Patents

Literature

65results about How to "Maximize system efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

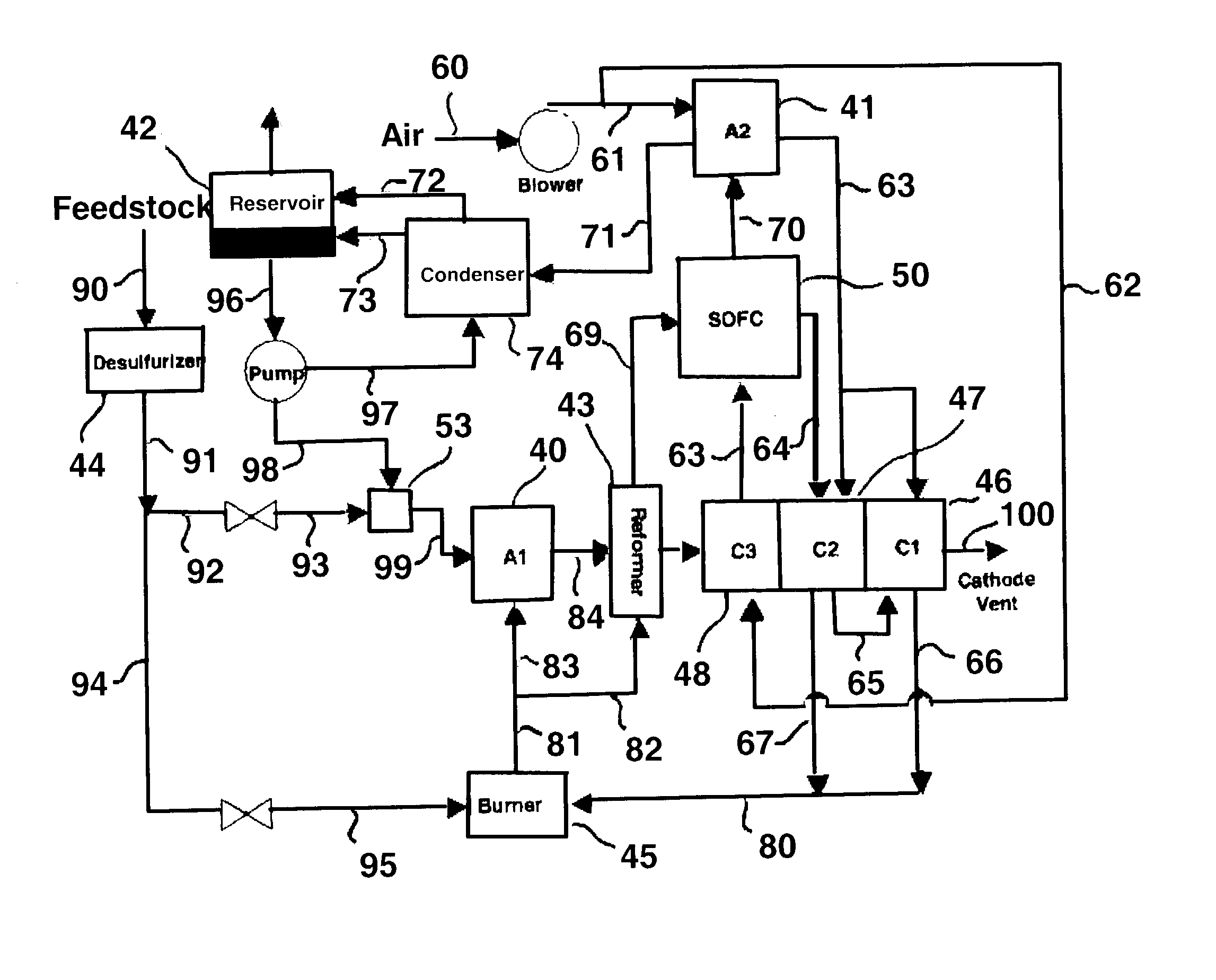

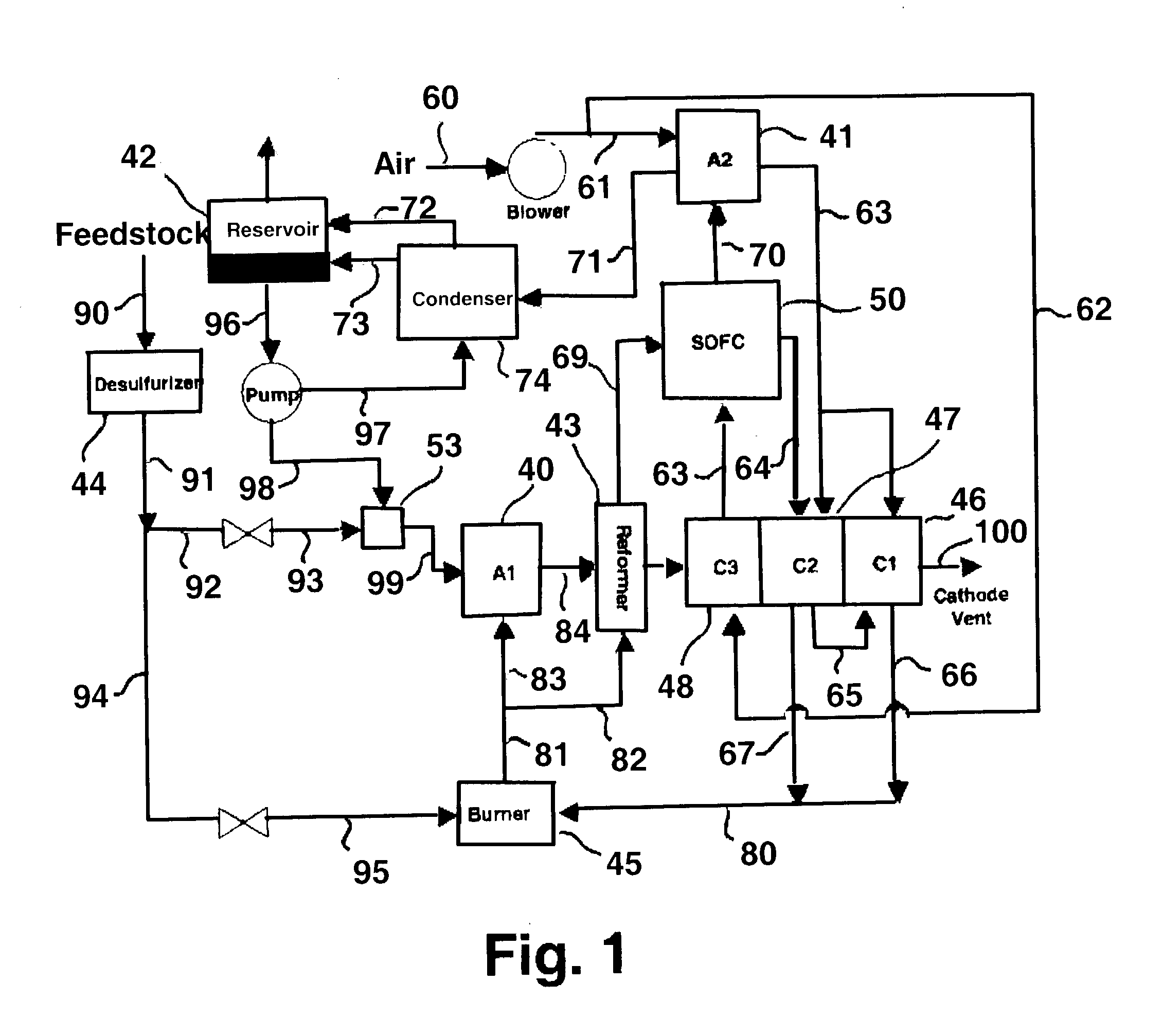

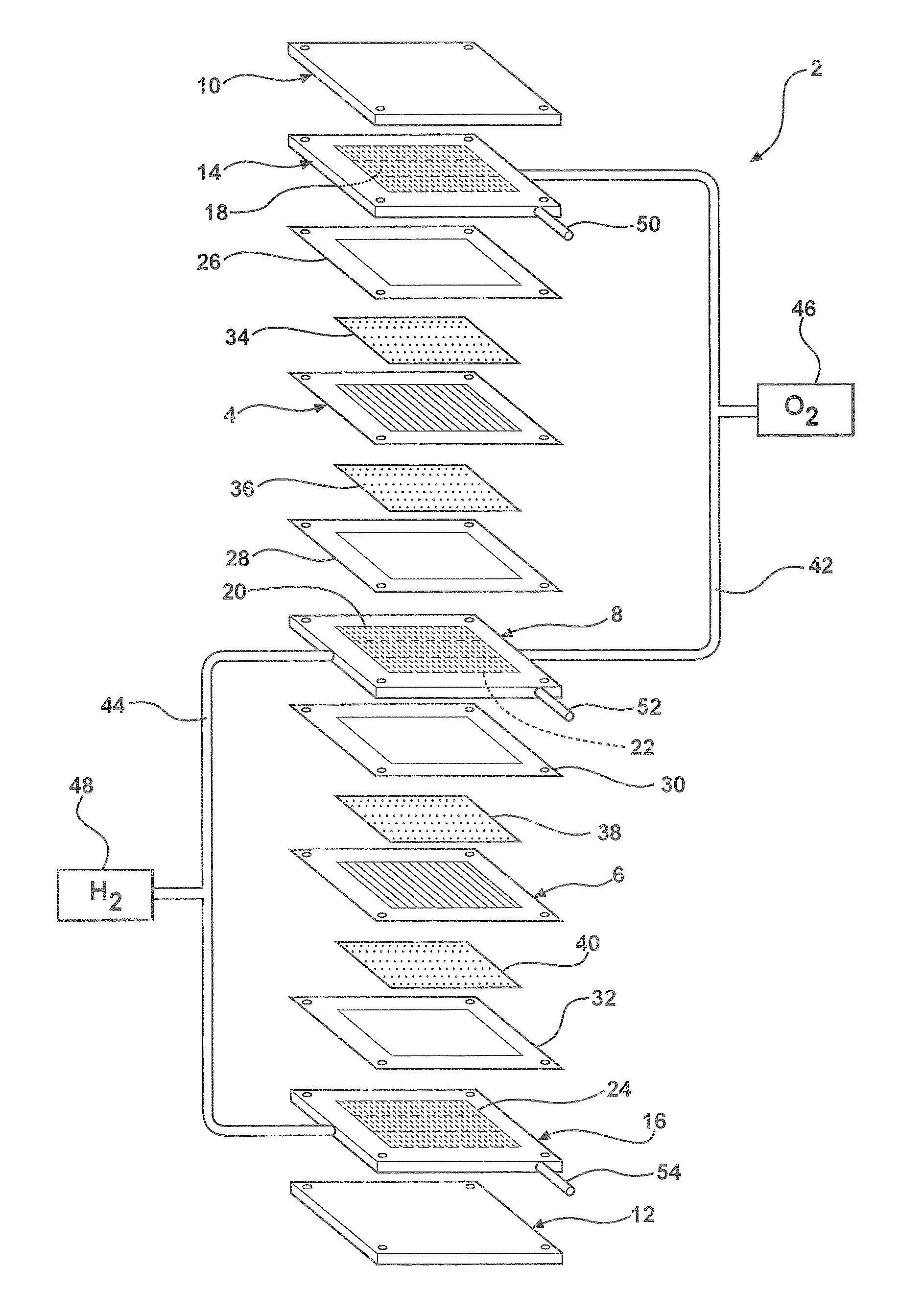

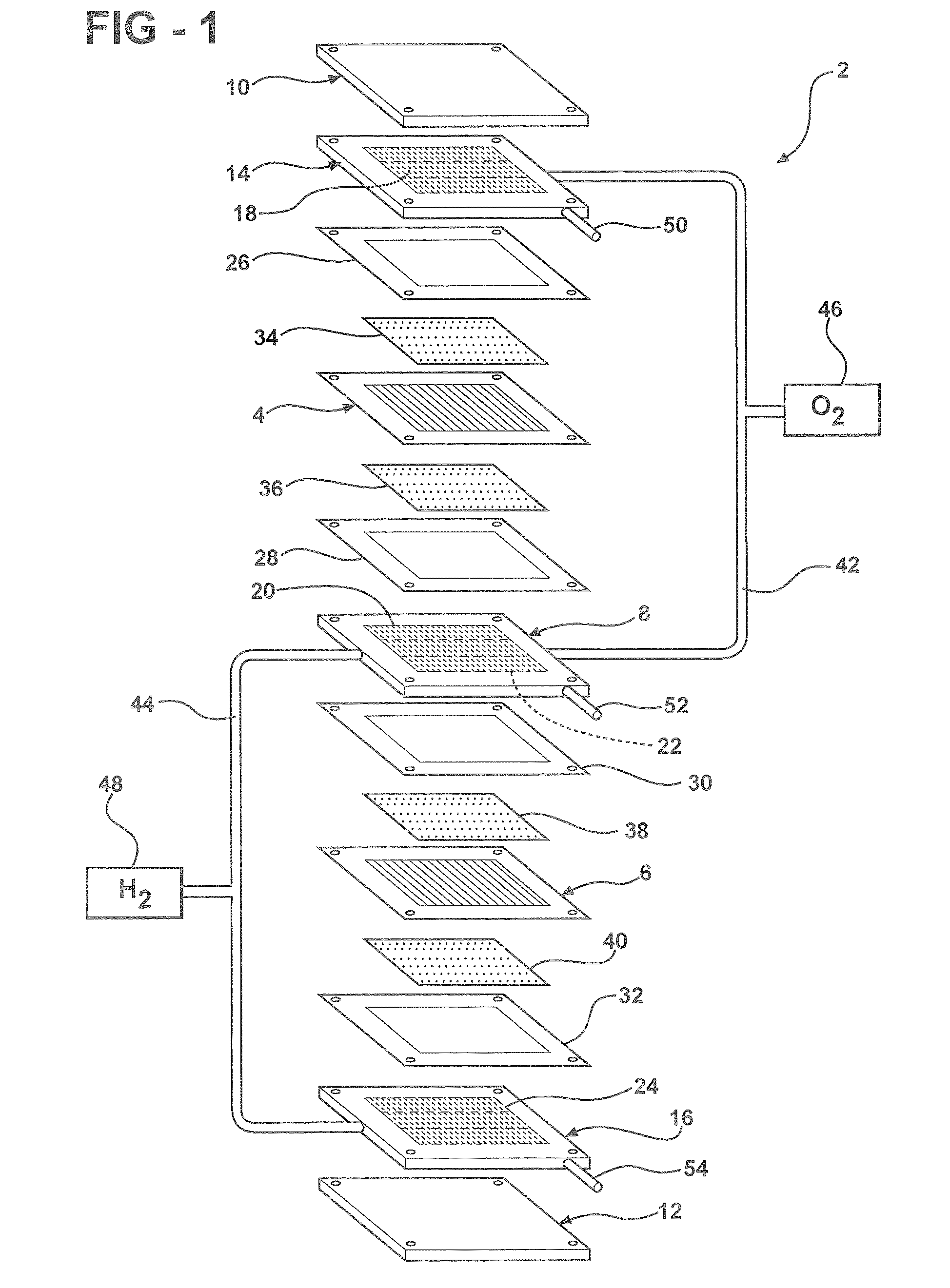

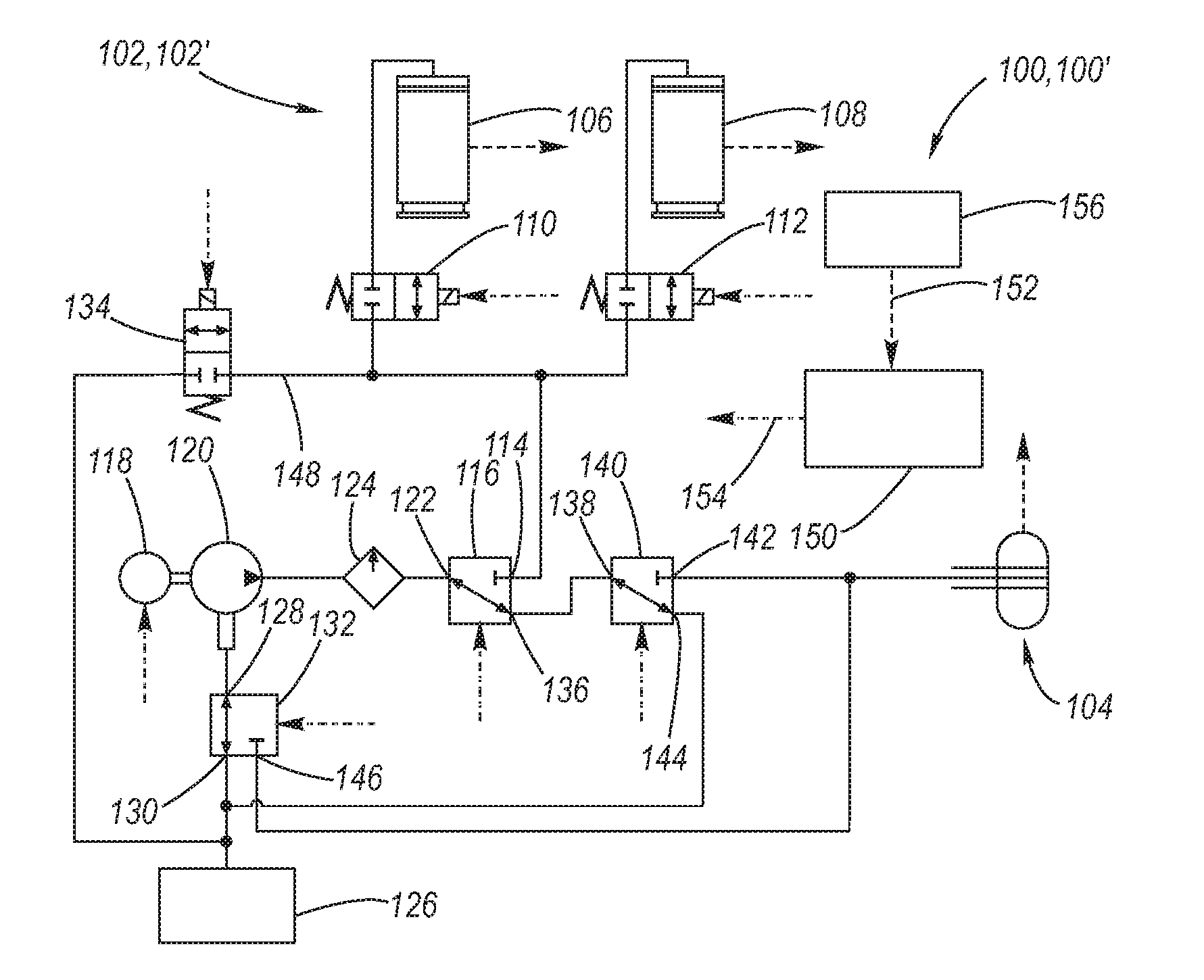

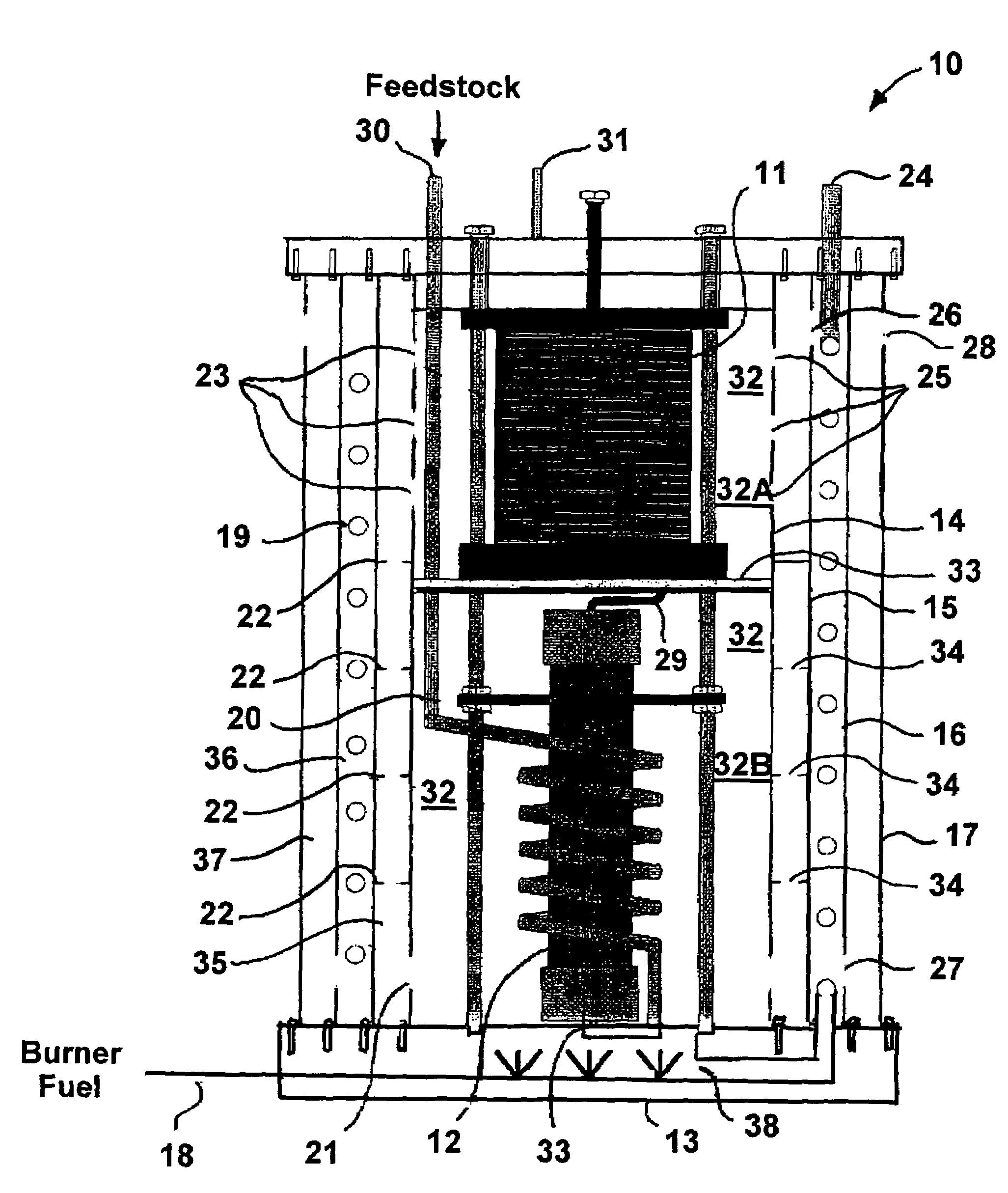

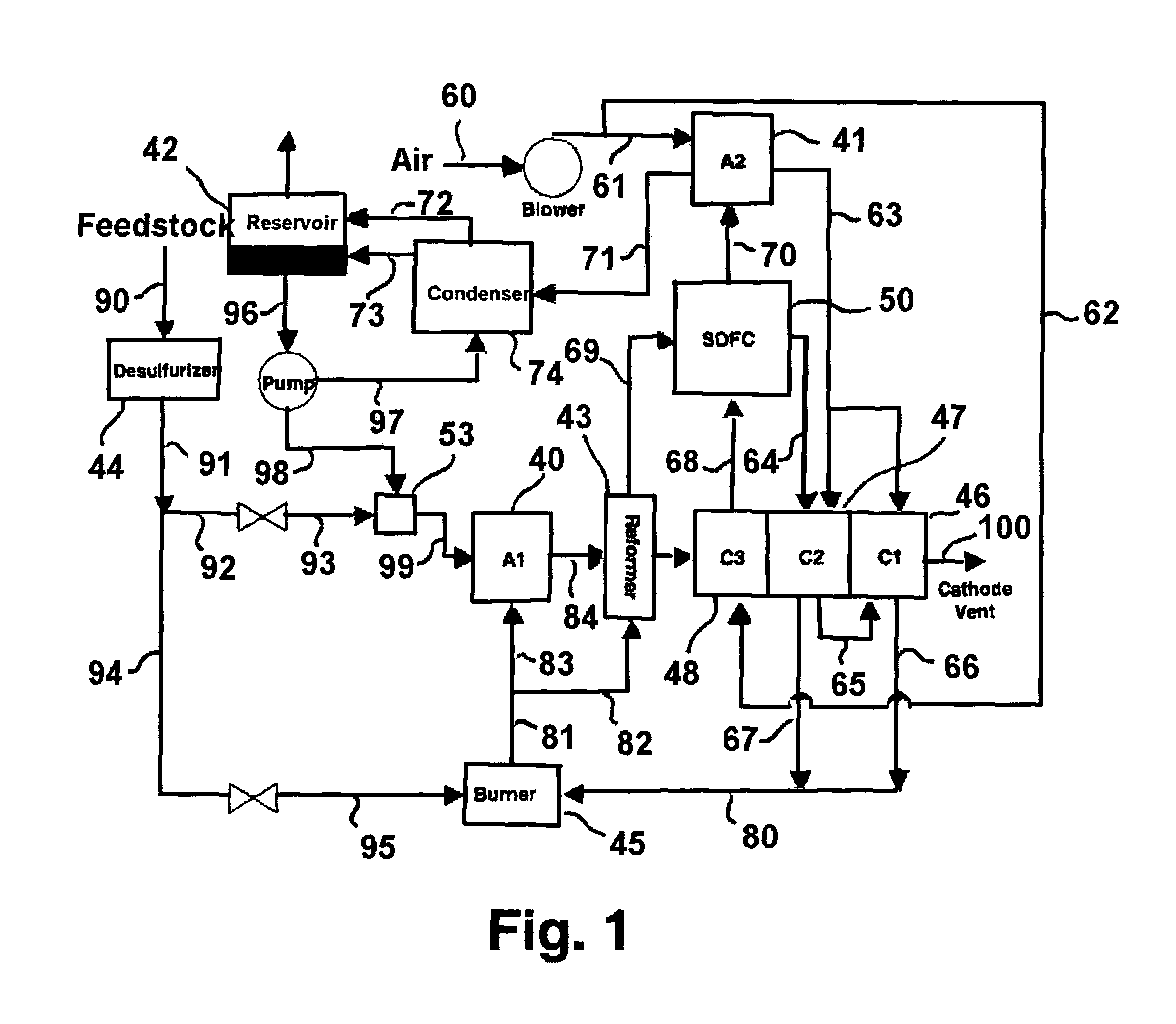

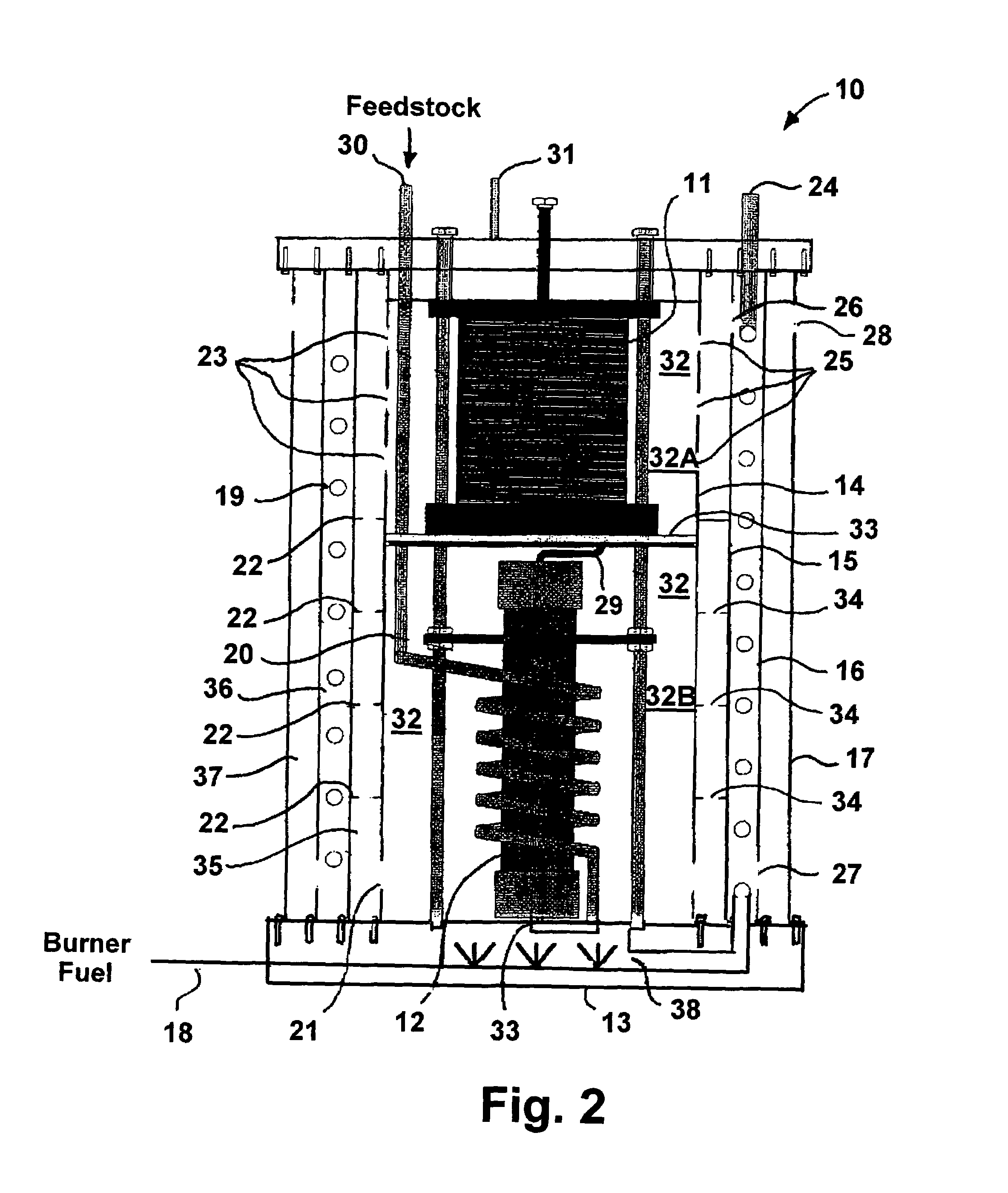

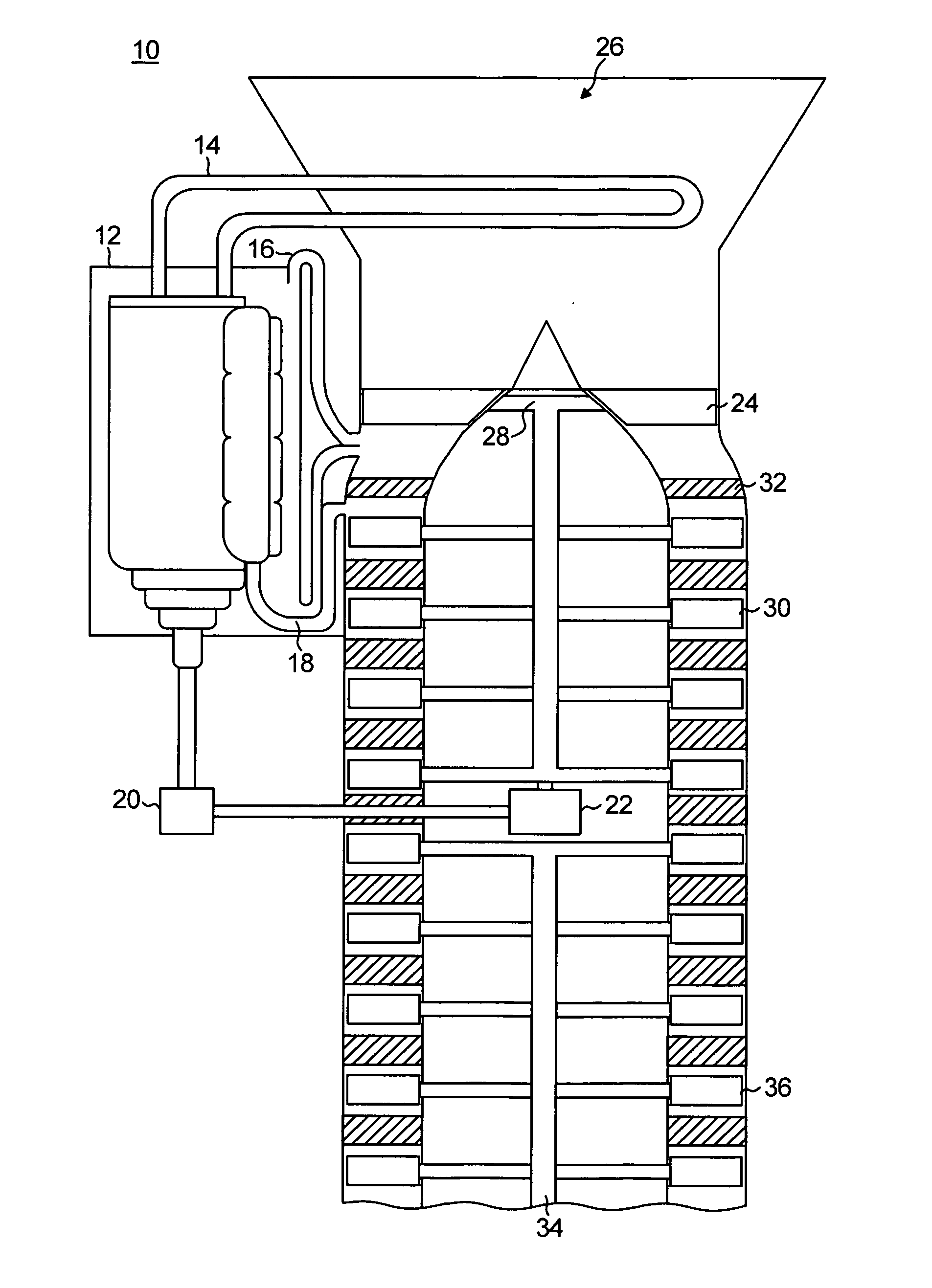

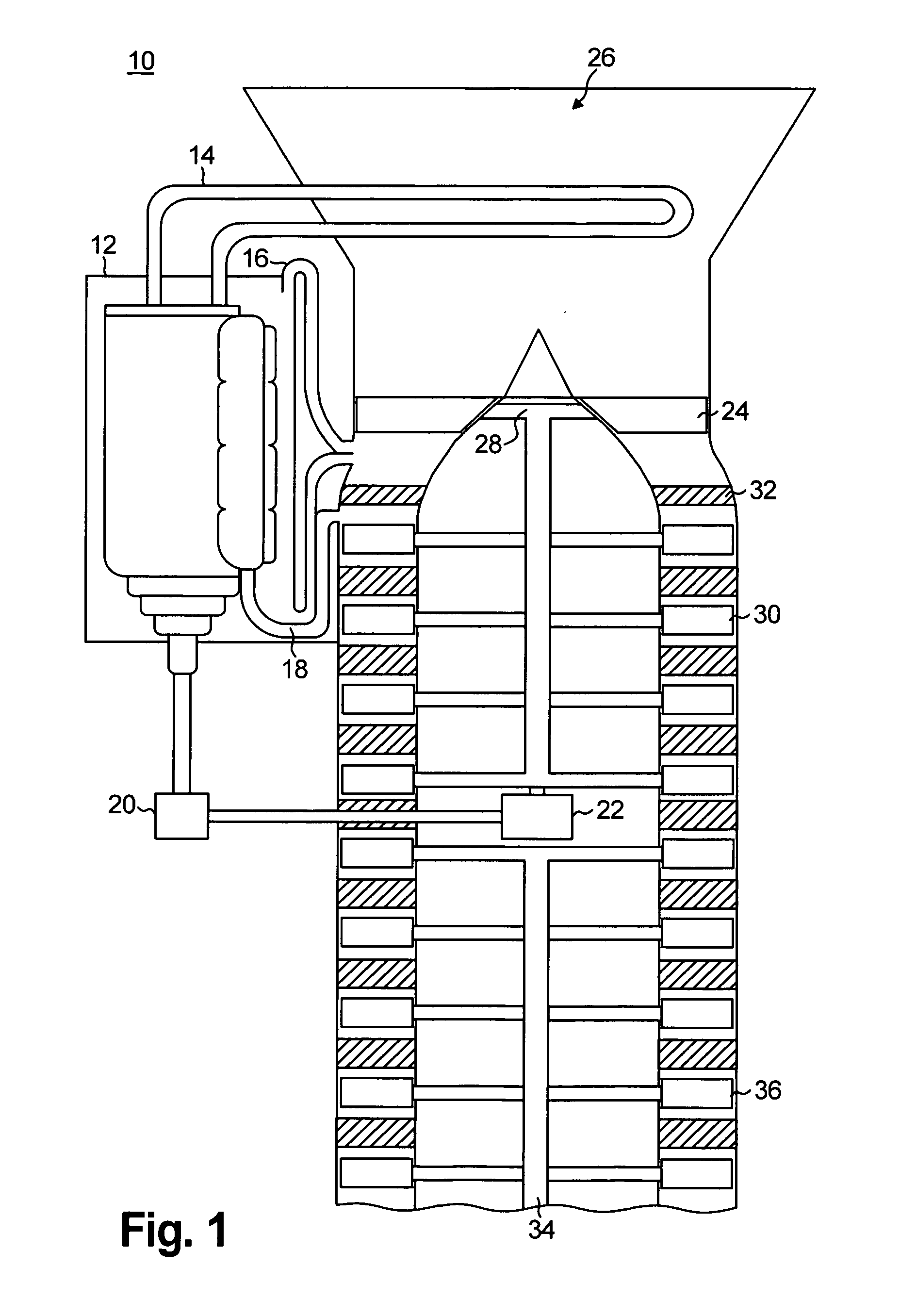

Thermally integrated fuel cell power system

InactiveUS20040146763A1Improve efficiencySimple designFuel cell heat exchangeFuel cells groupingFuel cellsHeat exchanger

A fuel cell power system having at least one fuel cell stack, at least one fuel processor in fluid communication with the at least one fuel cell stack and heat exchangers for transferring heat between the at least one fuel cell stack and the at least one fuel processor in which the at least one fuel cell stack and the at least one fuel processor are circumferentially surrounded by a plurality concentric heat exchanger shell assemblies.

Owner:GAS TECH INST

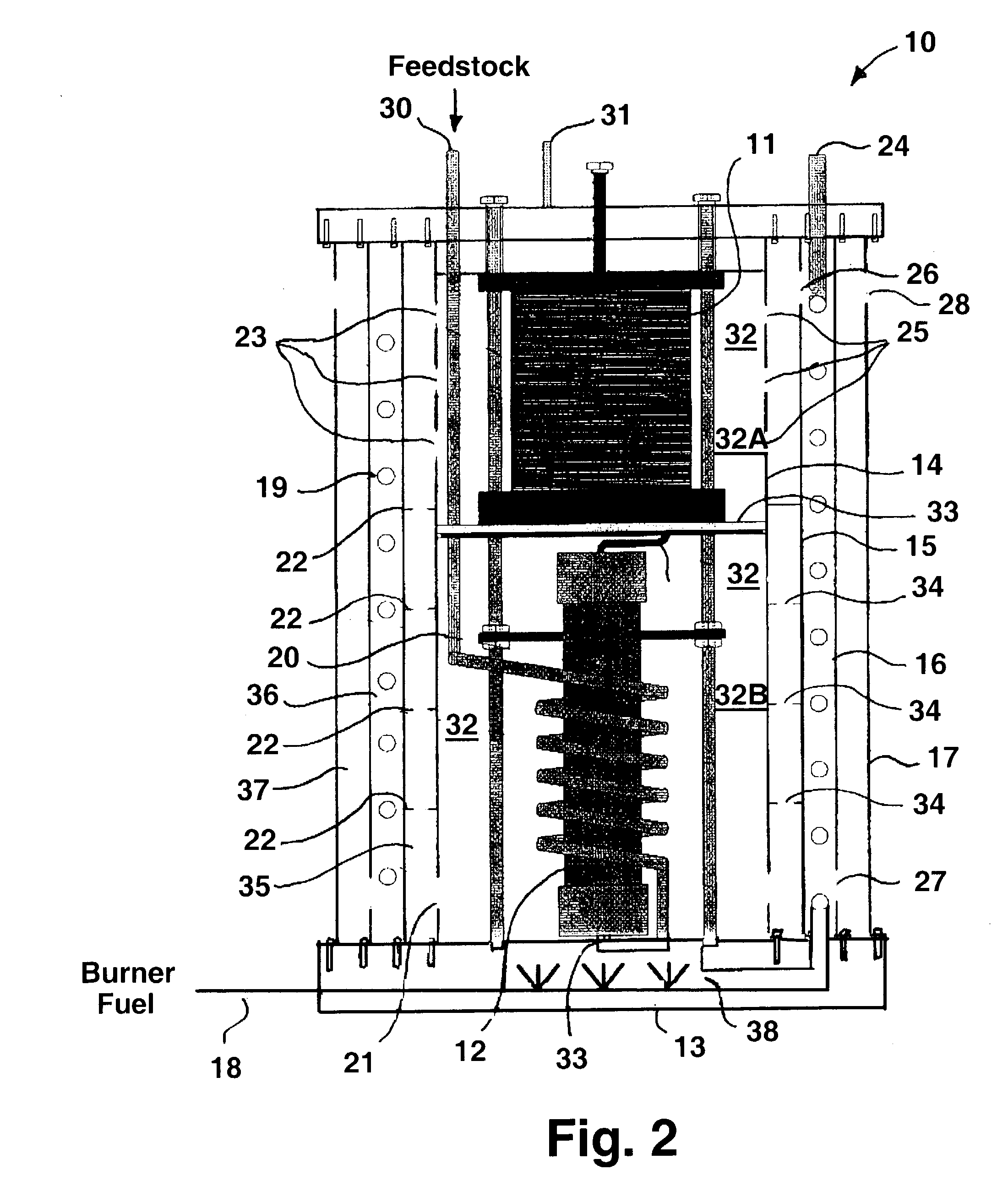

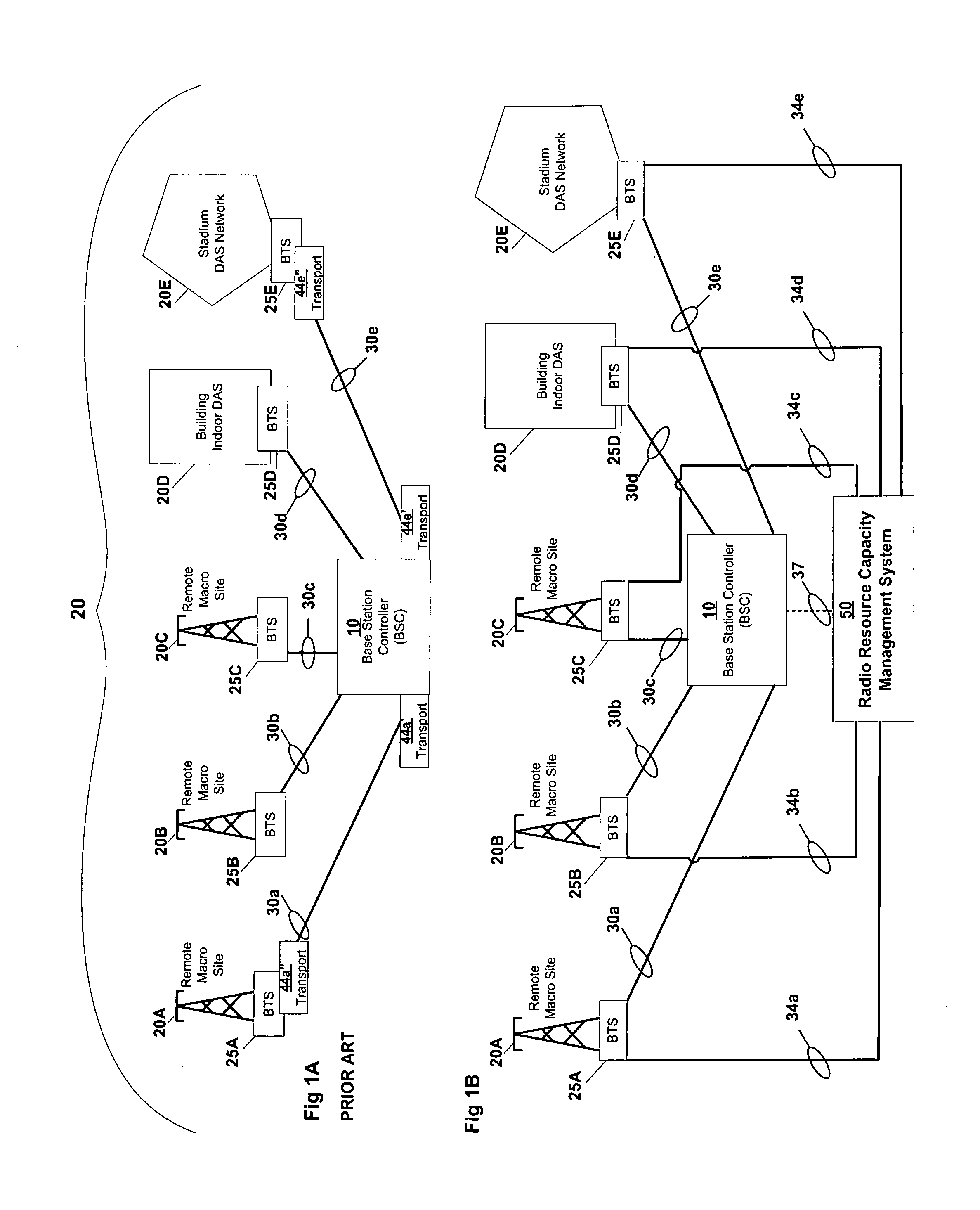

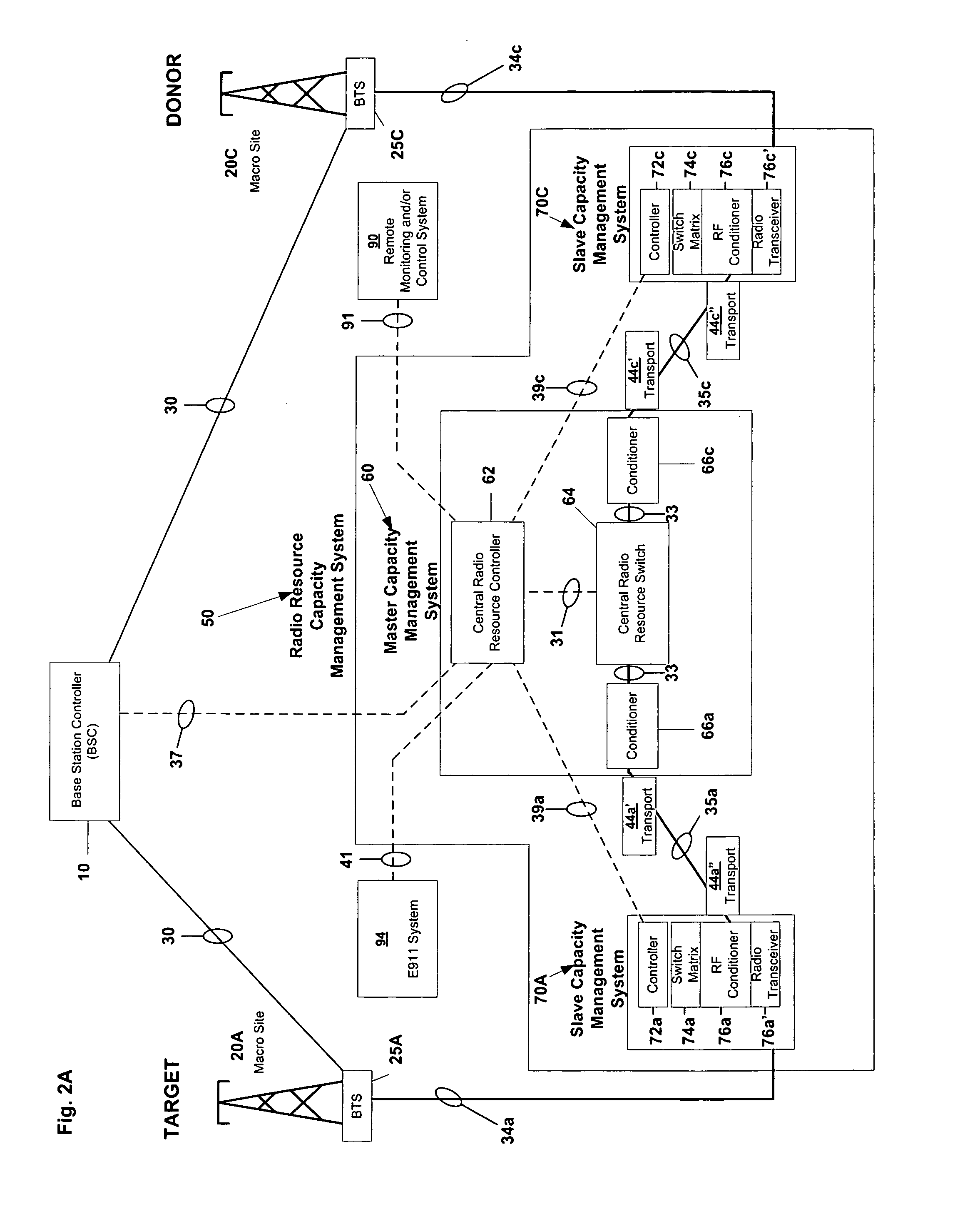

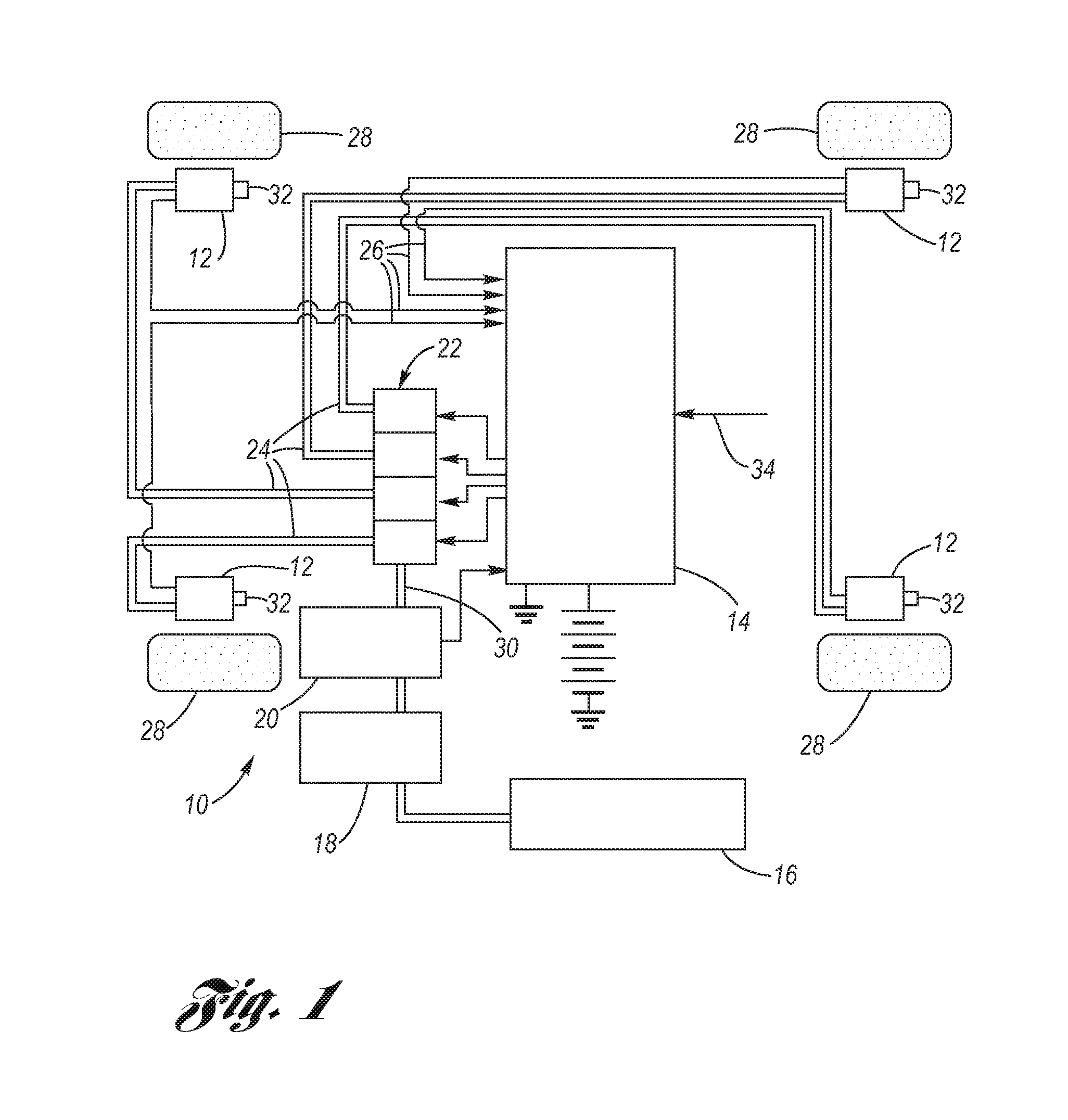

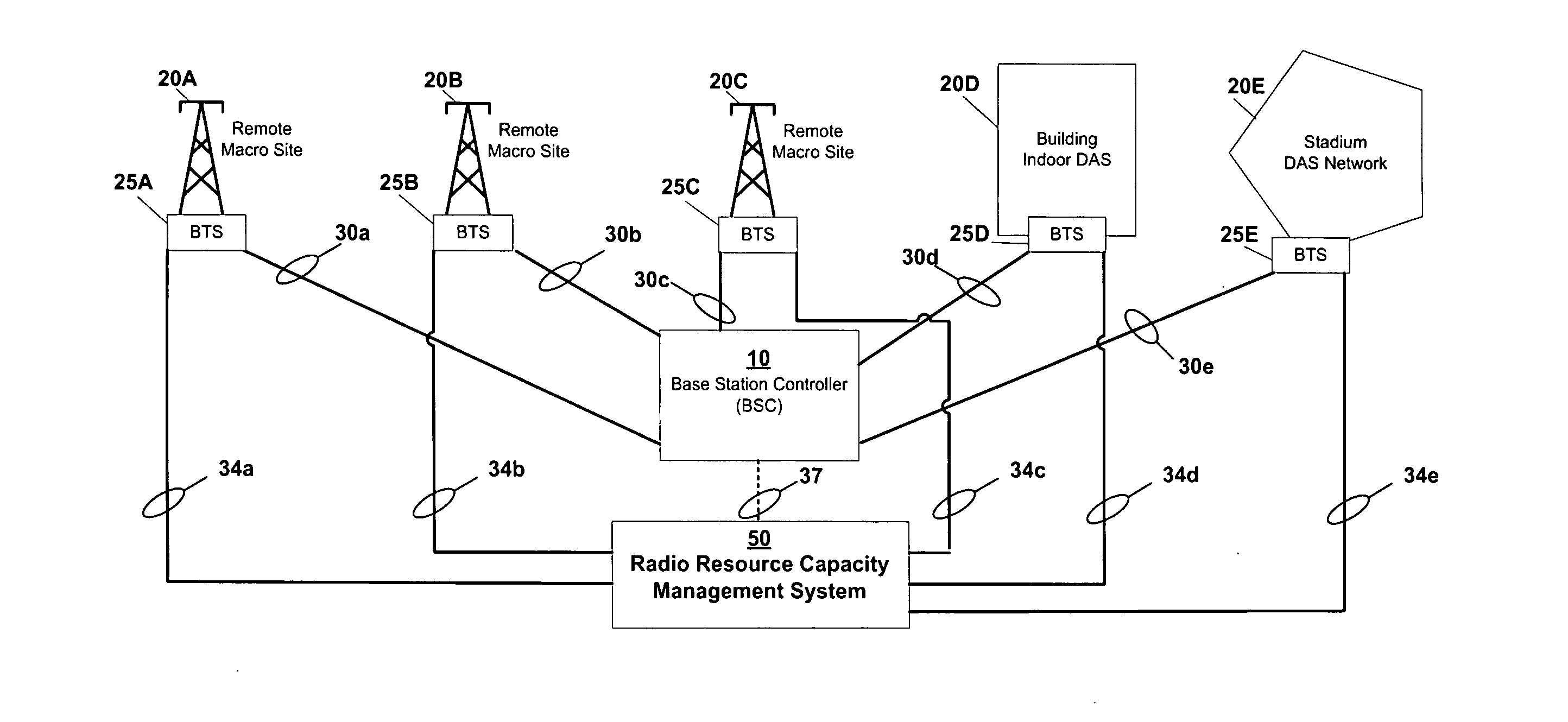

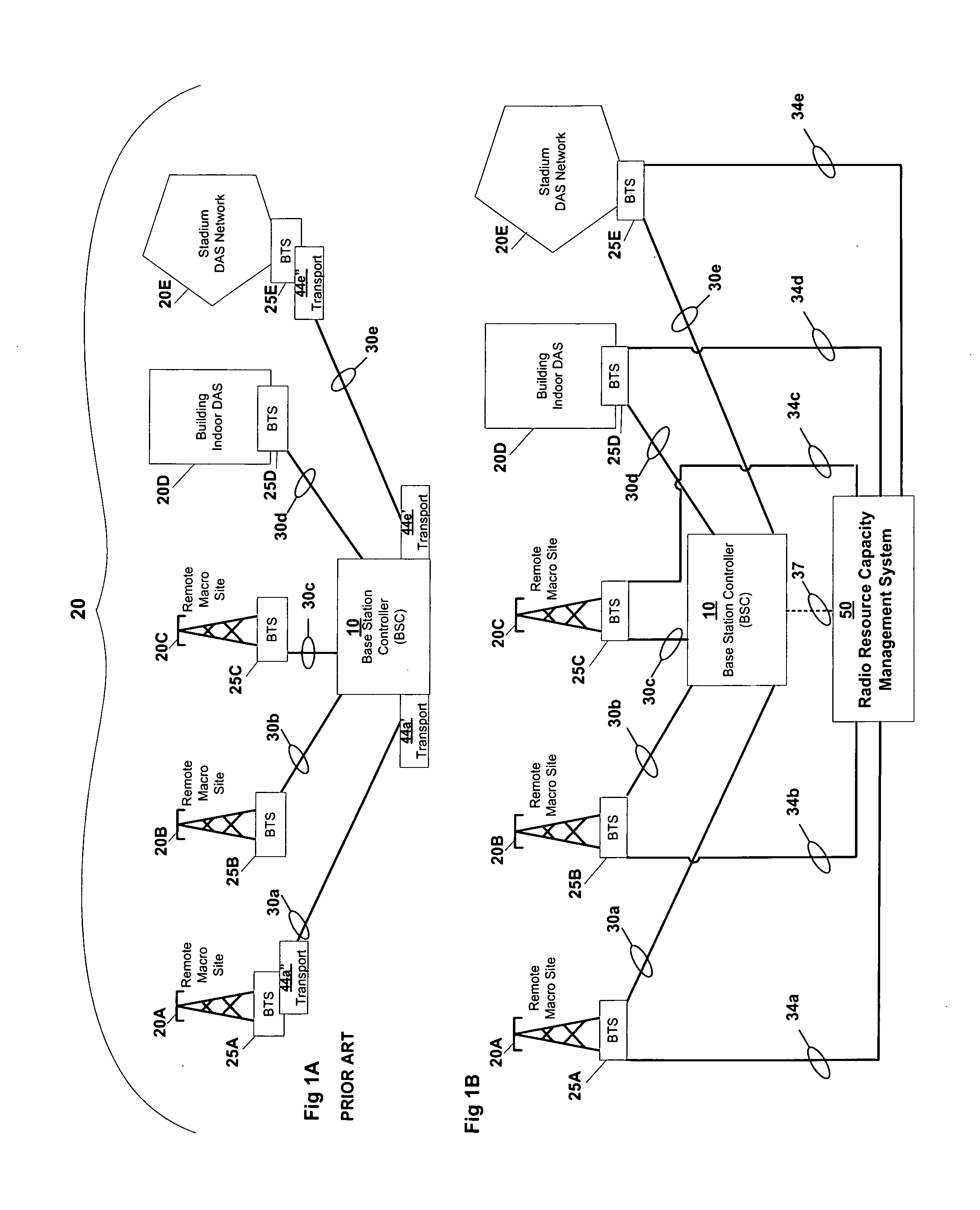

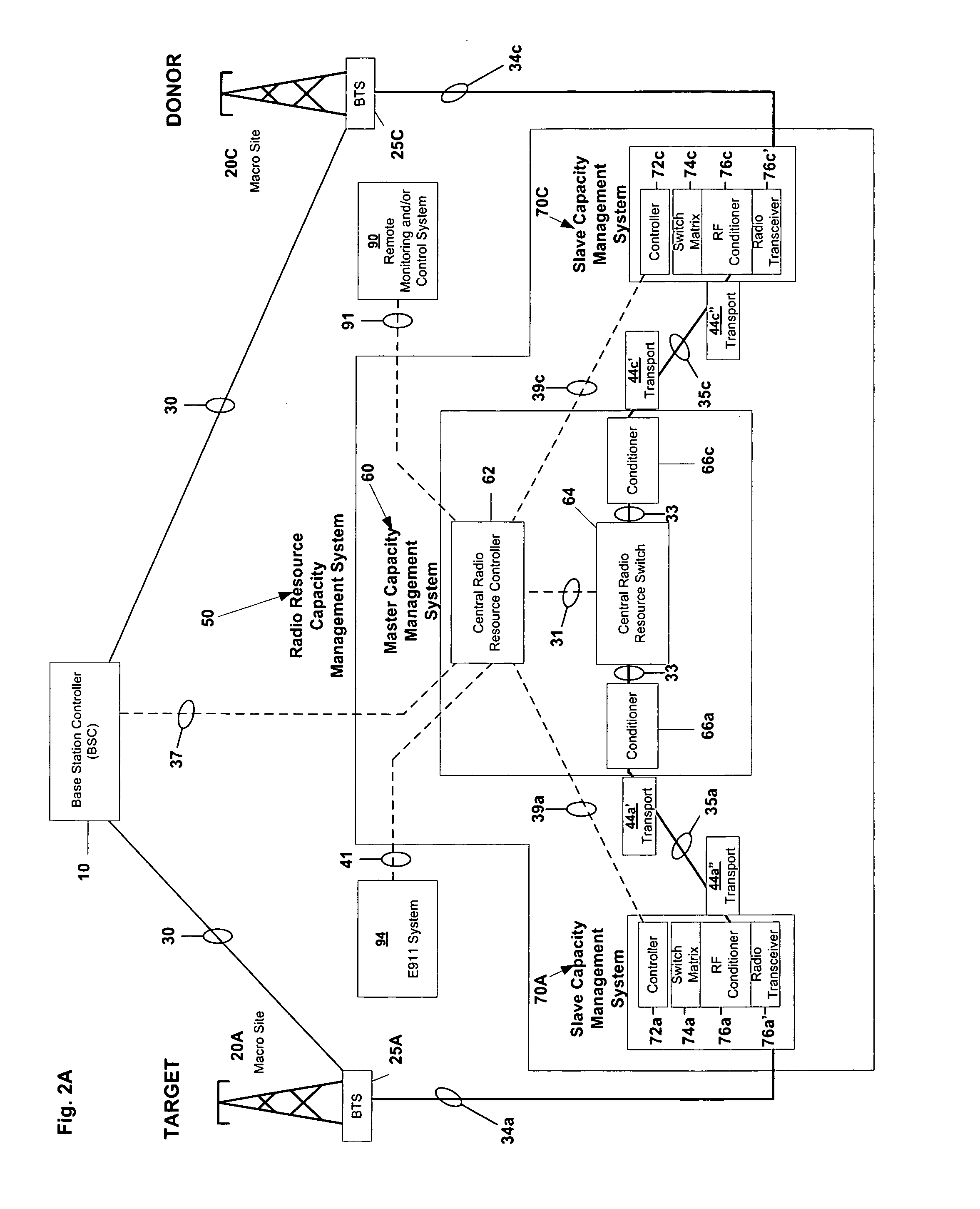

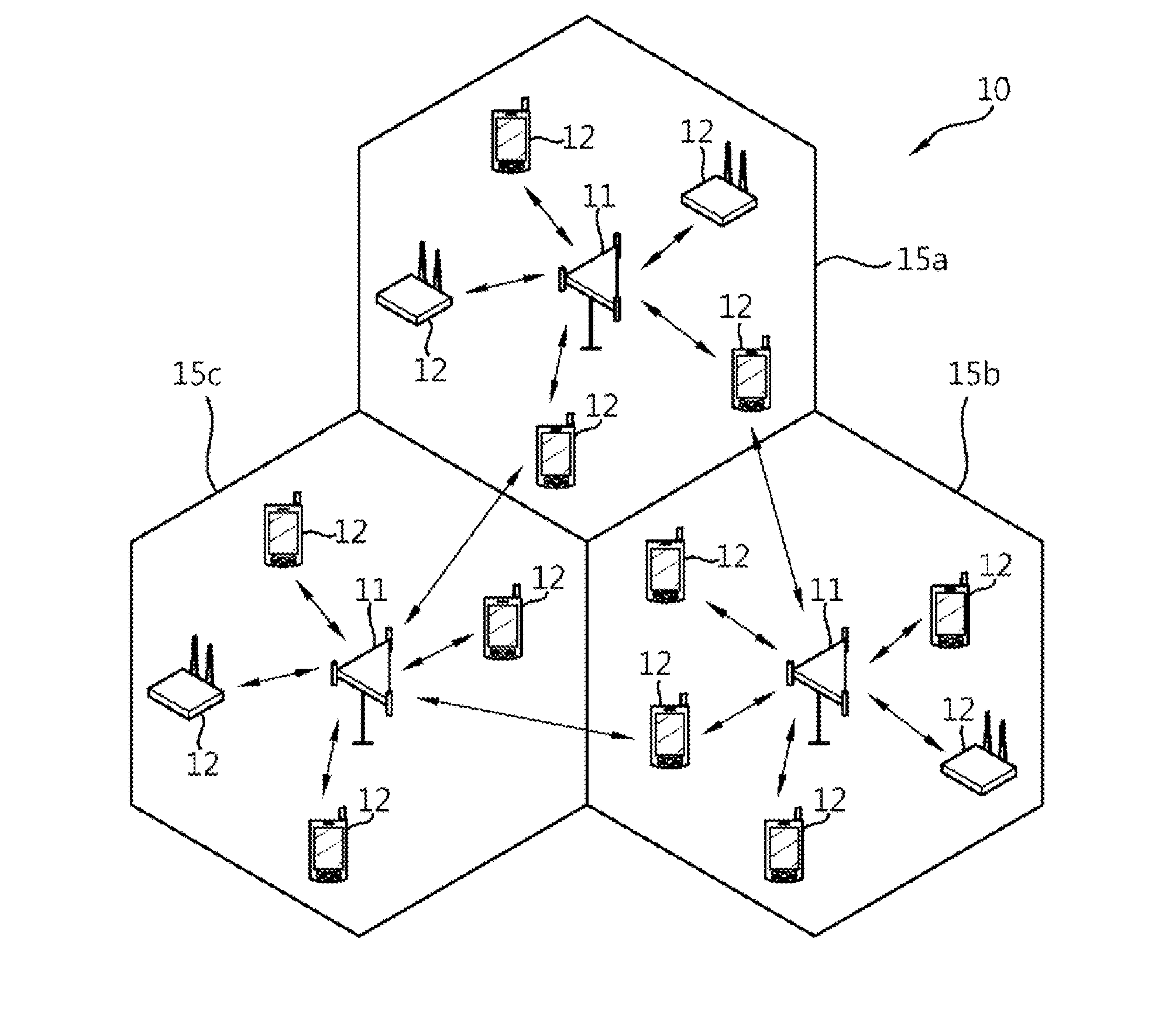

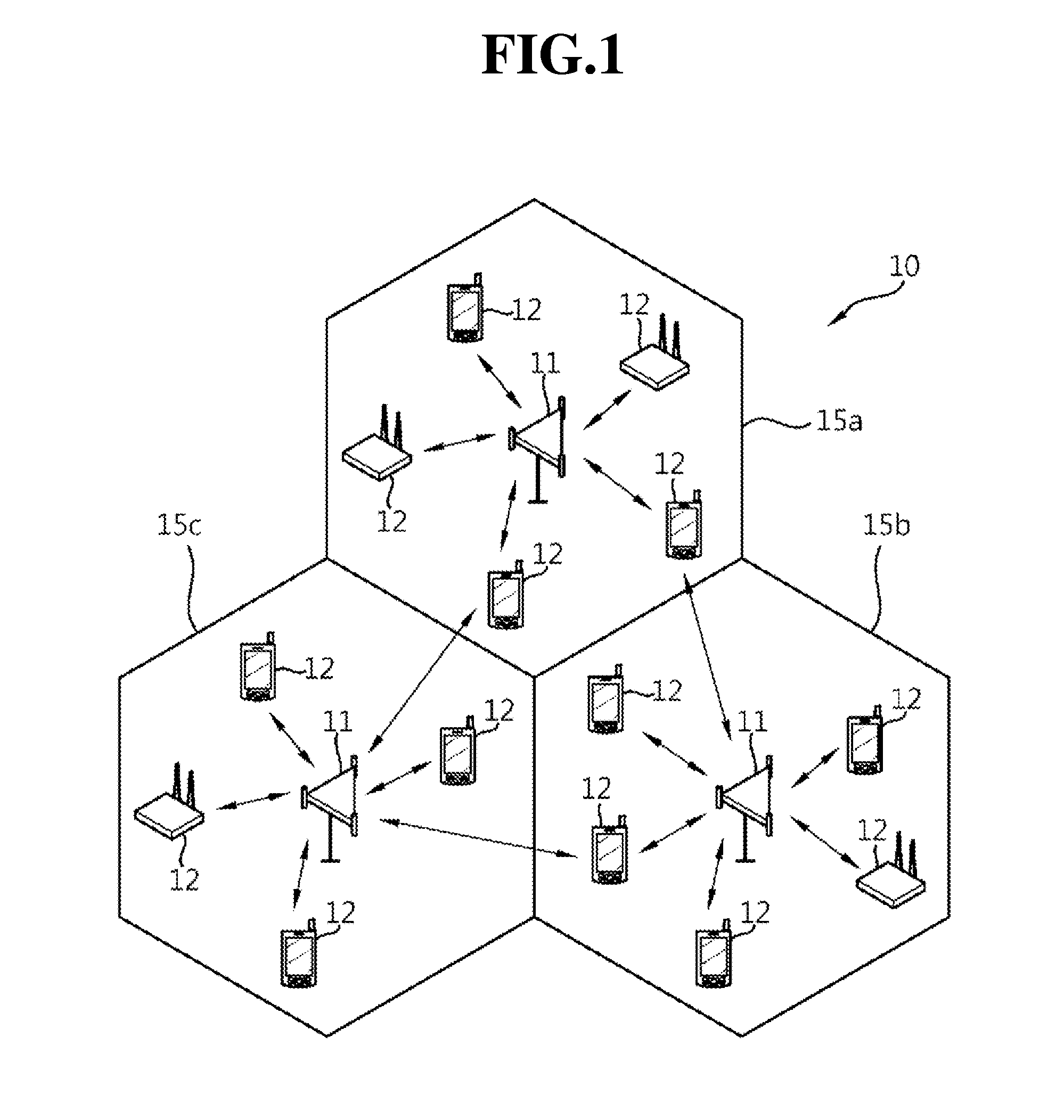

Method and system for switching cellular base station capacity

InactiveUS20120178483A1Maximize system efficiencyFacilitates physical transferNetwork traffic/resource managementSubstation equipmentTransceiverManagement system

A radio capacity management system (RCMS) and method are adapted to integrate within an existing network of cells that form a local cellular wireless communications network. The RCMS is not limited by the types or number of sites that form the cellular wireless communications network. Such sites have idle, redundant RF radio channel resources. The RCMS reallocates idle RF resources between the network of cells whether those resources are redundant or not. Reallocations are based on a dynamic, as-need basis or on historical quality-of-service data specific to each cell. The RCMS includes a master capacity management (MCMS) system that continuously communicates with a base station controller which provides resource capacity data from each site to the MCMS. The MCMS uses this date to determine when a cell requires additional radio transceiver capacity and where the capacity will be reallocated from.

Owner:UNBRIDLED NETWORKS

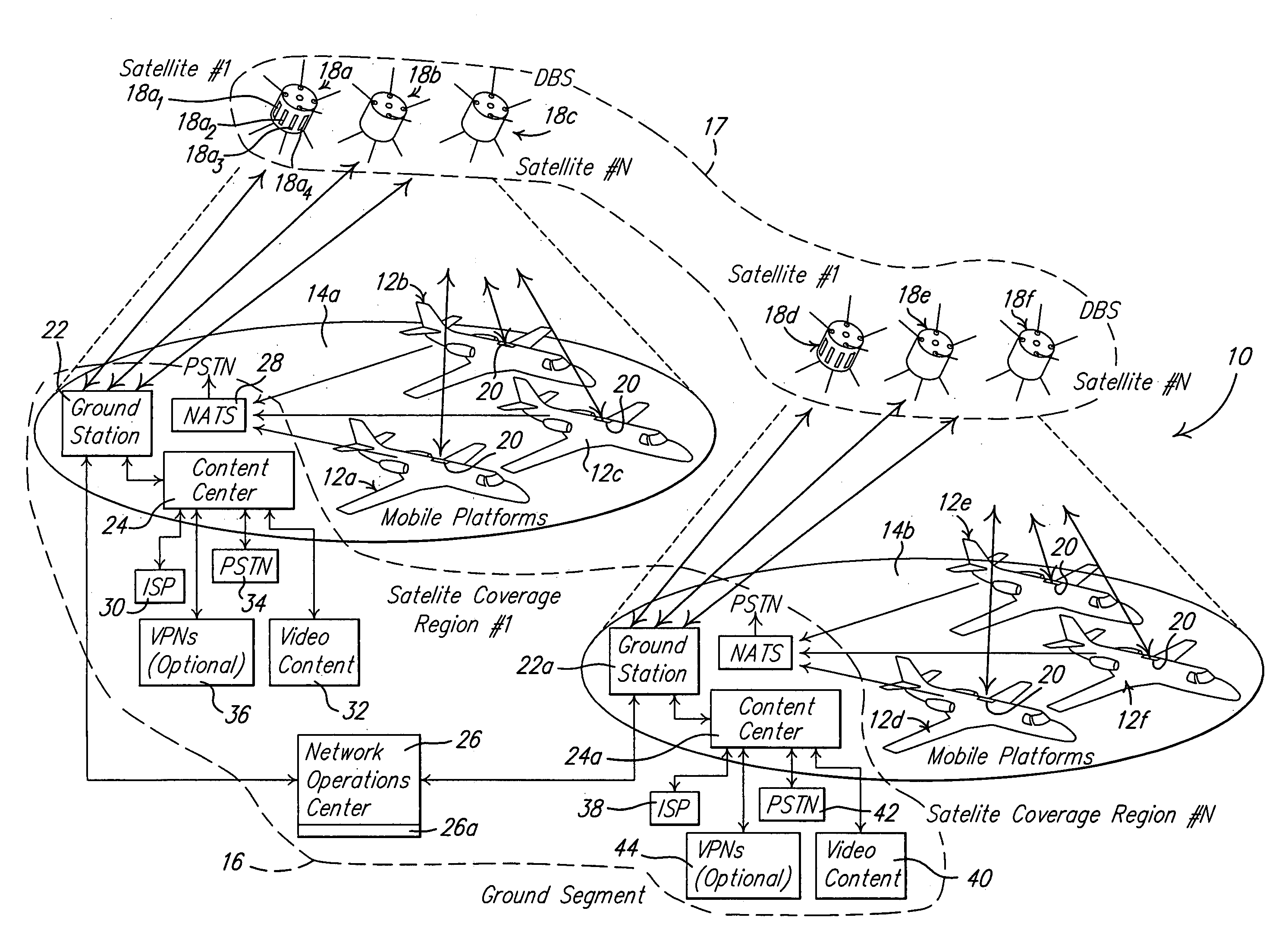

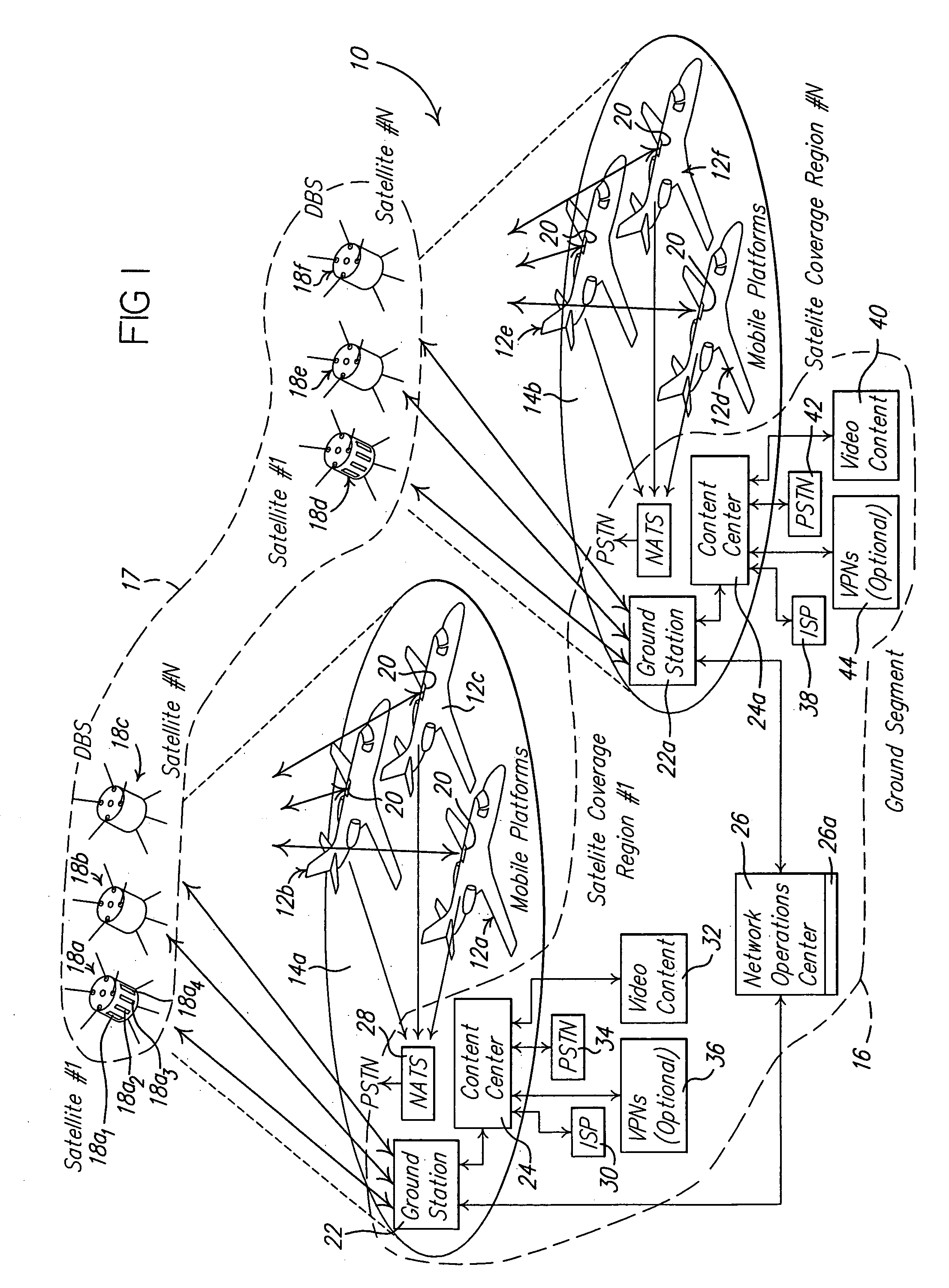

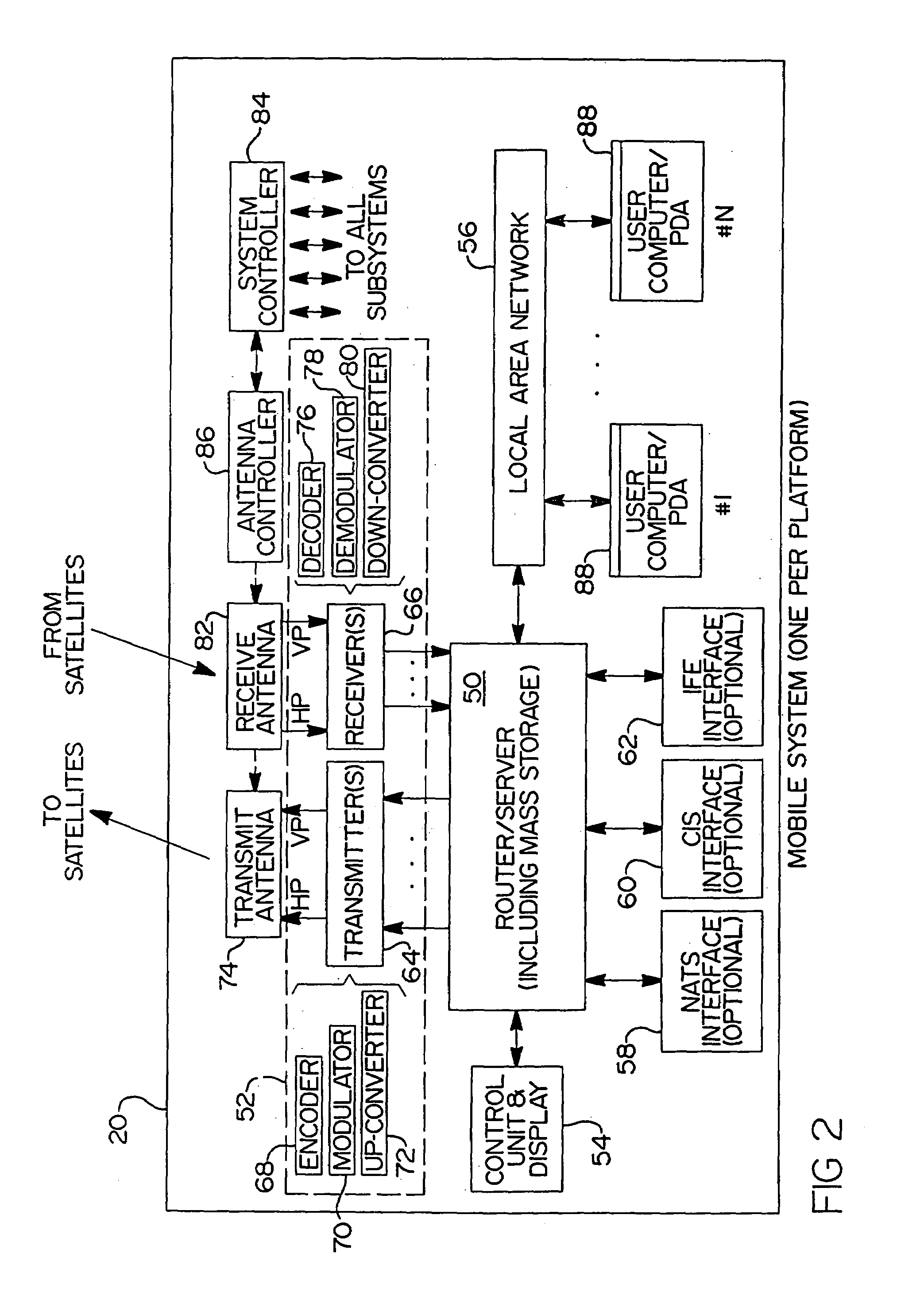

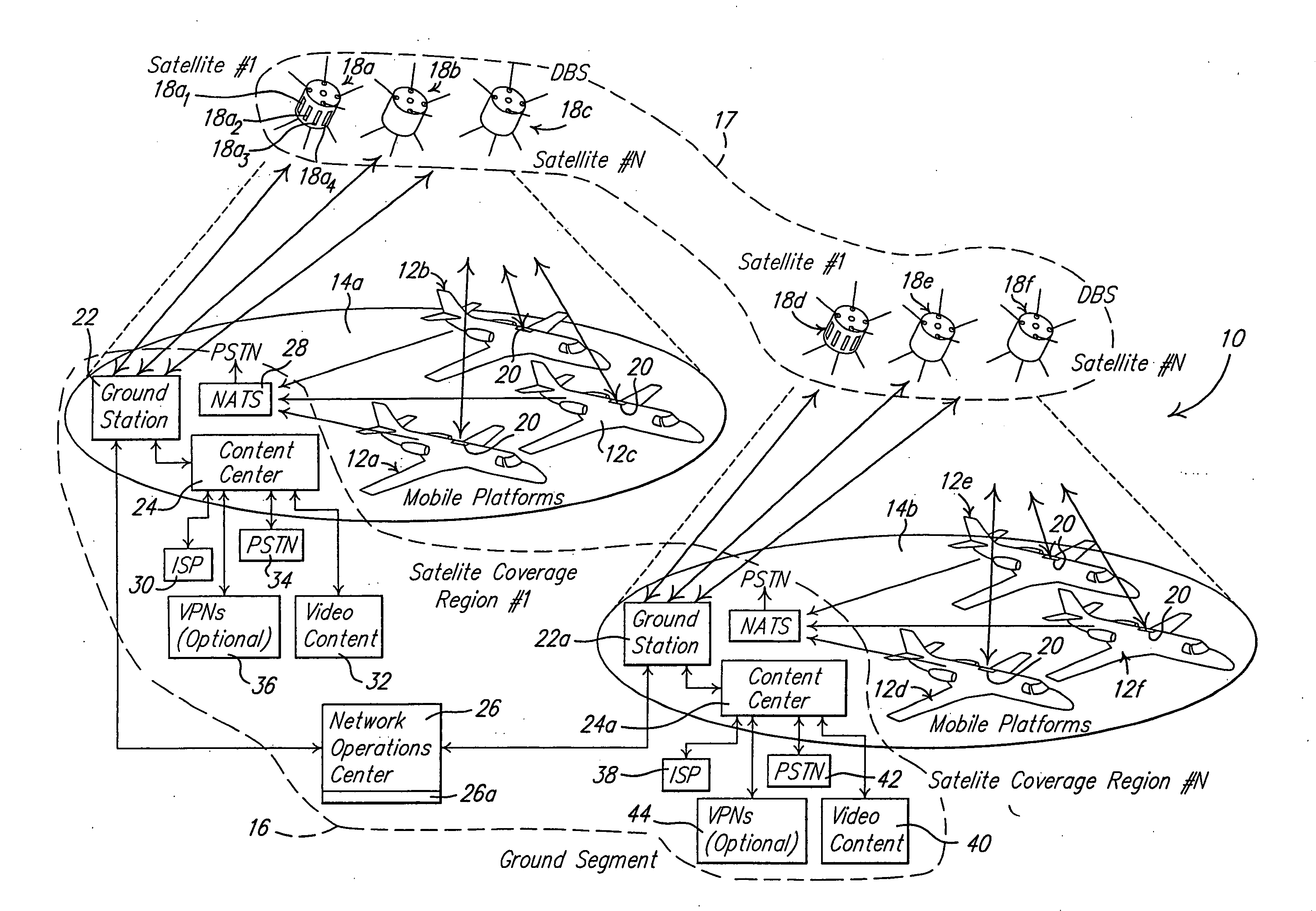

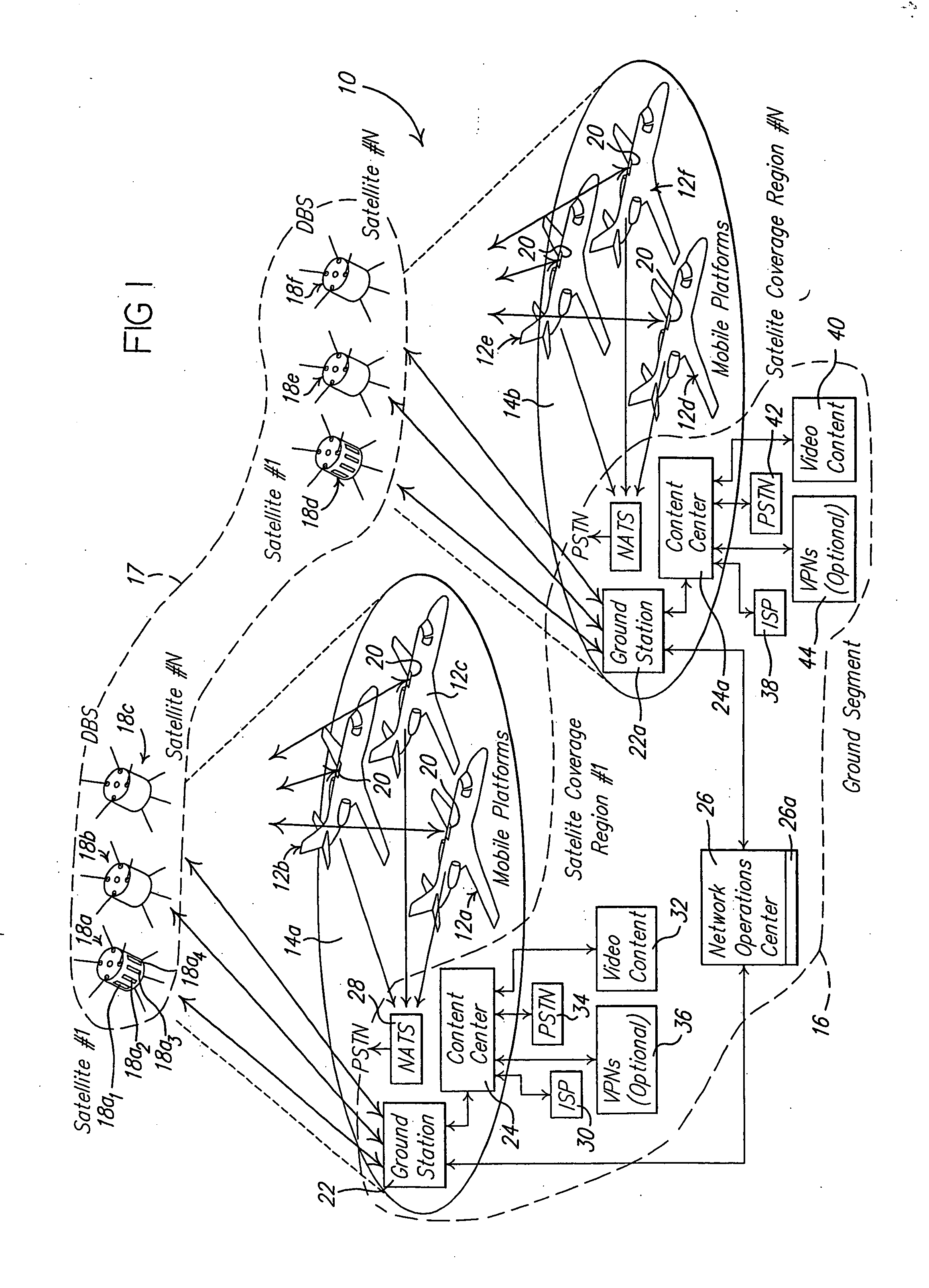

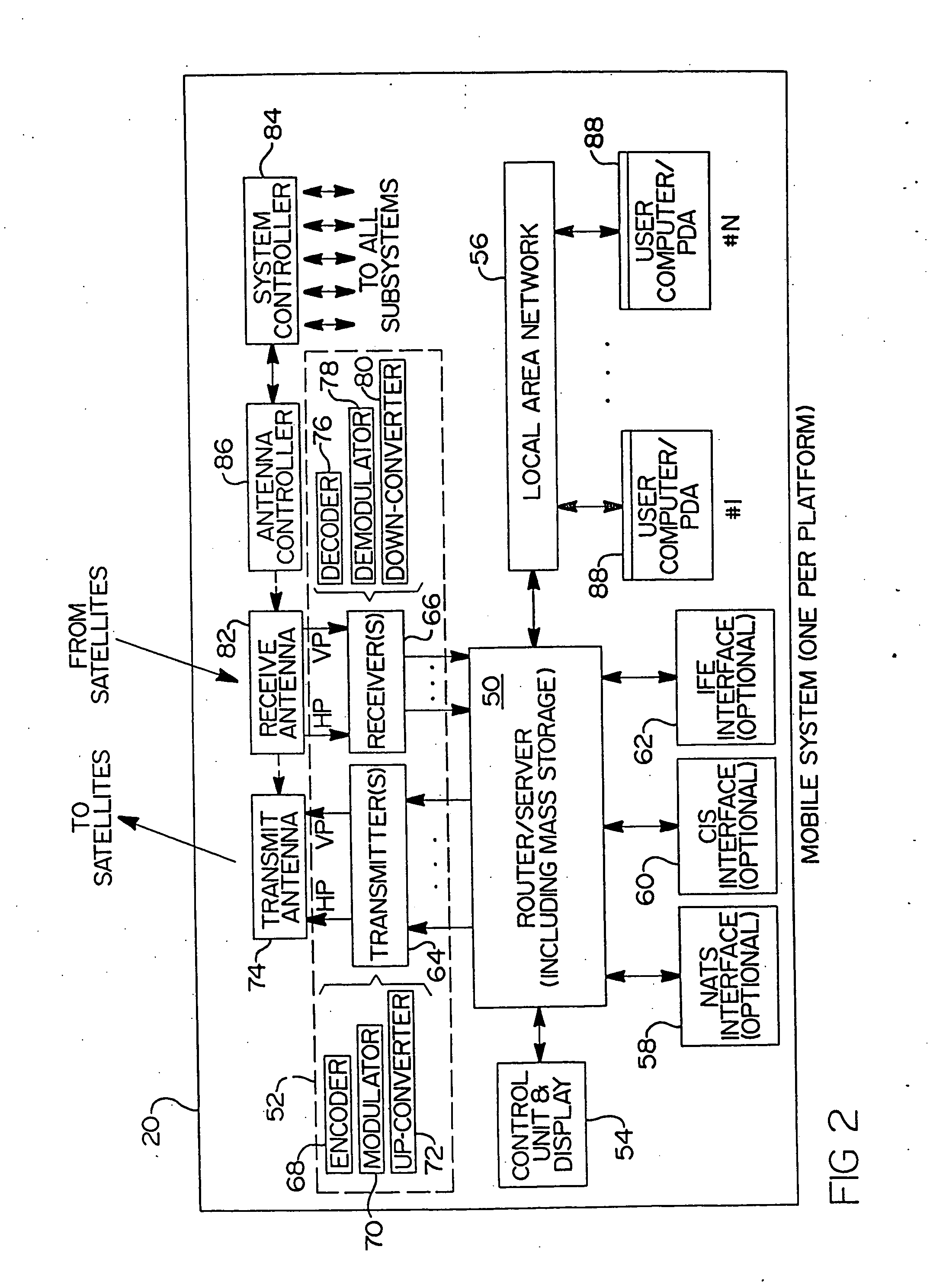

Return link design for PSD limited mobile satellite communication systems

InactiveUS7054593B2Maximize system efficiencyReduce system operating costsPower managementActive radio relay systemsTransmitted powerEngineering

A system and method for managing access to a satellite-based transponder by a plurality of aircraft each having a mobile radio frequency (RF) system. The system employs a ground-based, central control system for managing access to the satellite-based transponder so that the aggregate power spectral density (PSD) of the RF signals of all the mobile systems does not exceed, at any time, limits established by regulatory agencies to prevent interference between satellite systems. This is accomplished by a dual control loop arrangement for monitoring the signal-to-noise ratio (Eb / No) of the RF signal transmitted by the satellite-based transponder. A ground-based control loop is used whereby a ground-based central controller monitors the Eb / No and transmits commands to the aircraft (via the satellite transponder) to maintain the Eb / No of the transmitted signal within a predetermined range. A fast scan angle compensation is used by the mobile system of the aircraft to implement another control loop to further adjust the transmit power. This control loop maintains the Eb / No of the signal transmitted to the satellite-based transponder at the commanded level inbetween updates from the ground-based central controller.

Owner:THE BOEING CO

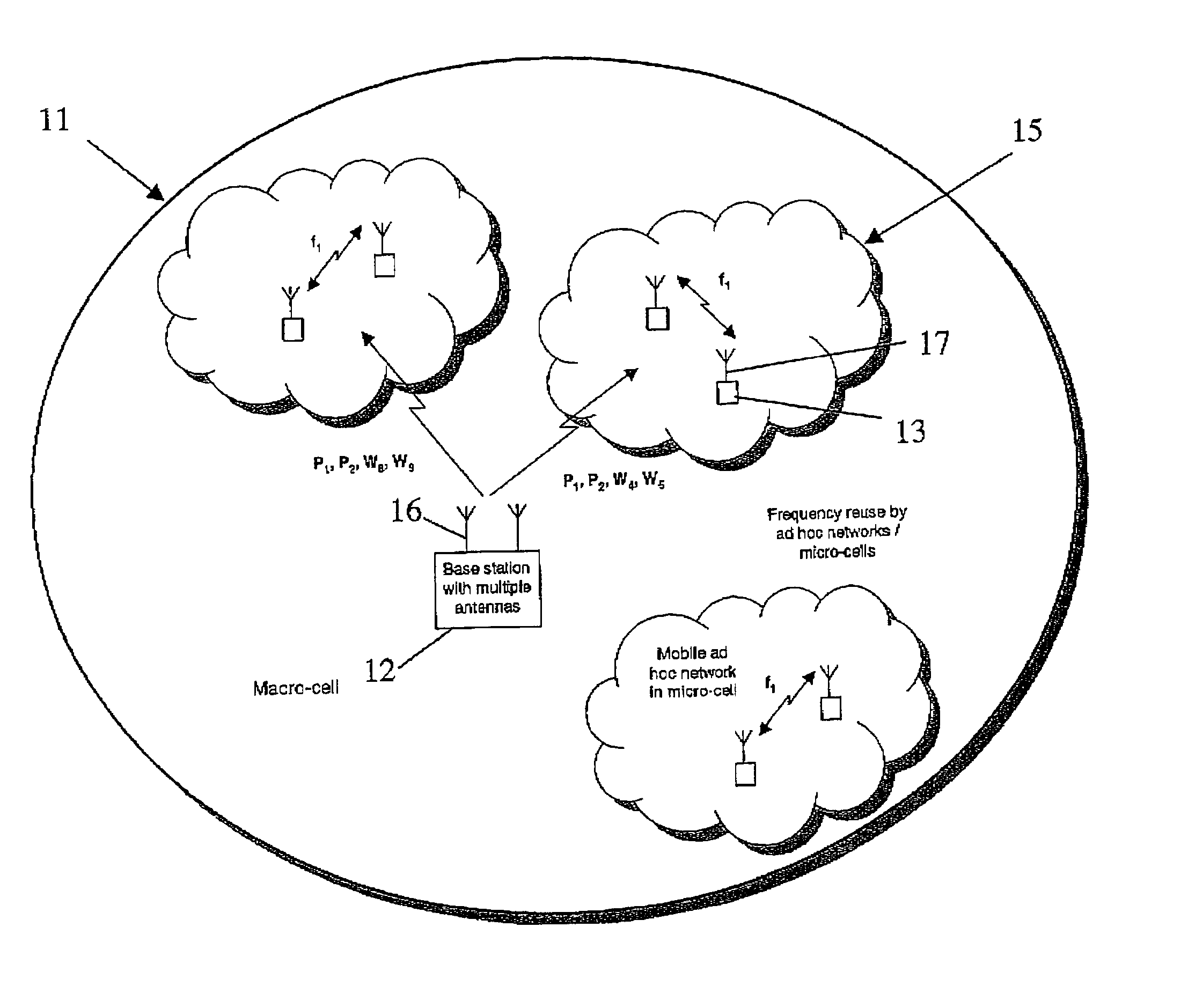

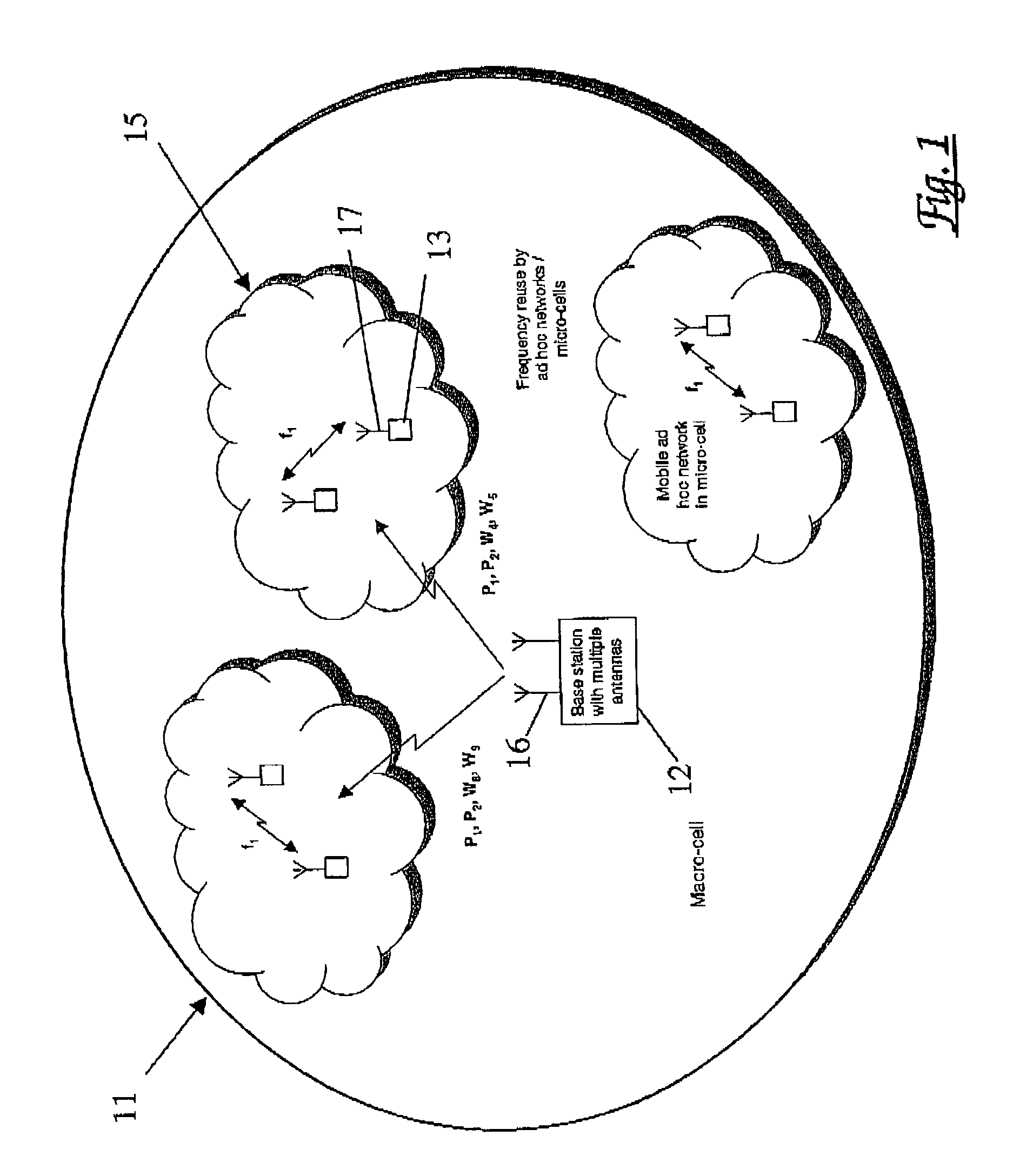

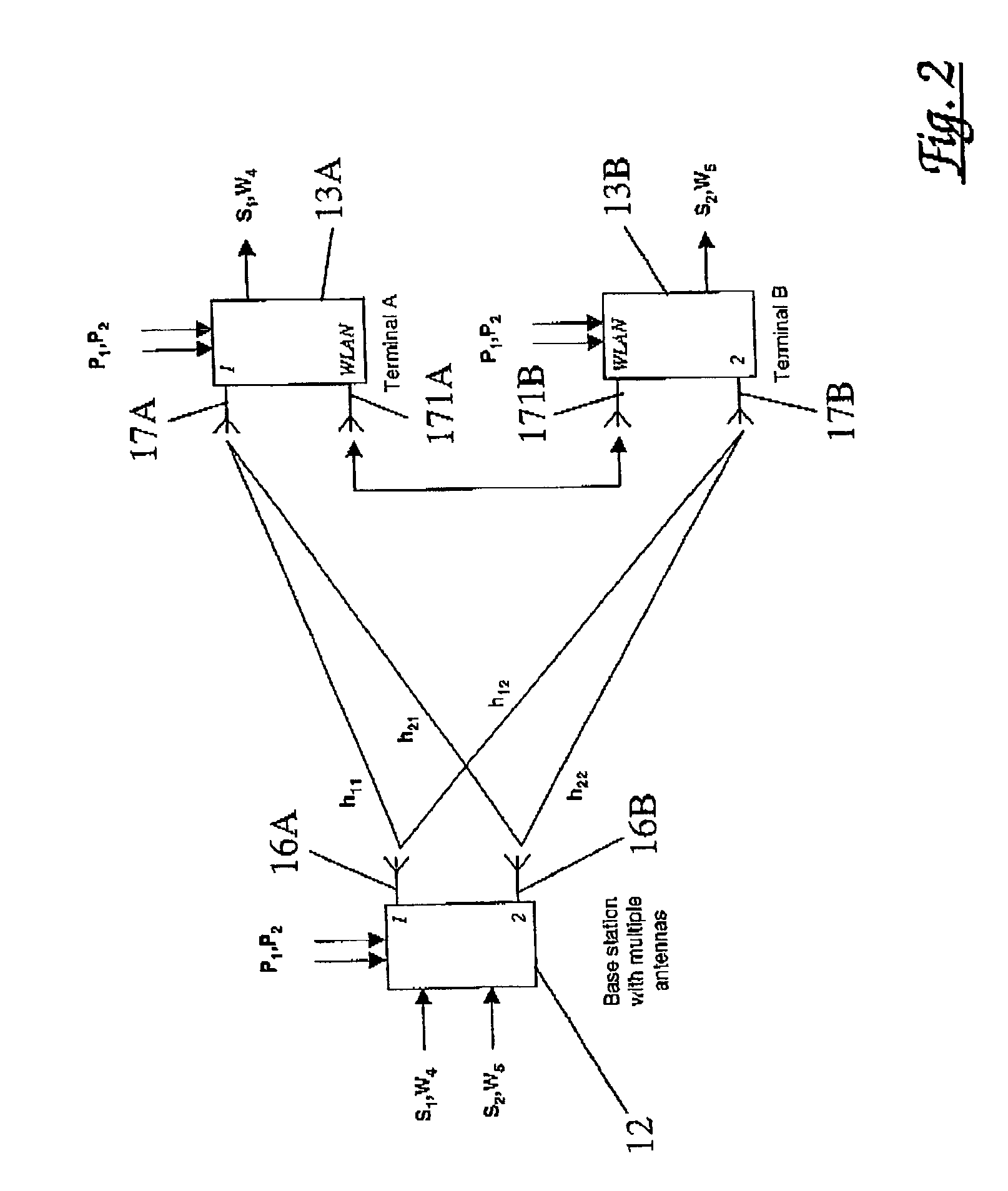

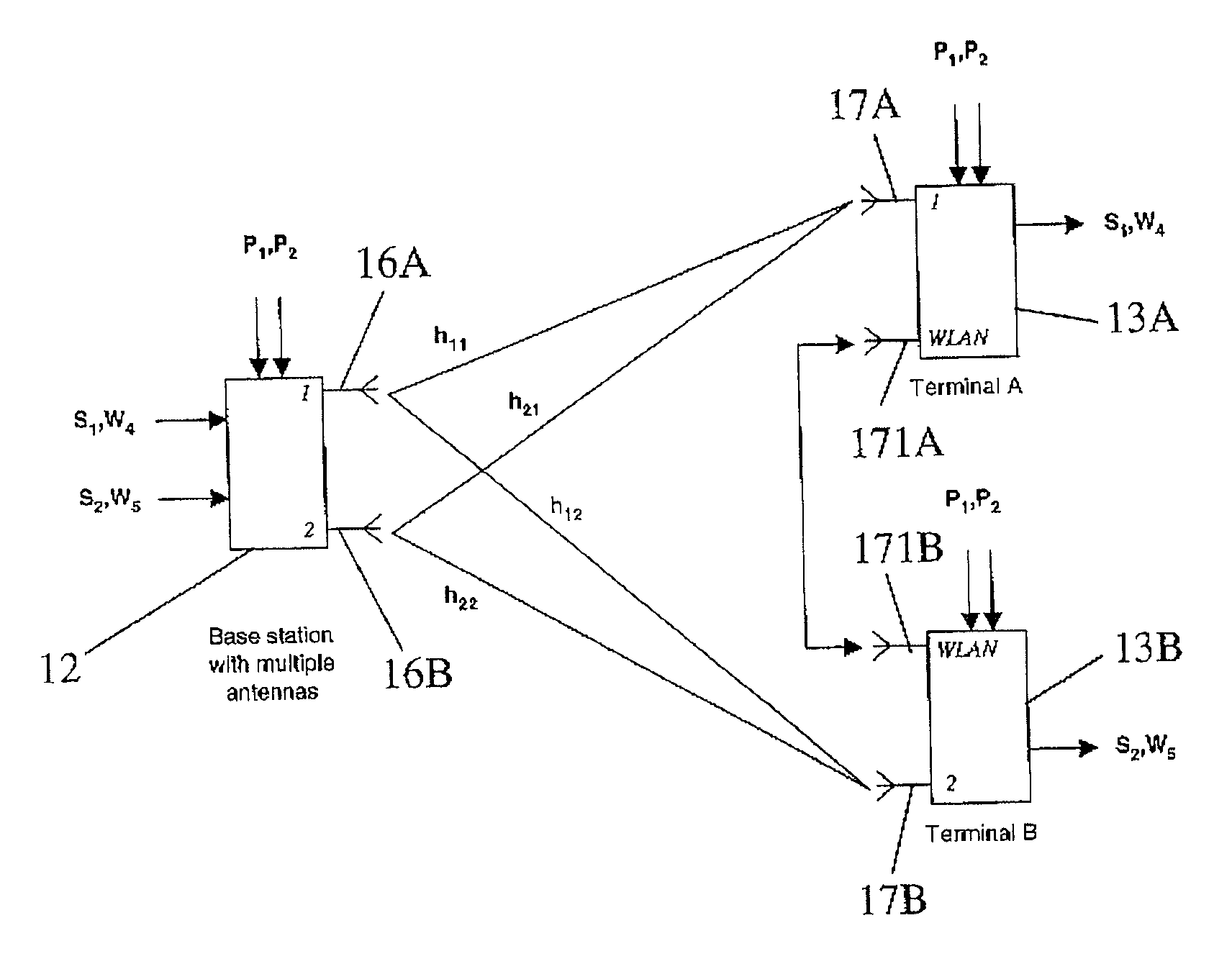

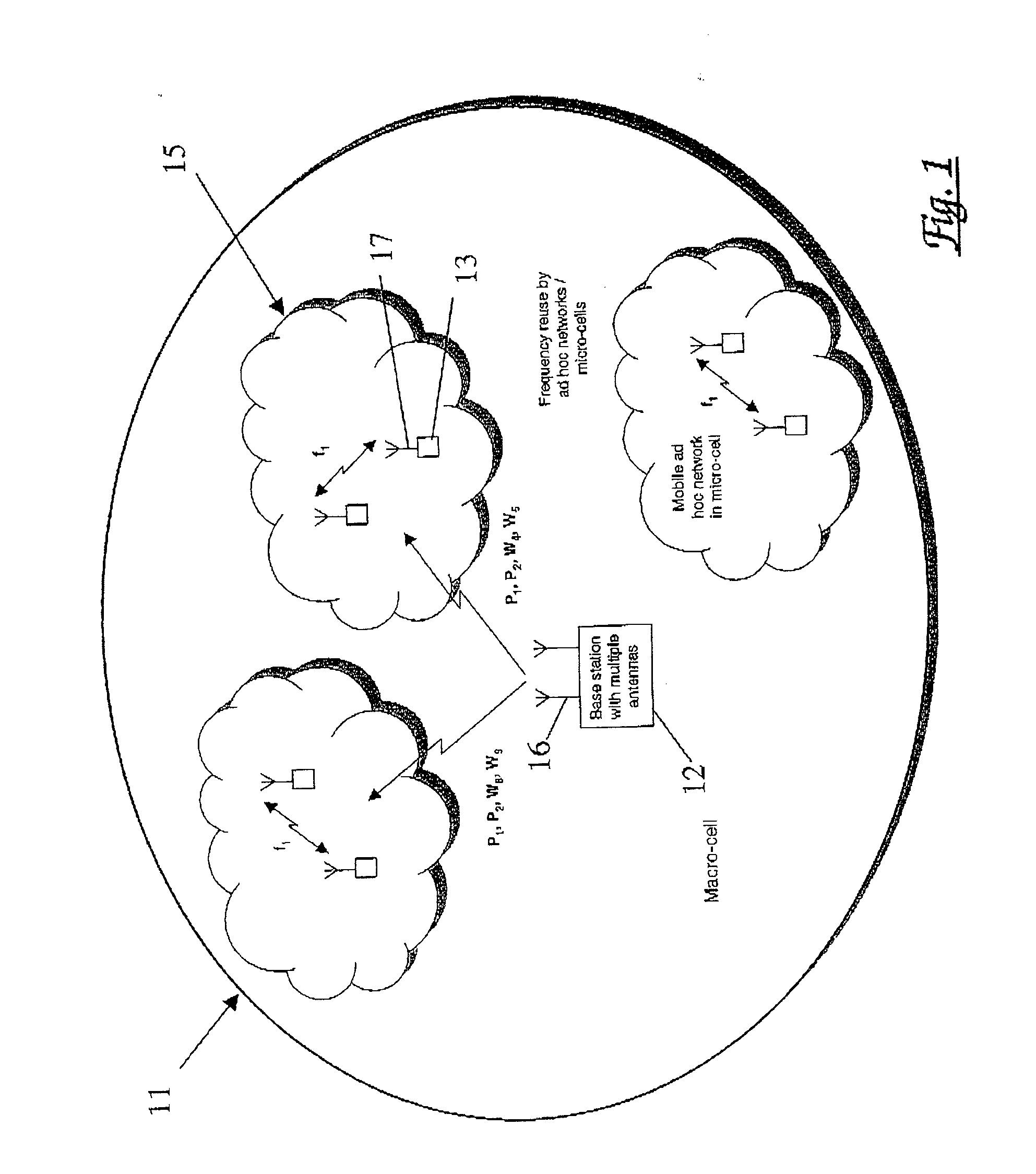

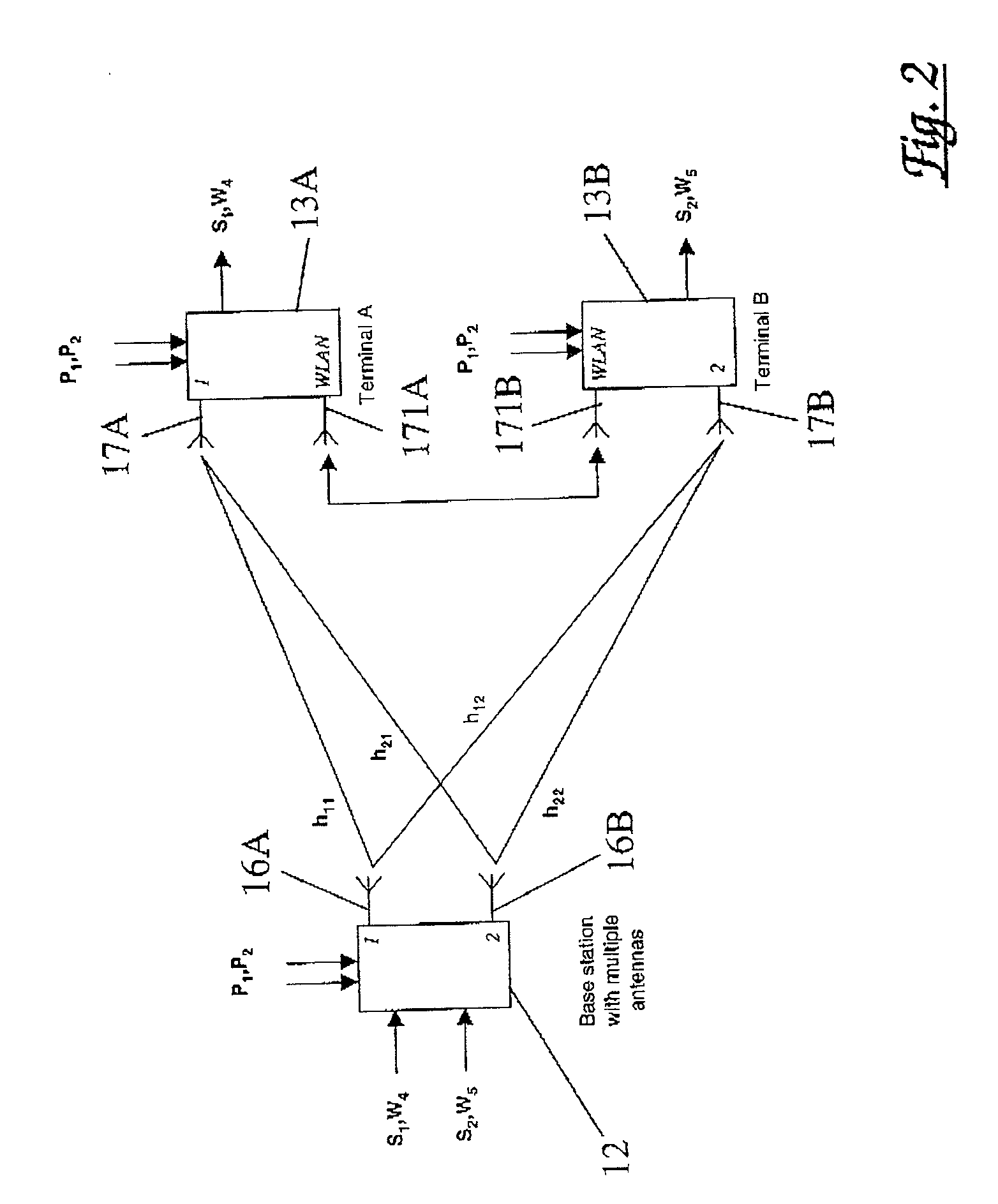

Wireless communications system and method

ActiveUS20030129985A1Maximize system efficiencyMaximize Spectral EfficiencyData switching by path configurationSubstation equipmentFrequency spectrumCommunications system

The invention is directed to a mobile communications system having improved spectral efficiency. The invention is further directed to methods and apparatus to achieve this improved spectral efficiency. In the mobile communications system communication with a plurality of mobile terminals is provided by a base station. Within the system terminals are adapted to communicate with one or more adjacent similar terminals to establish groups of terminals, called micro-cells. Each terminal within a micro-cell receives signals from the base station and then performs a first processing step on these signals. These processed signals are shared with all the other terminals within the micro-cell. Each terminal then performs a second processing step on the information it has received from all the other terminals within the micro-cell which enables it to derive a signal intended for reception by that terminal. The technique is applicable to both the uplink (user to base station) and the down link (base station to user) and also to peer to peer (user to user) communication.

Owner:APPLE INC

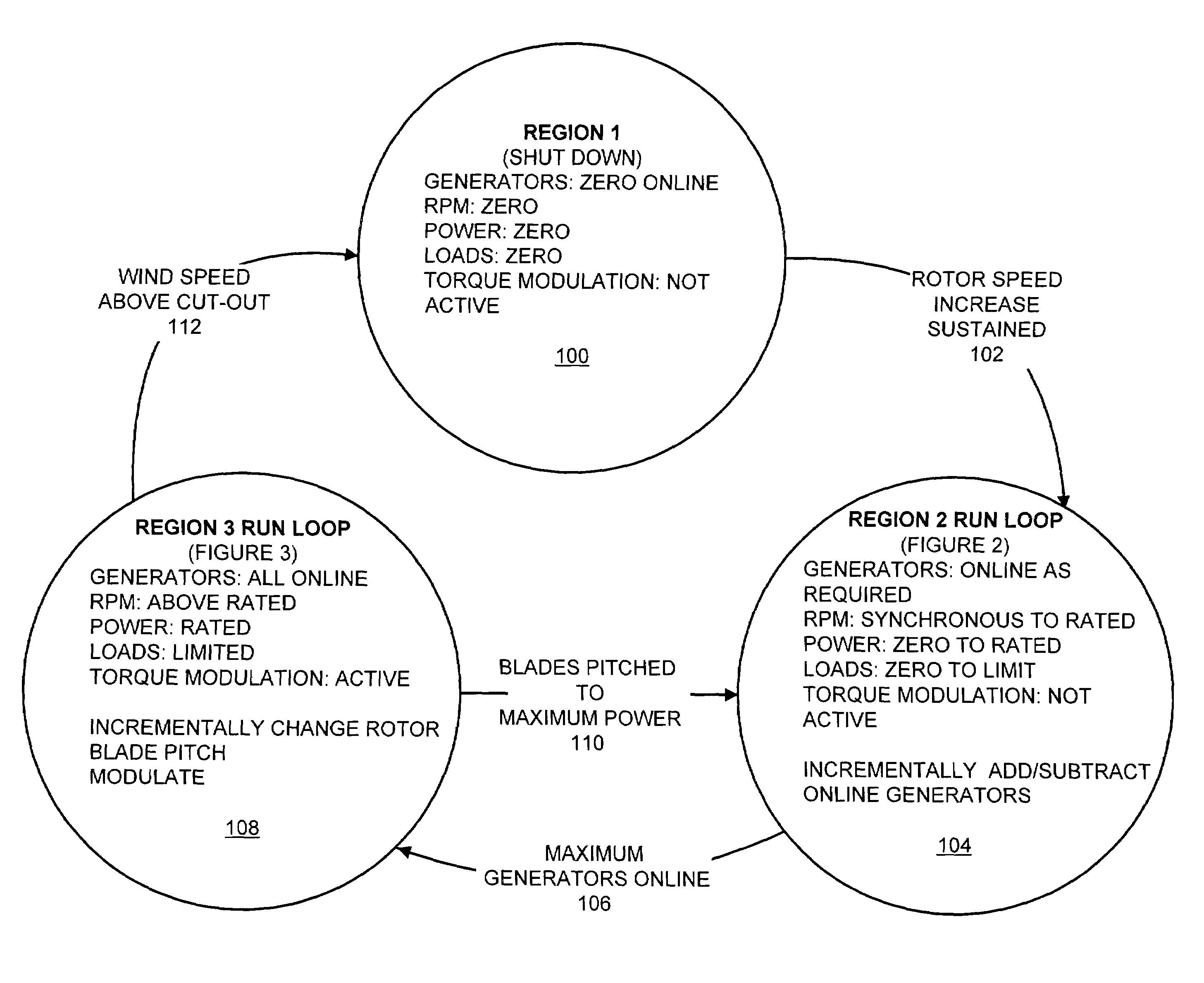

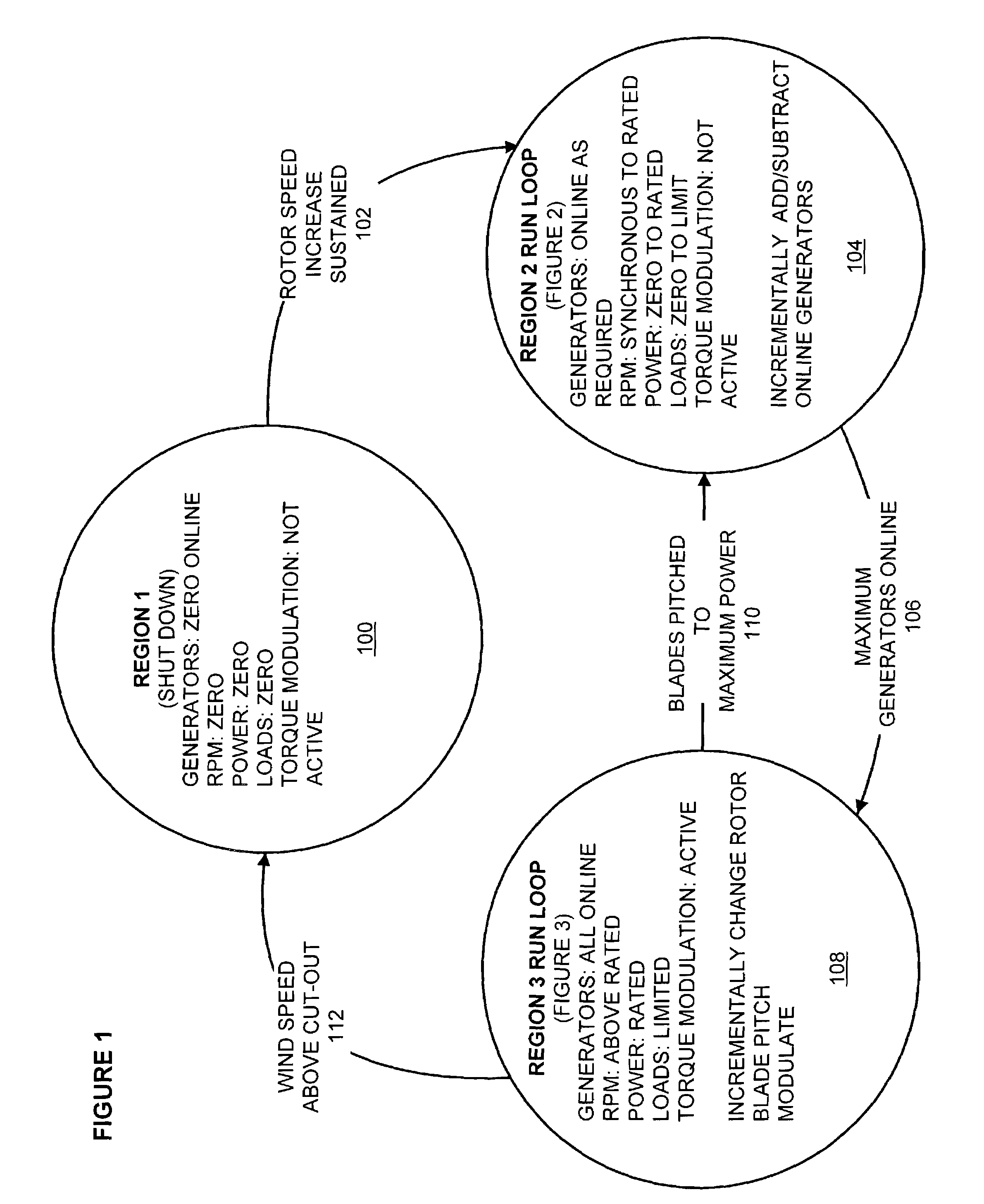

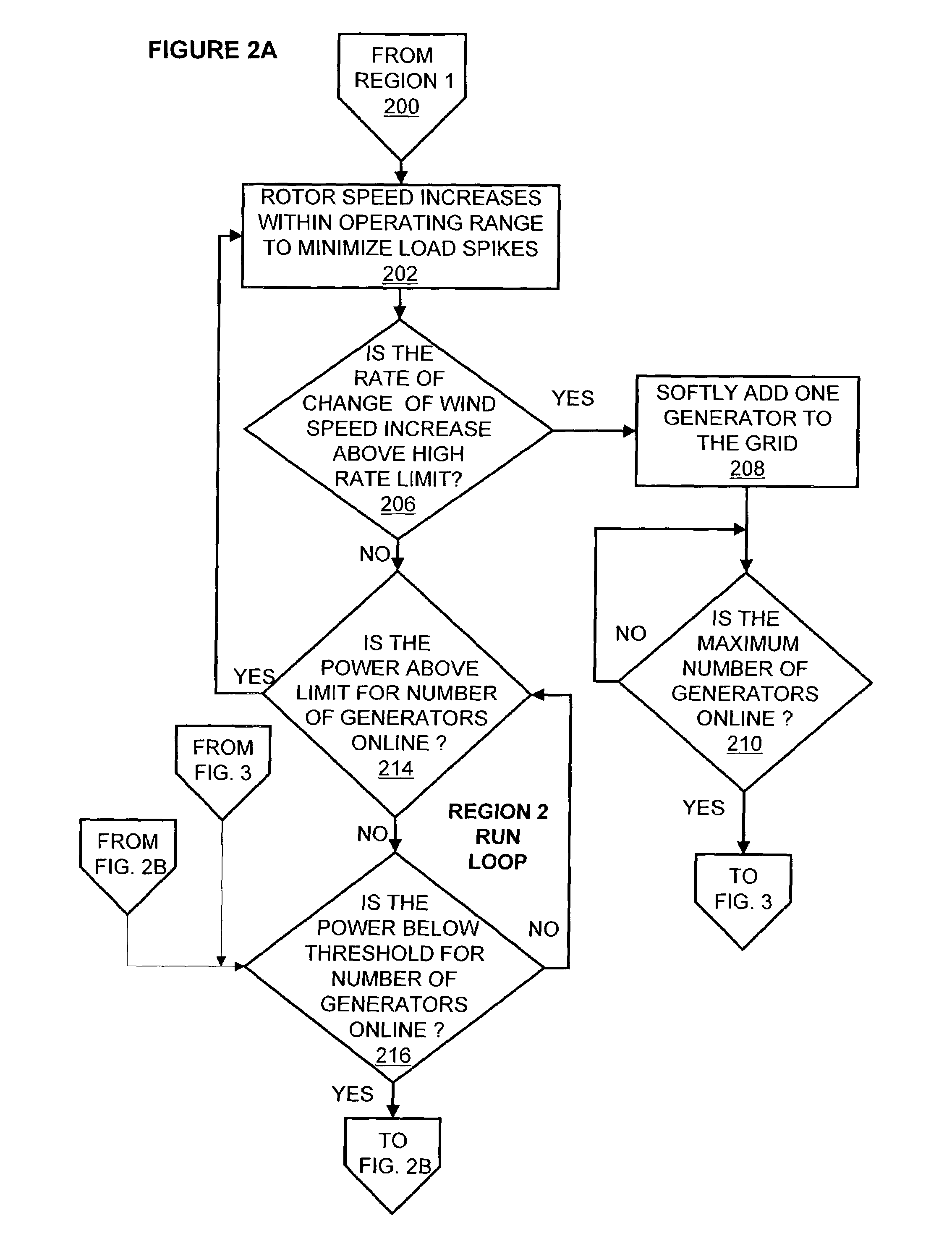

Method of controlling electrical rotating machines connected to a common shaft

InactiveUS7002259B2Avoid powerEvenly matchedWind motor controlWorking fluid for enginesGear wheelElectric machine

A controller for high torque, low RPM wind turbines and ocean current turbines. The turbine consists of a large, input power shaft-mounted, rotating bull-gear with stationary powertrains mounted around its periphery. The gear teeth on the bull-gear rotate past the teeth on pinions, causing the pinions to turn and delivering power to each smaller powertrain. A controller regulates torque experienced by each powertrain to assure that torques are balanced between generators at any given system load. The control method comprises the programmatically continuously looping steps of measuring a system parameter to be controlled, such as torque and / or speed, selecting the optimal number of generators to be connected / disconnected to a utility line, incrementally connecting or disconnecting generators to achieve the point of optimal performance, measuring the parameters, such as current and / or voltage, of the connected generators and adjusting the generator parameters to fine tune the system for optimal performance.

Owner:UNITED TECH CORP

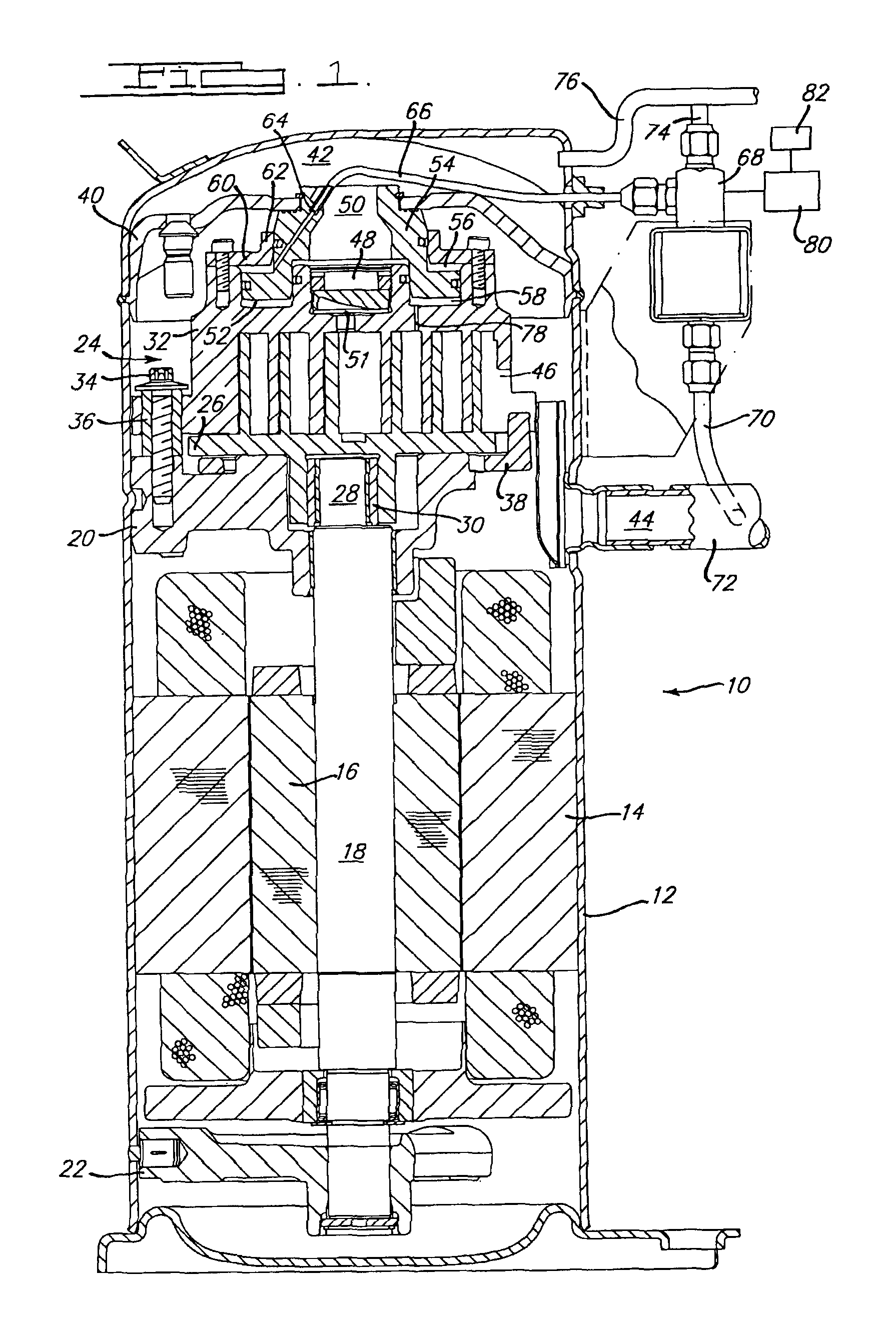

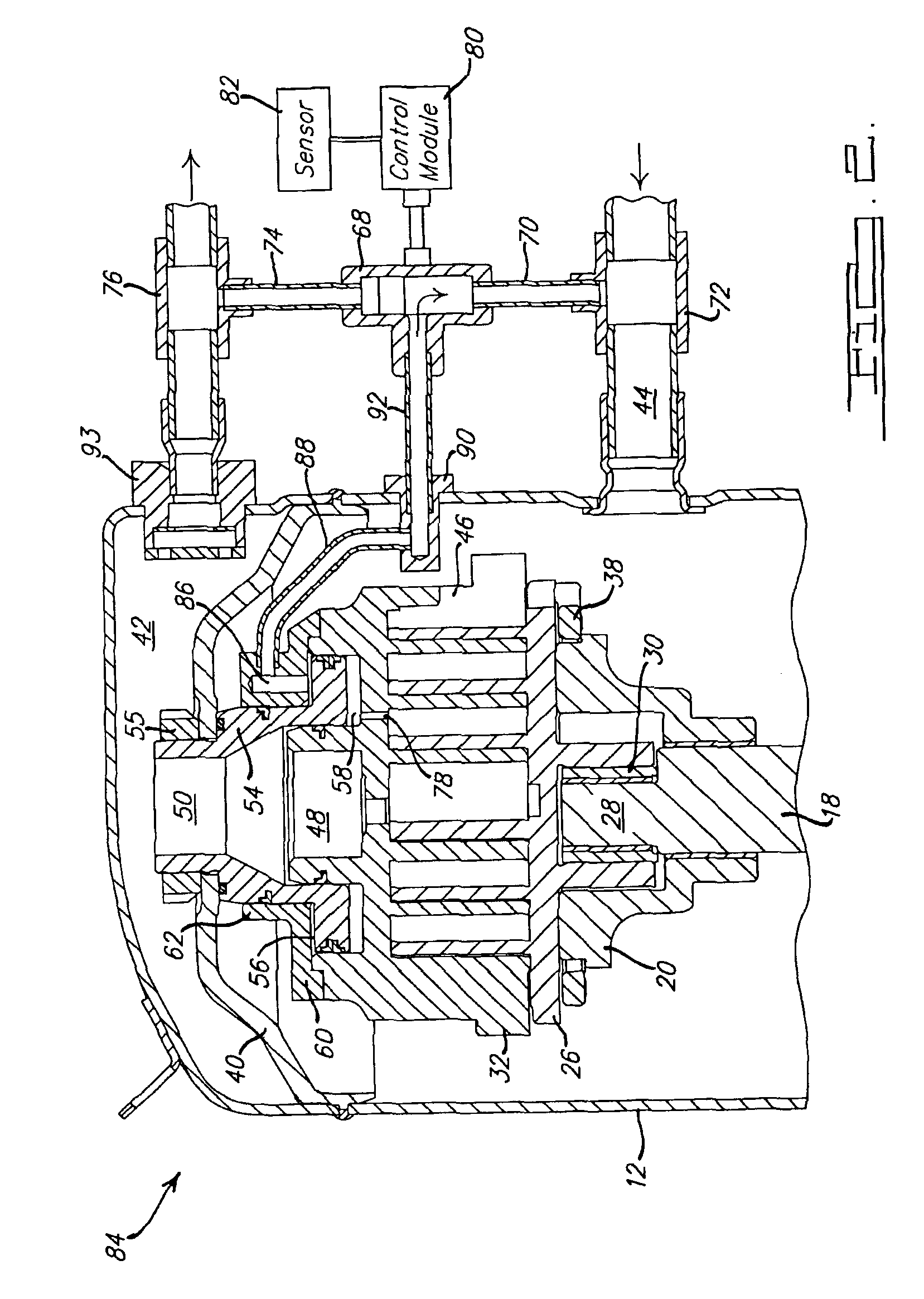

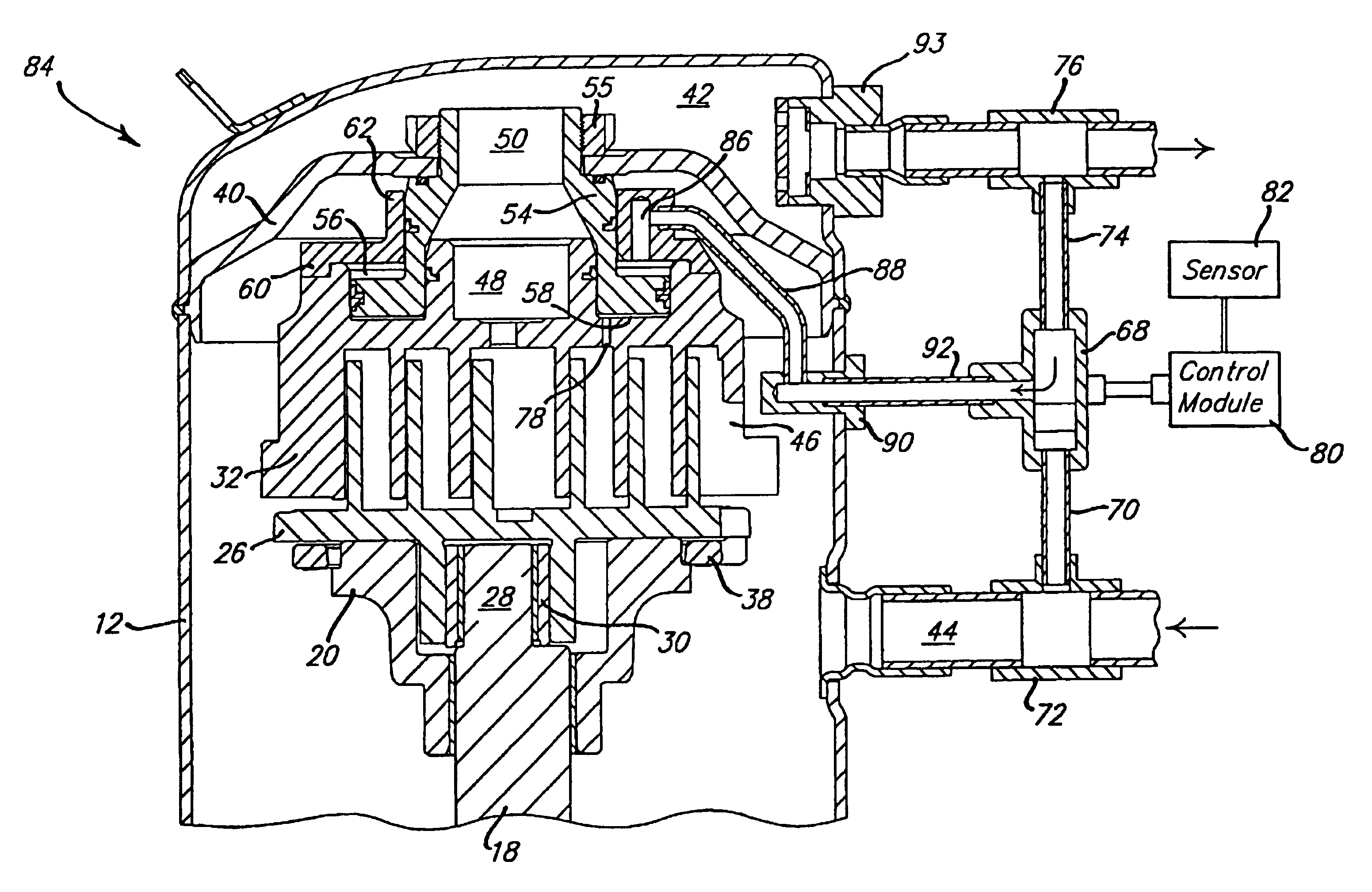

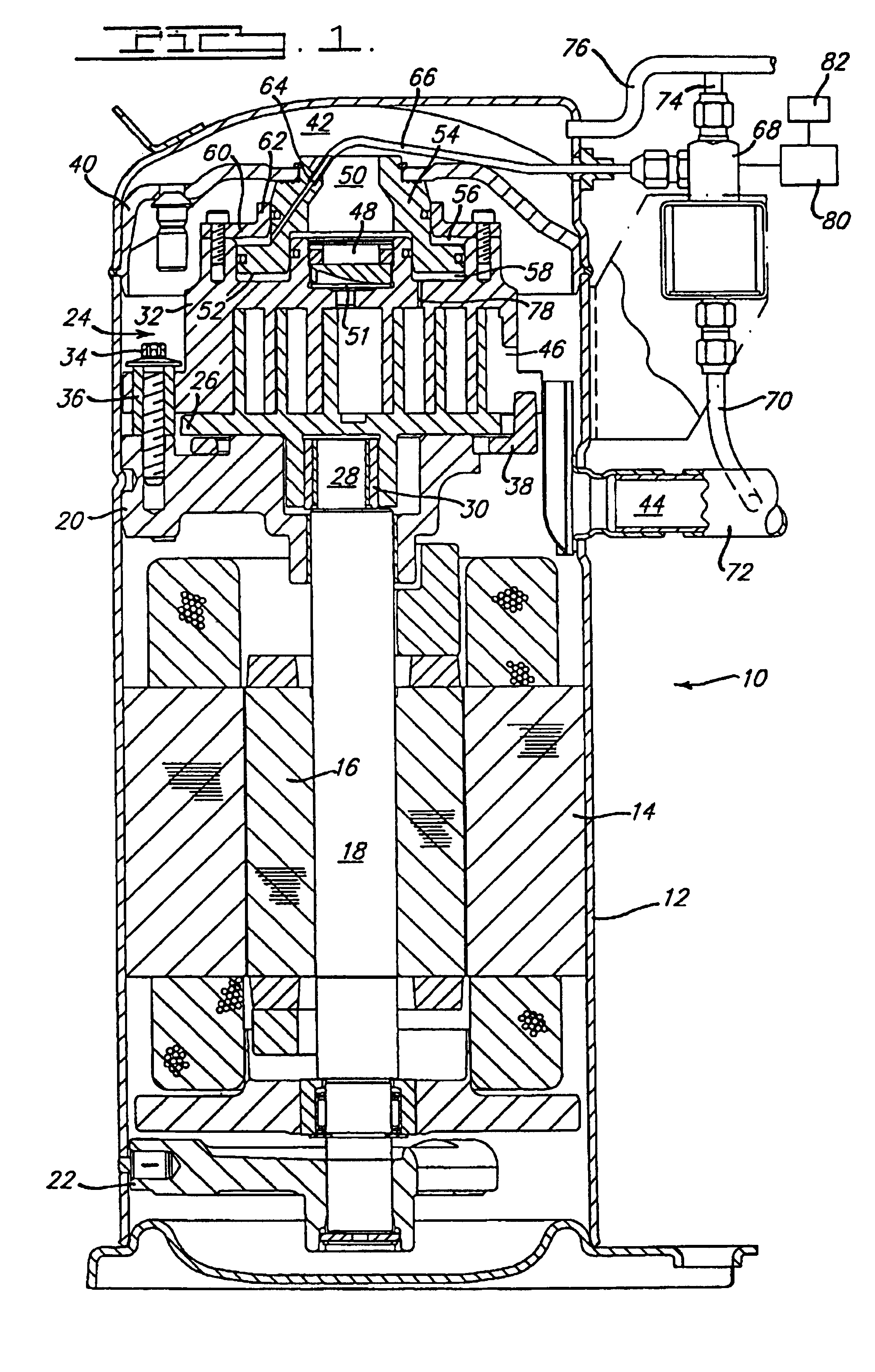

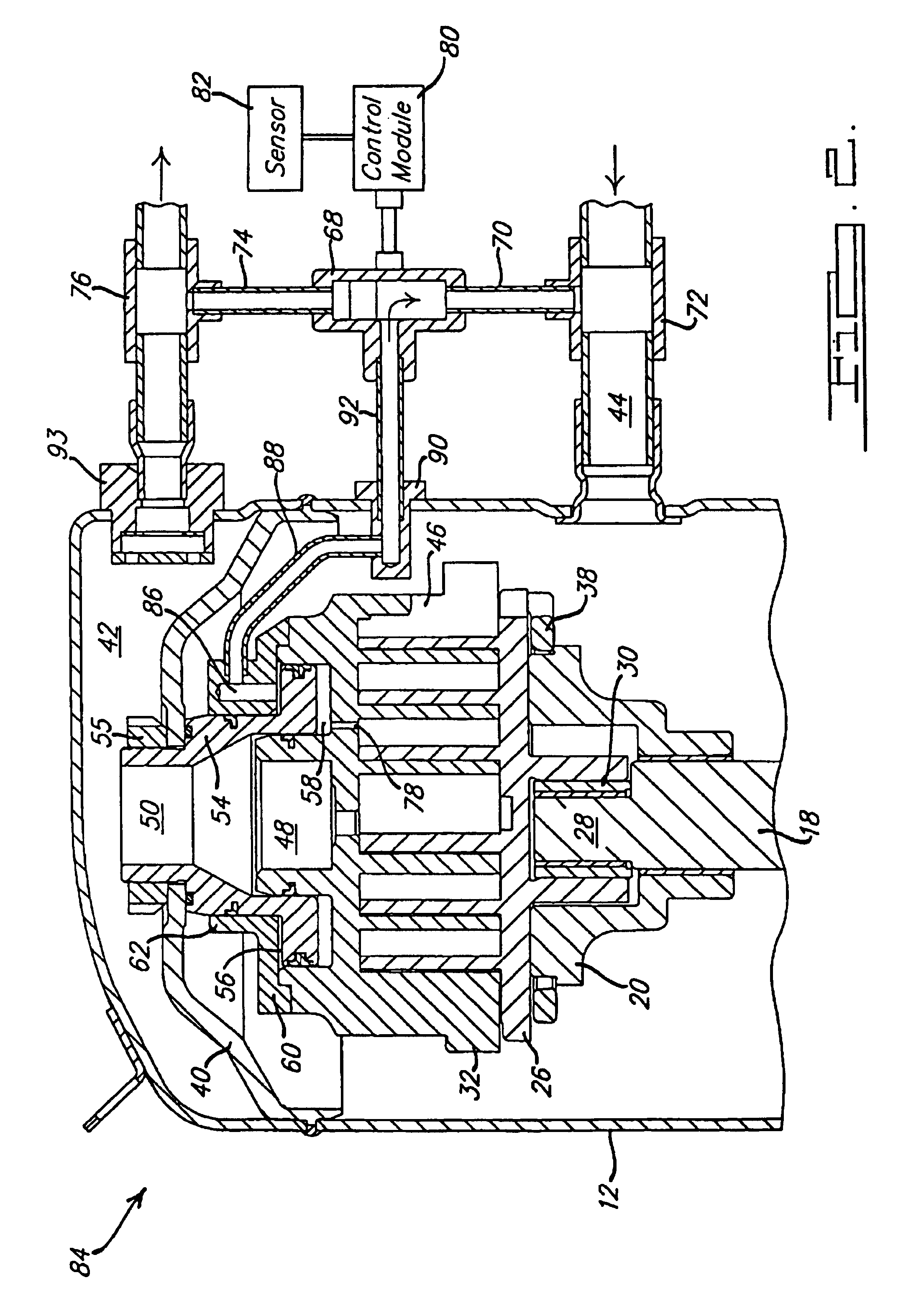

Capacity modulated scroll machine

InactiveUSRE40400E1Easy to operateImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMotor control

A scroll-type machine is disclosed which is particularly well suited for use as a compressor in refrigeration and air conditioning systems and incorporates a unique arrangement for modulating the capacity thereof. In one group of embodiments the capacity of the scroll-type machine is modulated by relative axial movement between the scroll members so as to form a leakage path across the wrap tips and opposed end plates. In another group of embodiments, modulation is achieved by reducing the orbital radius of one of the scroll members to thereby form a leakage path across the flank surfaces of the wraps. Both types of scroll separation may be accomplished in a time pulsed manner to thereby enable a full range of modulation with the duration of the loading and unloading periods being selected to maximize the efficiency of the overall system. A motor control arrangement is also disclosed which may be used with either of the modulation methods mentioned above to increase the efficiency of the motor during periods of reduced load. Additionally, either of the modulation arrangements mentioned above may be combined with a delayed suction form of capacity modulation with or without the motor control feature to thereby achieve better operating efficiency under certain conditions.

Owner:EMERSON CLIMATE TECH INC

Capacity modulated scroll machine having one or more pin members movably disposed for restricting the radius of the orbiting scroll member

InactiveUSRE40554E1Maximize efficiencyEasy to operateRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeMotor controlAir conditioning

Owner:EMERSON CLIMATE TECH INC

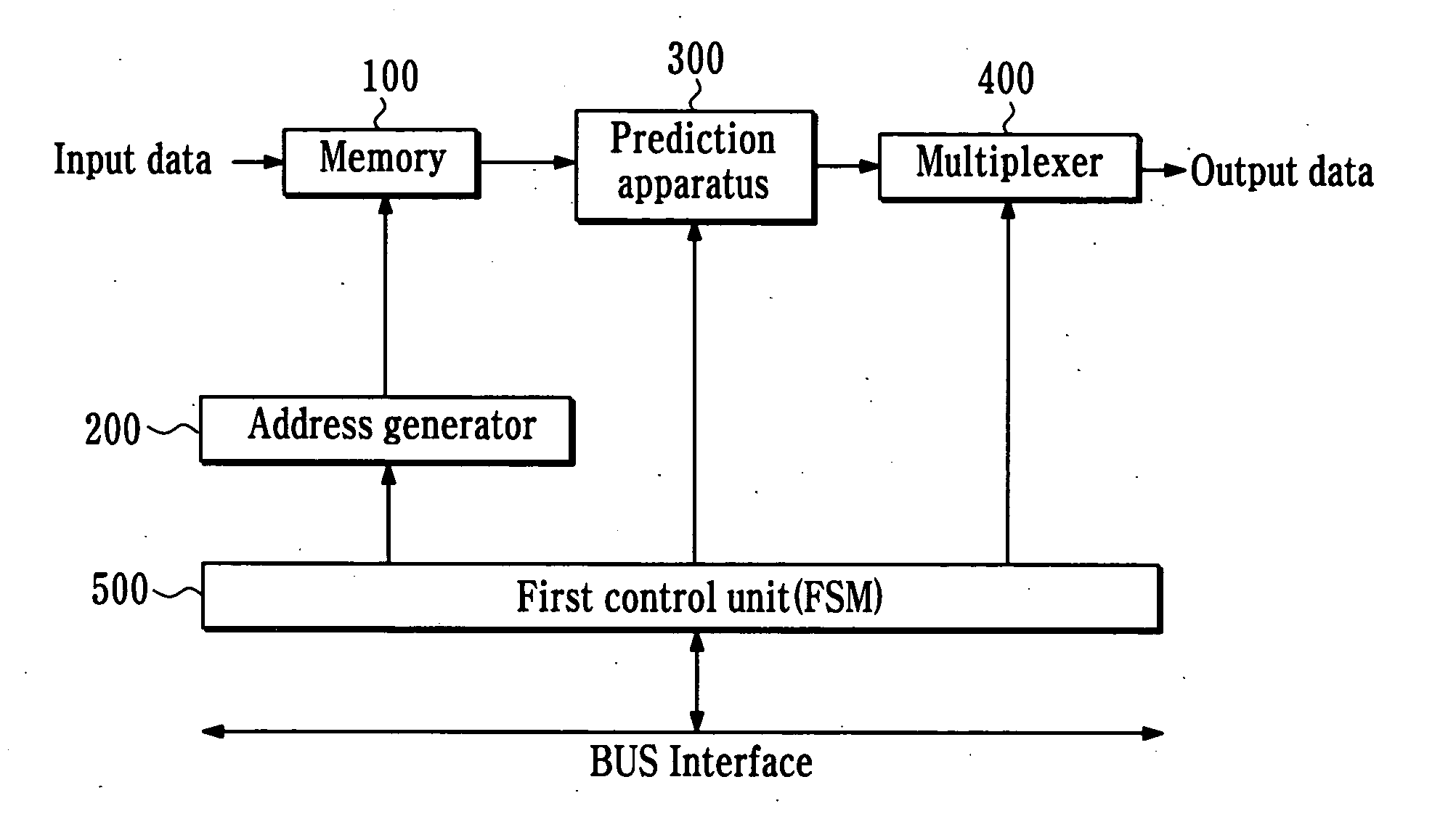

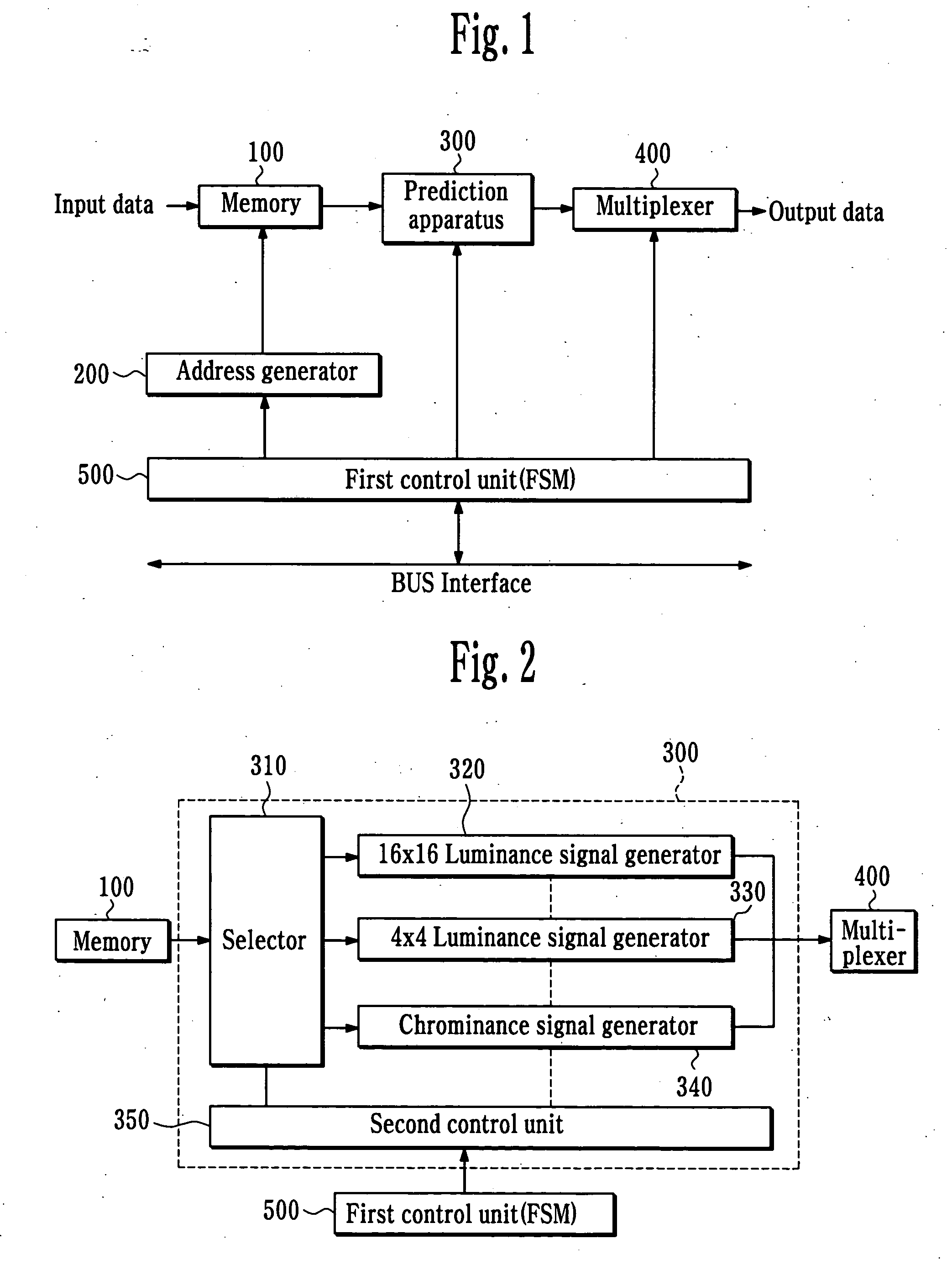

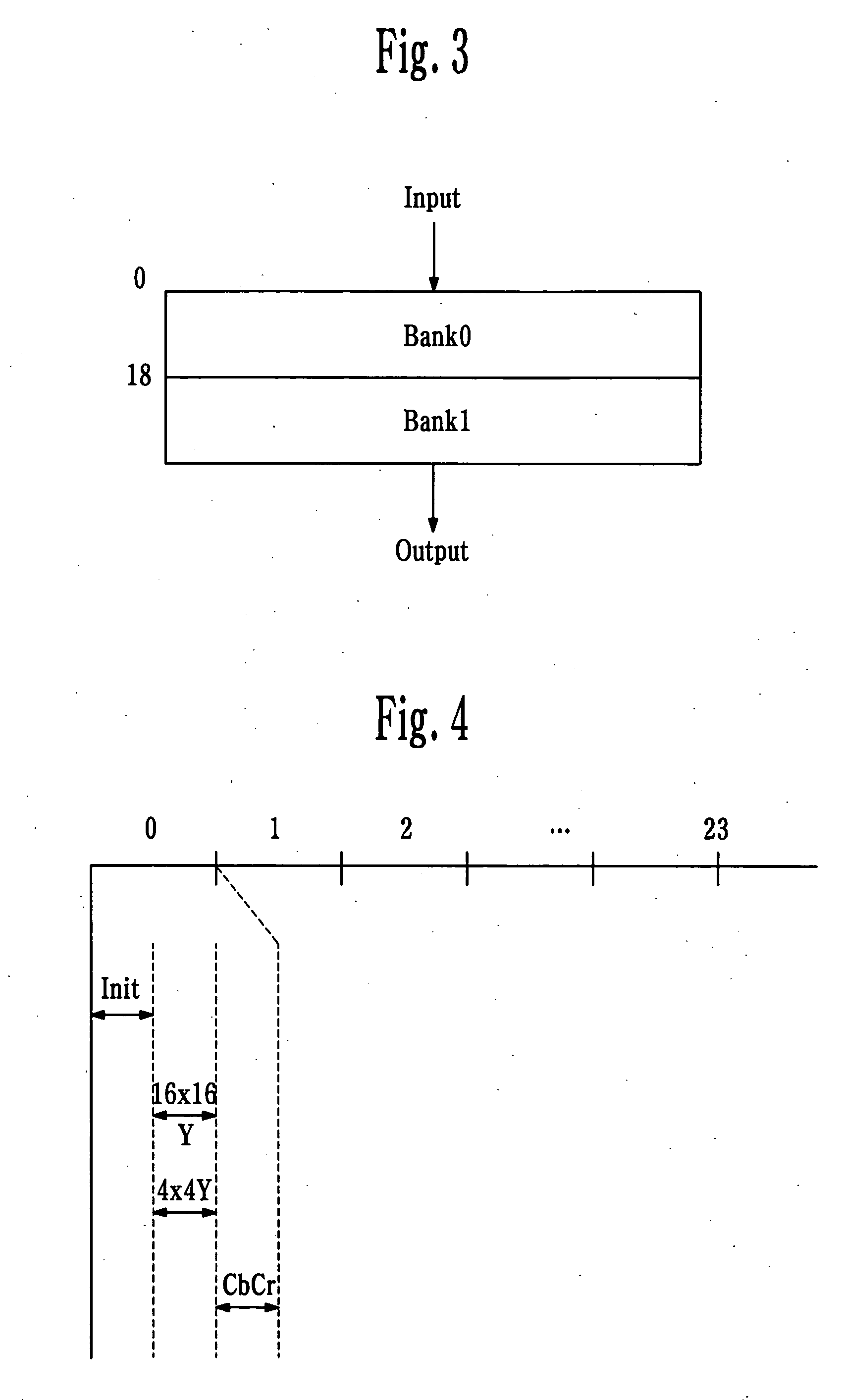

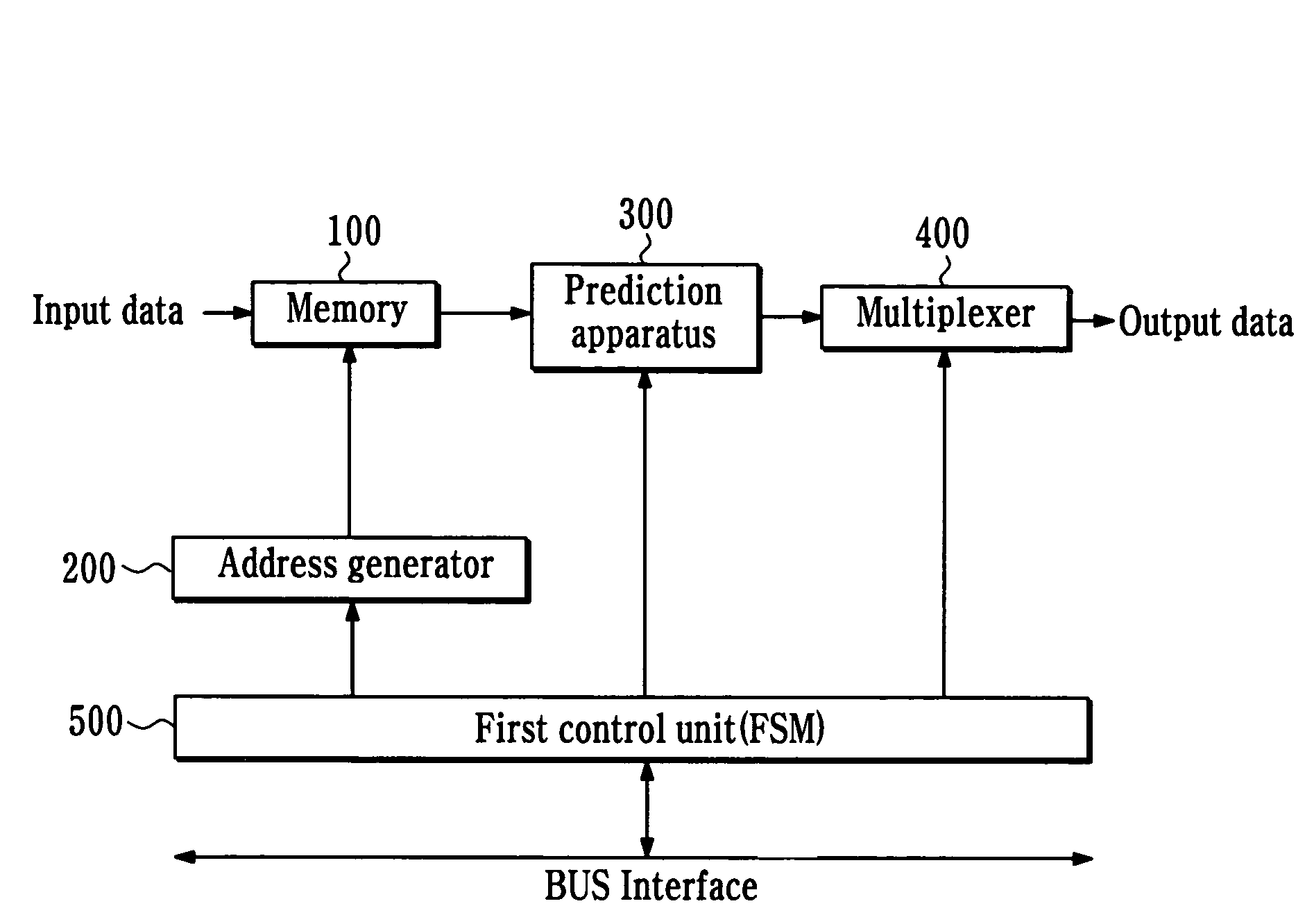

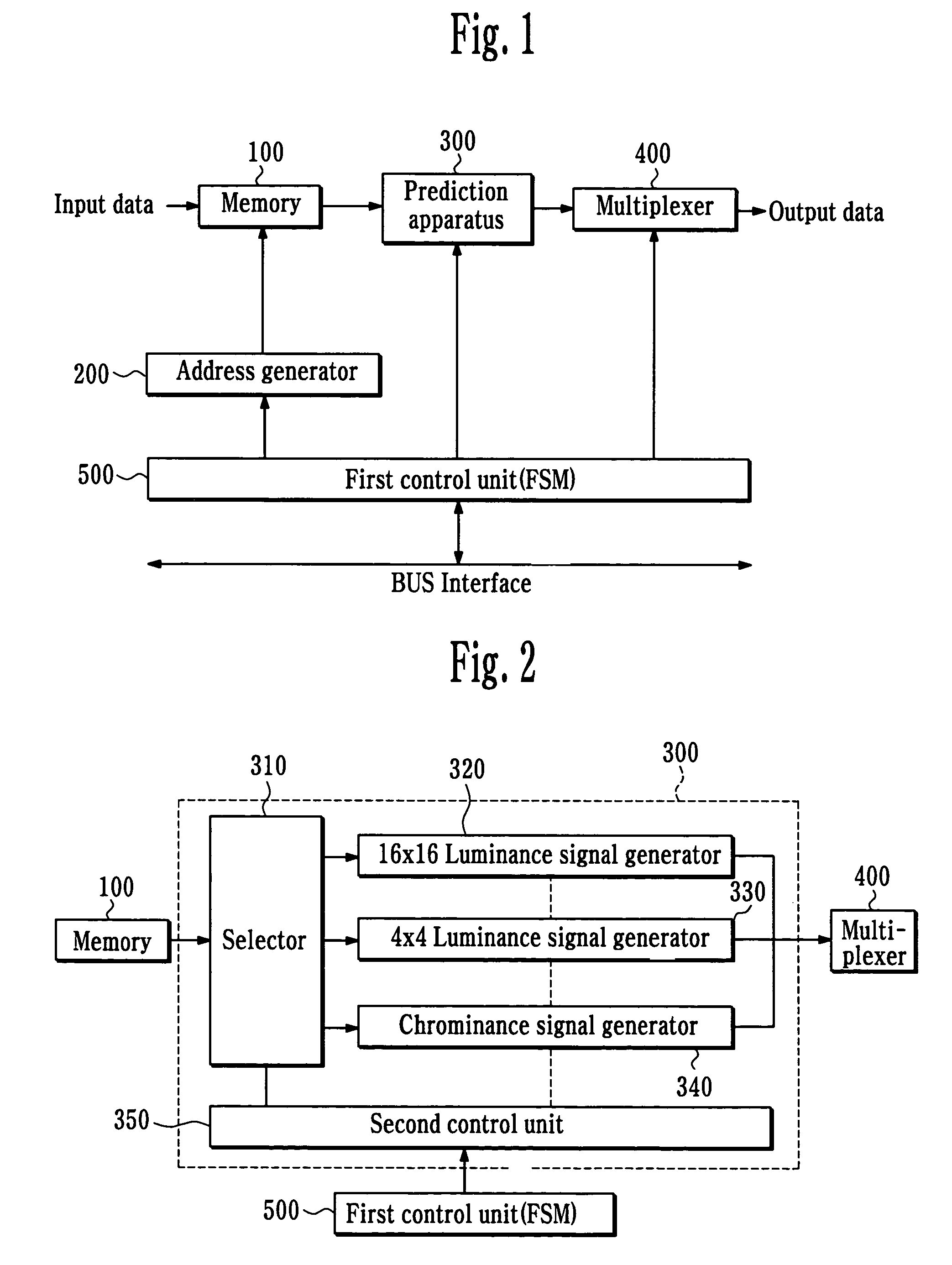

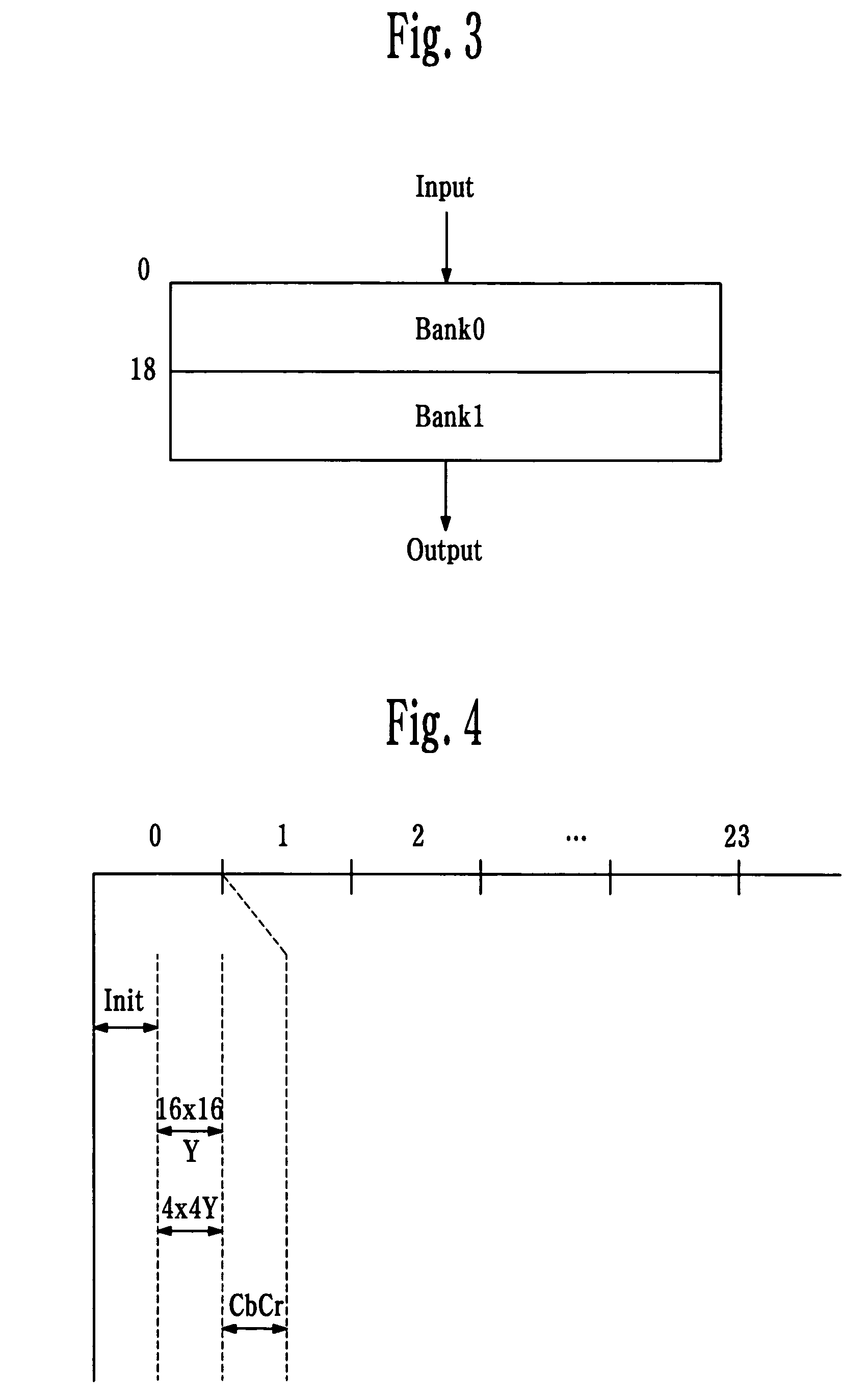

Apparatus and method for performing intra prediction for image decoder

InactiveUS20050141618A1Maximize system efficiencyReduce hardware costsColor television with pulse code modulationColor television with bandwidth reductionData inputProcess rate

Provided is an apparatus and method for performing intra prediction for an image decoder, in which by use of horizontal / vertical blocks adjacent to image data input from an external device, the intra prediction is performed in parallel with respect to 16×16 luminance component and 4×4 luminance component of the image data and then with respect to chrominance component, thereby maximizing efficiency of system to not only reduce execution time and hardware cost but also increase processing speed.

Owner:ELECTRONICS & TELECOMM RES INST

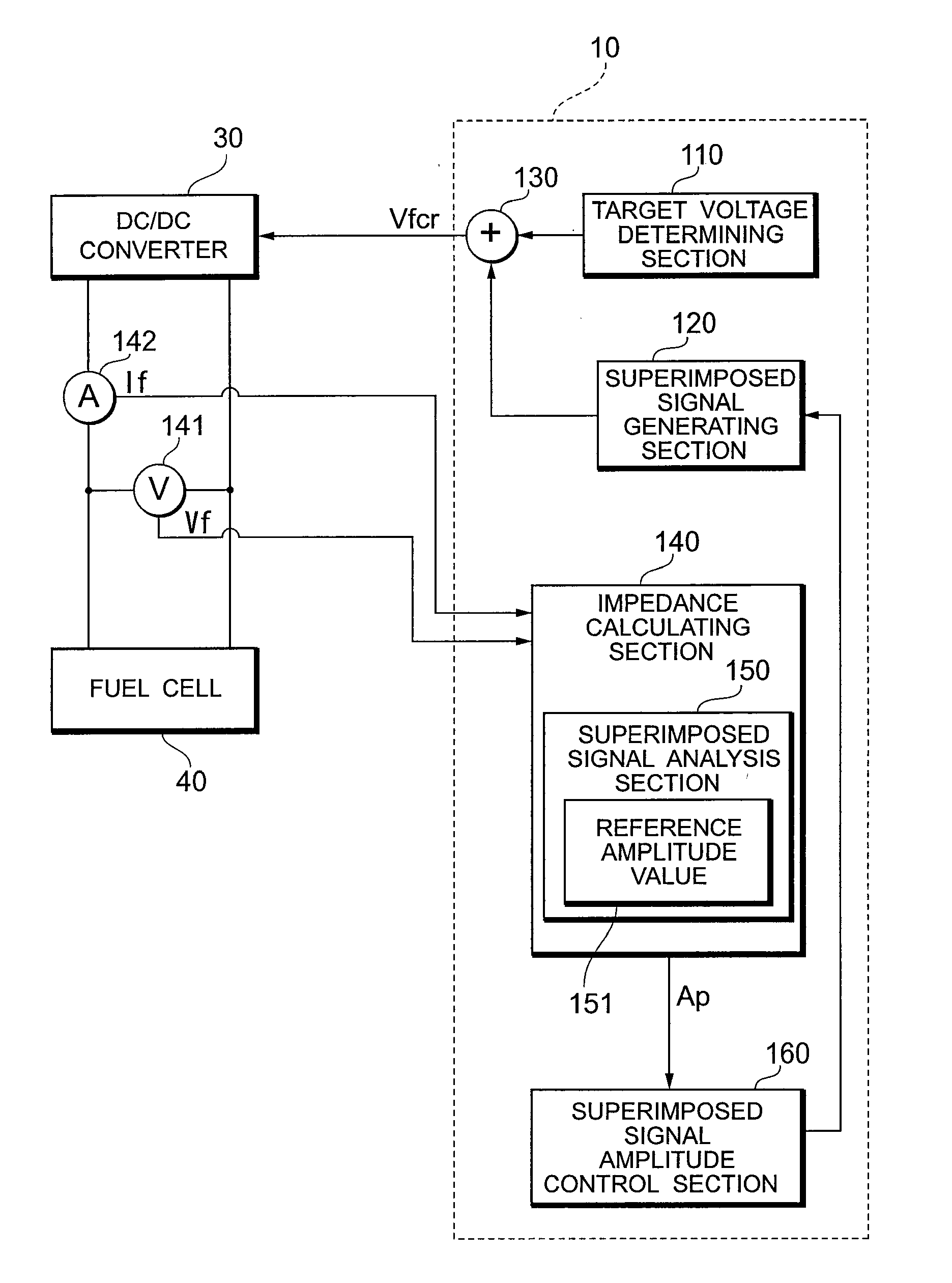

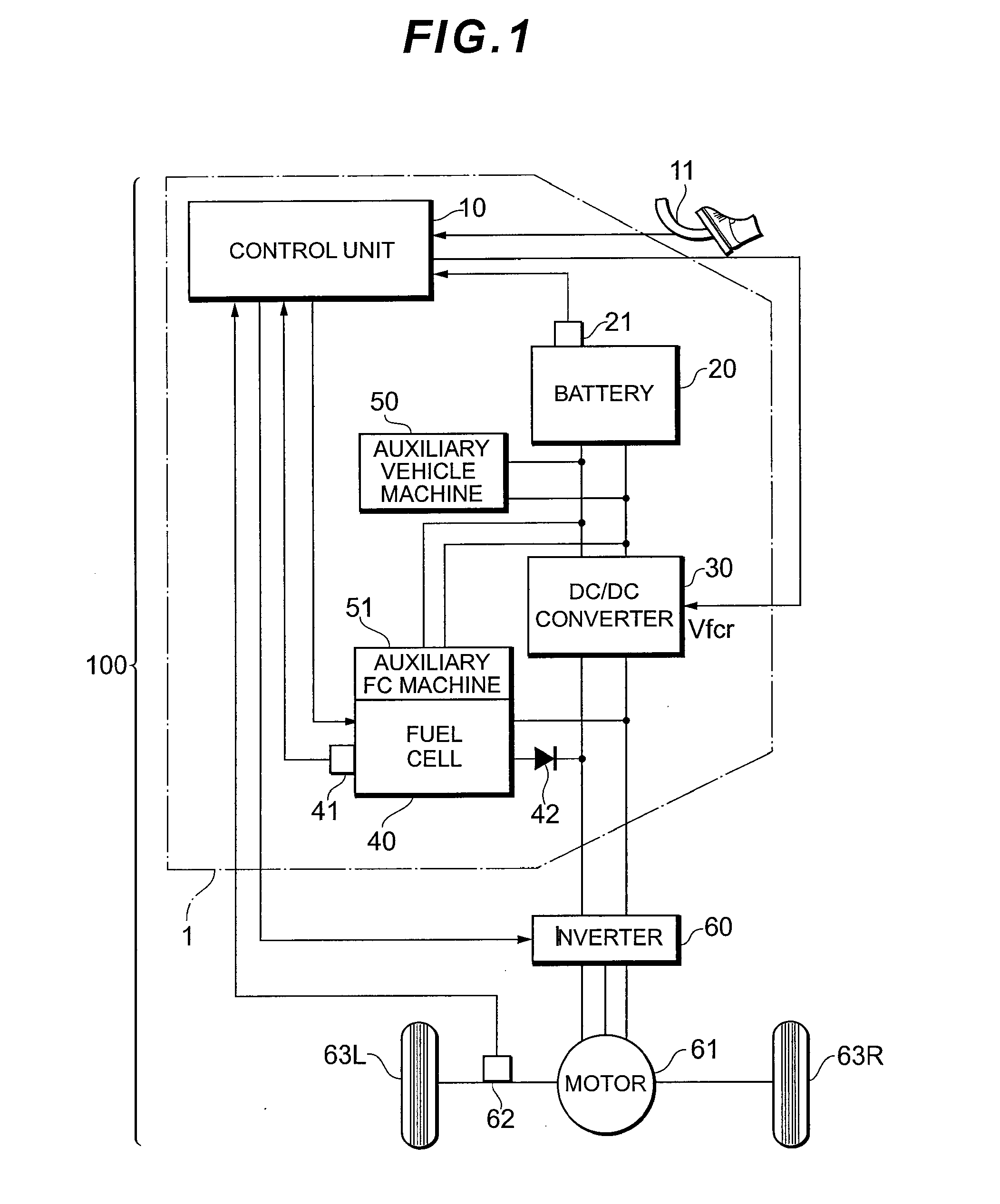

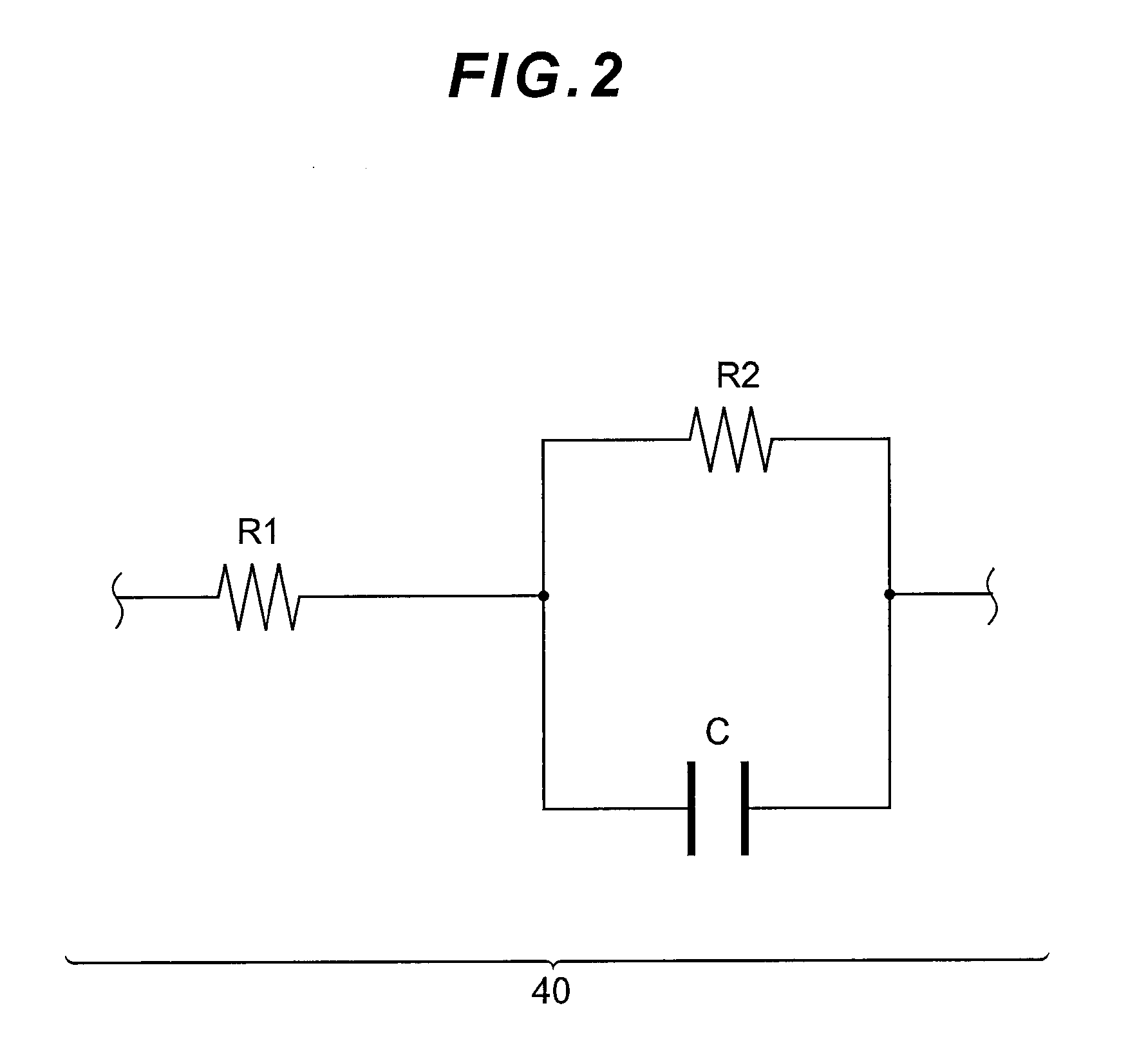

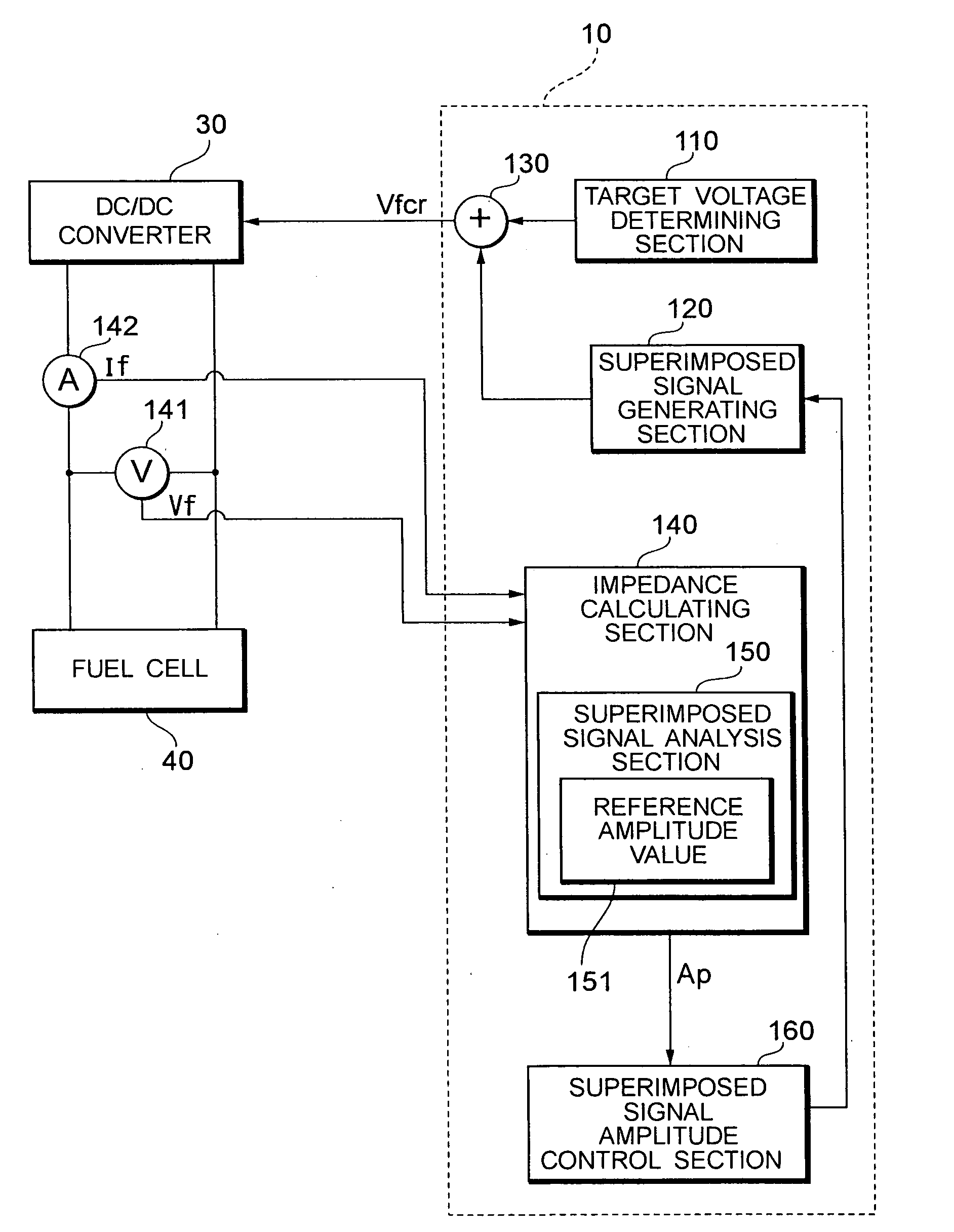

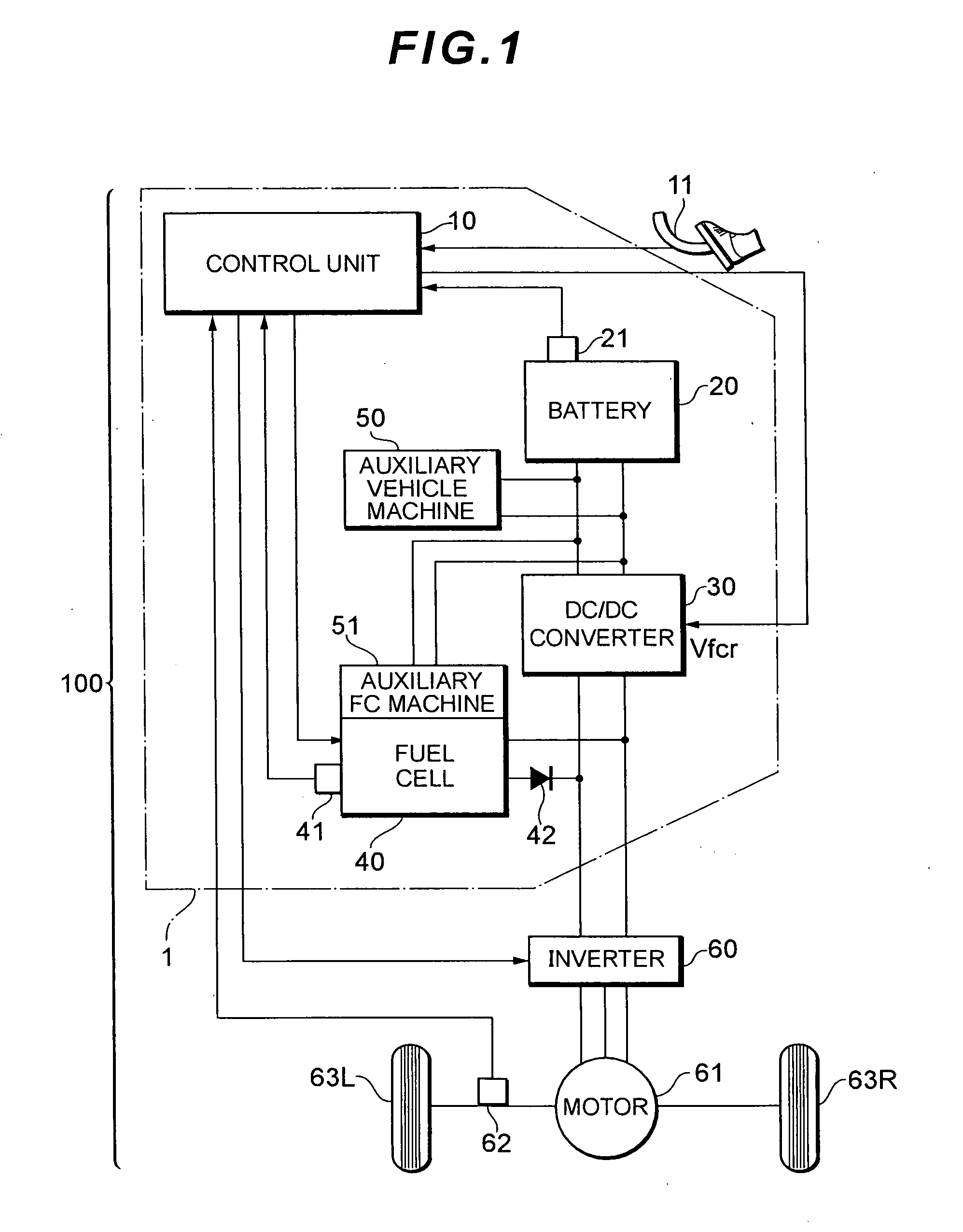

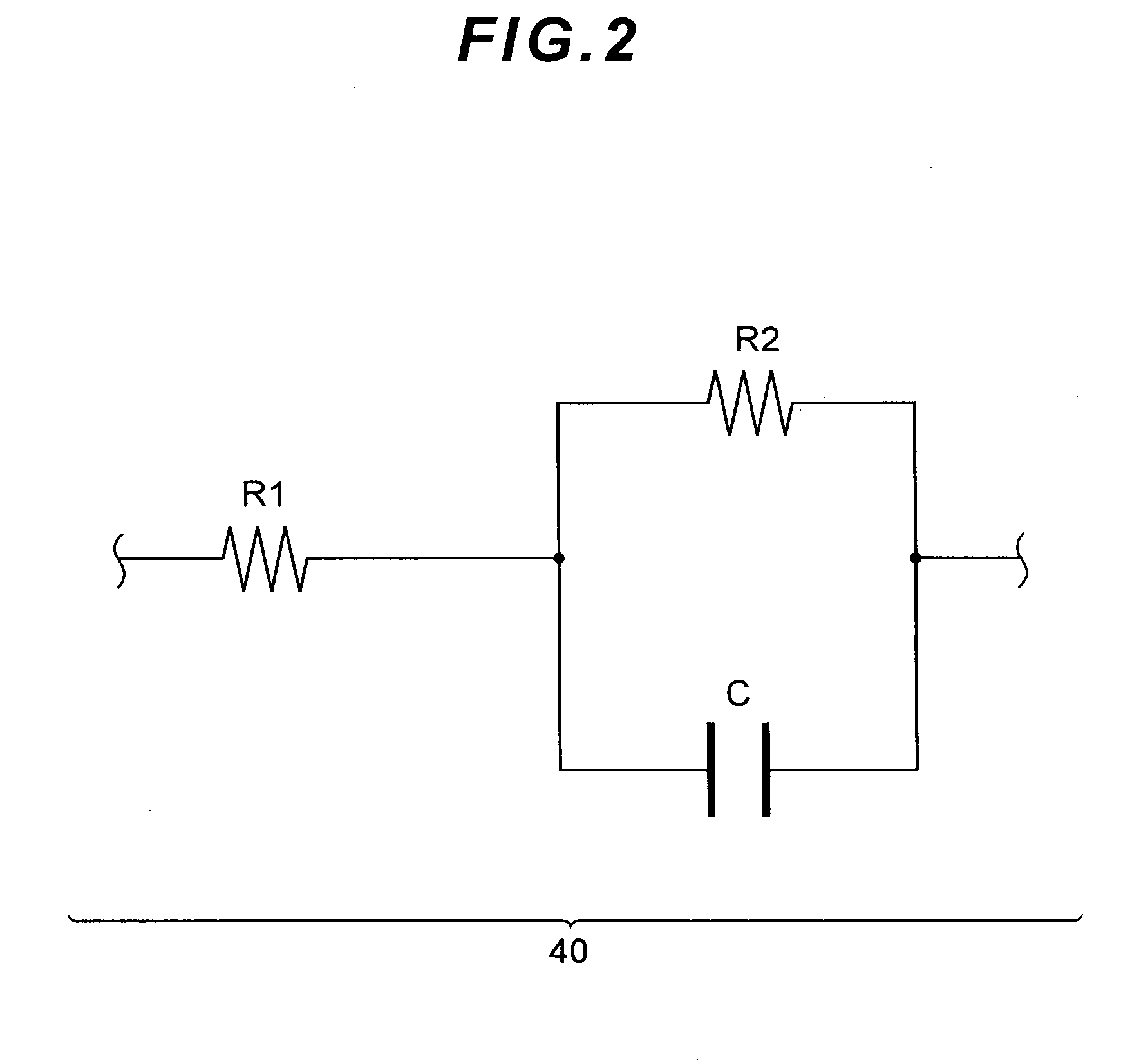

Fuel cell system

InactiveUS20110300461A1Maximize system efficiencyAccurate measurementResistance/reactance/impedenceFuel cell auxillariesFuel cellsAmplitude control

There is provided a fuel cell system in which a constantly accurate impedance measurement is made possible regardless of a response characteristic of the voltage converting device. A superimposed signal analysis section analyzes an impedance measuring signal after passing through a DC / DC converter to thereby notify a superimposed signal amplitude control section of an analysis result. A superimposed signal amplitude control section controls an amplitude value of the impedance measuring signal generated by a superimposed signal generating section based on the result notified from the superimposed signal analysis section.

Owner:TOYOTA JIDOSHA KK

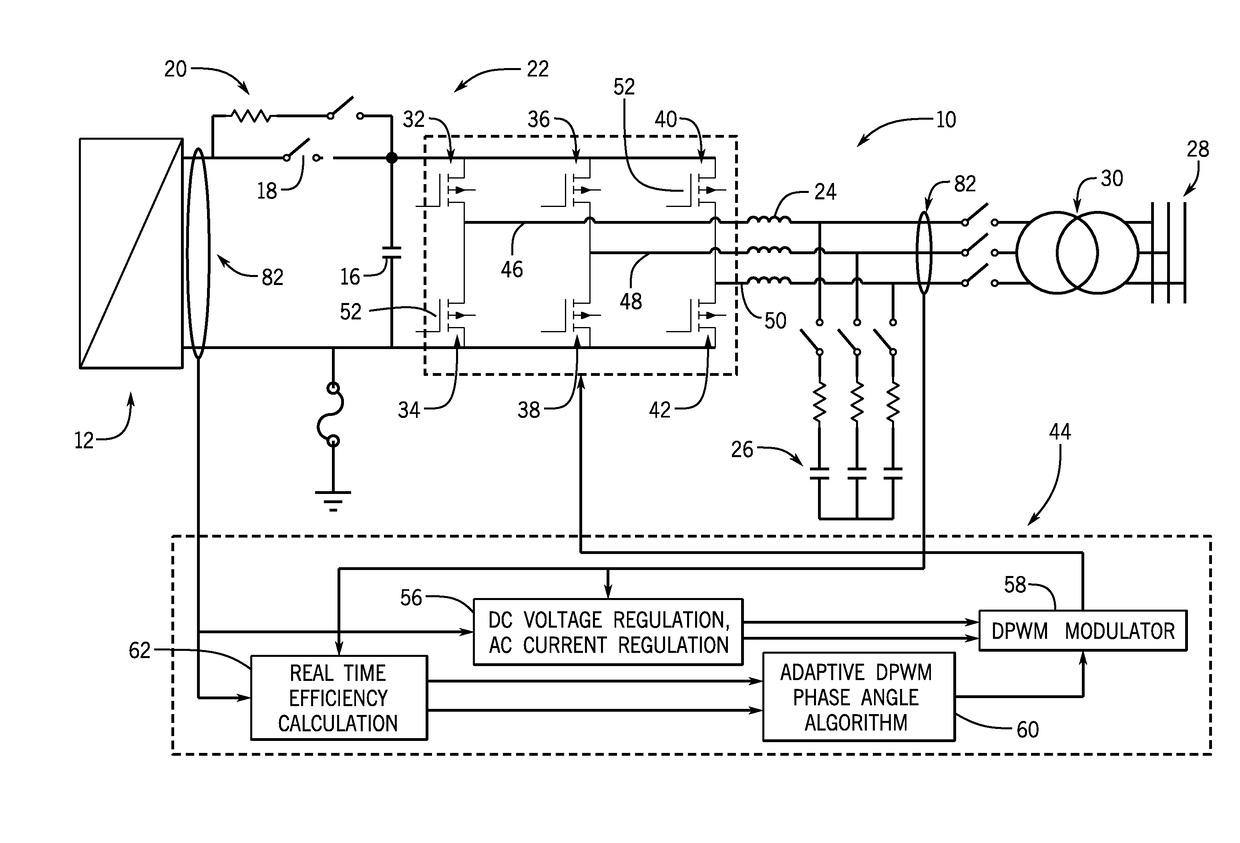

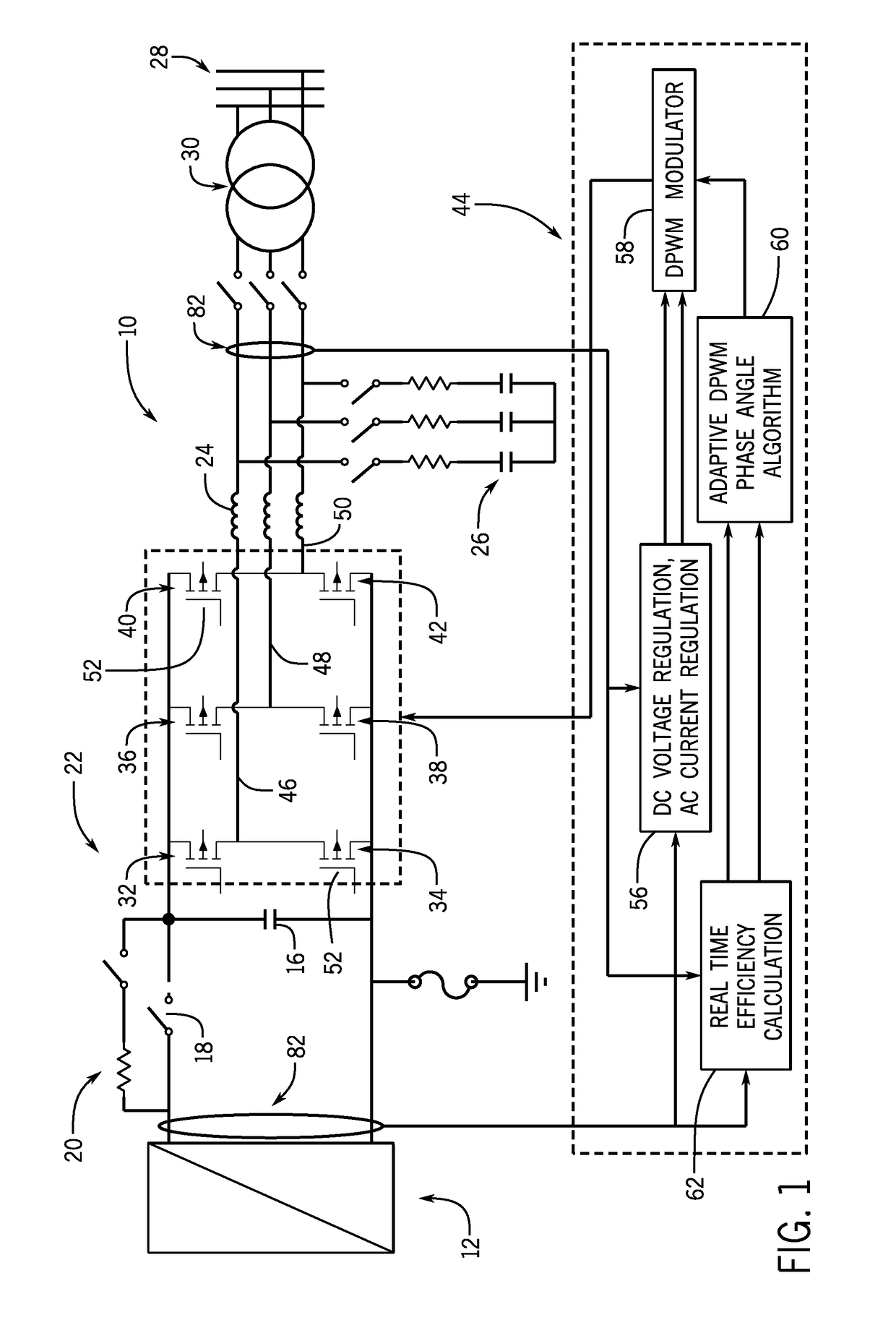

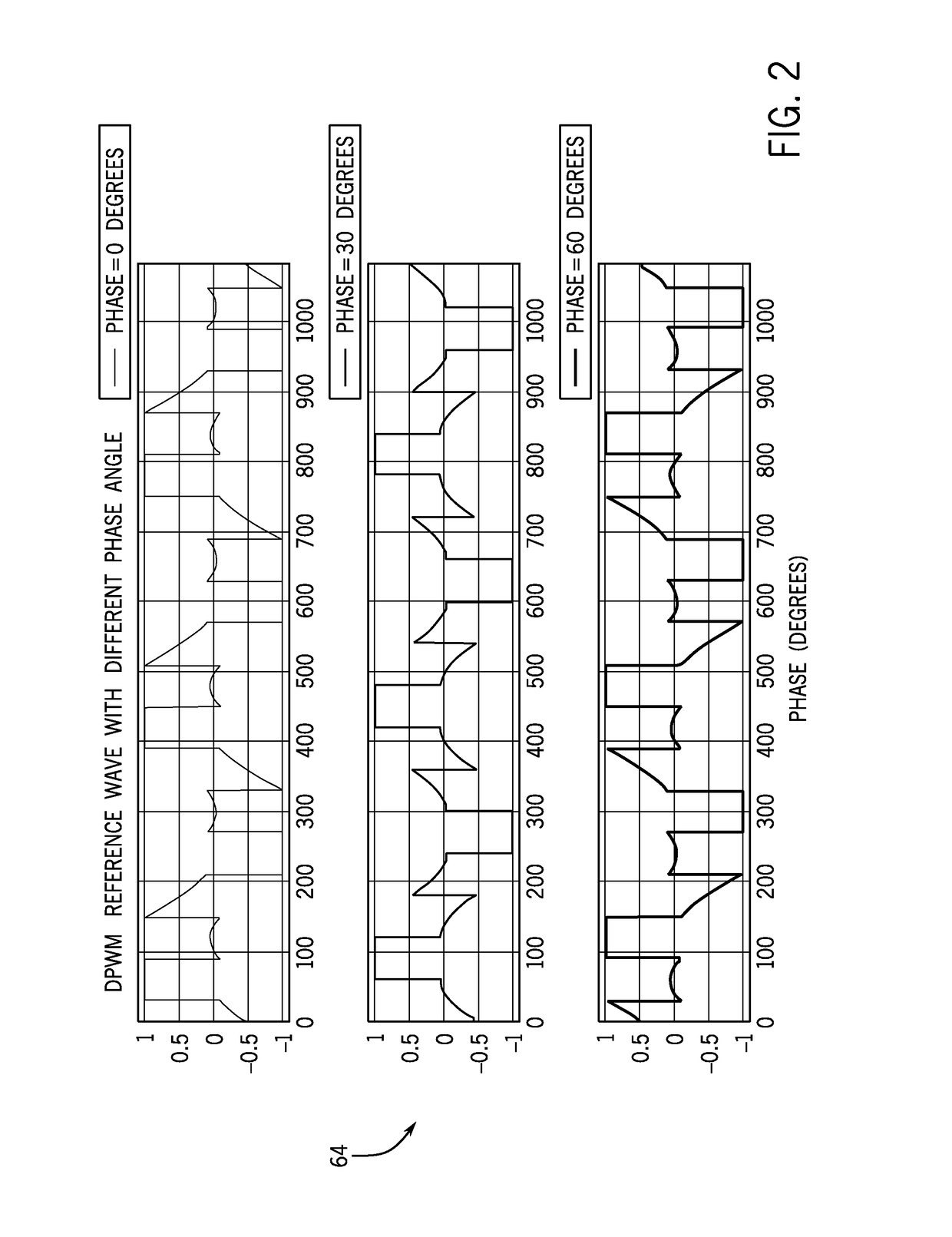

System and method for maximizing efficiency of three-phase inverter-based power systems

InactiveUS9654028B1Maximize system efficiencyEfficient power electronics conversionAc-dc conversionElectric power systemEngineering

A system and method for operating an inverter to maximize an overall efficiency of a power system is disclosed. A power system includes an inverter having an arrangement of switching devices that are selectively operable in On and Off states to invert a DC output to an AC output having controlled current and voltage. A controller selectively controls operation of the arrangement of switching devices via a discontinuous pulse width modulation (DPWM) scheme, so as to regulate an average voltage of the AC output. In controlling operation of the arrangement of switching devices via the DPWM scheme, the controller is programmed to generate a DPWM reference waveform having an initial phase angle, determine a system efficiency of the power system during operation, calculate an optimal phase angle for the DPWM reference waveform based on the determined system efficiency, and generate a DPWM reference waveform having the calculated optimal phase angle.

Owner:EATON INTELLIGENT POWER LTD

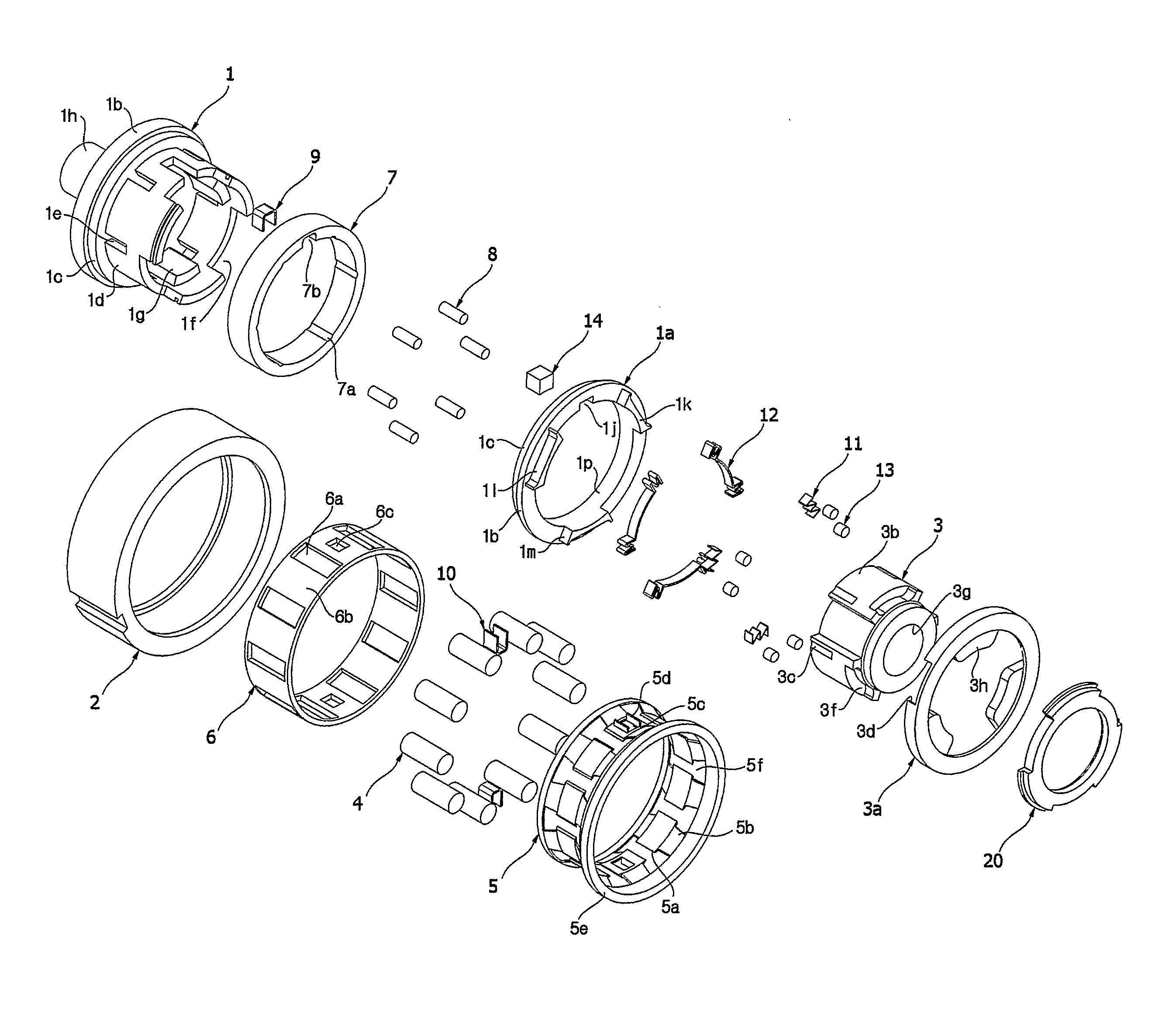

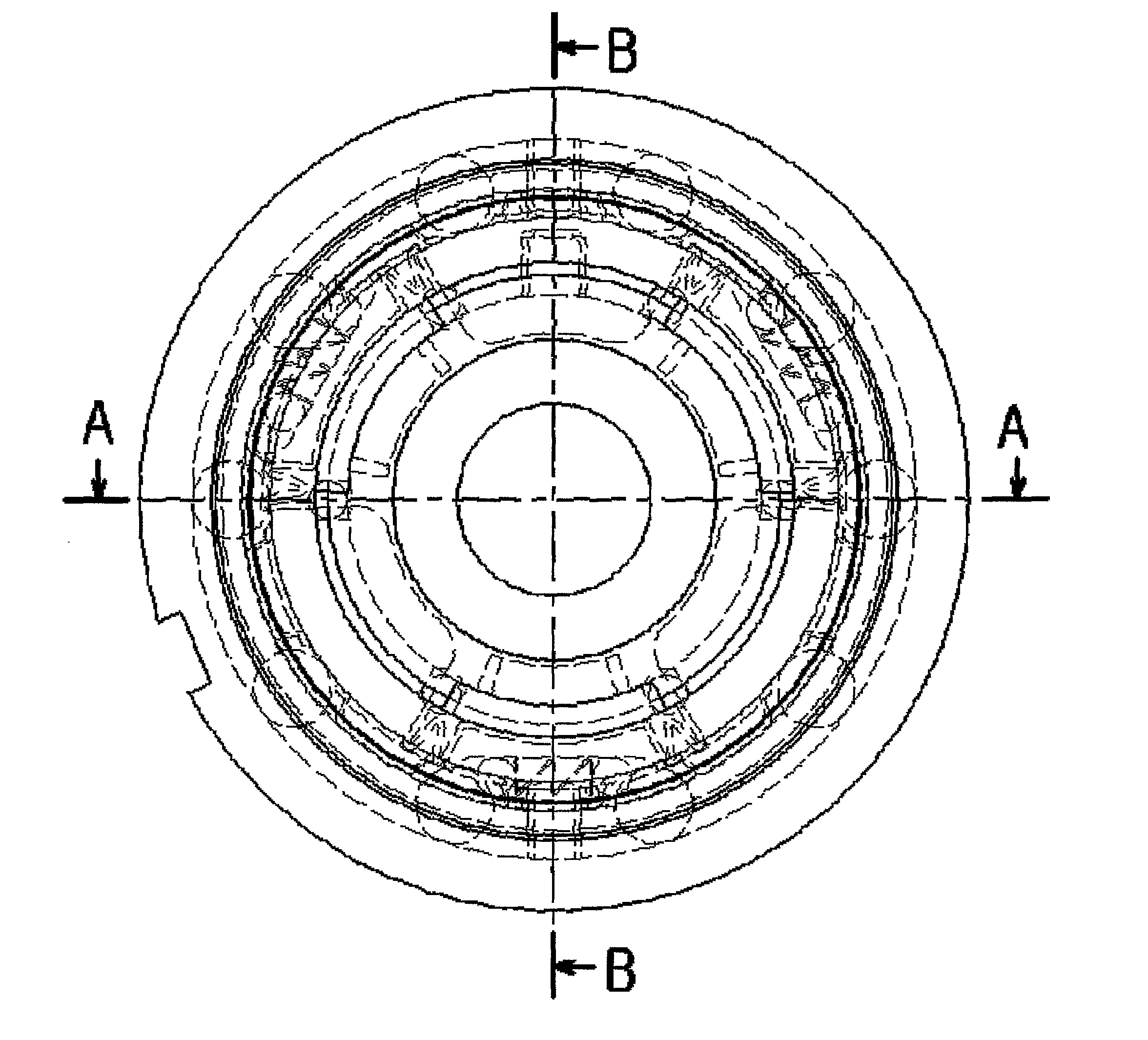

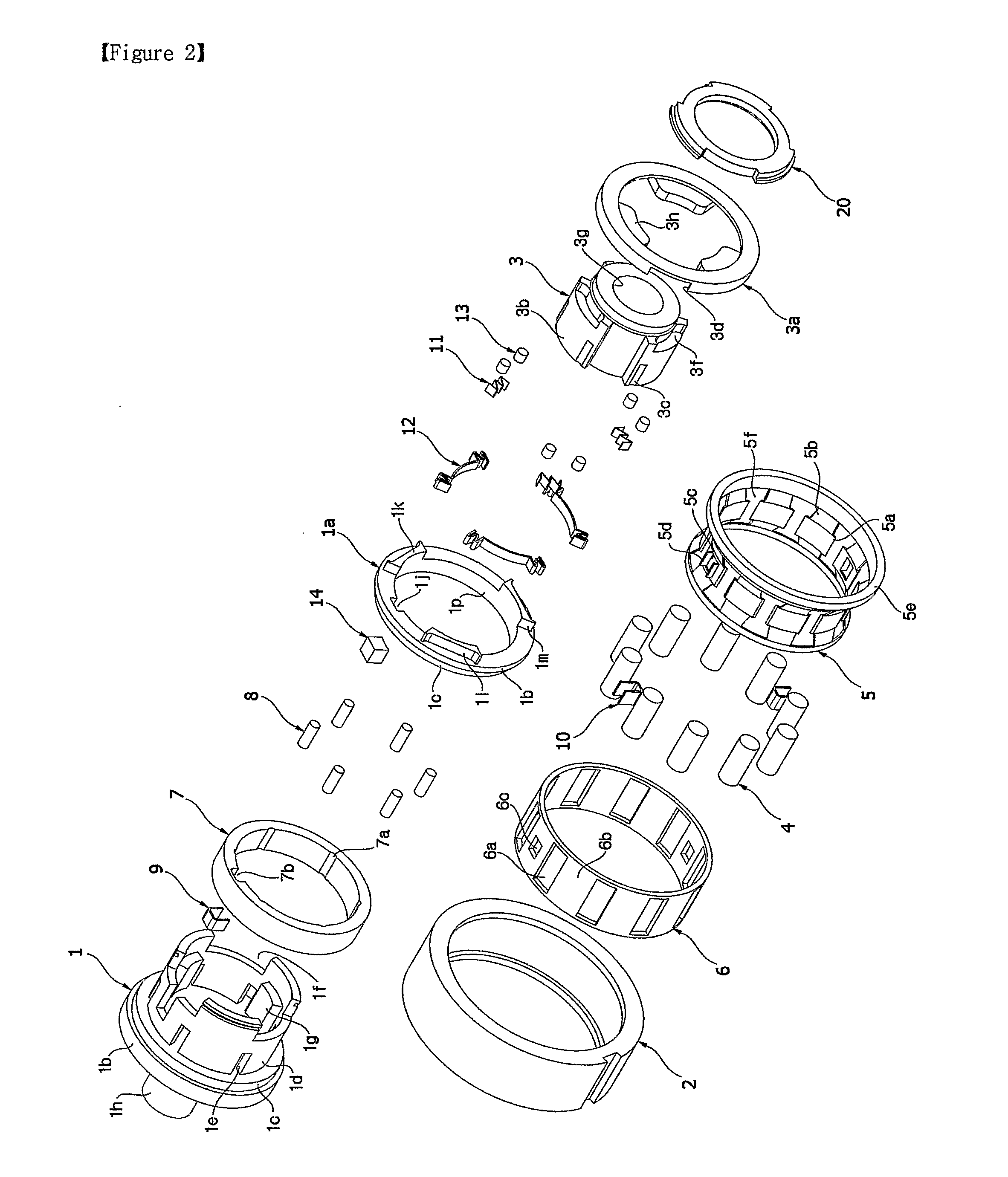

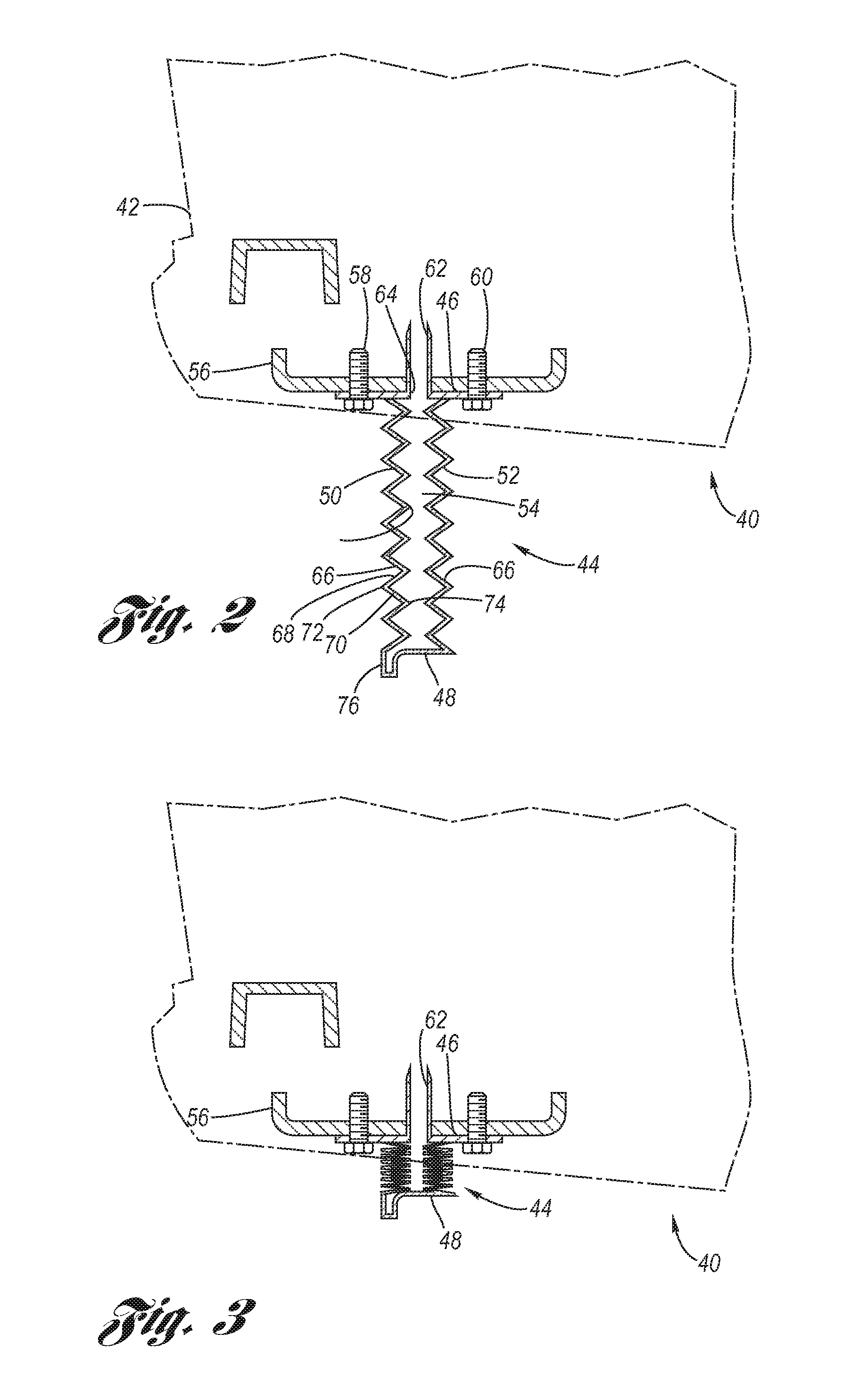

Reverse Input Prevent Clutch Bearing Assembly

InactiveUS20080179156A1Reduce in quantityMaximize system efficiencyYielding couplingFriction clutchesCoaxial lineOrbit

This invention presents a reverse input prevention clutch bearing assembly in which a forward and a reverse torque inputted from an input side is transmitted to a output side, while locks the transmission of the forward or the reverse torque inputted from the output side to the input side by locking the output side or by separating the output side from the input side. The reverse input prevention clutch bearing assembly has a first rotational member and a second rotational member which are arranged on a coaxial line and has orbit surfaces with different radii and a plurality of rolling members which are arranged in a circumferential shape between the two orbit surfaces so that the outer circumferential surfaces of the rolling members are contact-rotatable. The reverse input prevention clutch bearing assembly also has a cage which supports the rolling members so that the arrangement of the rolling members is maintained and a control member which has a rotational direction gap with respect to the first rotational member and is engaged with the first rotational member so that the torque of the forward and the reverse direction is transmitted with a delay by the gap. The reverse input prevention clutch bearing assembly has a distinguished wedge ring assembly which allows or does not allow the rolling members to rotate based on the change of the rotational direction gap between the first rotational member and the control member and the rotational direction of the control member. The reverse input prevention clutch bearing assembly can be used as one among a reverse input locking clutch bearing assembly, a reverse input shutoff clutch bearing assembly, a reverse input prevention two-way clutch bearing assembly, a reverse input prevention one-way clutch bearing assembly which can choose the lathing direction. The reverse input prevention clutch bearing assembly functions as the chosen clutch of the abovementioned assembly while, at the same time, functions as a bearing when the reverse input prevention clutch bearing assembly is not used as the clutch.

Owner:BYUN DONGHWAN

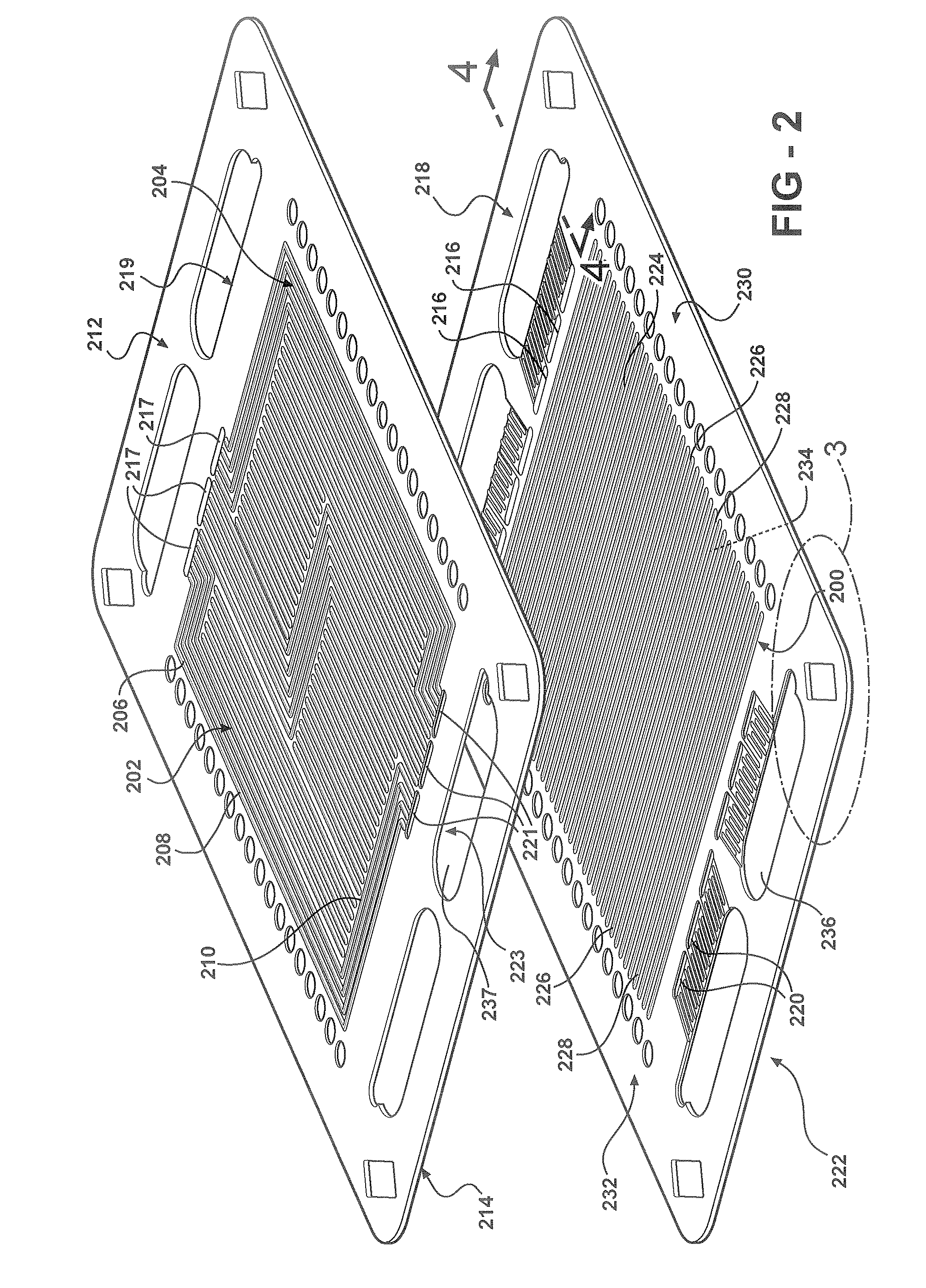

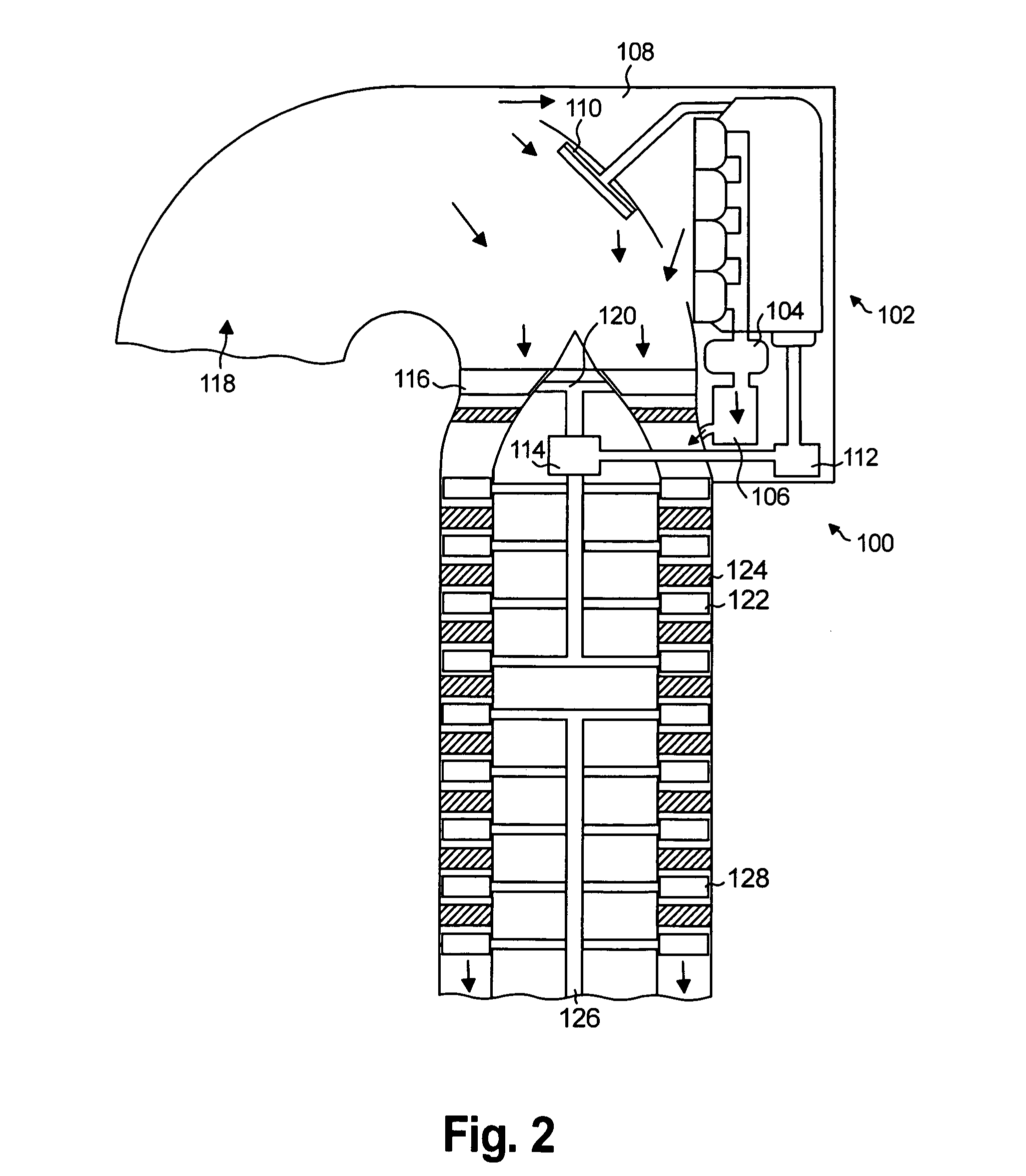

Water removal channel for PEM fuel cell stack headers

ActiveUS20080171253A1Maximize system efficiencyMinimise any dryingFuel cells groupingWater management in fuel cellsFuel cellsEngineering

A bipolar plate for a fuel cell is disclosed including a first unipolar plate having an active surface with a plurality of flowfield channels formed therein. The first unipolar plate further includes an inlet header disposed at a first end of the unipolar plate that is in communication with the active surface, and an outlet header disposed at a second end of the unipolar plate having an exhaust opening formed therethrough. A peripheral edge of the exhaust opening is chamfered and is also in communication with the active surface. The chamfered exhaust opening forms a water removal channel in the bipolar plate. A fuel cell stack including the bipolar plate is also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

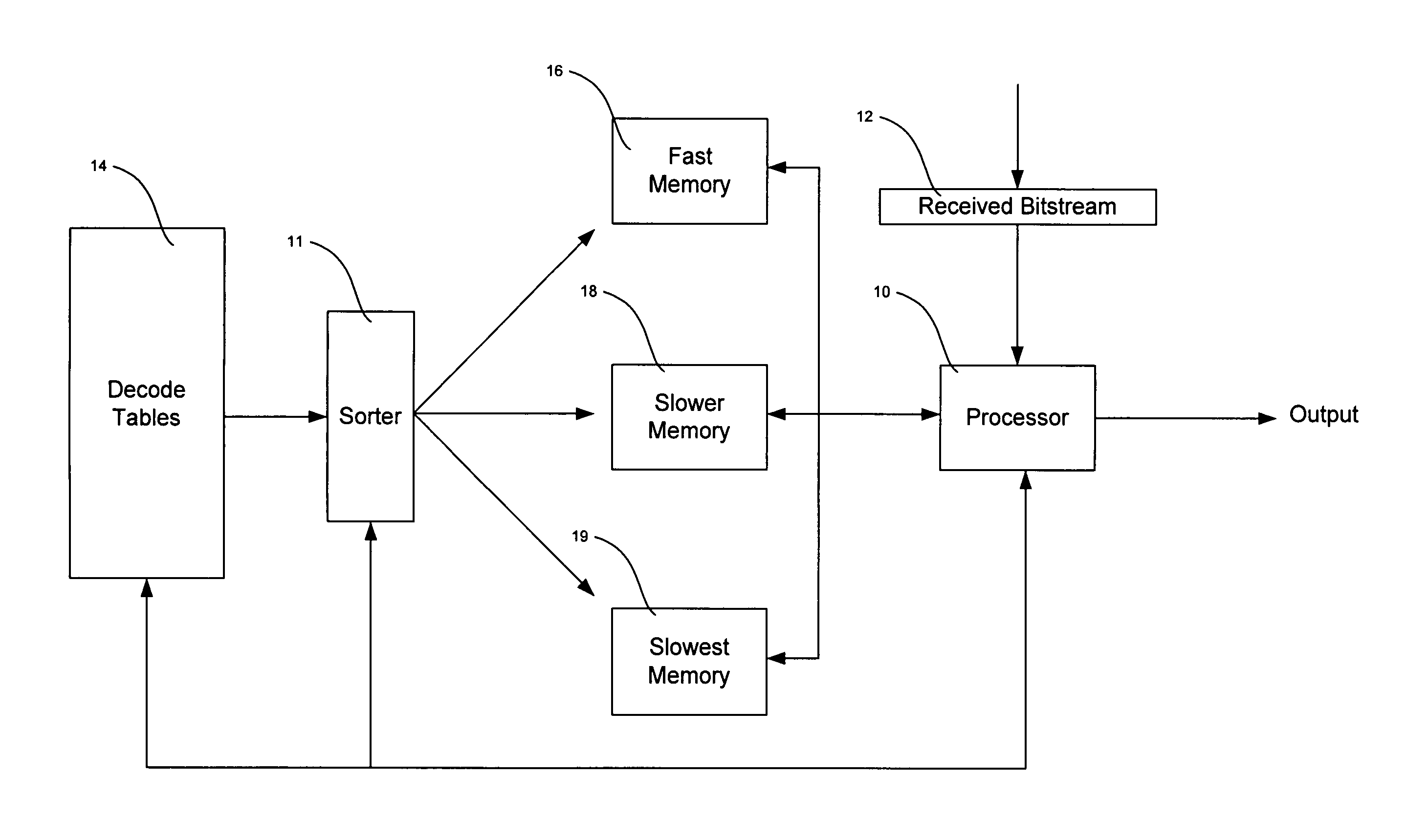

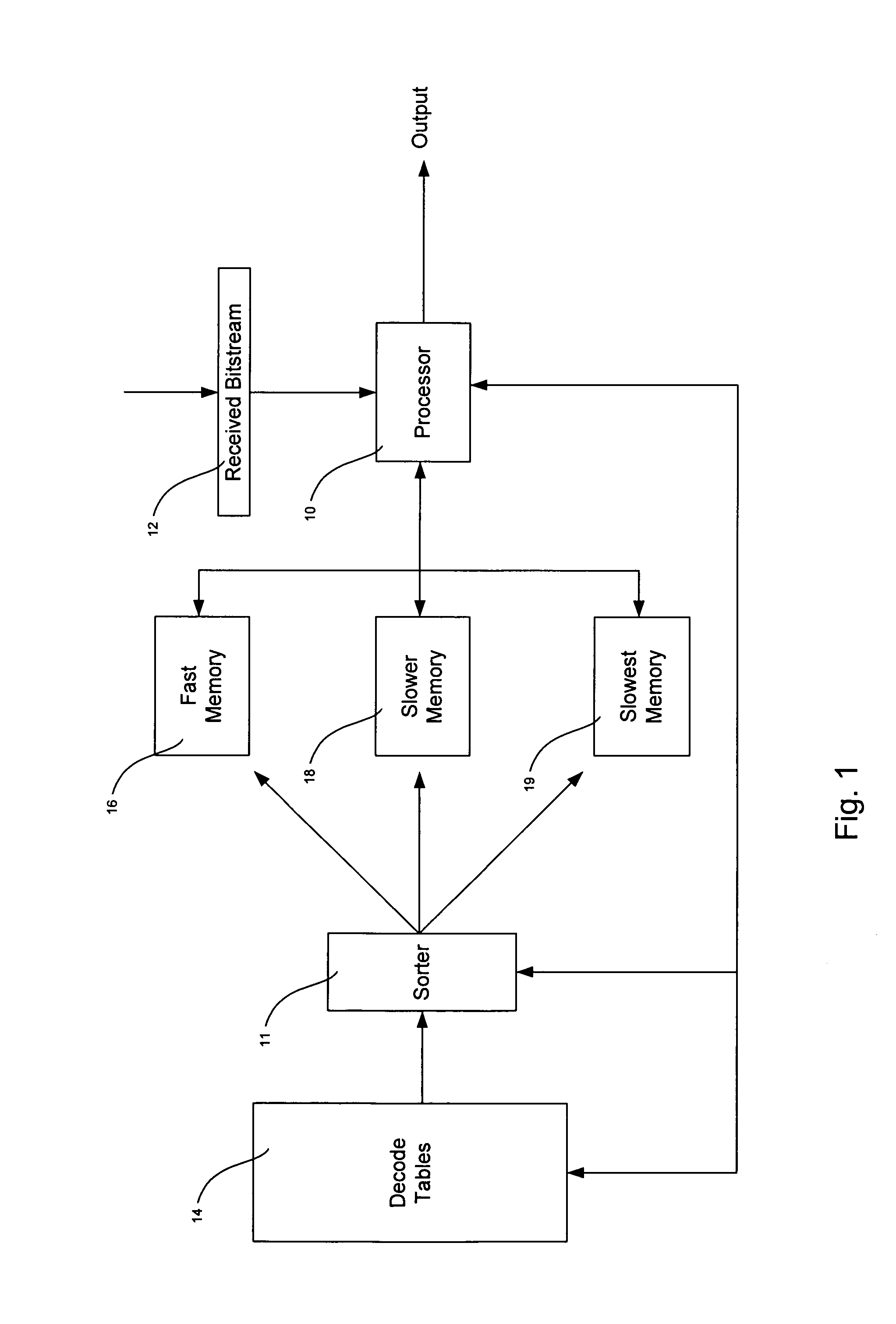

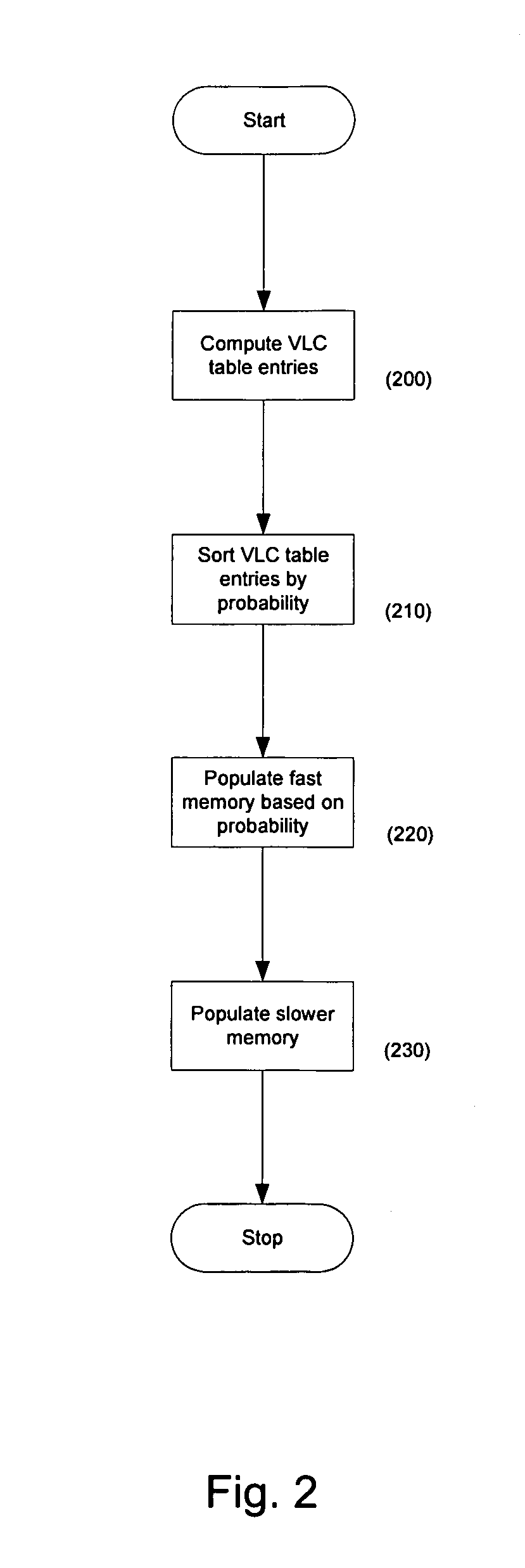

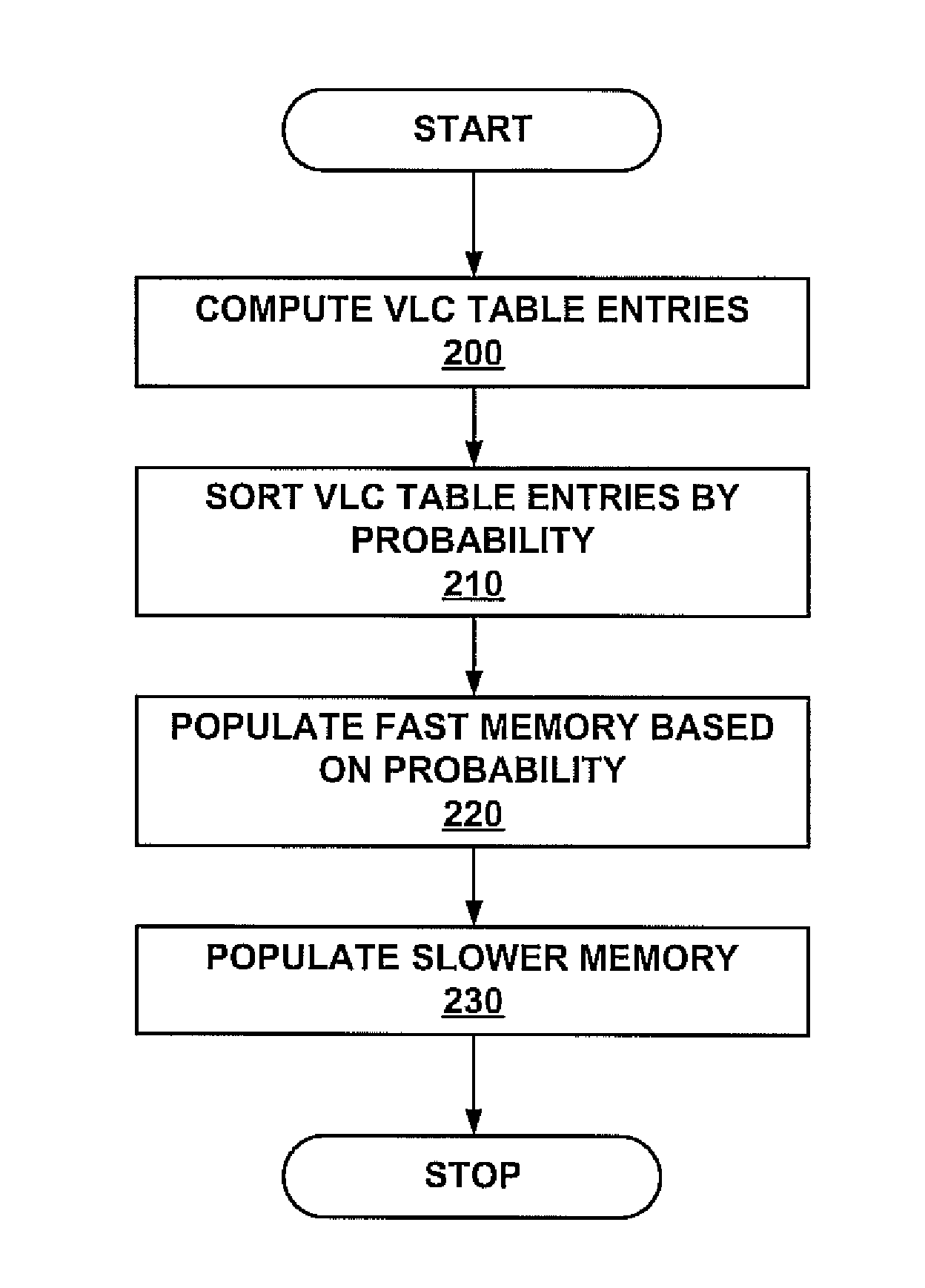

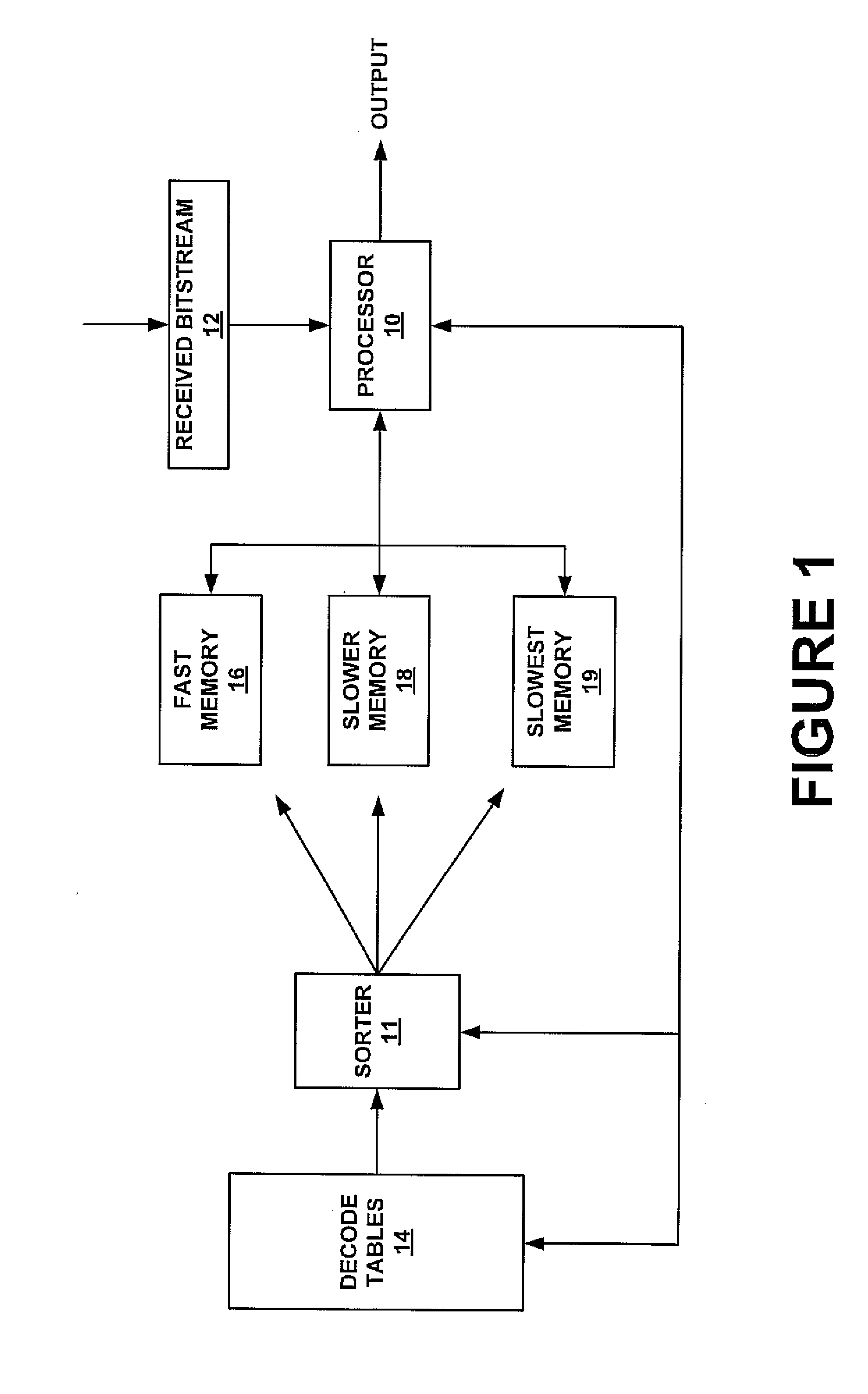

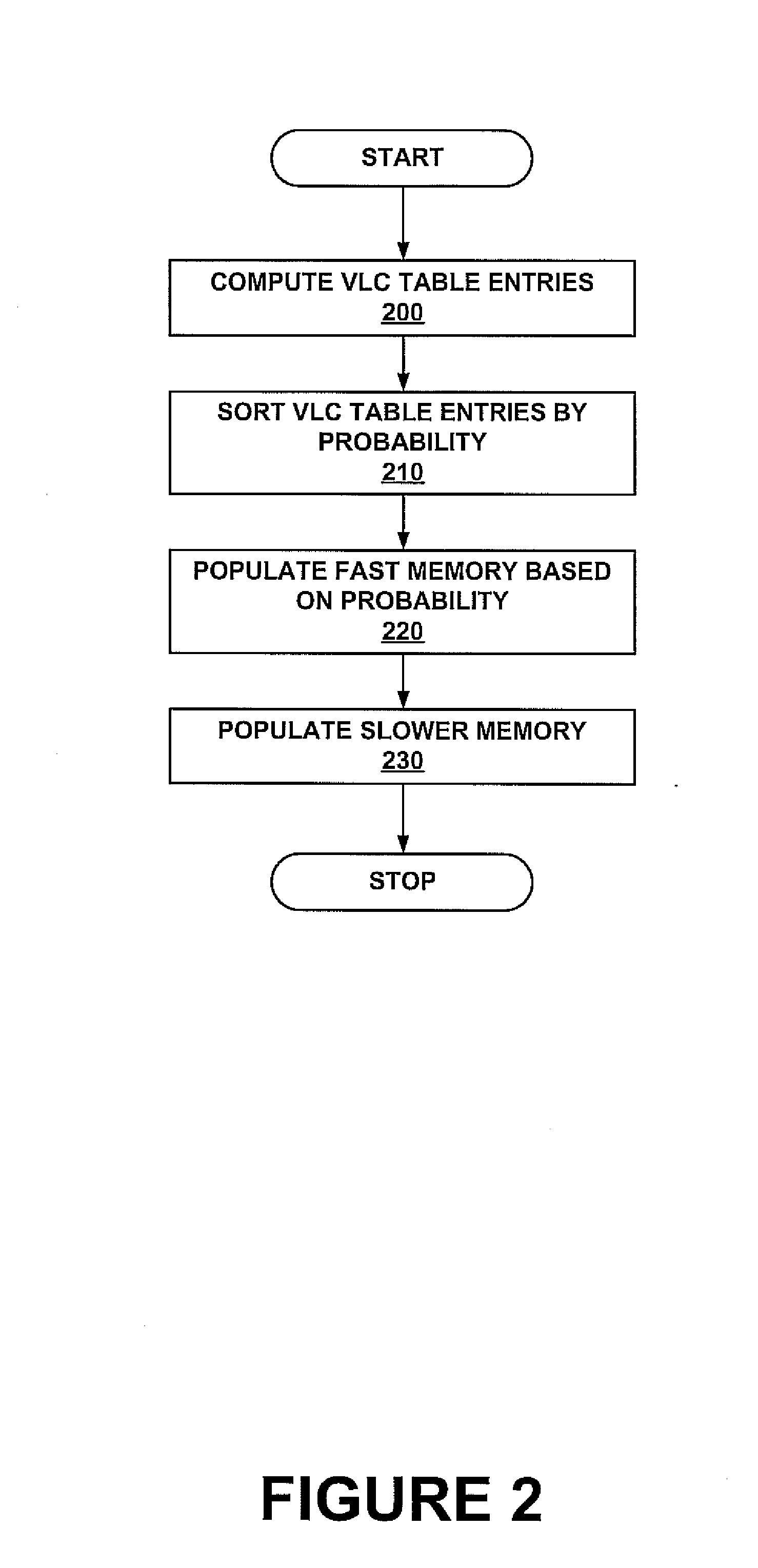

Optimization of decoder memory usage for VLC tables

ActiveUS7324026B2Optimizing storage of VLC tablesSave memory resourcesCode conversionDigital video signal modificationVariable lengthData mining

Systems and methods for optimizing system performance in variable length decoding systems are described. Embodiments are described in which decode tables are analyzed and elements of the tables sorted by probability of occurrence. Storage of elements can be determined by probability of occurrence and embodiments of the present invention can optimize system efficiency by storing most likely entries into fast-memory and least likely entries in slowest memory. In certain embodiments, a single large table is provided that cannot fit into decoder fast-memory. In some embodiments, individual elements can be optimized for storage in fast-memory by selecting more frequently occurring entries or groups of entries into decoder memory.

Owner:NVIDIA CORP

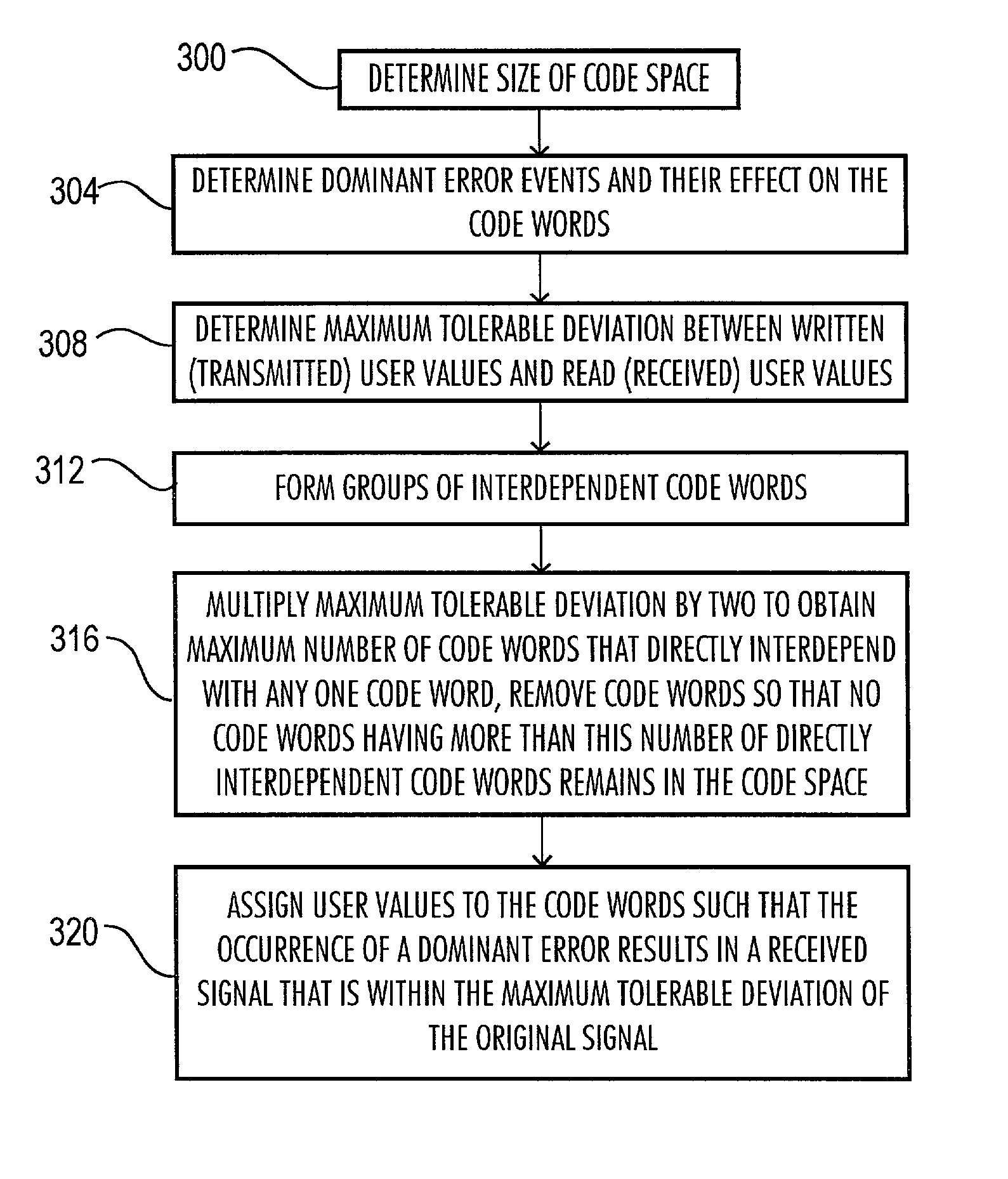

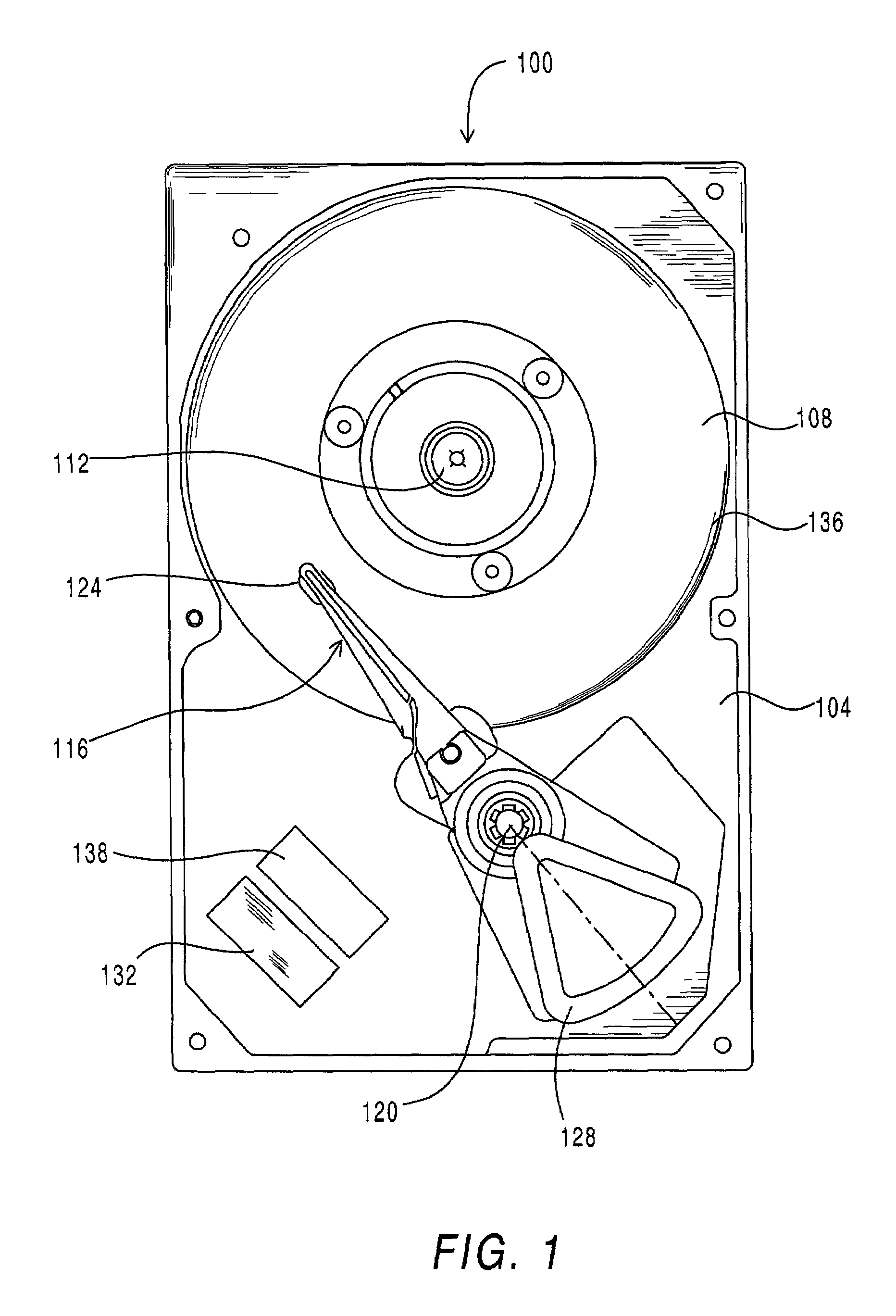

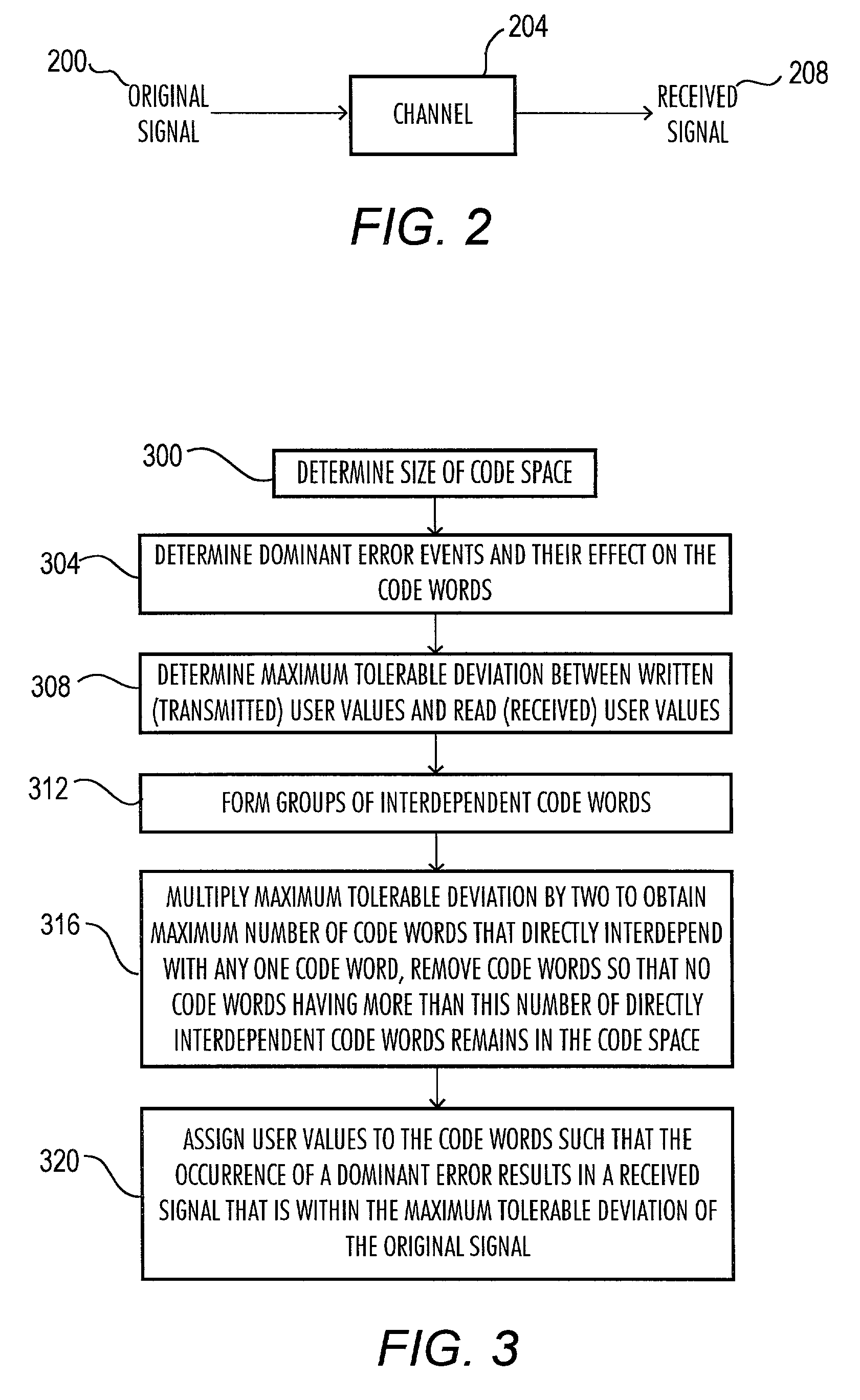

High efficiency, error minimizing coding strategy method and apparatus

InactiveUS7404131B2Improve efficiencyError minimizing strategyError preventionTransmission systemsHigh effectivenessComputer science

A method for creating a high efficiency, error minimizing code is provided. In addition, an apparatus having a high efficiency, error minimizing code is provided. In particular, the present invention provides a high efficiency, error minimizing code for use in connection with systems having a communication channel in which identifiable dominant errors occur, and that is used to transmit data that may be usefully applied in the system even though the received signal is not exactly equal to the original signal. Furthermore, the present invention provides a code that may be used to constrain the effects of dominant errors in a communication channel.

Owner:MAXTOR

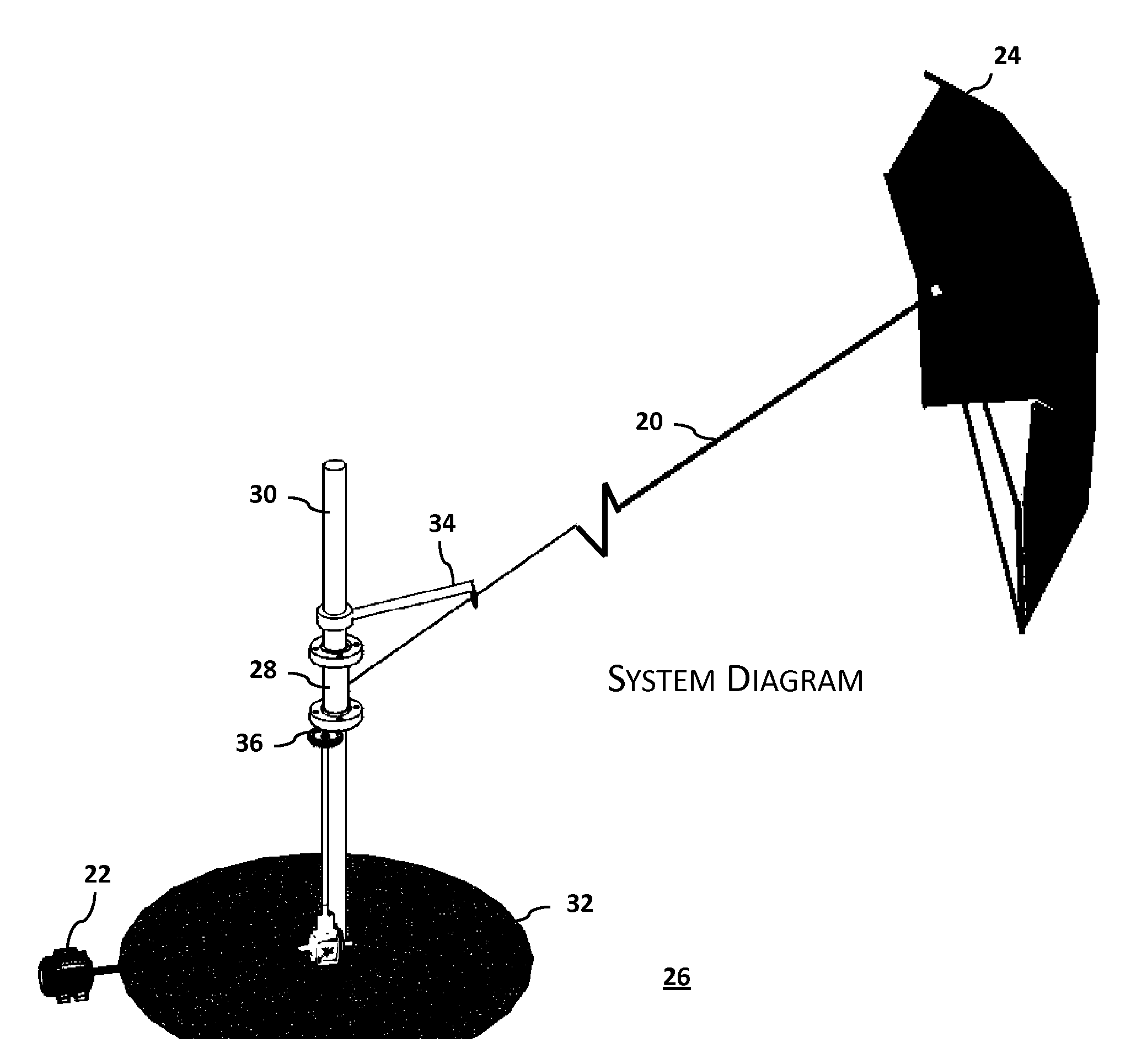

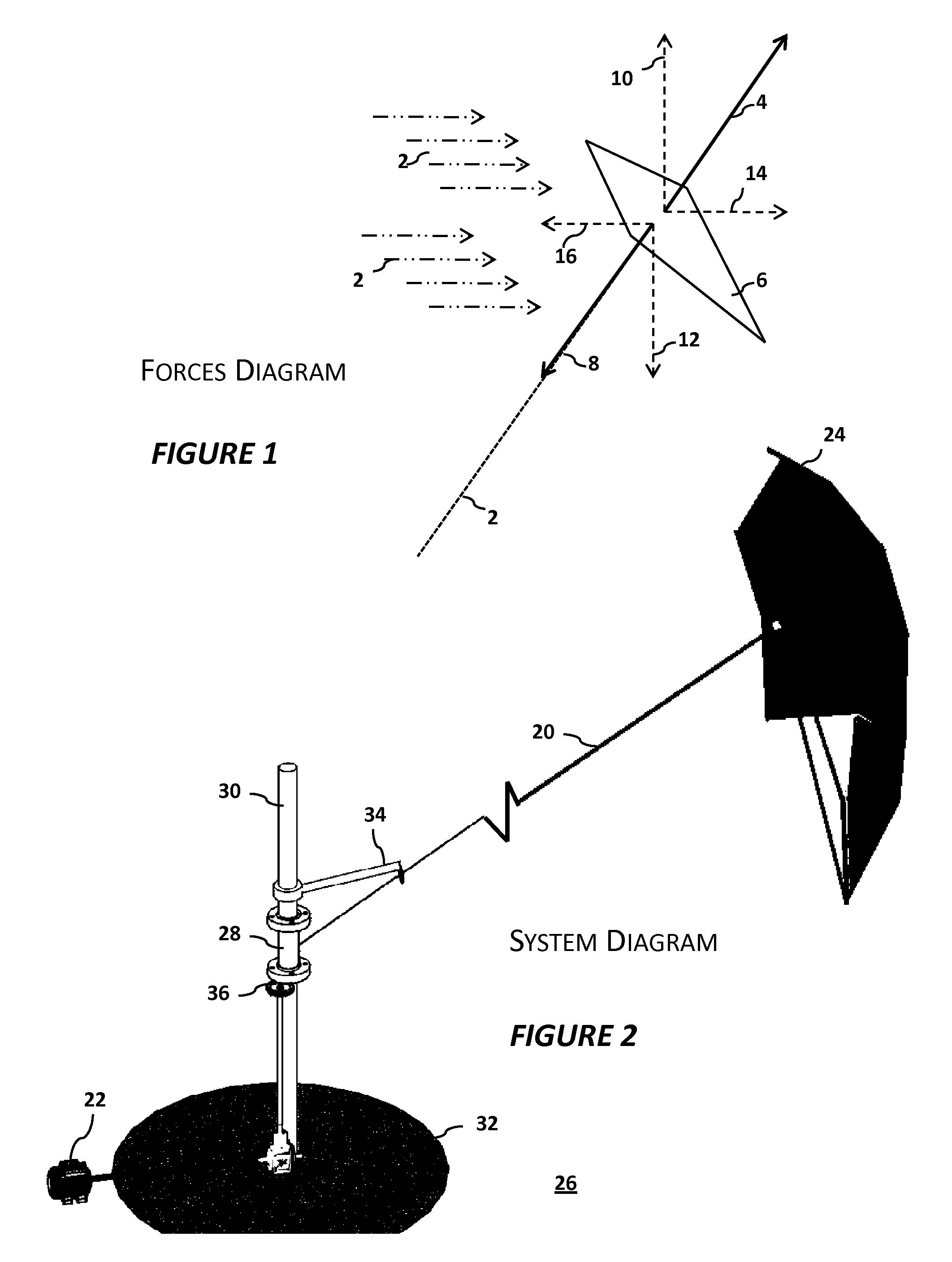

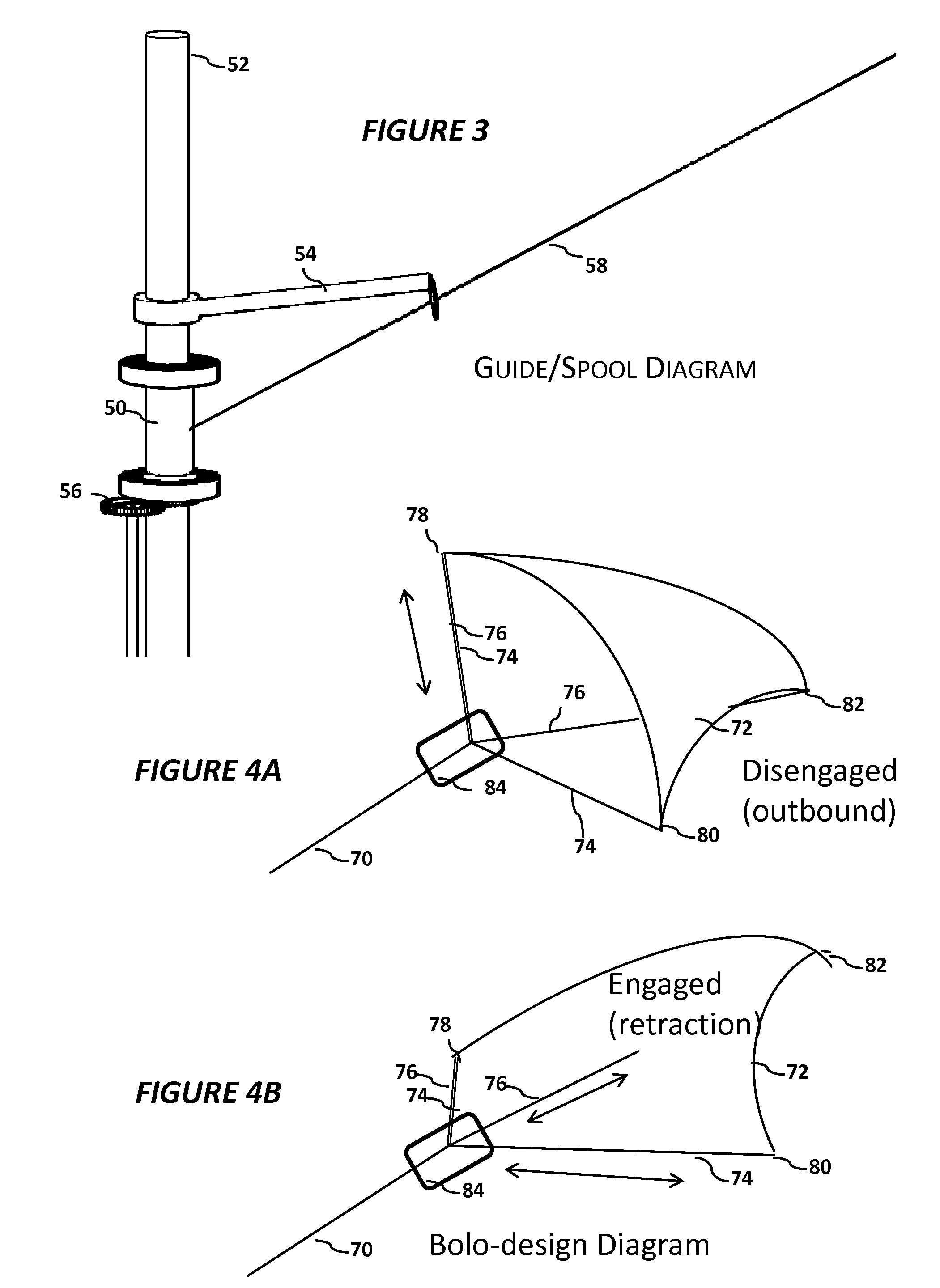

System and method for harnessing wind power at variable altitudes

InactiveUS20100032956A1High tensile strengthHigh strengthWind motor supports/mountsMachines/enginesEngineeringUltimate tensile strength

A system for harnessing power from wind using a wind capturing structure. An axis of rotation could be central to the system, and the lines could rotate around this axis. Features for the wind capturing structure include effective downwind power generation using a durable, lightweight, inexpensive structure that may be safe in the event of a crash, and easily modified to reduce drag for retraction. The capturing structure creates lift in a low altitude environment, capable of operating in high wind conditions. The lines include minimal mass to permit lift at low altitudes, and are constructed with maximum tensile strength to prevent failure in high winds. A versatile wind capturing structure could include a kite operable in variable conditions for efficient and consistent production of force. The power producing cycle of a system capturing power from wind should maximize the efficiency of the system.

Owner:CMNA POWER

Return link design for PSD limited mobile satellite communication systems

InactiveUS20060040614A1Quick fixAccurate power levelPower managementActive radio relay systemsTransmitted powerEngineering

A system and method for managing access to a satellite-based transponder by a plurality of aircraft each having a mobile radio frequency (RF) system. The system employs a ground-based, central control system for managing access to the satellite-based transponder so that the aggregate power spectral density (PSD) of the RF signals of all the mobile systems does not exceed, at any time, limits established by regulatory agencies to prevent interference between satellite systems. This is accomplished by a dual control loop arrangement for monitoring the signal-to-noise ratio (Eb / No) of the RF signal transmitted by the satellite-based transponder. A ground-based control loop is used whereby a ground-based central controller monitors the Eb / No and transmits commands to the aircraft (via the satellite transponder) to maintain the Eb / No of the transmitted signal within a predetermined range. A fast scan angle compensation is used by the mobile system of the aircraft to implement another control loop to further adjust the transmit power. This control loop maintains the Eb / No of the signal transmitted to the satellite-based transponder at the commanded level inbetween updates from the ground-based central controller.

Owner:THE BOEING CO

Fuel Cell System

InactiveUS20090117427A1Accurate impedance measurementMaximize system efficiencyResistance/reactance/impedenceFuel cell auxillariesFuel cellsAmplitude control

There is provided a fuel cell system in which a constantly accurate impedance measurement is made possible regardless of a response characteristic of the voltage converting device. A superimposed signal analysis section analyzes an impedance measuring signal after passing through a DC / DC converter to thereby notify a superimposed signal amplitude control section of an analysis result. A superimposed signal amplitude control section controls an amplitude value of the impedance measuring signal generated by a superimposed signal generating section based on the result notified from the superimposed signal analysis section.

Owner:TOYOTA JIDOSHA KK

Integrated Air Springs System and Inflatable Air Dam Assembly

InactiveUS20120153581A1Minimizes duplicityLowering vehicular weightVehicle seatsVehicle body stabilisationElectronic controllerGas compressor

An integrated pneumatic system including a motor, air compressor, air dryer, valves, air lines and electronic controller pneumatically controls both an air springs system and an inflatable air dam assembly, wherein the trim height adjustment of the air springs may be individual or collective, and wherein the trim height adjustment of the air springs and the inflation and deflation of the inflatable air dam assembly may be mutually coordinated with respect to vehicular speed and the duration of vehicular speed ranges.

Owner:GM GLOBAL TECH OPERATIONS LLC

Apparatus and method for performing intra prediction for image decoder

InactiveUS7830959B2Maximize system efficiencyReduced execution timeColor television with pulse code modulationColor television with bandwidth reductionParallel computingImaging data

Owner:ELECTRONICS & TELECOMM RES INST

Method and system for switching cellular base station capacity

InactiveUS8521172B2Facilitates physical transferMaximize system efficiencyNetwork traffic/resource managementSubstation equipmentQuality of serviceTransceiver

A radio capacity management system (RCMS) and method are adapted to integrate within an existing network of cells that form a local cellular wireless communications network. The RCMS is not limited by the types or number of sites that form the cellular wireless communications network. Such sites have idle, redundant RF radio channel resources. The RCMS reallocates idle RF resources between the network of cells whether those resources are redundant or not. Reallocations are based on a dynamic, as-need basis or on historical quality-of-service data specific to each cell. The RCMS includes a master capacity management (MCMS) system that continuously communicates with a base station controller which provides resource capacity data from each site to the MCMS. The MCMS uses this date to determine when a cell requires additional radio transceiver capacity and where the capacity will be reallocated from.

Owner:UNBRIDLED NETWORKS

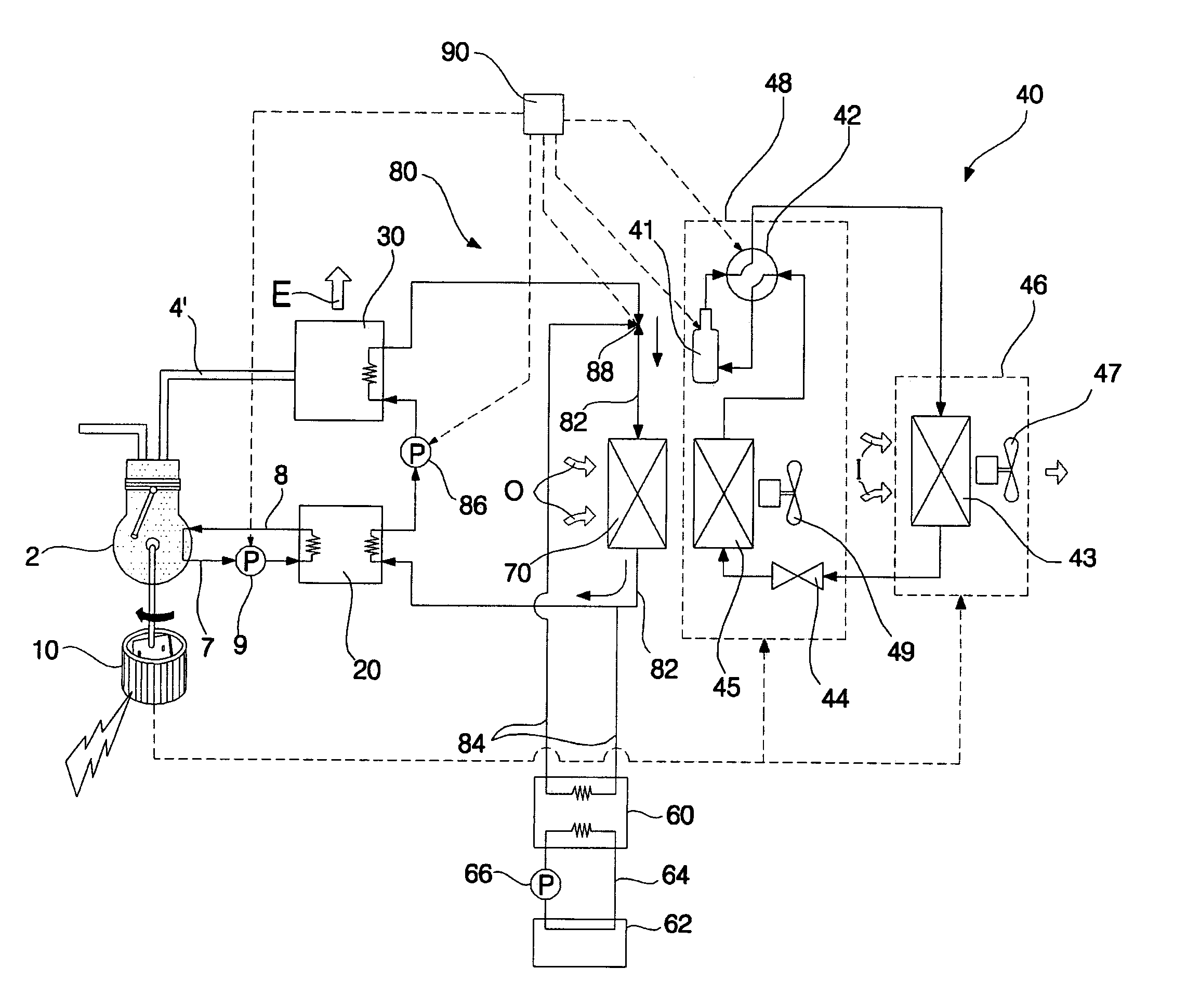

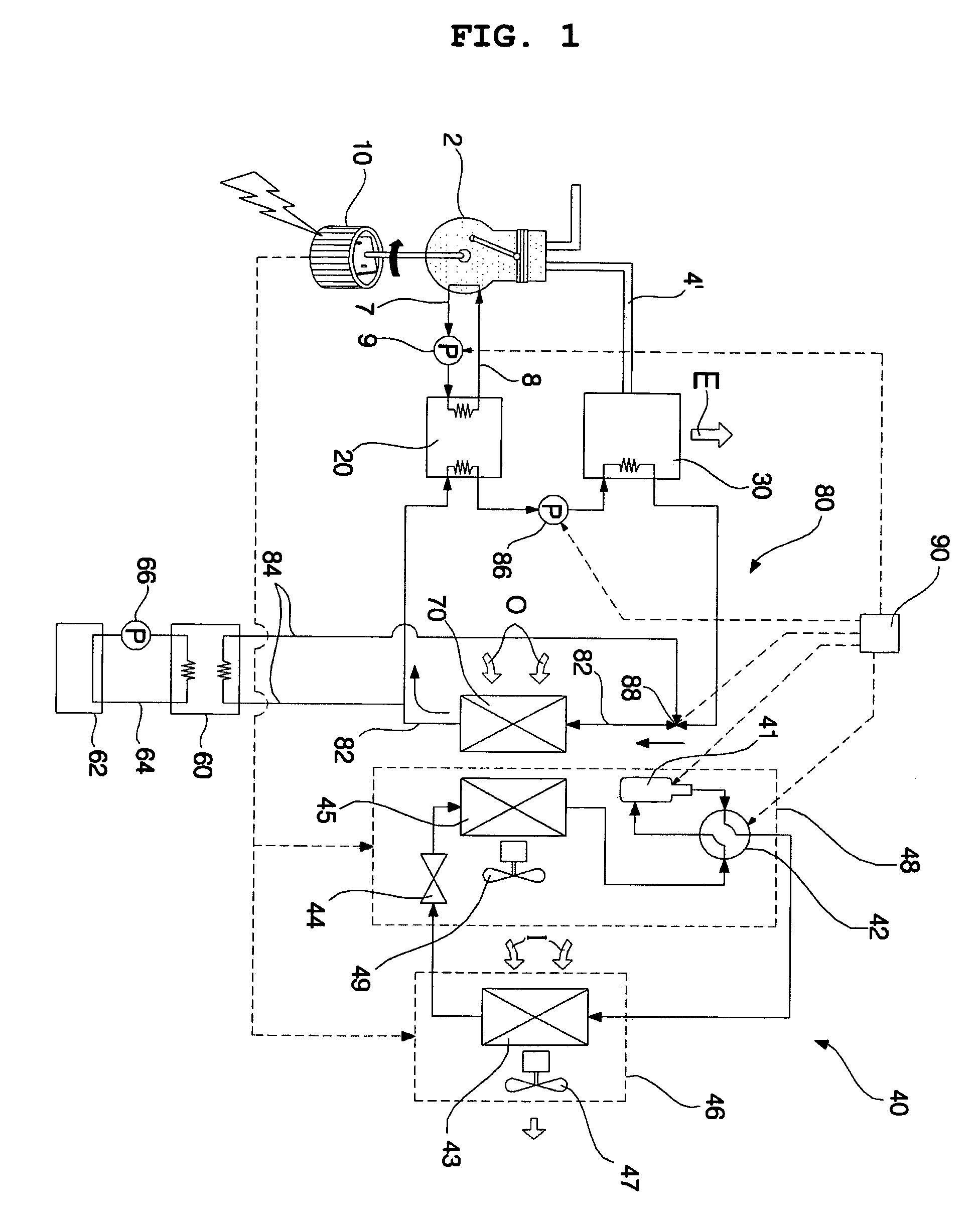

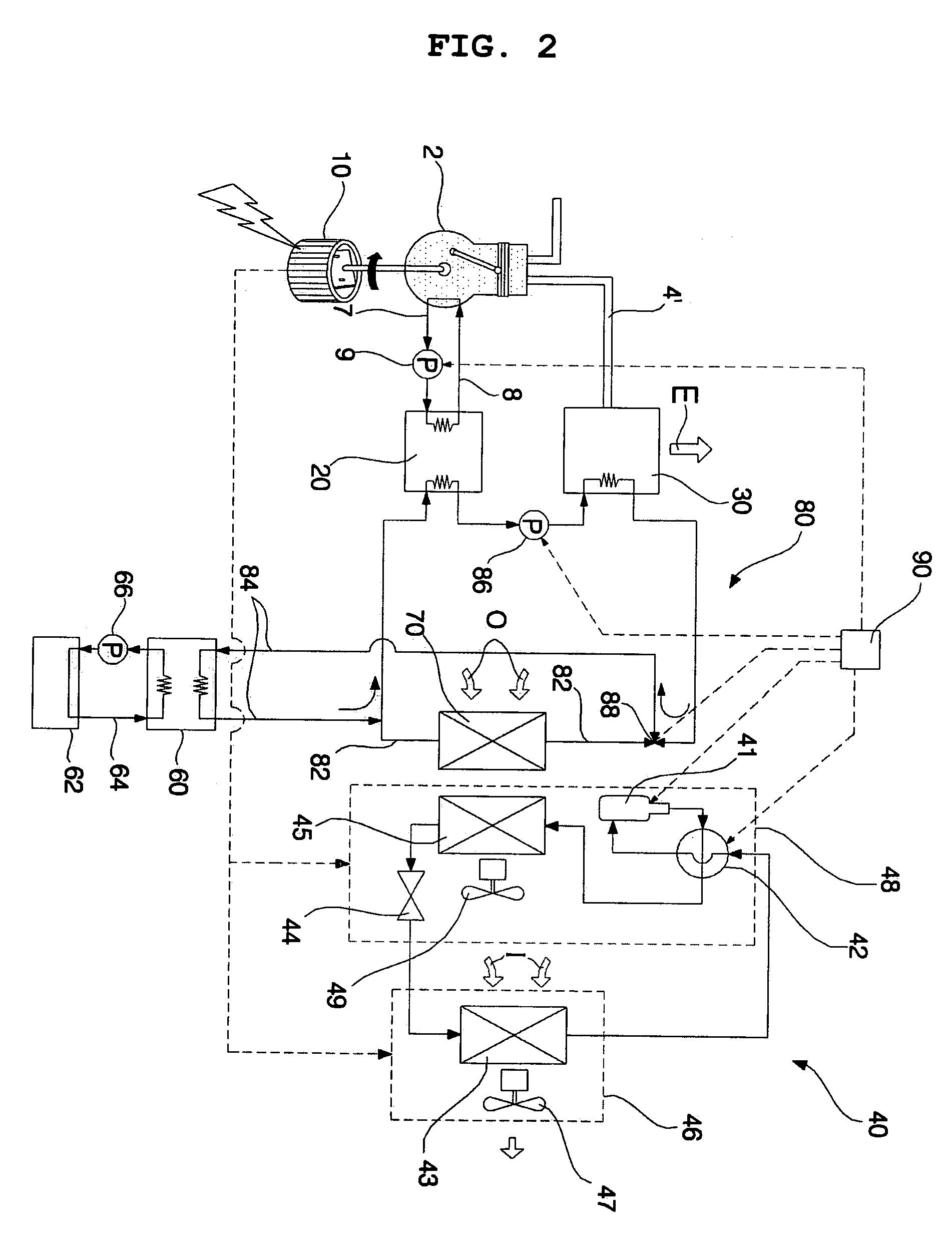

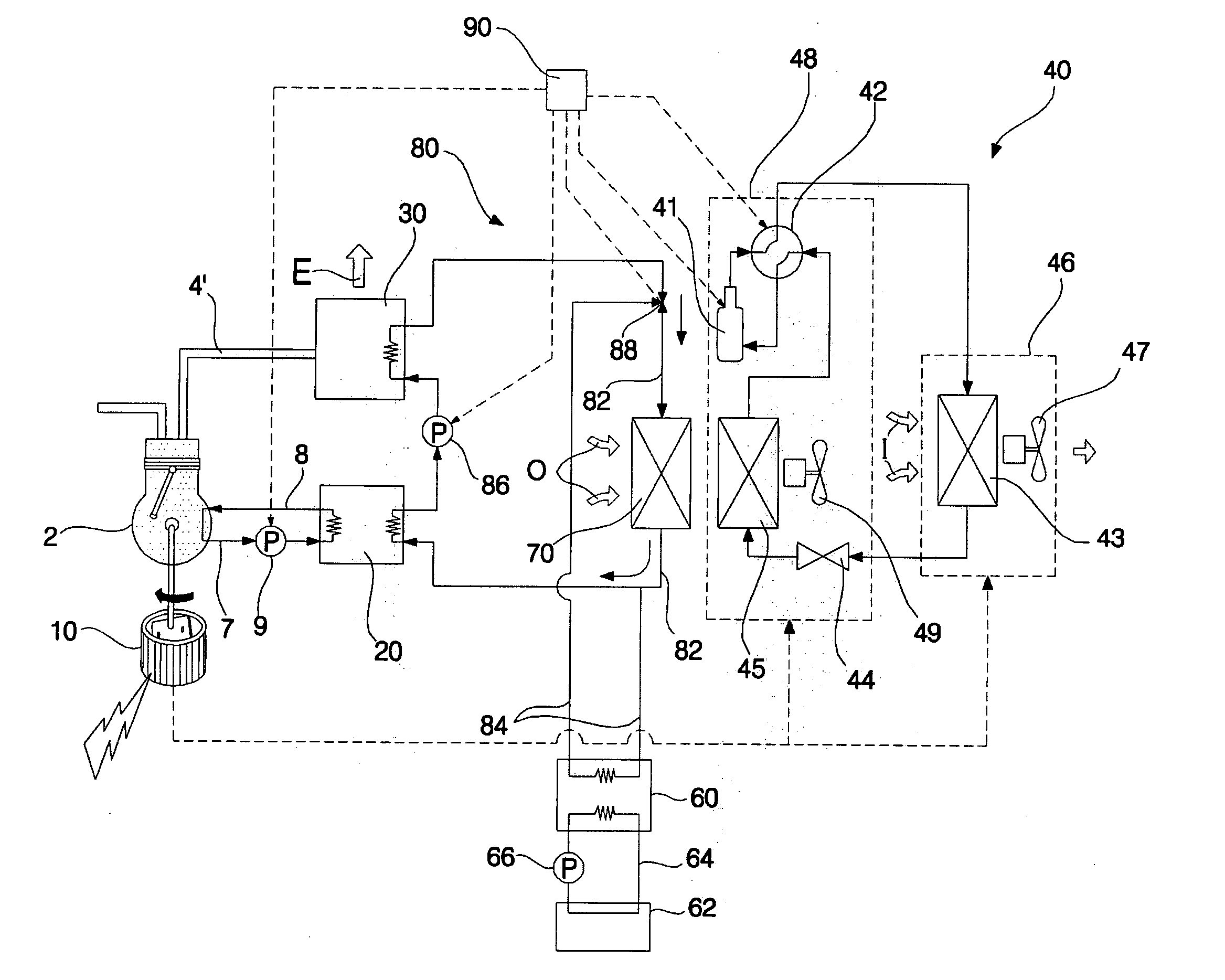

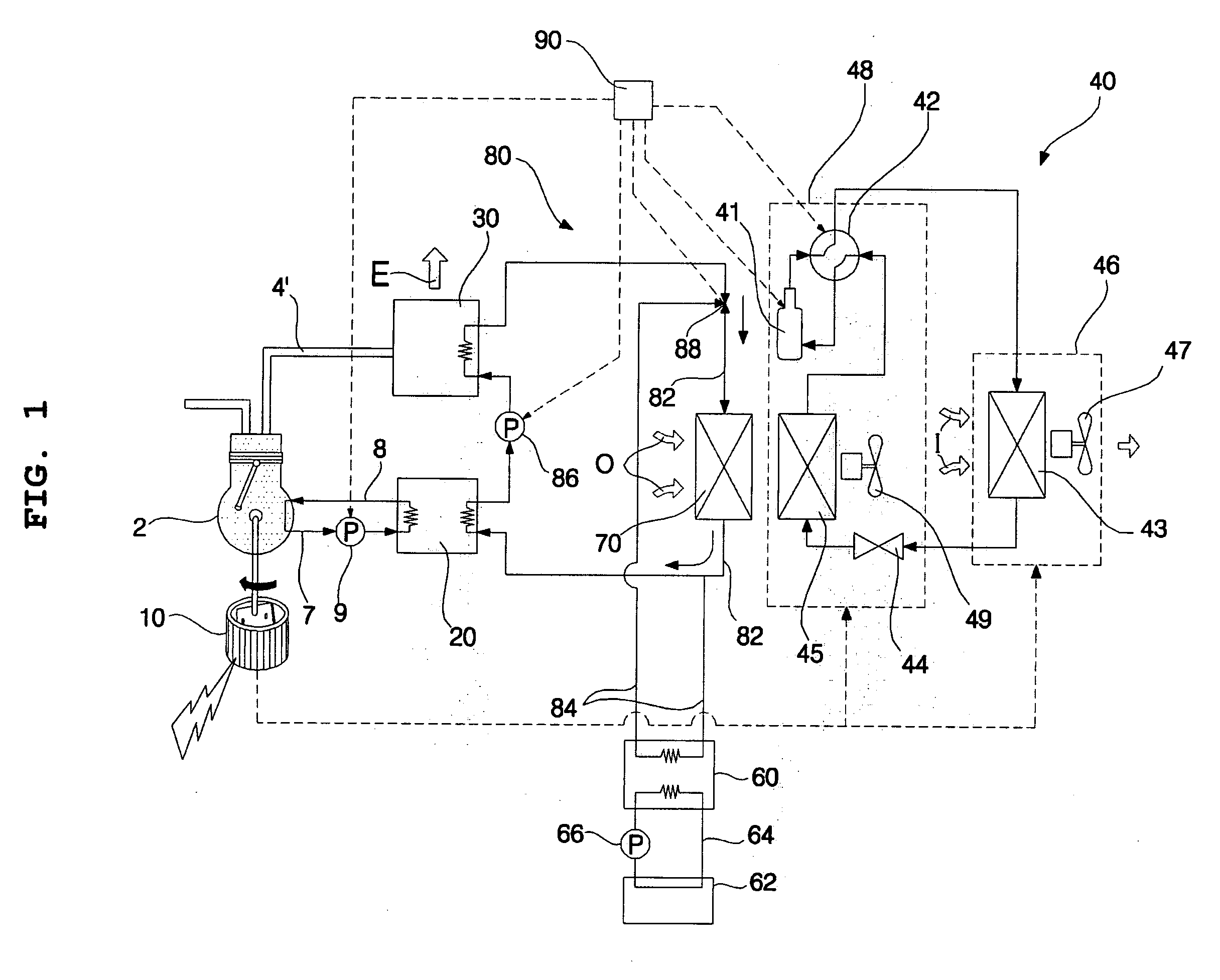

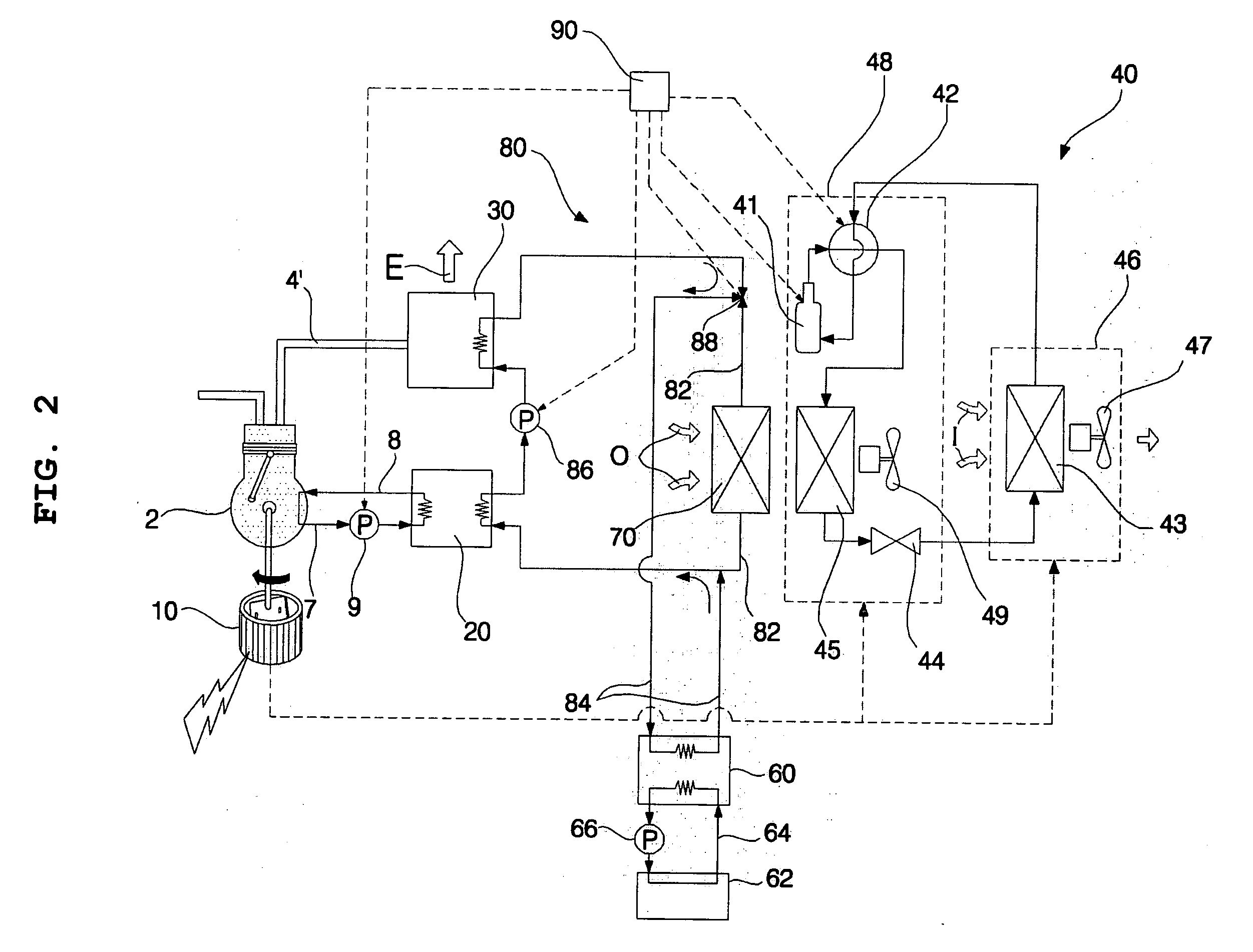

Electricity generating and air conditioning system with water heater

InactiveUS7170191B2Improve energy efficiencyGood air effectHeat pumpsClimate change adaptationElectricityHigh energy

A cogeneration system includes an engine, a generator connected to an output shaft of the engine to generate electricity, a heat pump type air conditioner, which uses the electricity generated from the generator, and includes a compressor, a directional valve, an outdoor heat exchanger, an expansion device, and an indoor heat exchanger, a fluid-heating heat exchanger to heat a fluid, and a waste heat recovering means to supply waste heat of the engine to the heat pump type air conditioner or to the fluid-heating heat exchanger, so that the system exhibits a high energy efficiency.

Owner:LG ELECTRONICS INC

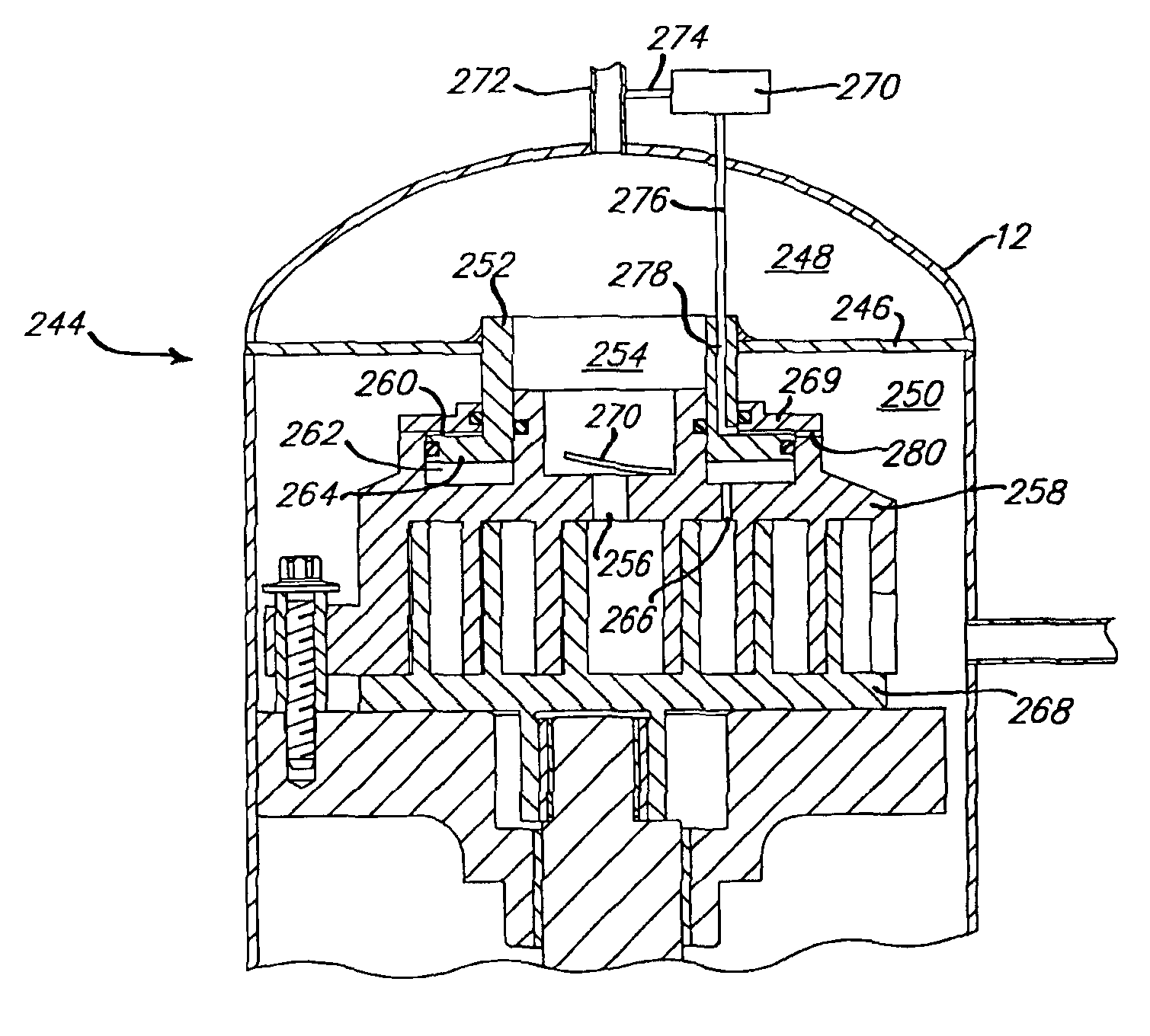

Thermally integrated fuel cell power system

InactiveUS7008711B2Improve efficiencySimple designFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A fuel cell power system having at least one fuel cell stack, at least one fuel processor in fluid communication with the at least one fuel cell stack and heat exchangers for transferring heat between the at least one fuel cell stack and the at least one fuel processor in which the at least one fuel cell stack and the at least one fuel processor are circumferentially surrounded by a plurality concentric heat exchanger shell assemblies.

Owner:GAS TECH INST

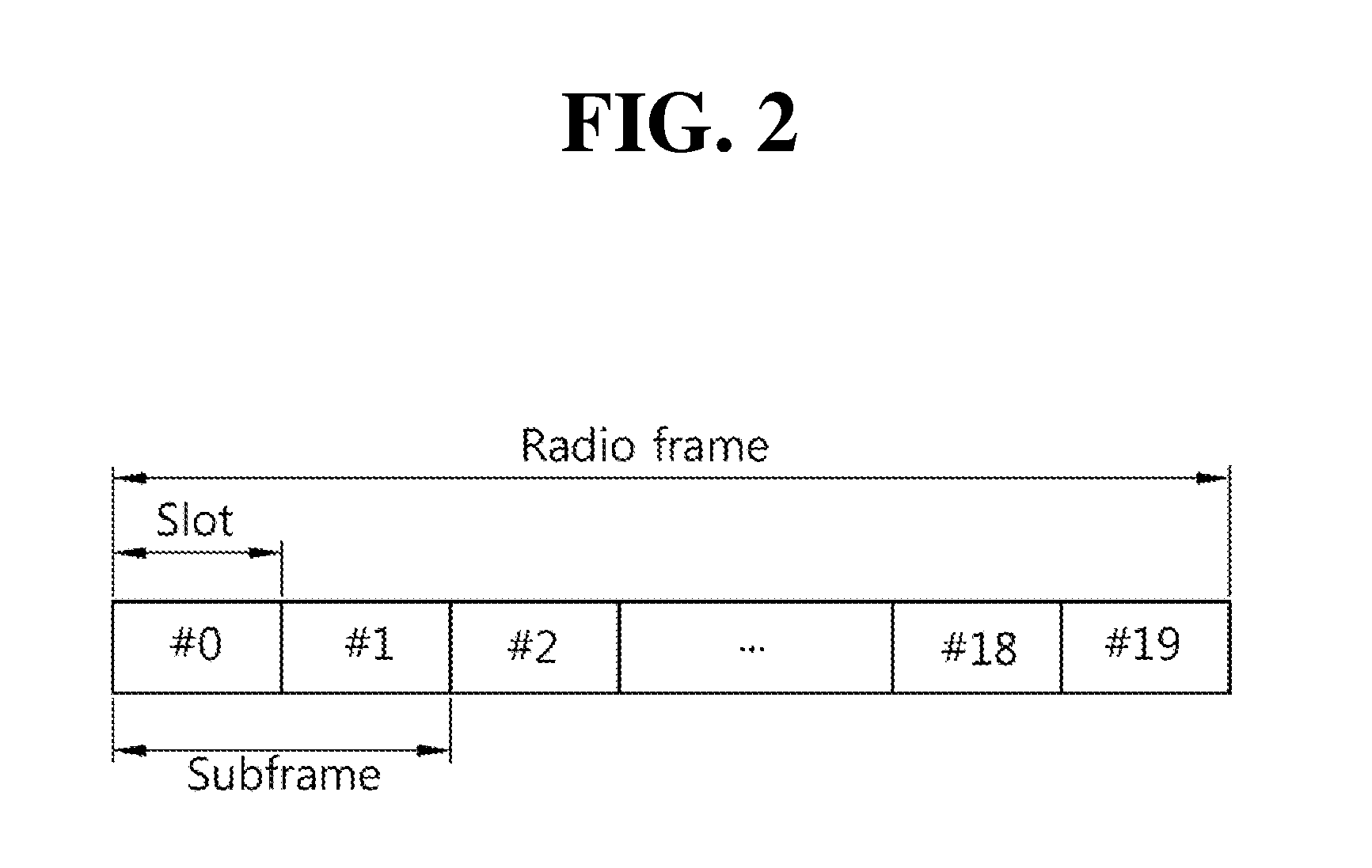

Method of determining sub frame in wireless communication system

InactiveUS20150195113A1Easy to operateFlexible operationTransmission path divisionMulti-frequency code systemsCommunications systemCyclic prefix

A disclosure of the present invention provides a method of determining subframes. According to the method, subframe configuration information on a plurality of subframes is received from a base station. Here, each of the subframes may include a plurality of OFDM symbols, each of the OFDM symbols may include a cyclic prefix (CP) that is equal to or longer than zero in length, and the CP length may be the same across the plurality of OFDM symbols in a subframe. Also, according to the method, the CP length of a subframe to be received is determined based on the subframe configuration information. Here, the subframe configuration information may indicate that the CP length of each of the subframe is any one of a first CP length and a second CP length.

Owner:LG ELECTRONICS INC

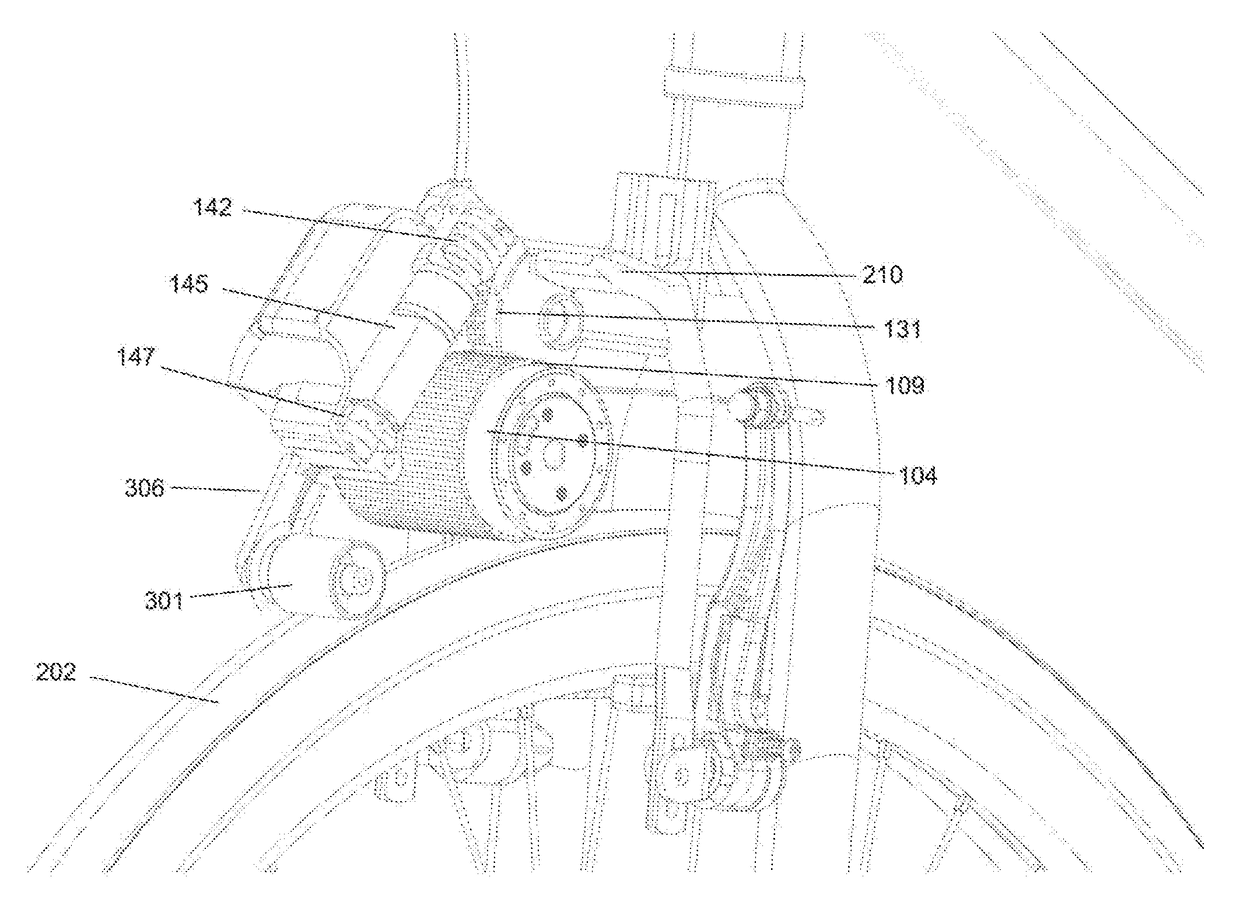

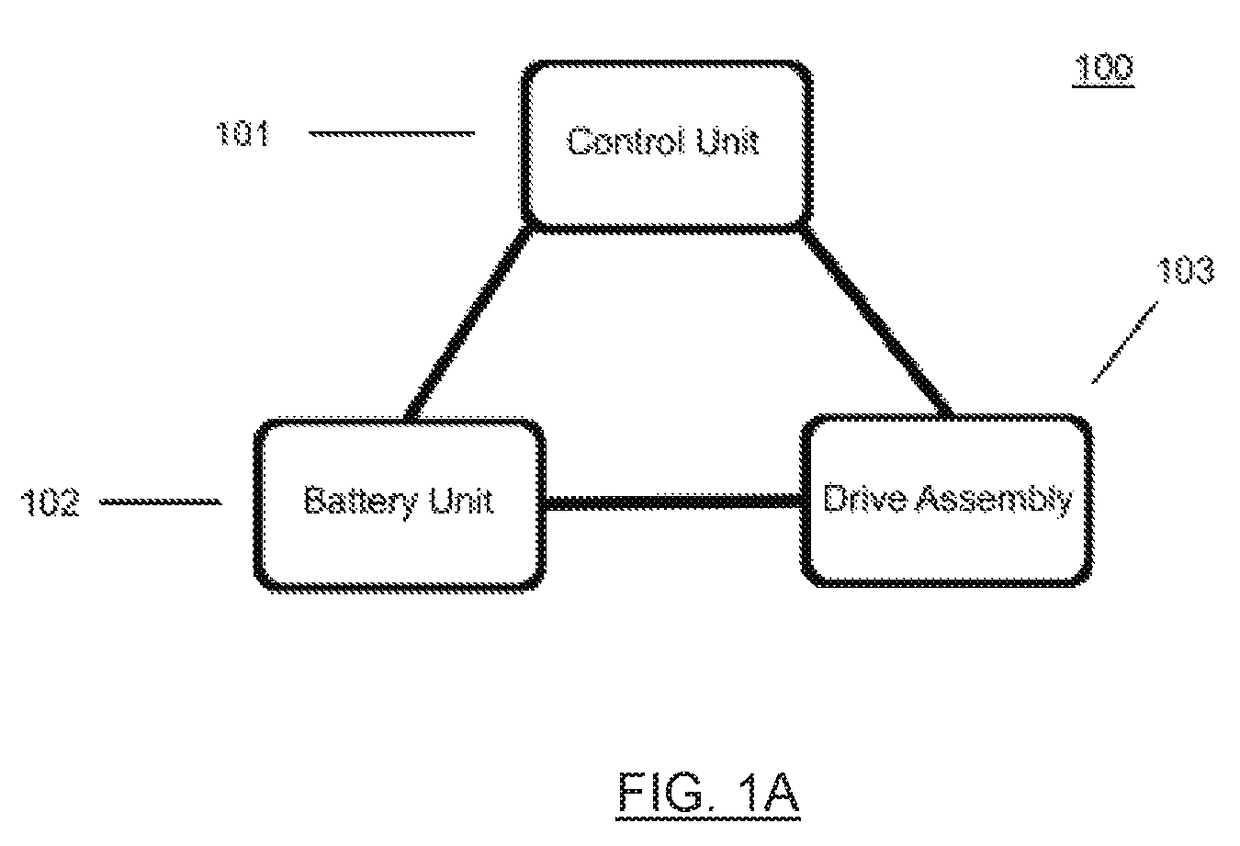

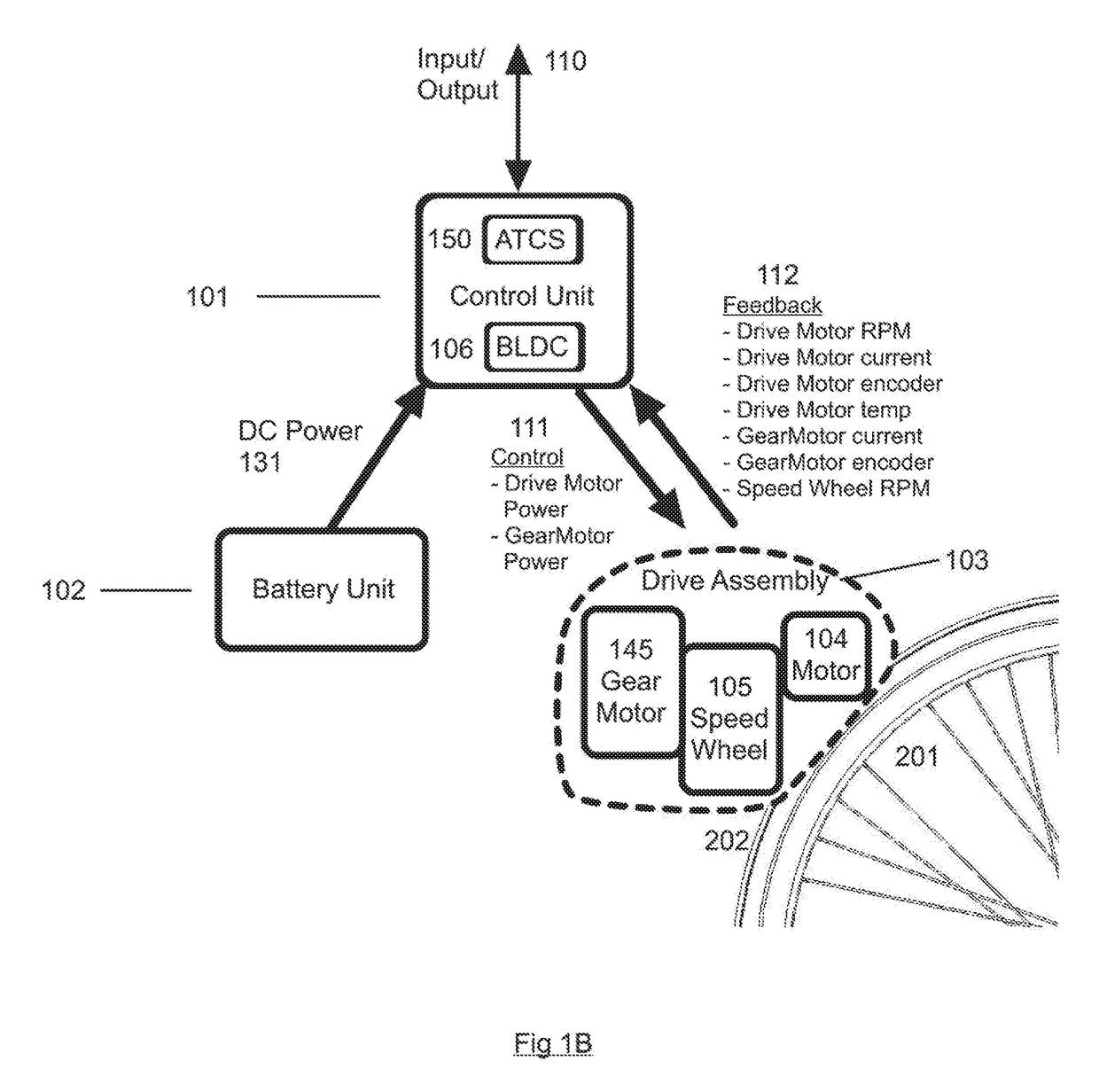

Friction drive with speed wheel and automatic traction control

InactiveUS20180072381A1Accurate measurementReliably determine whether slippage is occurringFriction grip releasable fasteningsMotorcyclesAutomatic train controlTraction control system

Embodiments of a friction drive system include a battery, a drive motor, a control unit, and a speed wheel. When the friction drive system is mounted on a wheeled vehicle, the speed wheel provides an accurate measurement of the vehicle speed by maintaining contact with a tire of the vehicle. An automatic traction control system, which may be part of the control unit, compares the speed of the speed wheel with the speed of the drive motor to determine whether slippage is occurring. If slippage is detected, then embodiments of an automatic traction control system automatically increase an amount of normal force between a contact surface on the drive motor and the tire, by advancing a position of the drive motor relative to a fixed mounting point. If no slippage is detected, then embodiments of an automatic traction control system automatically reduce the amount of normal force, by retracting a position of the drive r elative to a fixed mounting point. In embodiments of a friction drive system, the relative position of the drive motor may be controlled by powering a worm gear motor attached to a worm gear in response to commands from the control unit.

Owner:SHAREROLLER LLC

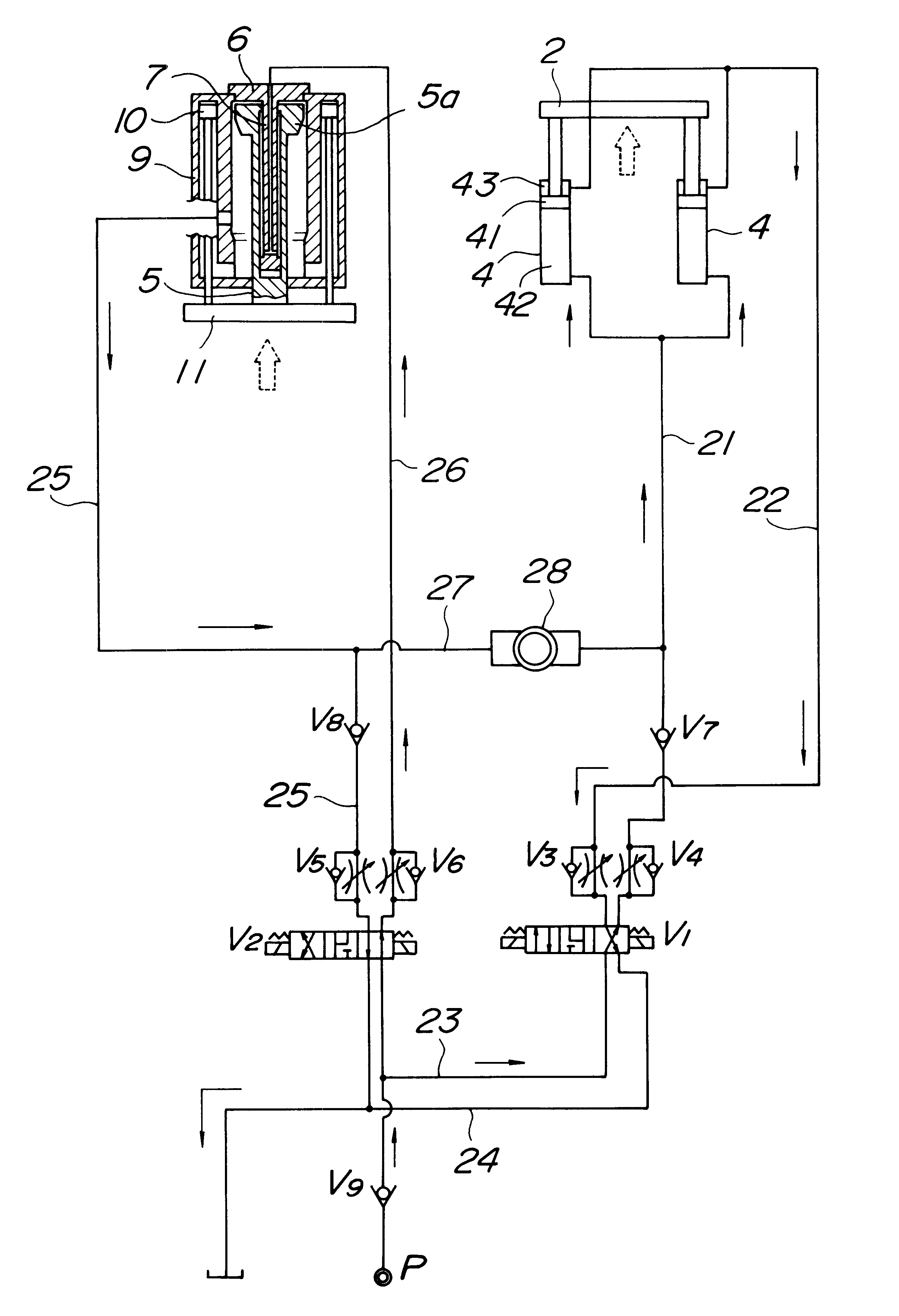

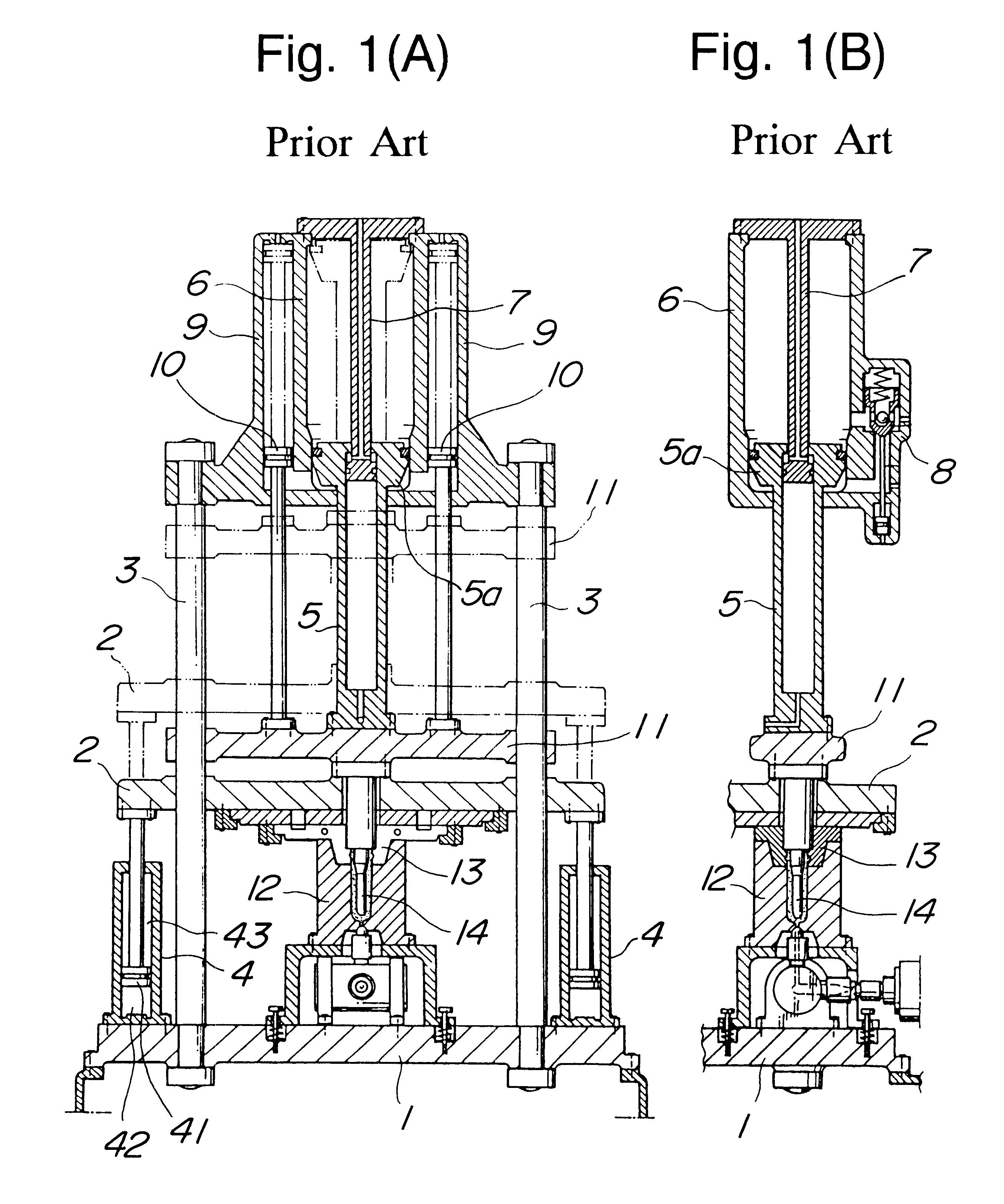

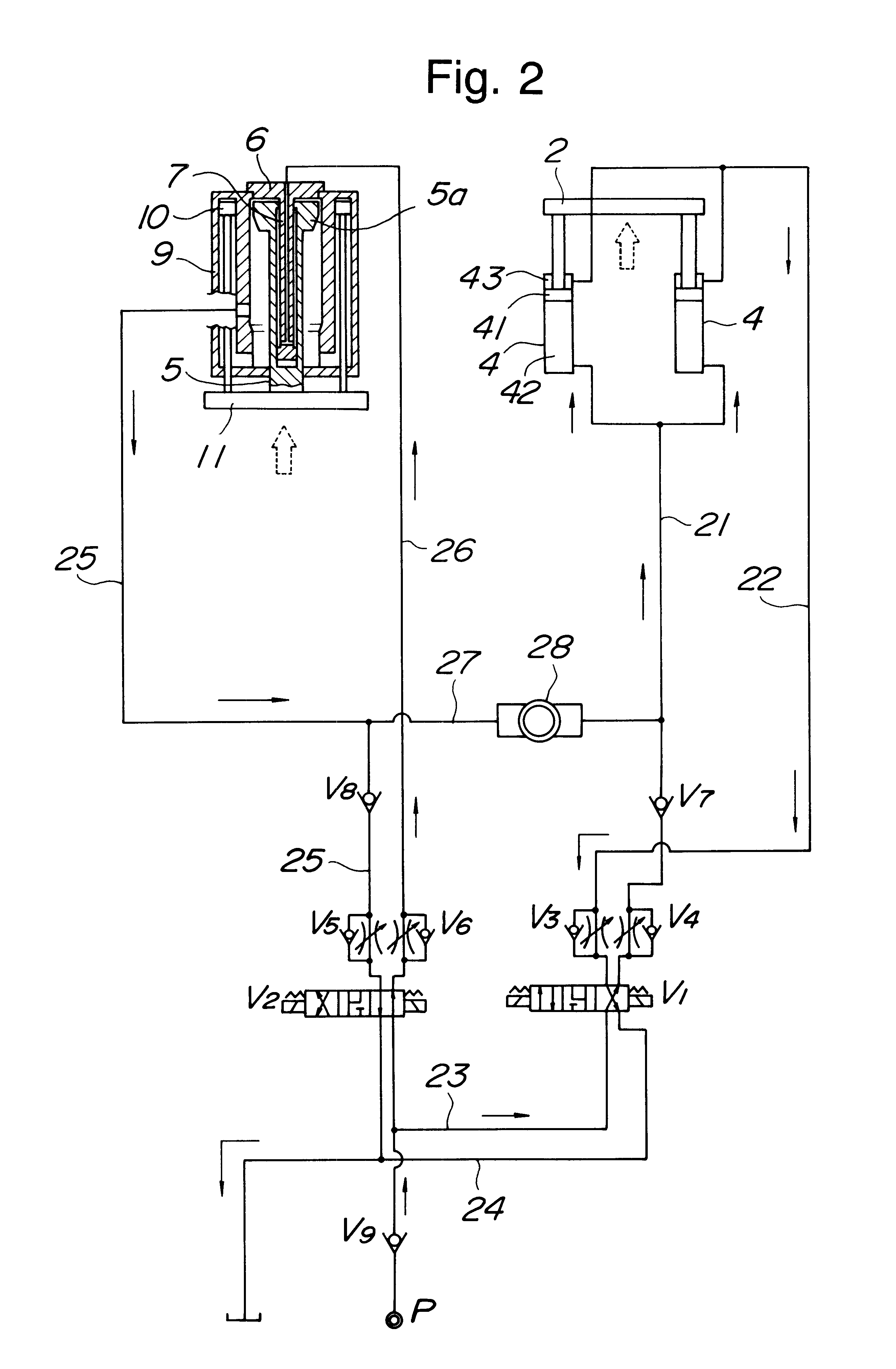

Mold clamping apparatus

A mold clamping apparatus in which hydraulic oil that is forcibly discharged into hydraulic lines from one of two kinds of cylinders, that is, a differential mold clamping cylinder and a mold clamping oil chamber of a mold opening / closing cylinder, is, in an alternating manner, provided to the other cylinder as its operating oil. This feature enables the simultaneous operation of the two kinds of cylinders as well as reduction in operating time in which the mold is opened or closed. The mold clamping apparatus includes a stationary mold, a movable mold which closes with respect to the stationary mold, a core movable through the movable mold into and out of the stationary mold. The movement of the core into and out of the stationary mold is effected by a differential mold clamping cylinder which is separate from a mold opening / closing cylinder for the movable mold and is fitted with a booster ram. A hydraulic line on the mold opening side of the mold opening / closing cylinder and a hydraulic line for the differential mold clamping cylinder are interconnected to one another via a communication passage with a pressure / flow control valve disposed thereon. While the movable mold is opened and closed and the core is moved into and out of the stationary mold, a volume of hydraulic oil that is discharged into these hydraulic lines is alternately provided to the mold opening oil chamber or to the differential mold clamping cylinder.

Owner:A K TECH LAB INC

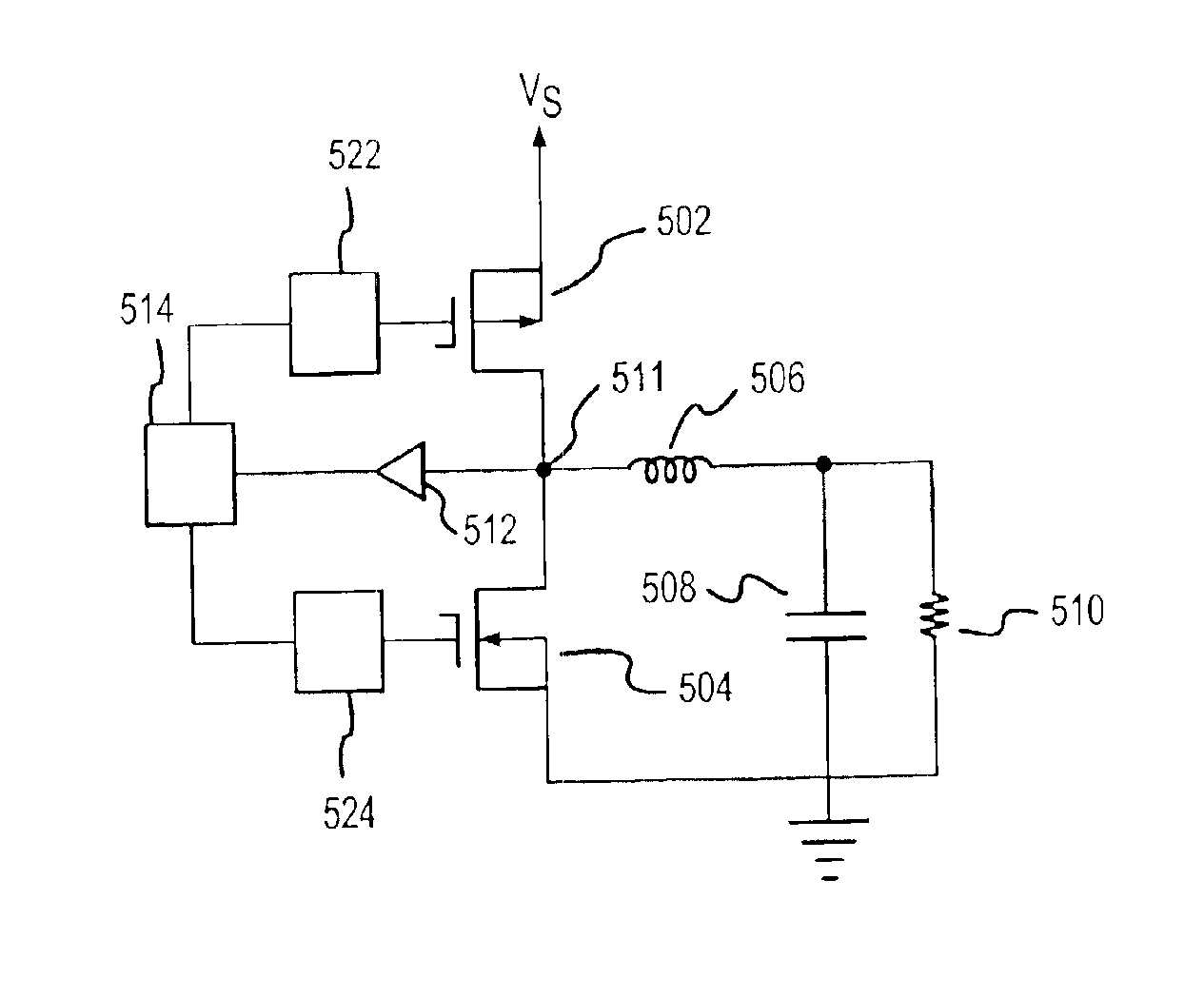

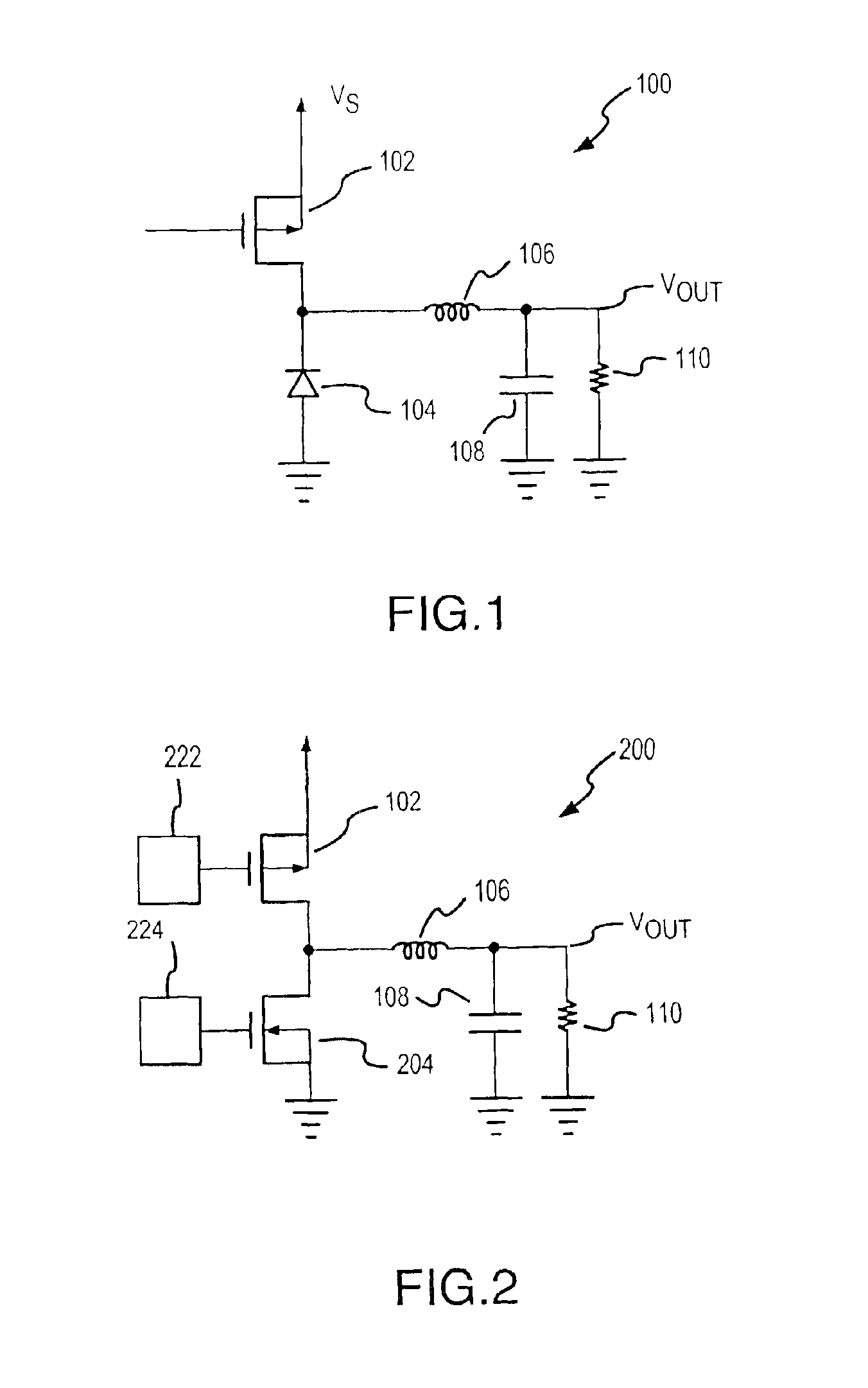

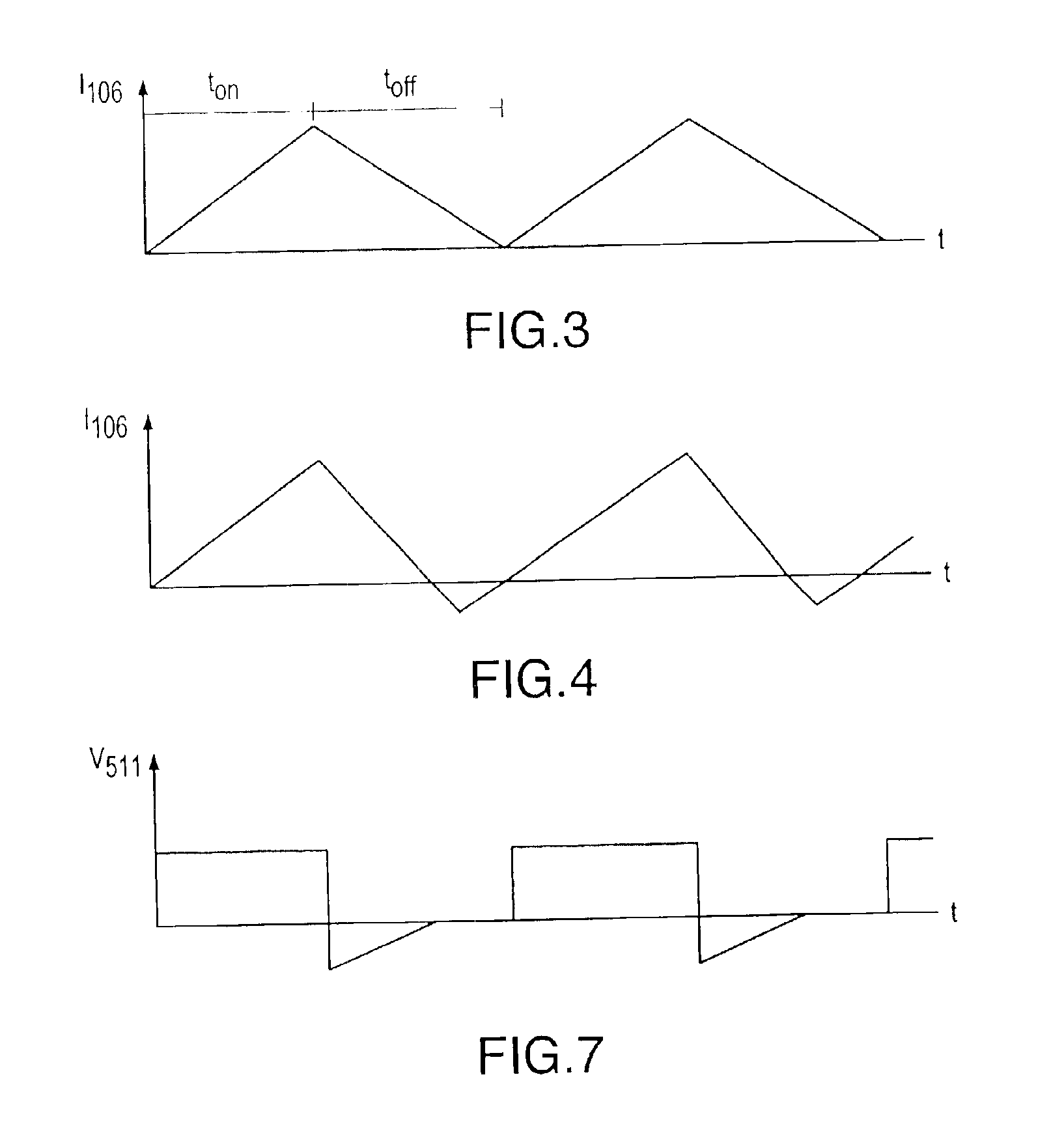

System and method for detection of zero current condition

InactiveUS6847197B2Maximize system efficiencyShorten the switching timeEfficient power electronics conversionCurrent/voltage measurementInductorEngineering

A method for converting power includes charging an inductor by coupling the inductor to a voltage source for a predetermined amount of time. Thereafter, the inductor is discharged by coupling the inductor to a ground until the current flowing through the inductor equals zero. A method for detecting a zero current flowing through the inductor includes coupling the inductor to a transistor and comparing the output of that transistor to a transistor coupled to ground.

Owner:INFINEON TECH AUSTRIA AG

Optimization of decoder memory usage for vlc tables

ActiveUS20080204287A1Optimizing storage of VLC tablesSave memory resourcesCode conversionDigital video signal modificationVariable lengthData mining

Systems and methods for optimizing system performance in variable length decoding systems are described. Embodiments are described in which decode tables are analyzed and elements of the tables sorted by probability of occurrence. Storage of elements can be determined by probability of occurrence and embodiments of the present invention can optimize system efficiency by storing most likely entries into fast-memory and least likely entries in slowest memory. In certain embodiments, a single large table is provided that cannot fit into decoder fast-memory. In some embodiments, individual elements can be optimized for storage in fast-memory by selecting more frequently occurring entries or groups of entries into decoder memory.

Owner:NVIDIA CORP

Hybrid air turbine engine with heat recapture system for moving vehicle

InactiveUS20110277467A1Increase powerMaximize efficiencyRailway vehiclesCombustion enginesMobile vehicleTurbine

A non-fuel combusting air turbine assembly suitable as an auxiliary or primary power propulsion system for a vehicle. The system includes an air turbine engine powered by a compressor mechanism to increase the potential energy that can be harnessed by the turbines, having a noise reducing air intake section for delivering air to the compressor. Additionally, the system includes a turbine mechanism comprising plural sets of stationary vanes and rotating vanes, preferably arranged alternatively; and a battery rechargeable by a generator operable by the rotating turbine vanes.

Owner:DRAVIS MARTIN

Wireless Communications System and Method

InactiveUS20120149420A1Maximize system efficiencyMaximize Spectral EfficiencyNetwork topologiesData switching by path configurationFrequency spectrumCommunications system

A mobile communications system having improved spectral efficiency, and methods and apparatus to achieve this improved spectral efficiency. In the mobile communications system communication with a plurality of mobile terminals is provided by a base station. Within the system terminals are adapted to communicate with one or more adjacent similar terminals to establish groups of terminals, called micro-cells. Each terminal within a micro-cell receives signals from the base station and then performs a first processing step on these signals. These processed signals are shared with all the other terminals within the micro-cell. Each terminal then performs a second processing step on the information it has received from all the other terminals within the micro-cell which enables it to derive a signal intended for reception by that terminal. The technique is applicable to both the uplink and the down link and also to peer to peer communication.

Owner:APPLE INC

Electricity generating and air conditioning system with water heater

InactiveUS20060038404A1Reduce heat loadMaximize system efficiencyHeat pumpsClimate change adaptationHigh energyEngineering

An electricity generating and air conditioning system with a water heater. The system includes an engine, a generator connected to an output shaft of the engine to generate electricity, a heat pump type air conditioner, which uses the electricity generated from the generator, and comprises a compressor, a directional valve, an outdoor heat exchanger, an expansion device, and an indoor heat exchanger, a water-heating heat exchanger to heat water, and a waste heat recovering means to supply waste heat of the engine to the heat pump type air conditioner or to the water-heating heat exchanger, so that the system exhibits a high energy efficiency.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com