Carbon fiber reinforcement system

a technology of carbon fiber reinforcement and fiber reinforcement, which is applied in the direction of building repair, transportation and packaging, walls, etc., can solve the problem of limited space between fibers for propagation of micro-cracks formed between fibers, and achieve the effect of minimizing structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The following description of the preferred embodiment is merely exemplary in nature, and is in no way intended to limit the invention, or its application, or uses.

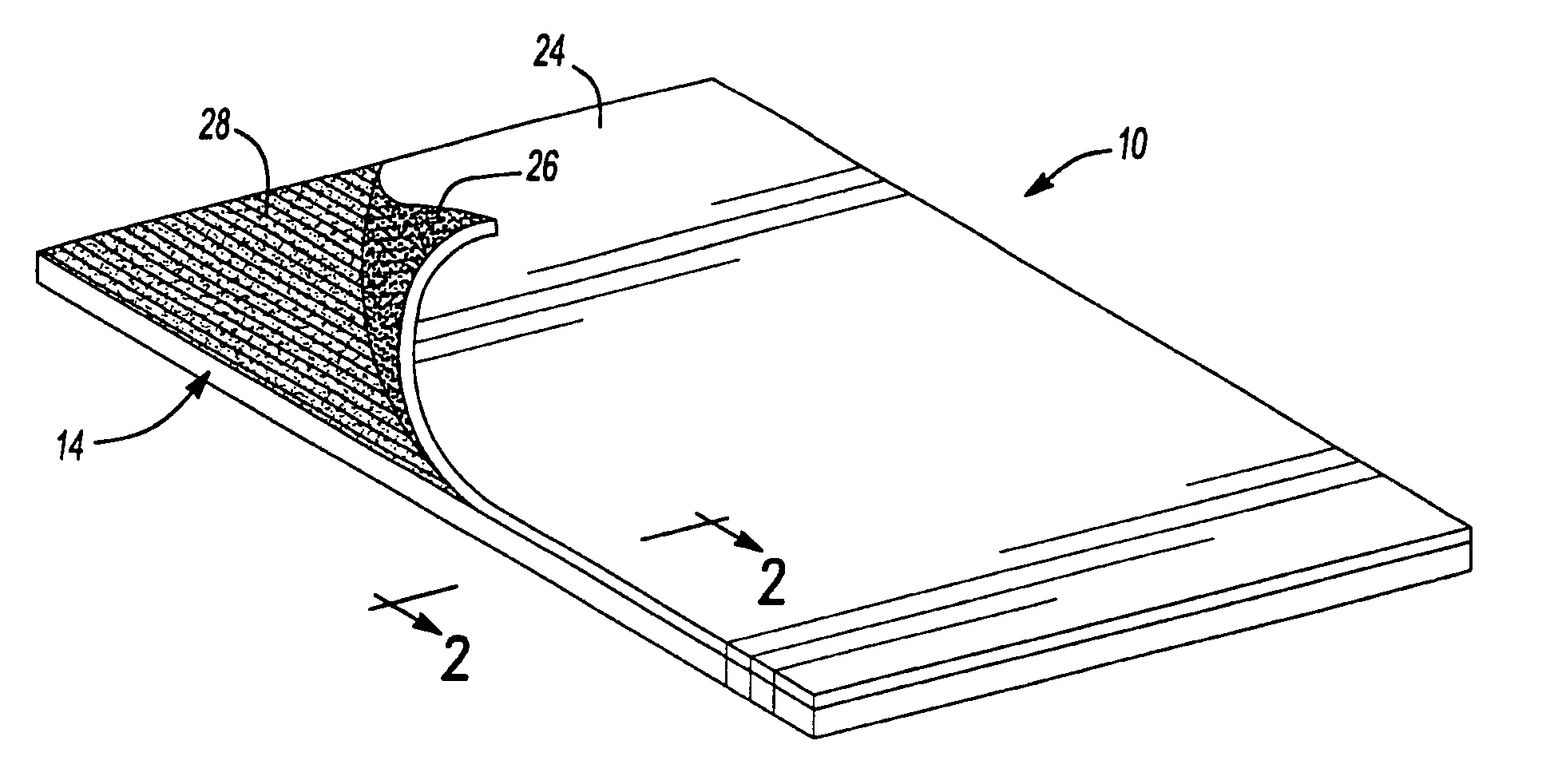

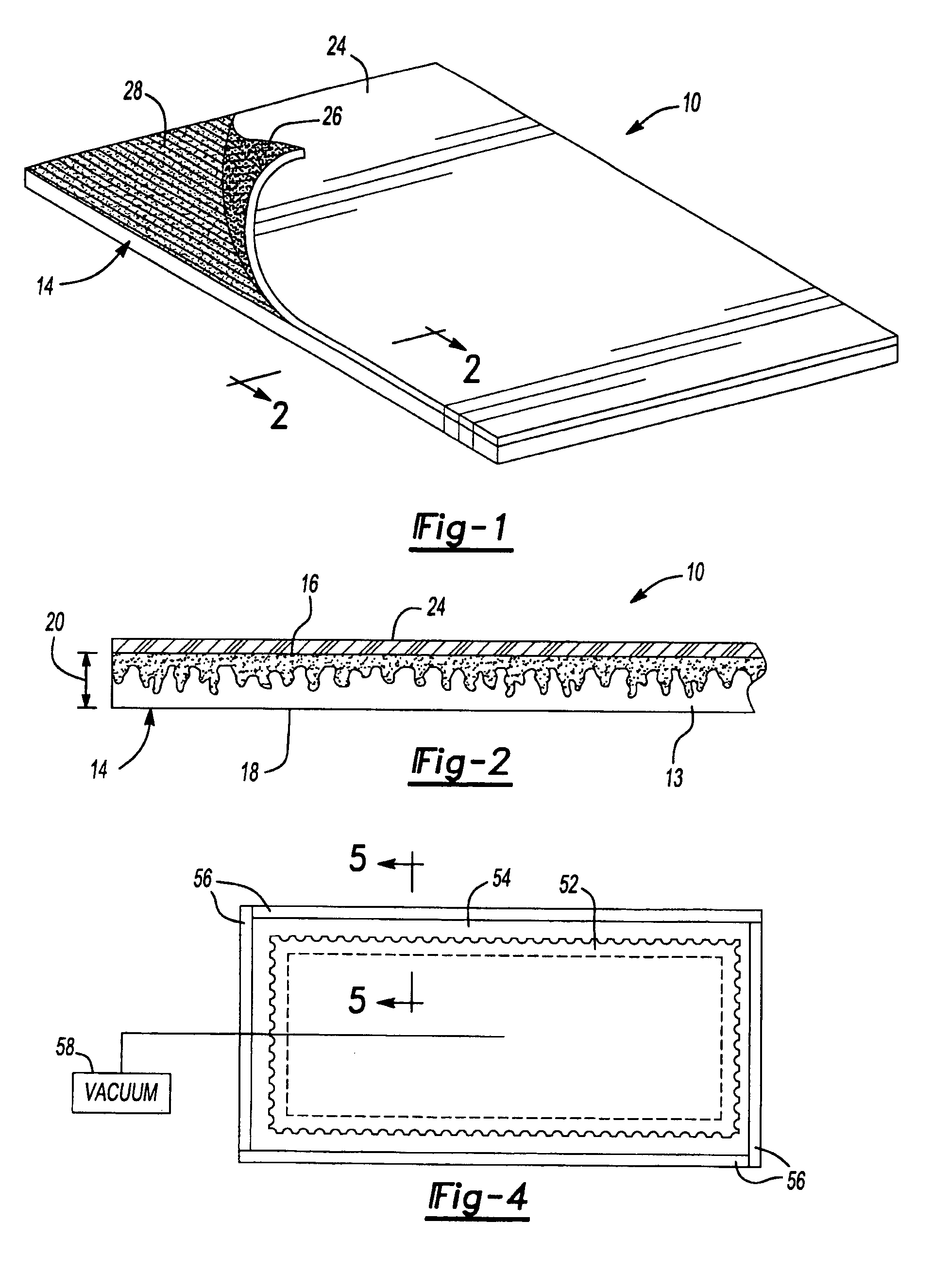

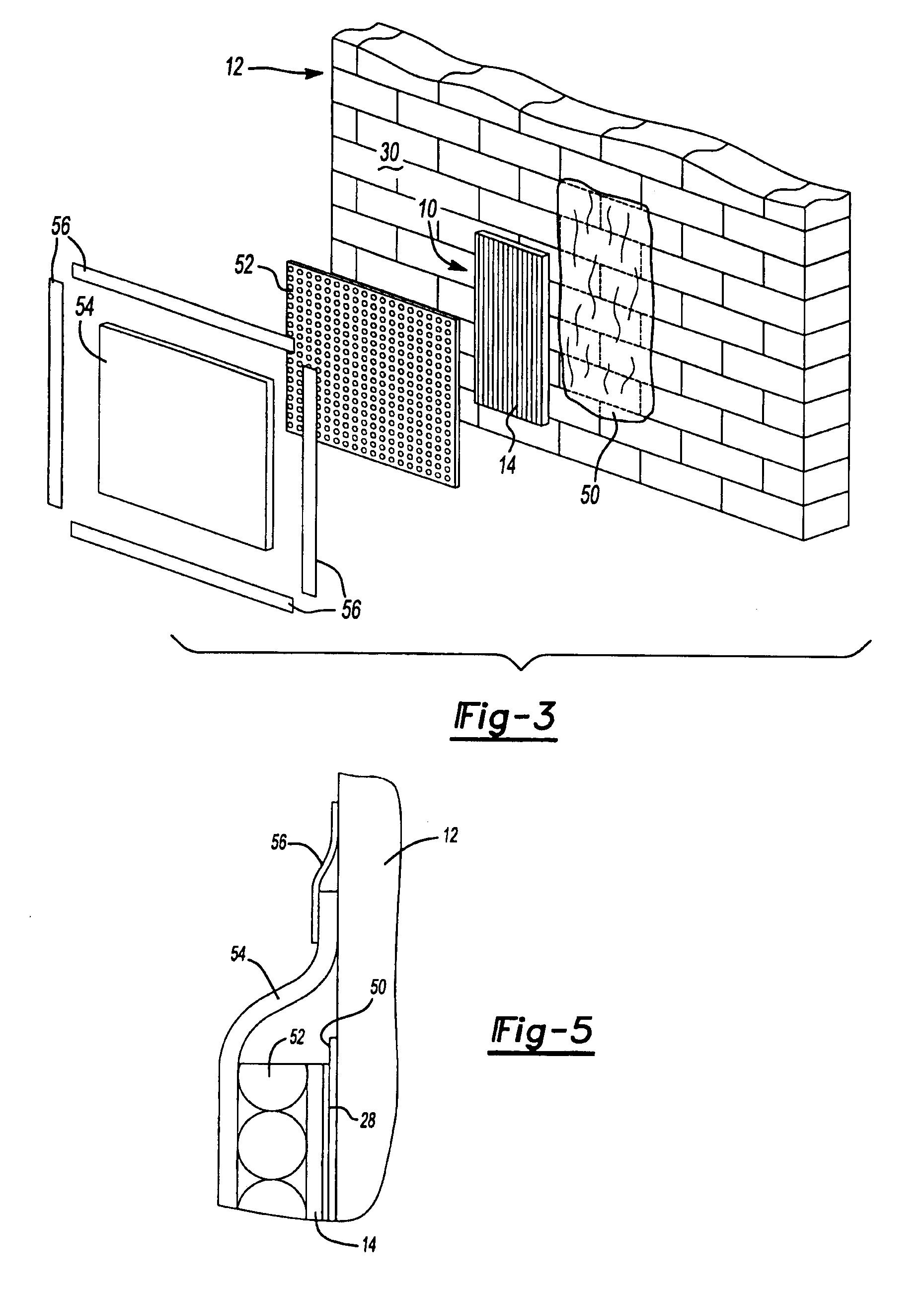

[0052]Referring now to the drawings, shown in FIG. 1 is an article, a carbon fiber strip assembly 10 (here after just strip 10) for use in reinforcing structure element 12, such as a concrete block wall, as seen in FIG. 3. In accordance with the teachings of the present invention, the strip 10 comprises a carbon fiber sheet 14 having a roughened surface 28 exposed or produced upon removal of a cover sheet 24.

[0053]To obtain the strip 10, a layer of carbon fiber 13 having a first surface 16 and a second surface 18, is provided. The first surface 16 and the second surface 18 of the carbon fiber 13 define a thickness 20. The fibers (not shown specifically in the drawings) of the carbon fiber 13 are generally axially oriented with respect to the strip 10 for good tensile strength as is well known.

[0054]Referring in parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com