Compressor pulse width modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

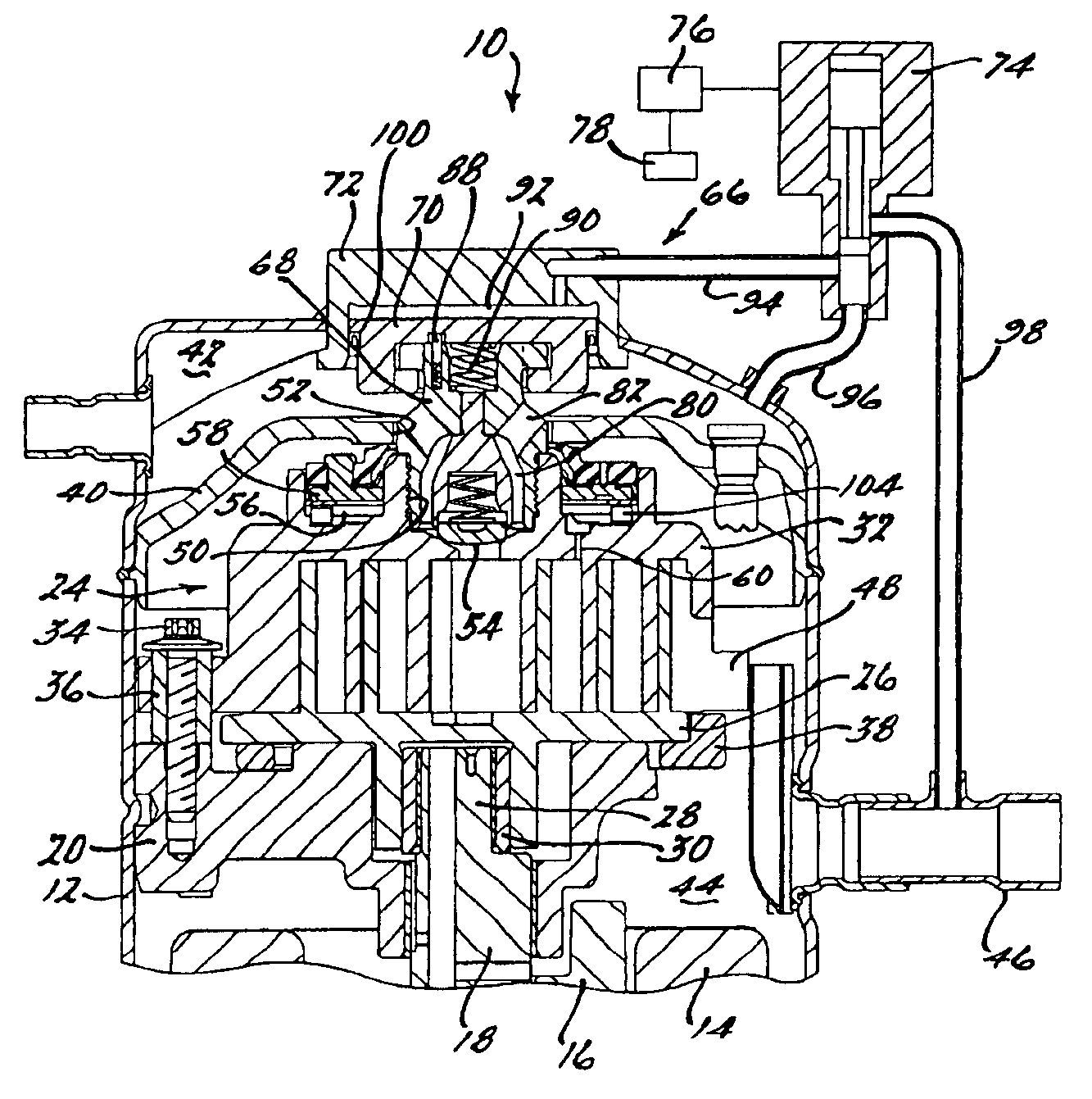

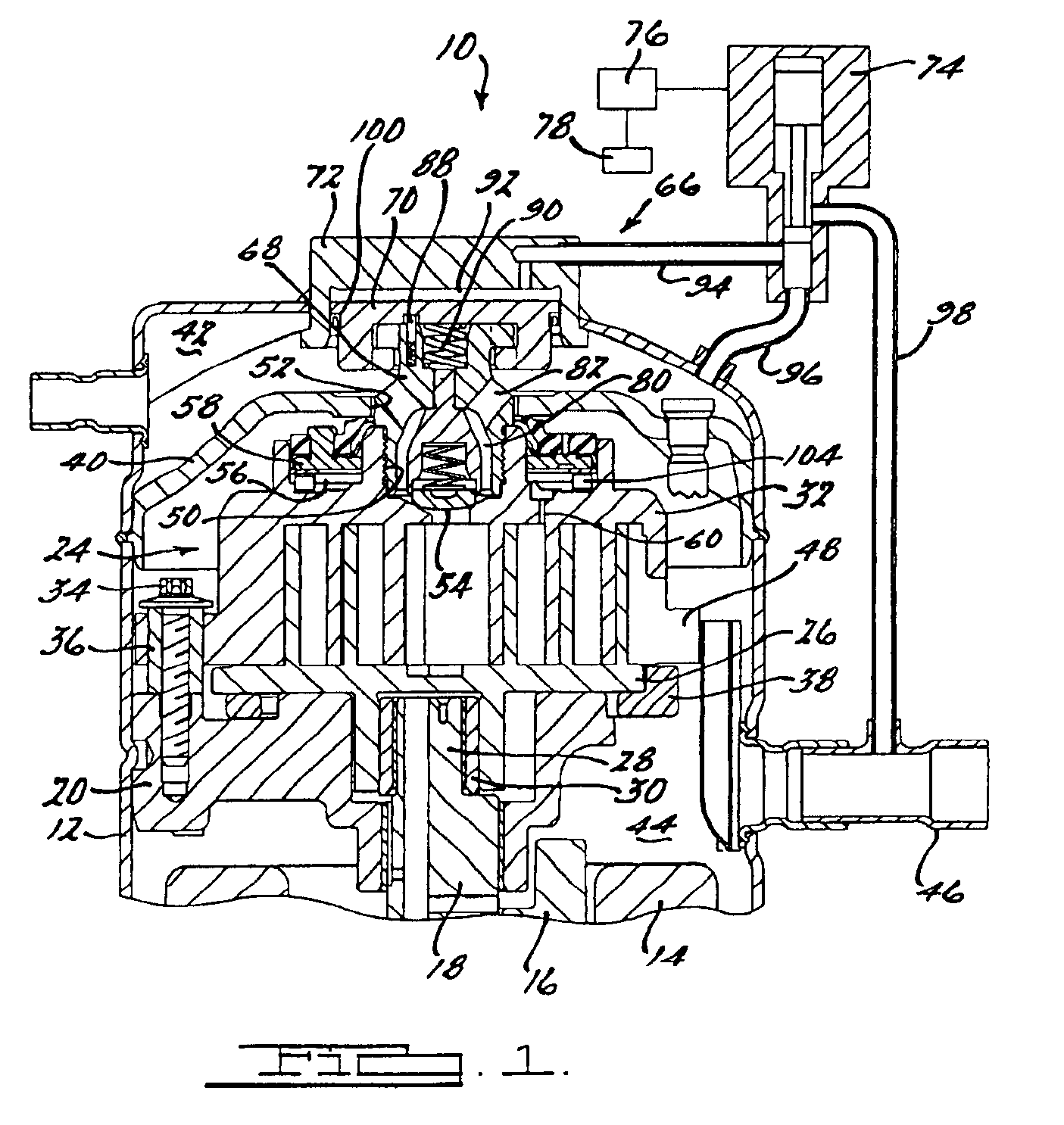

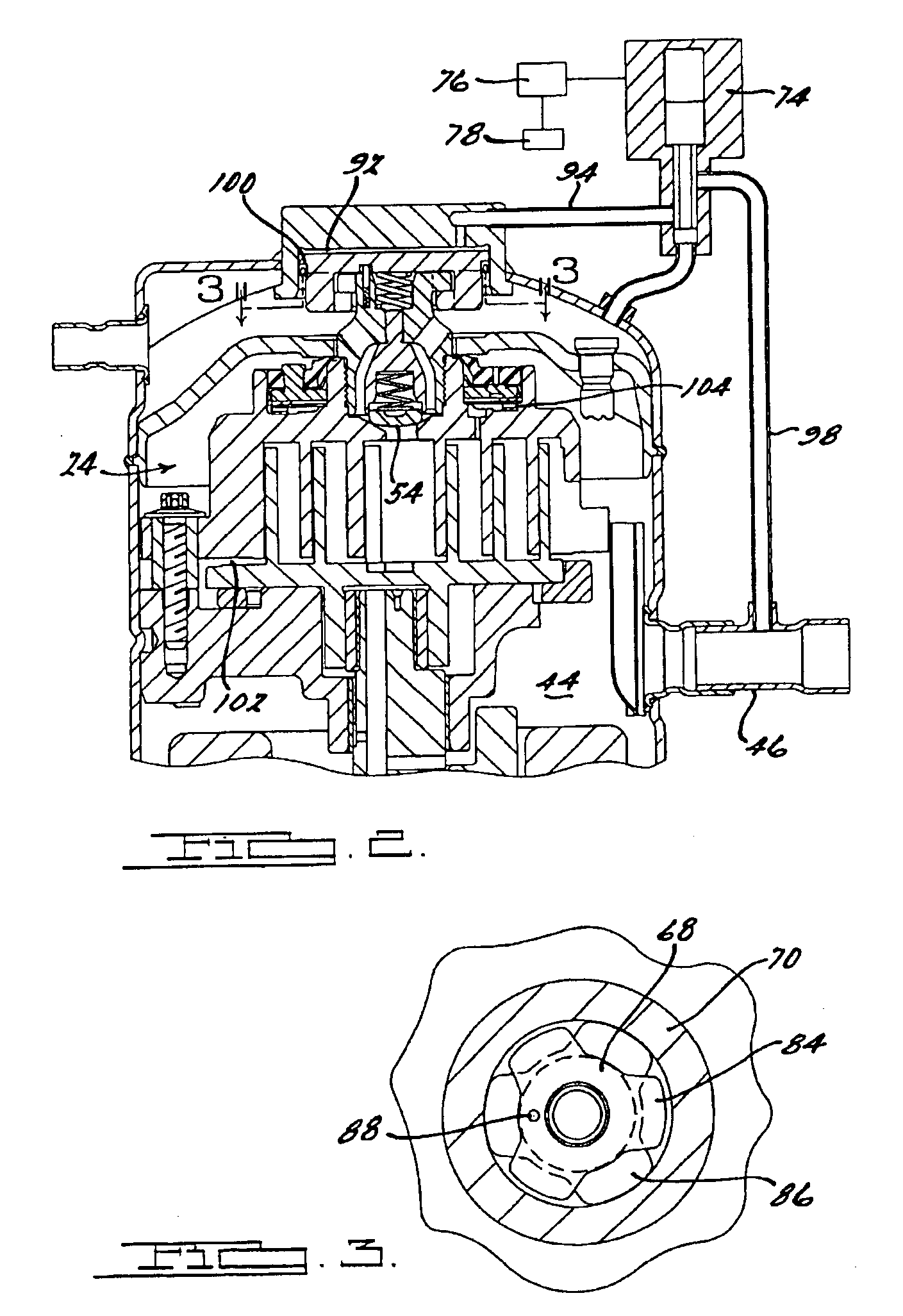

[0025]Referring now to the drawings in which like reference numerals designate like or corresponding parts throughout the several views, there is shown in FIG. 1 a scroll compressor which includes the unique capacity control system in accordance with the present invention and which is designated generally by the reference numeral 10. Scroll compressor 10 is generally of the type described in Assignee's U.S. Pat. No. 5,102,316, the disclosure of which is incorporated herein by reference. Scroll compressor 10 comprises an outer shell 12 within which is disposed a driving motor including a stator 14 and a rotor 16, a crankshaft 18 to which rotor 16 is secured, an upper bearing housing 20 and a lower bearing housing (not shown) for rotatably supporting crankshaft 18 and a compressor assembly 24.

[0026]Compressor assembly 24 includes an orbiting scroll member 26 supported on upper bearing housing 20 and drivingly connected to crankshaft 18 via a crankpin 28 and a drive bushing 30. A non-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com