Leak resistant battery cover

a battery cover and leak-proof technology, applied in the direction of non-aqueous electrolyte accumulator electrodes, cell components, electrical equipment, etc., can solve the problems of large chamber configuration, significant threat to person and property, and battery leakage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

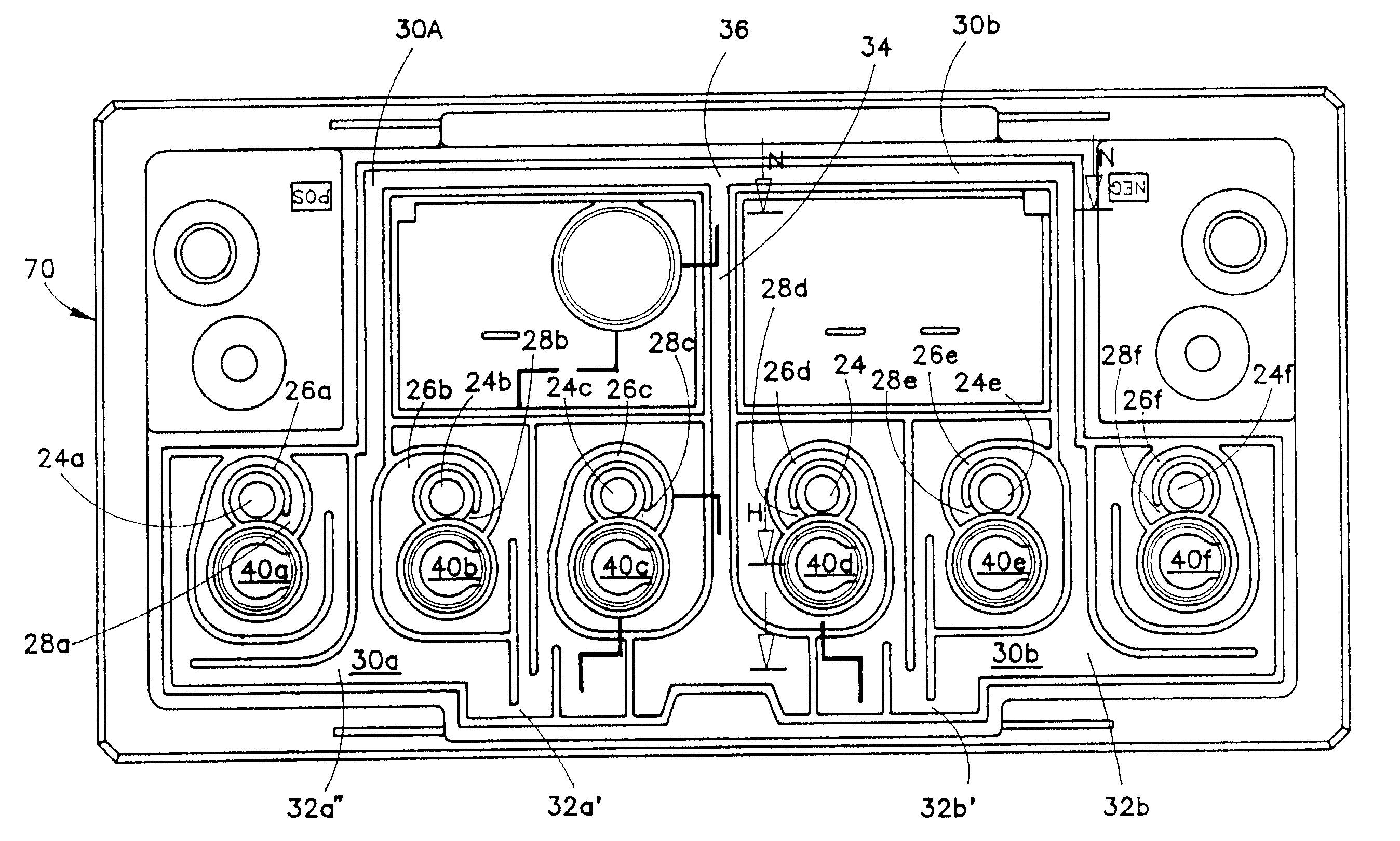

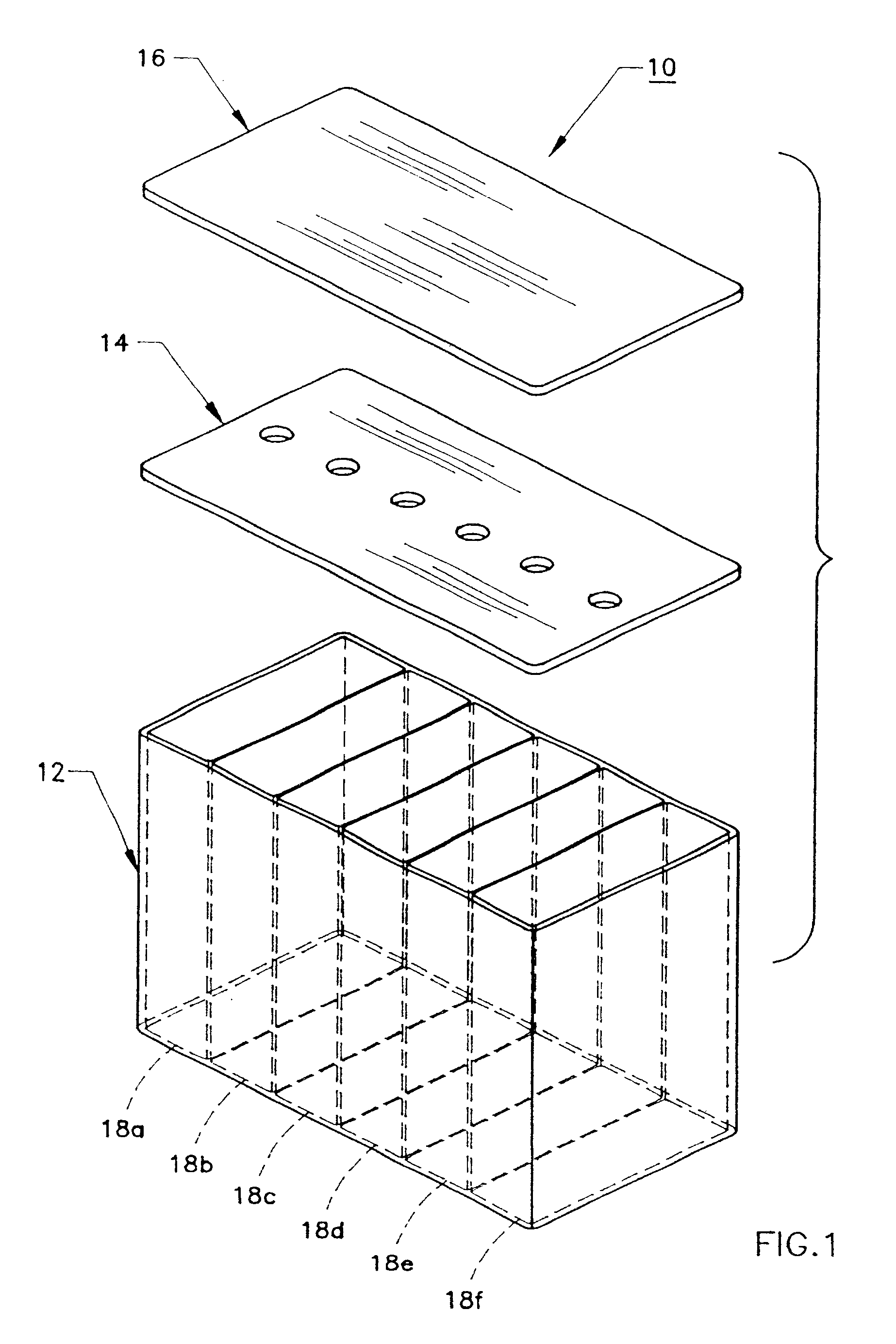

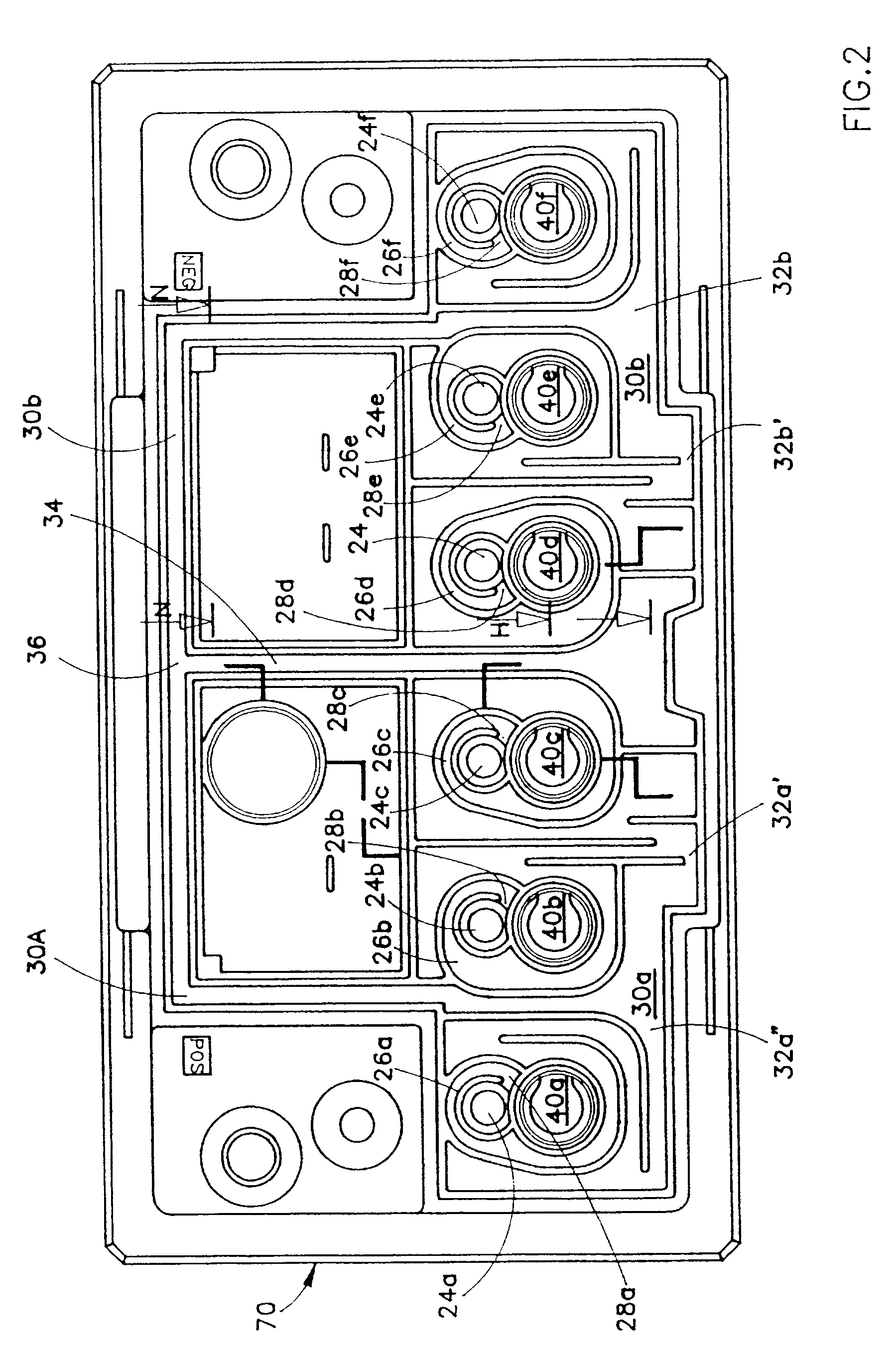

When electrolyte gas escapes through cell vent 22, it communicates into an initial passage 26 of the labyrinth 20 through a passage entrance 28. Each cell 18 is associated with one initial passage 26A-F and one passage entrance 28A-F. The initial passage 26 ultimately leads to atmosphere. Multiple initial passages 26A-F converge into a first common passage 30 at a first convergent point 32. Although there may be many convergent points, the first embodiment initially brings two passages 26B-C, 26D-E together at the first convergent point 32A', 32B'. The paths from the outermost initial passages 26A, 26F join at points 32A" and 32B", respectively. Thus, the first common passages 30A', 30B' form a portion of the path to atmosphere for three cells 18A-C, 18D-F, respectively. The two first common passages 30A', 30B' ultimately combine to form a final common passage 34 at a final convergence point 36. The path to atmosphere for each cell 18 is provided by the final common passage 34. The ...

second embodiment

FIG. 4 shows the battery cover constructed according to the present invention. As with the embodiment in FIG. 2, electrolyte gases escape through cell vents 122, communicate into an initial passage 126 of the labyrinth 120 through a passage entrance 128 and converges into a first common passage 130A, 130B at a first convergent point 132A, 132B. The three initial passages 126A-C, 126D-F for each side of the battery converge into the common passages 130A, 130B, at convergence points 132A, 132B, respectively. The common passage 130A ultimately combines with a similar common passage 130B from the other half of the battery to form a final common passage 134 at a final convergent point 136.

FIG. 13 shows yet a further cover embodiment. Similar to the earlier embodiments, the third embodiment allows electrolyte gas to escape through a cell vent 222 into an initial passage 226 through a passage entrance 228. In the third embodiment, the initial passages 226A, 226B and 226C converge into a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com