Unitary filter cartridge

a filter cartridge and unitary technology, applied in the field of industrial baghouses, can solve the problems of increasing industrial emissions regulatory controls, difficult installation and removal of filter cartridges of this type, and difficult installation and maintenance of filter cartridges, so as to maintain the flexibility of the upper sleeve and minimize the collection of dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

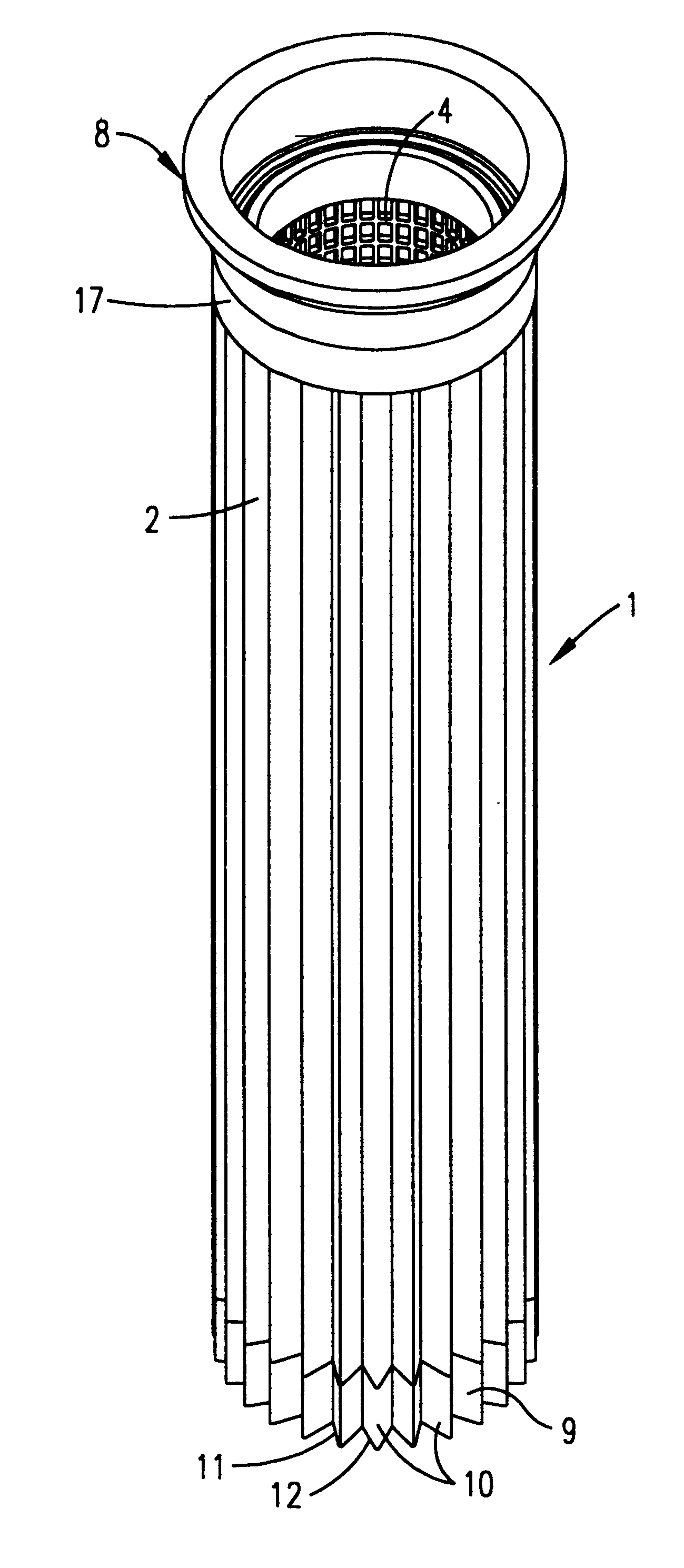

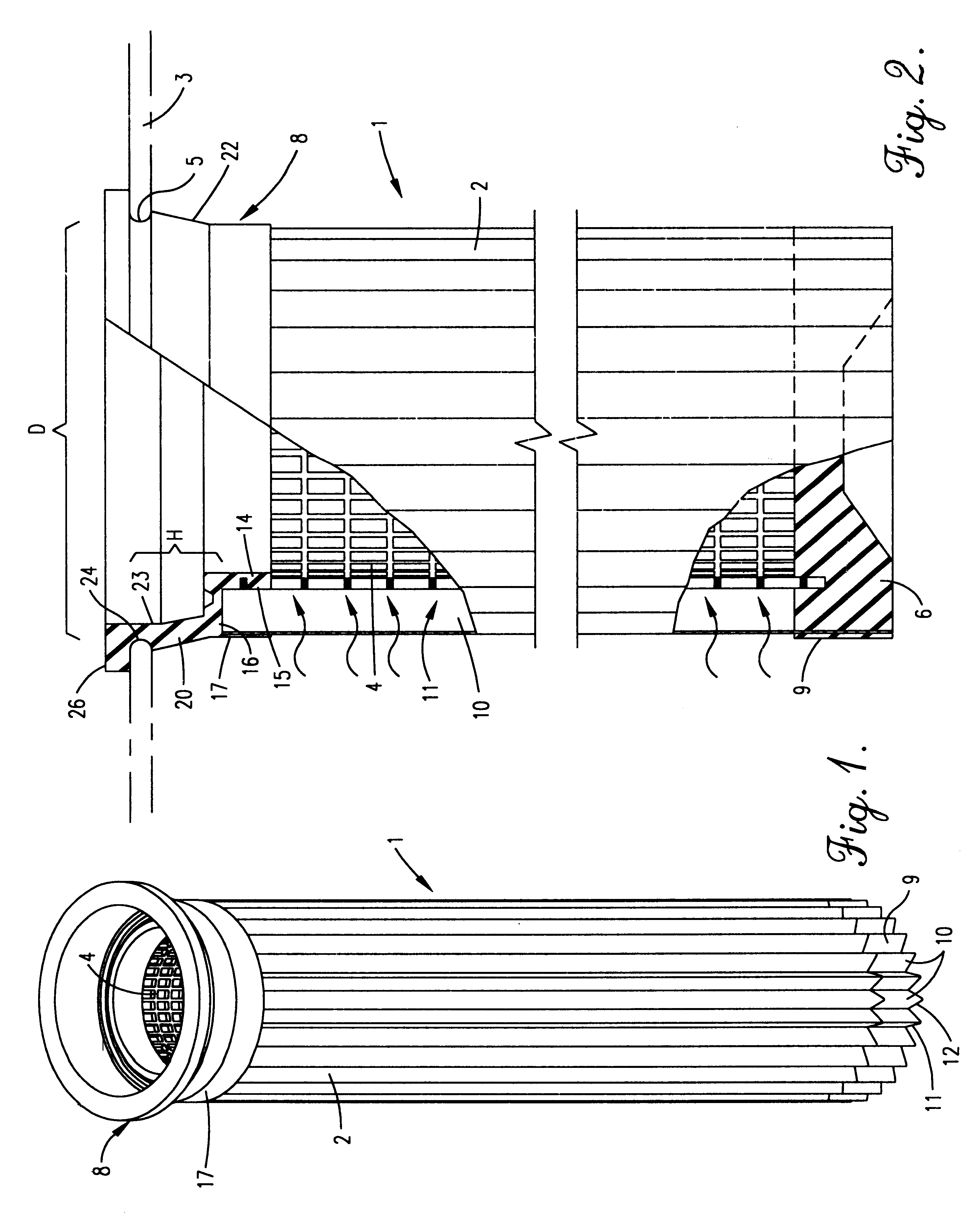

FIG. 1 generally illustrates a filtered cartridge according to the present invention as designated by the reference numeral 1. The filter cartridge 1 is received within a tube sheet 3 having an opening 5 therethrough with a diameter D. The cartridge 1 filters particulate material from air or liquid as the air or liquid passes radially inward through the cartridge 1 and upward through the opening 5. The filter cartridge 1 includes a pleat pack 2 (also referred to as a filter sheet or filter medium) formed in a substantially tubular shape about a filtered chamber with accordion folds about a perimeter thereof. The pleat pack 2 may be constructed of any conventionally known filtering medium. Each fold is constructed with outer filter walls 10 extending along the length of the cartridge 1. Adjoining filter walls 10 form internal and external V-shaped voids 11 and 12.

The pleat pack is formed about, and abuts firmly against, a tubular inner screen 4 having a rectangular mesh pattern there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com