One-way clutch apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

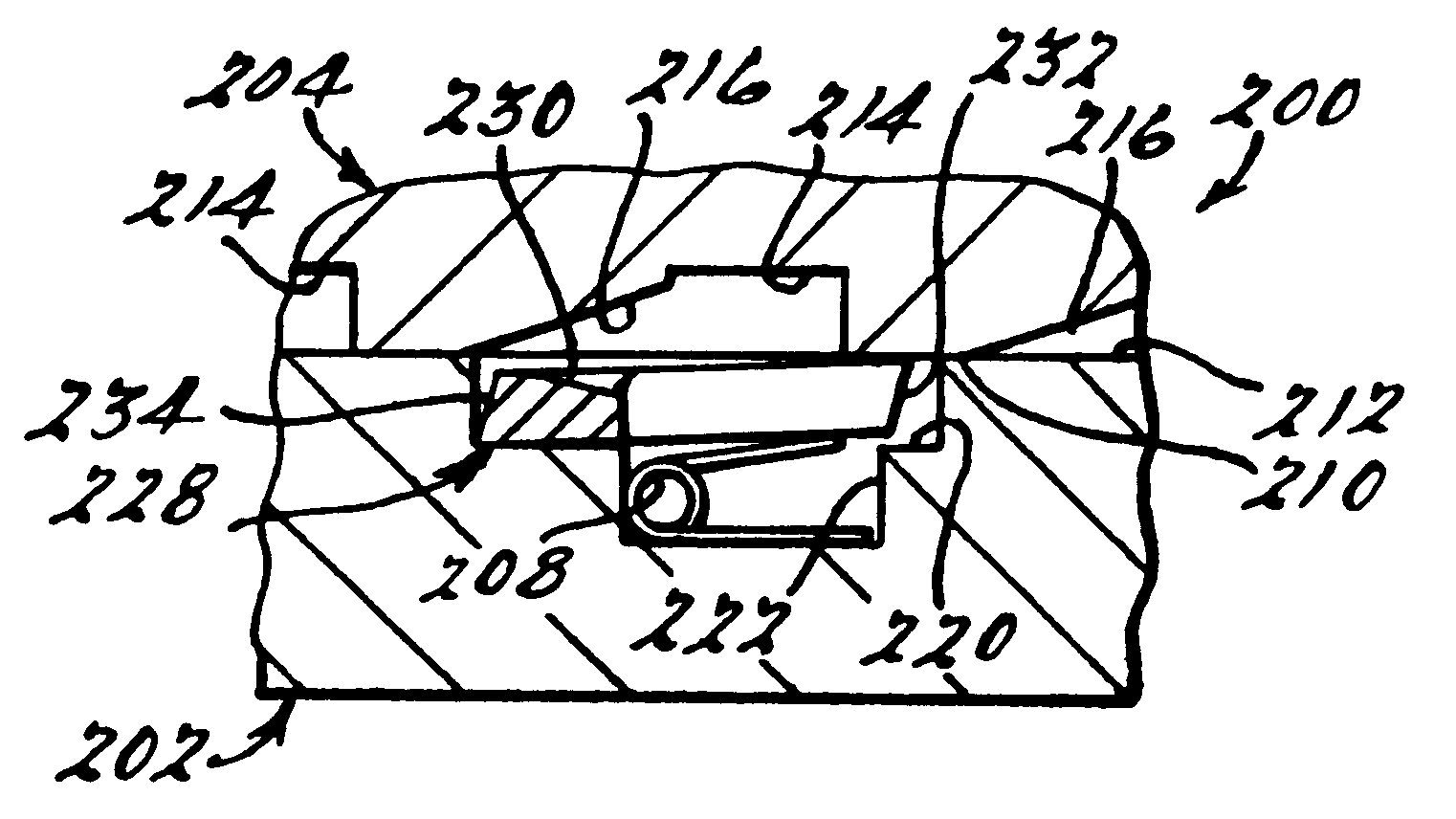

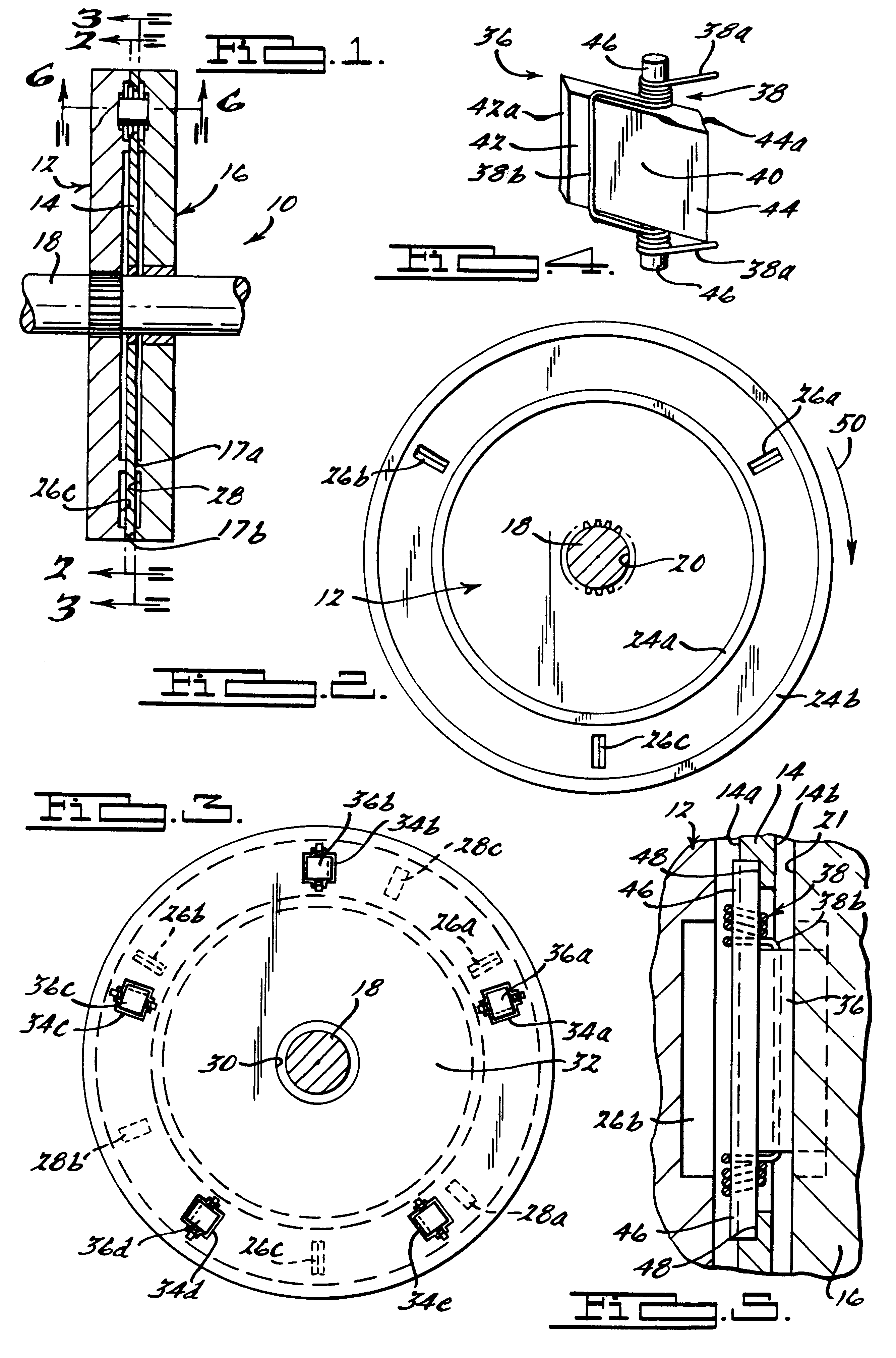

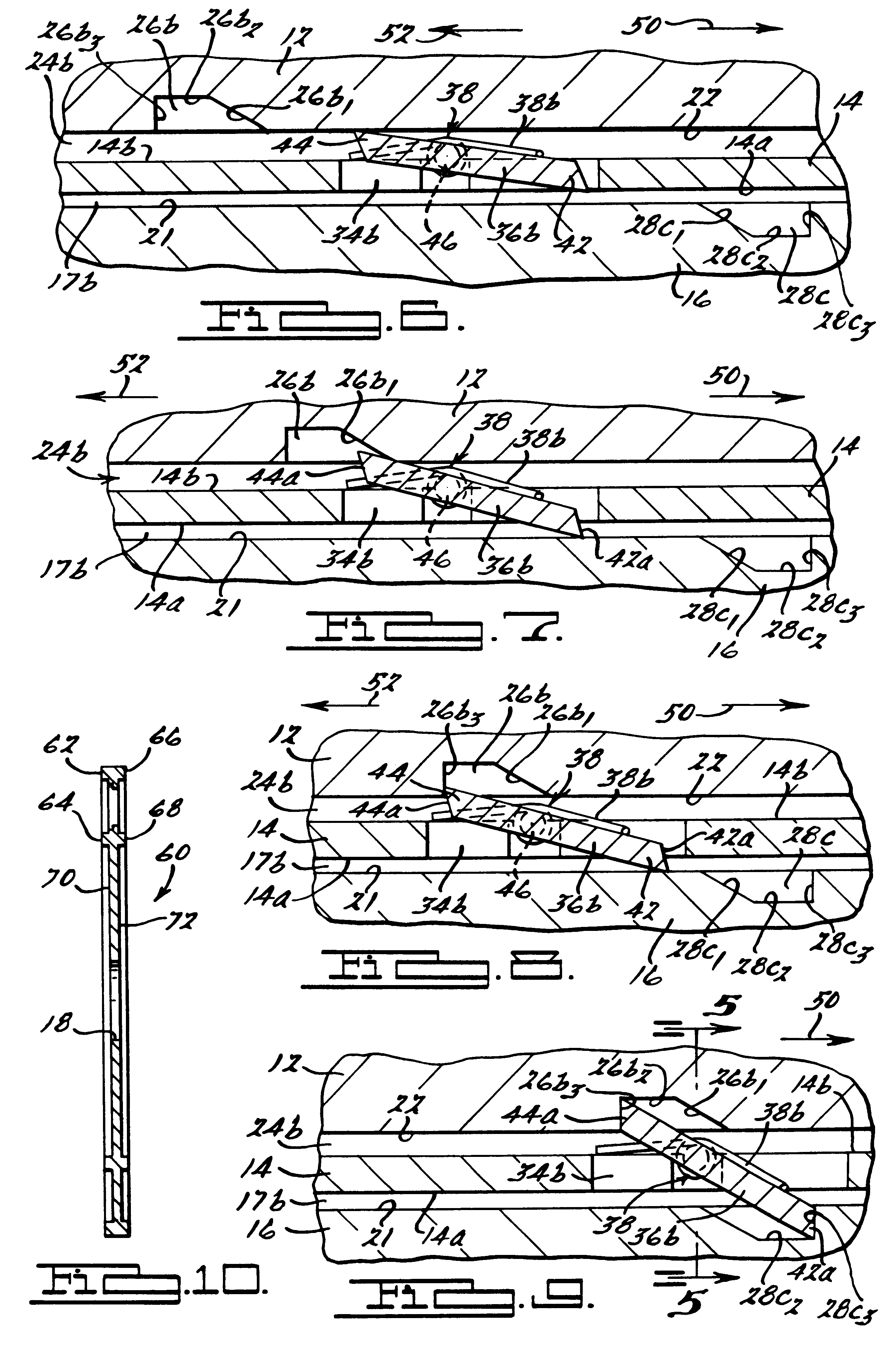

Referring to FIG. 1, there is shown a one-way clutch apparatus 10 in accordance with a preferred embodiment of the present invention. The apparatus 10 generally includes a driving member 12 in the form of a drive plate or disk, a carrier plate 14 in the form of a plate or disc, and a driven member 16 in the form of a driven plate or disk. For purposes of illustration, the driving plate 12 is shown splined to a drive shaft 18 such that rotational movement of the drive shaft 18 causes a corresponding rotational movement of the driving member 12. Also for purposes of illustration, the carrier plate 14 and driven member 16 are shown concentrically disposed about the drive shaft 18 such that each is free to remain stationary when the one-way clutch 10 is not engaged. It will be appreciated that the driving member 12 and driven member 16 could just as easily be switched such that member 16 imparts a motive force to member 12. Furthermore, it should be appreciated that one or the other of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com