said underpants. As seen in FIG. 2, the underpants 1 comprise a topsheet 6 and a backsheet 7 respectively made of fibrous nonwoven fabric being elastic both in length and width, a mat-like absorbent core 8 sandwiched between these sheets, and said elastic members 4, 5. The topsheet 6 and the backsheet 7 are respectively provided in opposite sides with notches 13a, 13a and with notches 13, 13b. The core 8 is also provided in opposite sides with notches 10, 10 so as to present so-called sandglass-shape. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com