Component shelf system

a shelf system and component technology, applied in the field of shelves, can solve the problems of reducing the amount of useable storage space, destroying shelves no longer needed, and creating problems, so as to increase the stability of the entire shelf, prevent lateral movement of the vertical edges, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

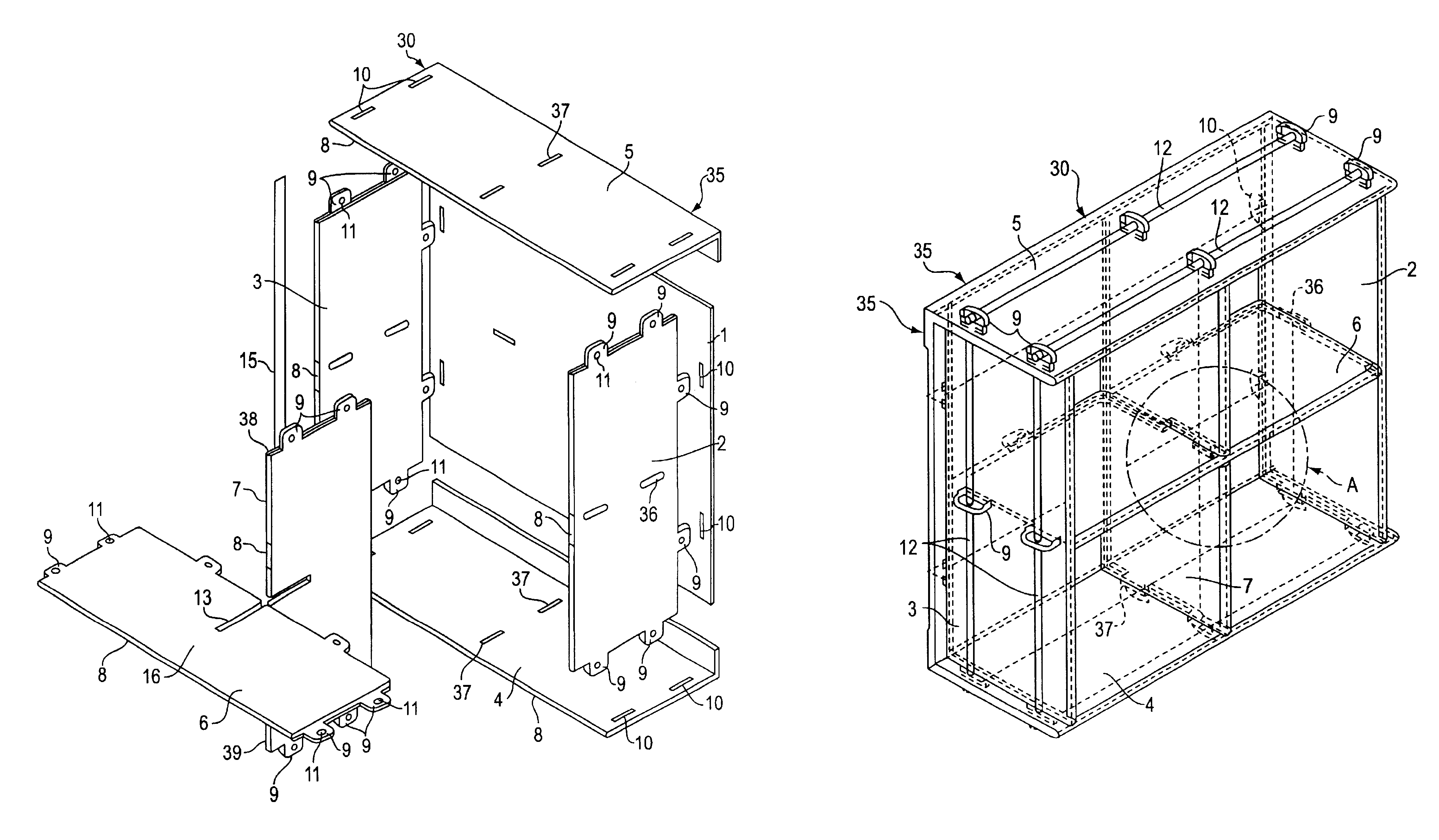

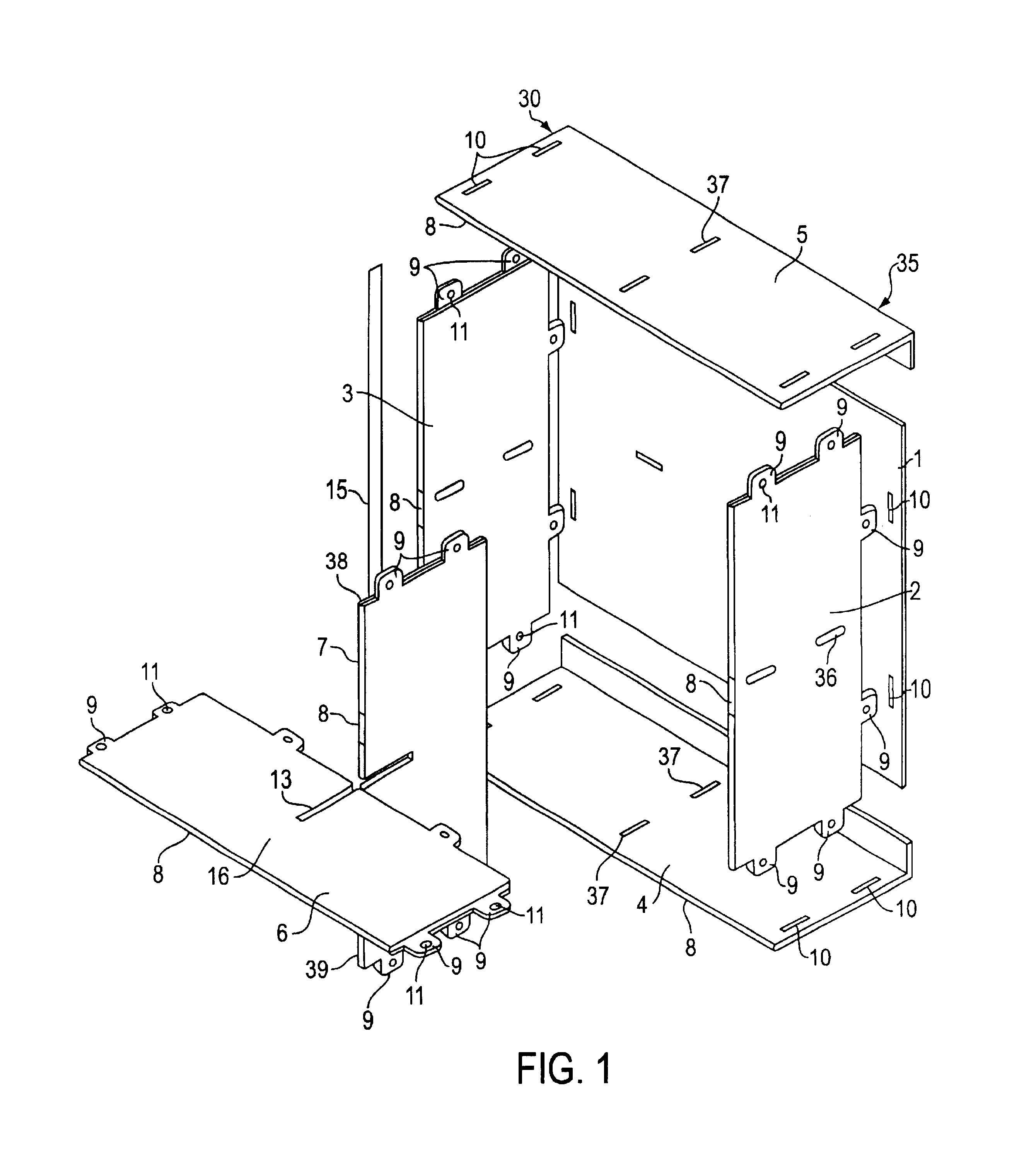

Turning now in detail to the drawings, FIG. 1 shows a component shelf system 30 comprising a frame 35 having a back wall 1, a pair of side walls 2 and 3, a bottom wall 4, and a top wall 5; at least one horizontal compartment divider 6, and at least one vertical compartment divider 7 having a top end 38 and a bottom end 39. Note that only one compartment divider is shown in each case for the sake of simplicity.

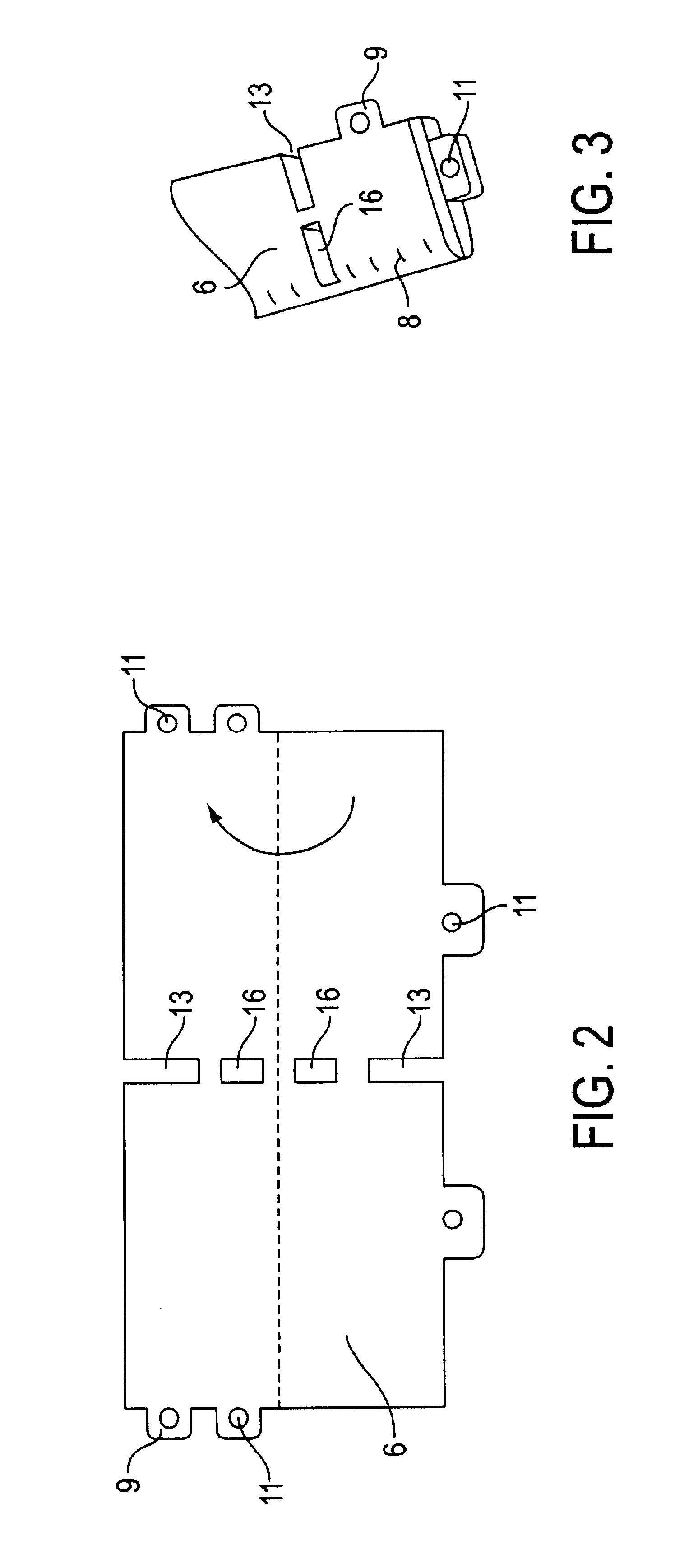

Side walls 2 and 3, top wall 5, bottom wall 4 as well as the horizontal compartment divider 6 and vertical compartment divider 7 consist of folded rectangularly shaped cuts from cellular plastic boards each forming a rounded folding edge 8. Using this process, the shelf does not have any sharp edges on the circumferential surfaces of the stabilizing elements or the like as the edges 8 are always rounded.

Side walls 2 and 3 contain at least one horizontal receiving slot 36 and at least one tab 9. Horizontal compartment divider 6 and vertical compartment divider 7 each have at lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com