Device for extruding a polymer frame onto a plate-shaped object

a technology of polymer frame and plate, which is applied in the direction of drawing profiling tools, turning machine accessories, windows, etc., can solve the problems of duplication operation, handling and storage problems, and difficulty in precisely placing the polymer frame on the edge of the pane, and achieve the effect of facilitating sliding movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

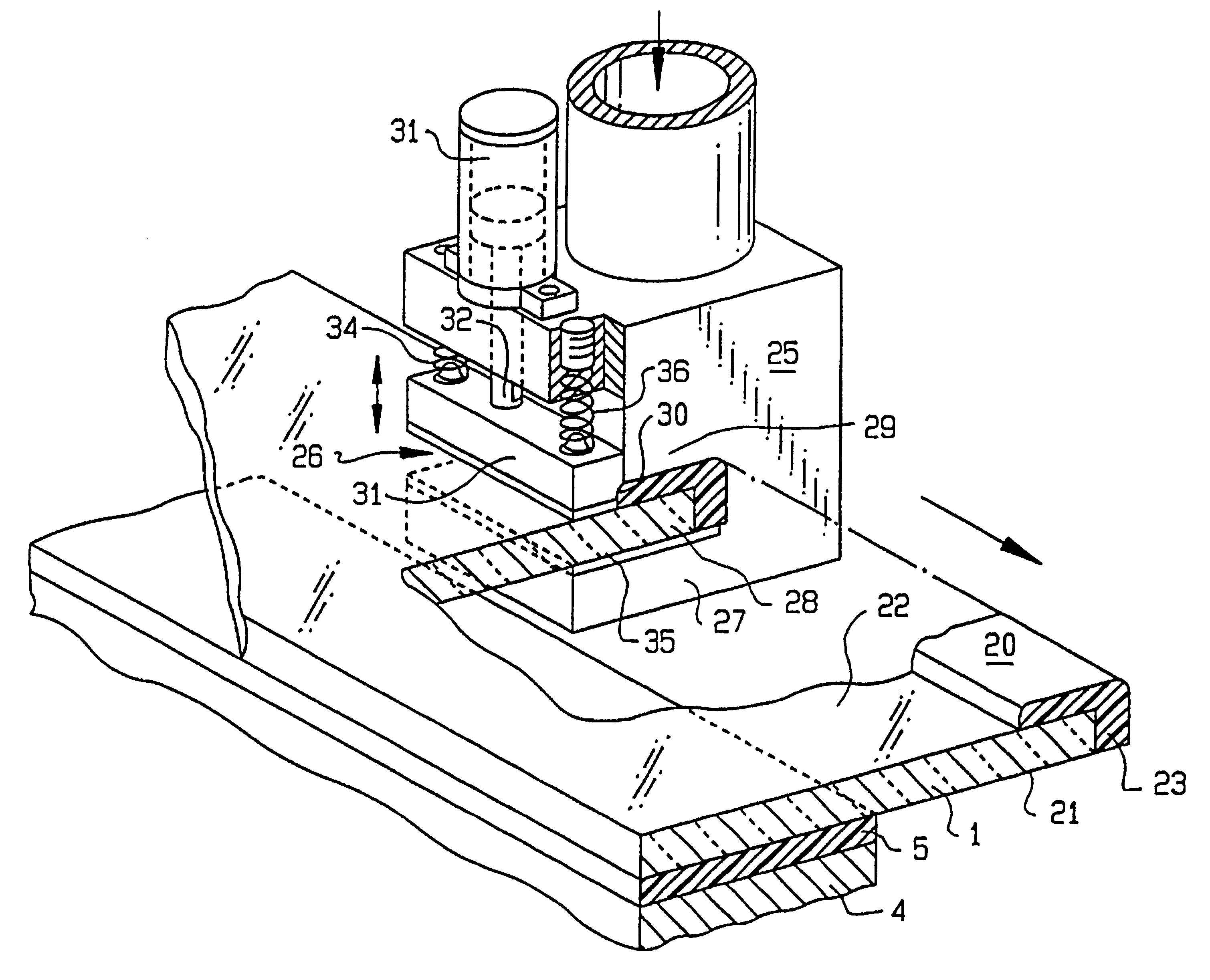

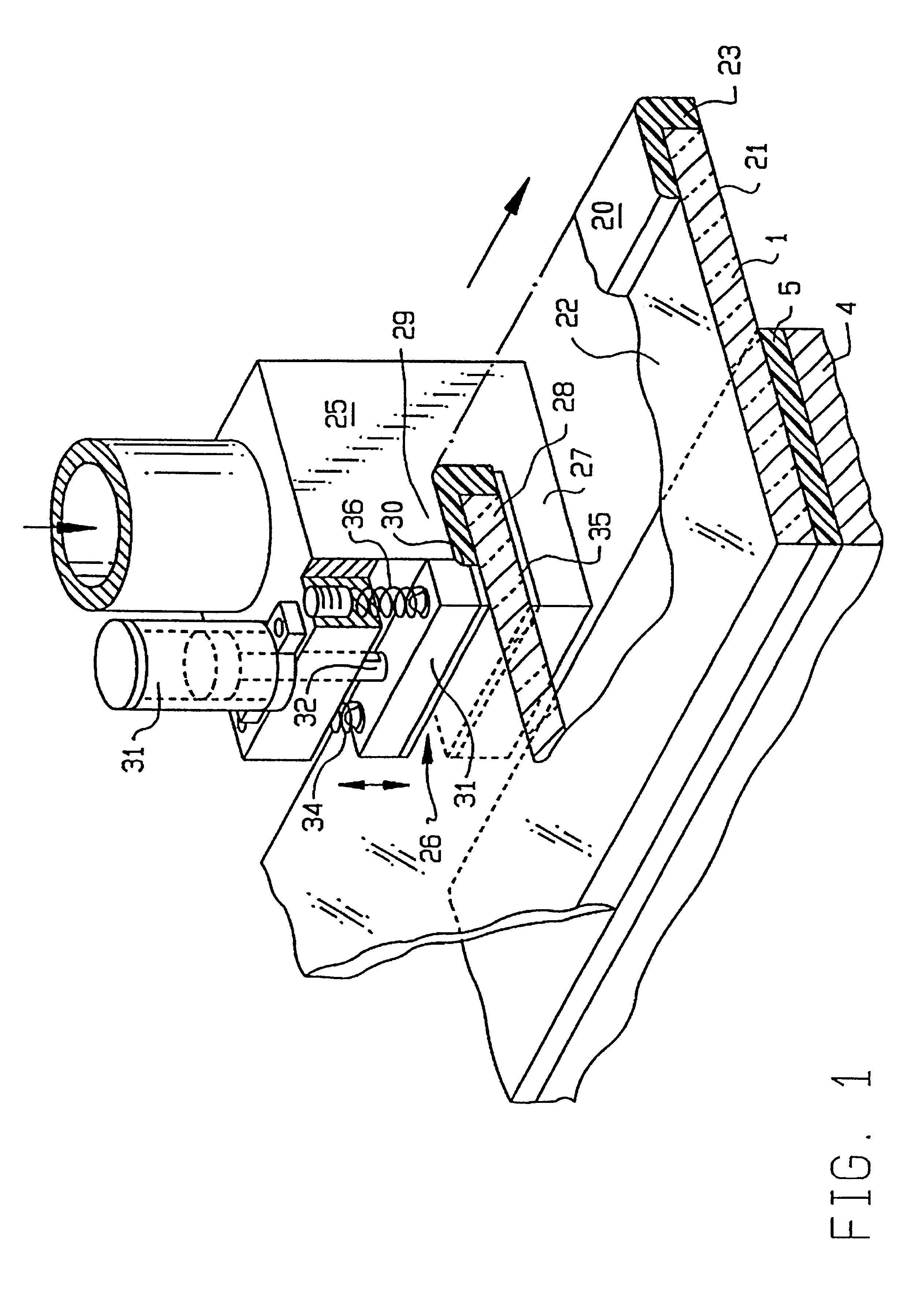

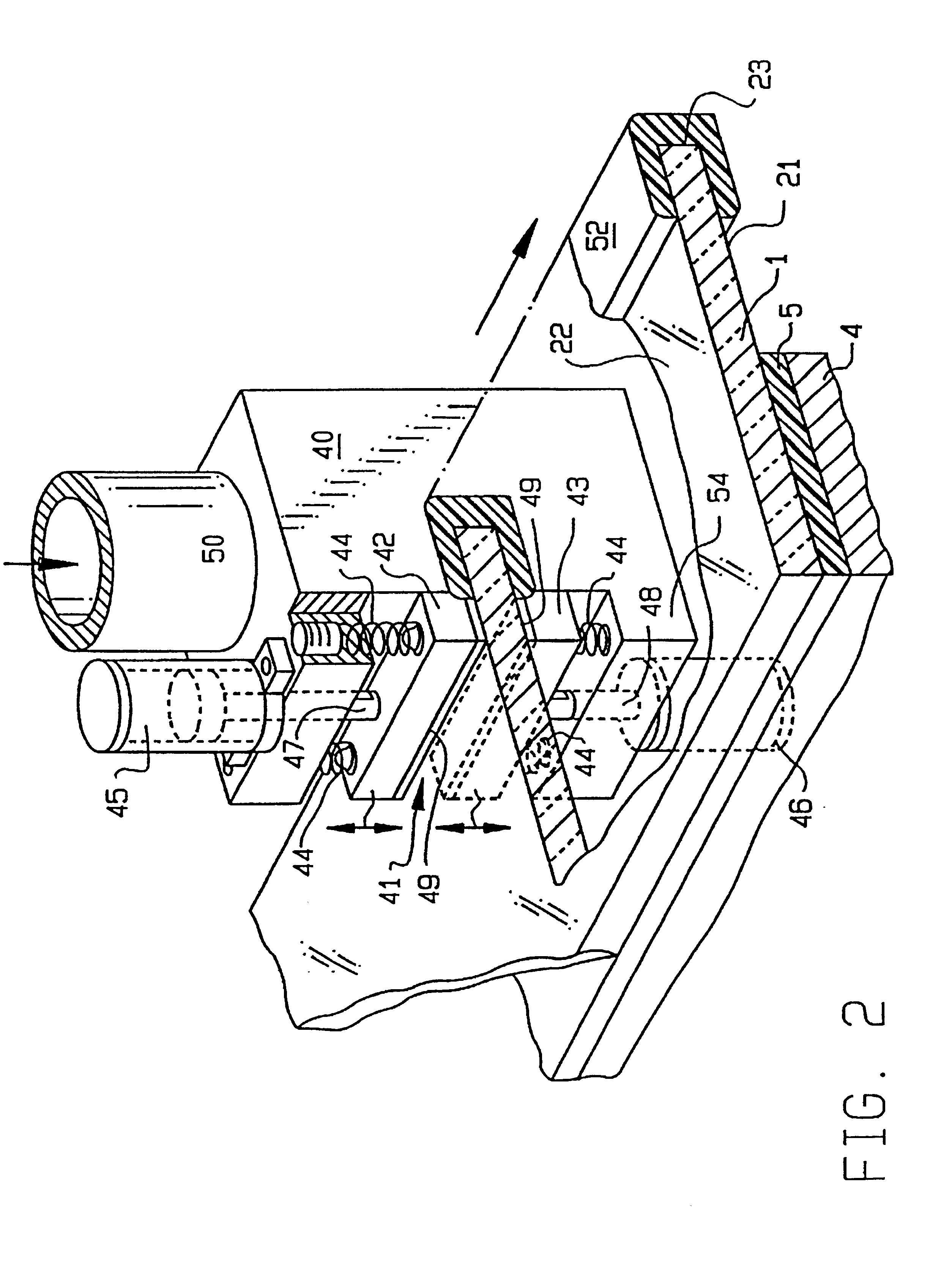

The invention has as its objective to produce an extrusion head that will make possible the extrusion of a polymer onto the periphery of a plate, such as an automobile pane, for the purpose of producing a profile which rests on the edge face of the pane and on at least one of its main faces. Independently of the variations in thickness of the pane, the extrusion head must allow a proper and geometrically accurate transition to be made between the profiled member and the face or faces of the pane.

The invention proposes a device for extruding a profiled cord of polymer onto the periphery of a plate, in particular an automobile pane. The device comprises an extrusion head in relative displacement along the periphery of the plate, against the edge face of which it bears upstream, at the same time as at least one half-jaw bears on a main face of the plate. The downstream wall aft of the extrusion head comprised of an extrusion nozzle, the orifice of which is bounded, amongst other things...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| elastic | aaaaa | aaaaa |

| shape tolerances | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com