Shower bath apparatus and spray nozzle

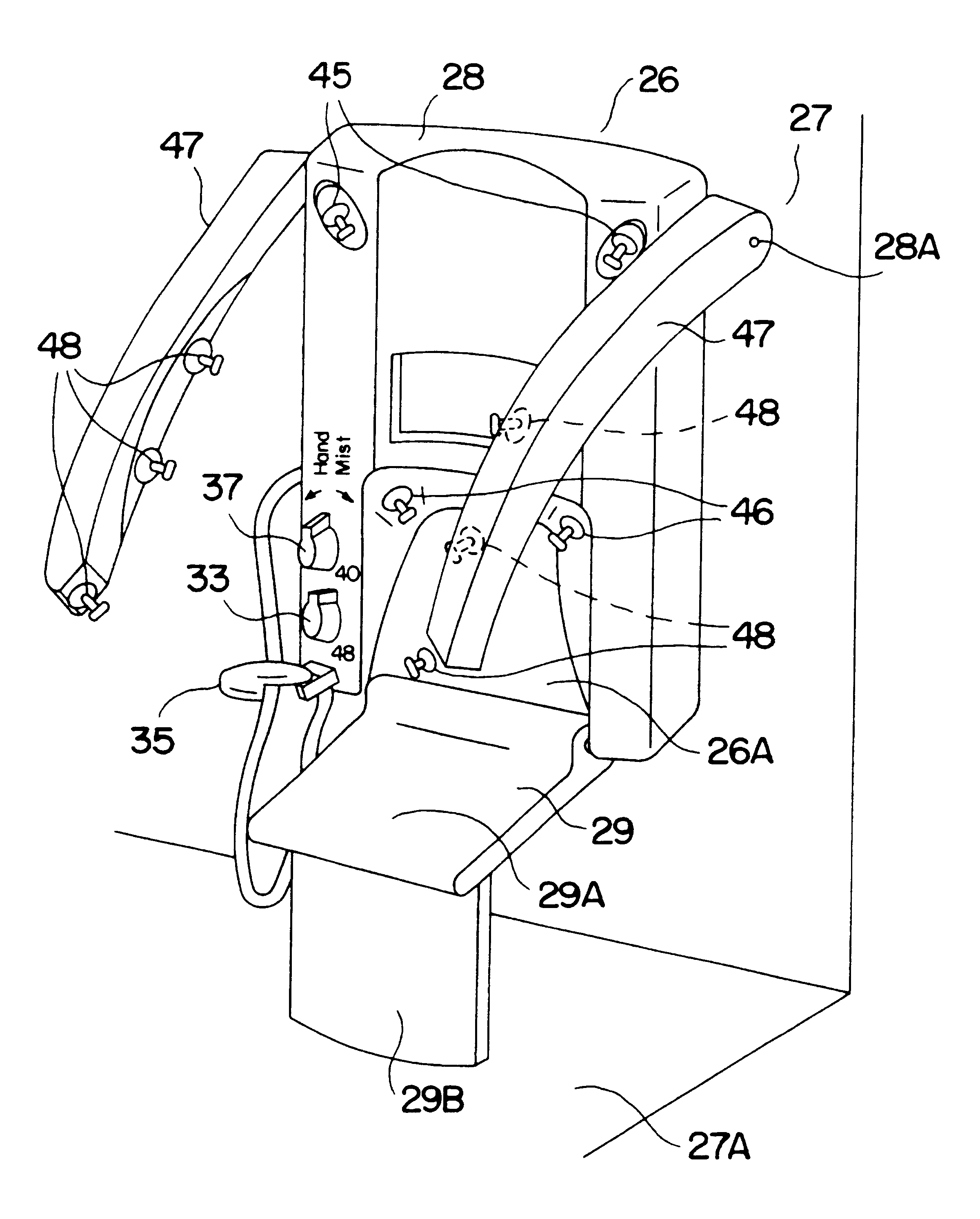

a technology of showering apparatus and spray nozzle, which is applied in the field of showering apparatus, can solve the problems of narrow spay angle, insufficient swirl force of fluid, and difficult to obtain relaxation feeling of showering, so as to reduce the loss of swirl force, and suppress the heat of the user.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0120](1) Embodiment 1

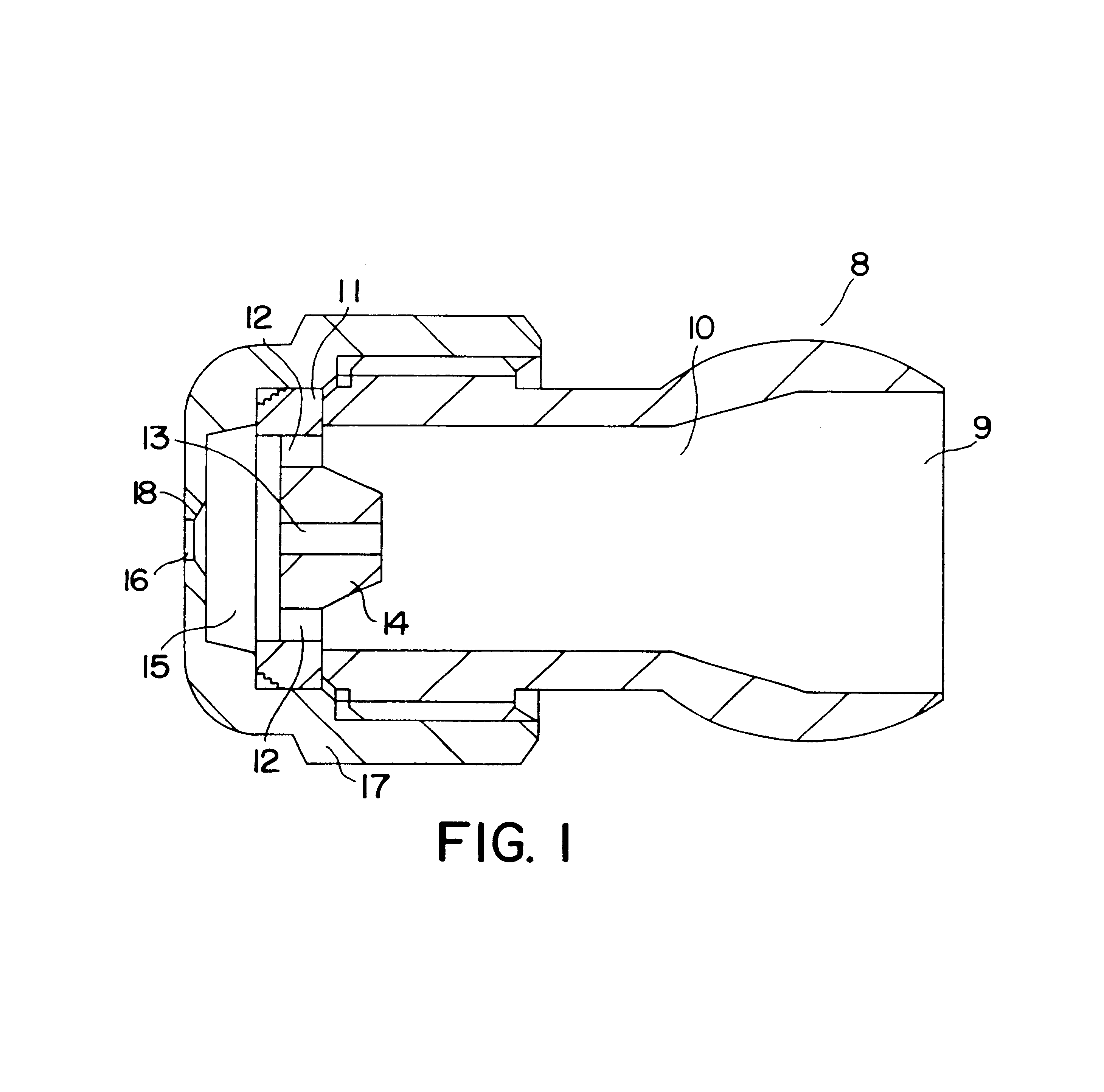

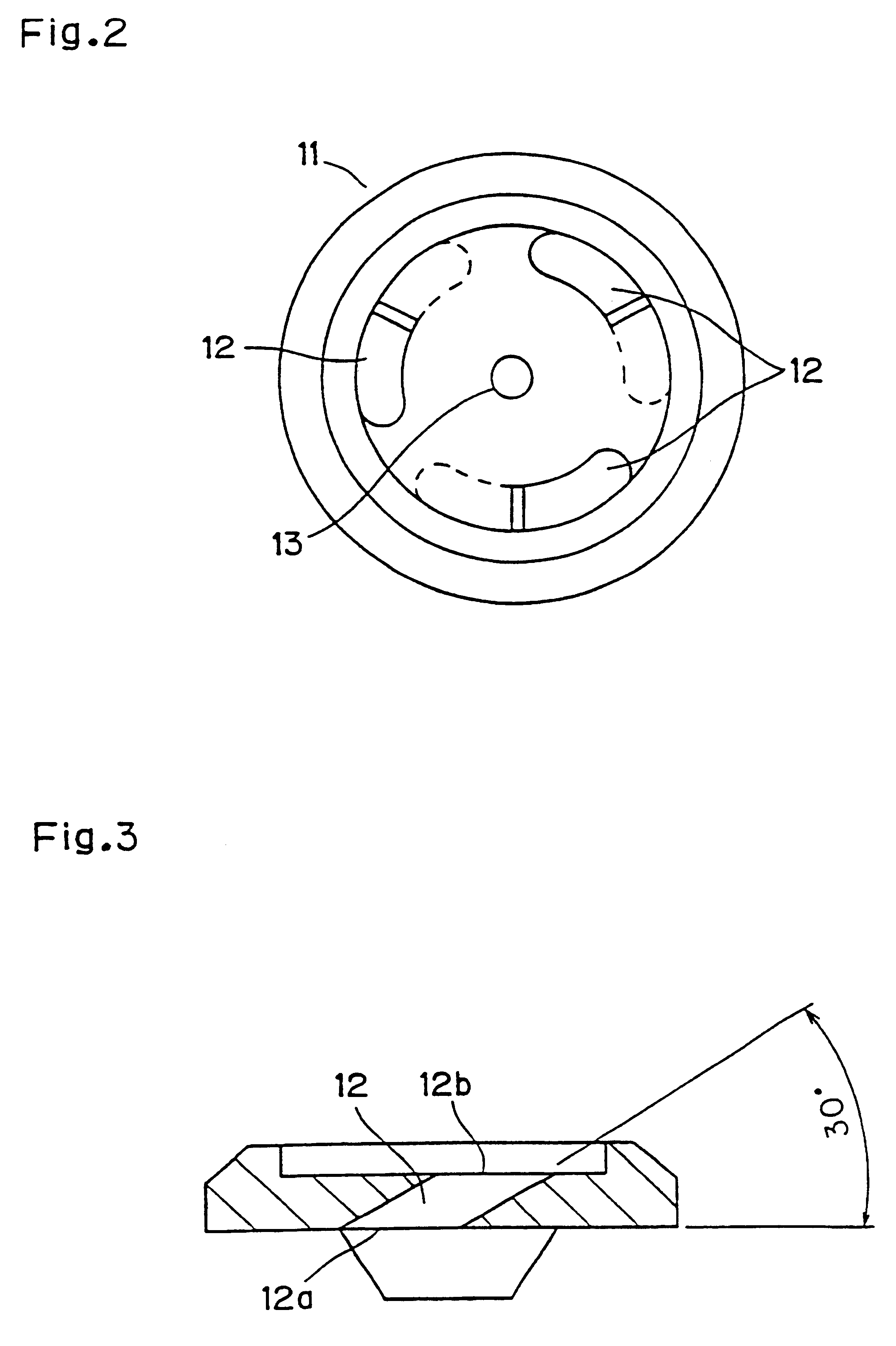

[0121]Referring now to FIG. 1, embodiment 1 of the invention is described below.

[0122]FIG. 1 is a sectional view of spray nozzle in embodiment 1 of the invention.

[0123]In FIG. 1, a flow inlet 9 and a flow passage 10 through which fluid flows are provided in a nozzle main body 8. Reference numeral 11 is a swirl tip for swirling the fluid flowing in through the flow passage 10, and as shown in FIG. 2, moreover, swirl holes 12 are disposed as swirl units at three positions on the circumference, while a central hole 13 is provided nearly in the center of the swirl holes. The three swirl holes 12 are equal in the opening area and are provided to divide the circumference in three equal sections so that the swirl flows coming out of the swirl holes 12 may be uniform. The swirl holes 12 are, in order to increase the opening area and heighten the swirl force, in a slender shape centered on the circumference in which the three swirl holes 12 are provided. FIG. 3 is a par...

embodiment 2

[0136](2) Embodiment 2

[0137]Embodiment 2 of the invention is described below while referring to FIGS. 6 and 7.

[0138]FIG. 6 is a sectional view of a spray nozzle in embodiment 2, and FIG. 7 is an appearance drawing of a swirl tip 11. In embodiment 2, what differs from embodiment 1 is that the central hole 13 is not provided in the center of the three swirl holes 12 of the swirl tip 11.

[0139]In this constitution, only the action different from embodiment 1 is described. The incoming fluid reaches the swirl tip 11, and is equally divided into three swirl holes 12. The fluid does not form central axial flow, but when the flow rate is the same, the generated swirl force is increased by the increment portion of the swirl flow rate. Therefore, the swirl force of the jet flow passing through the injection hole 16 increases, and the spray angle is further increased at low flow rate and low pressure.

[0140]Incidentally, when the injection hole 16 is formed smoothly without chamfering portion 1...

embodiment 3

[0141](3) Embodiment 3

[0142]Embodiment 3 of the invention is described below by referring to FIG. 8, referring only to the difference from embodiment 1. FIG. 8 is a sectional view of the spray nozzle of embodiment 3.

[0143]In FIG. 8, a nozzle main body 19 is provided with a flow inlet 9 and a flow passage 10 through which the fluid flows in, and at the flow-out side of the flow passage 10, swirl holes 20 are provided as swirl units at three positions on the same circumference, together with a central hole 21 nearly in the center of swirl hole. The nozzle main body 19 has a nozzle cap 17 forming an injection hole 16 for injecting the fluid, which is engaged with a threaded portion 22 as spray variable means, and by rotating the nozzle cap 17, the distance of swirl holes 20 and injection hole16 can be adjusted. A seal member 23 is provided at the junction of the nozzle main body 19 and the nozzle cap 17, and leak of fluid from the threaded portion 22 is prevented.

[0144]Reference numera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com