Capacity modulated scroll machine having one or more pin members movably disposed for restricting the radius of the orbiting scroll member

a scroll machine and capacity modulation technology, which is applied in the direction of positive displacement liquid engines, instruments, lighting and heating apparatus, etc., can solve the problems of increasing the cost of approach, reducing the compression ratio of compressors, and requiring additional space, so as to maximize the efficiency of compressors and/or refrigeration systems, maximize overall system efficiency, and increase efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

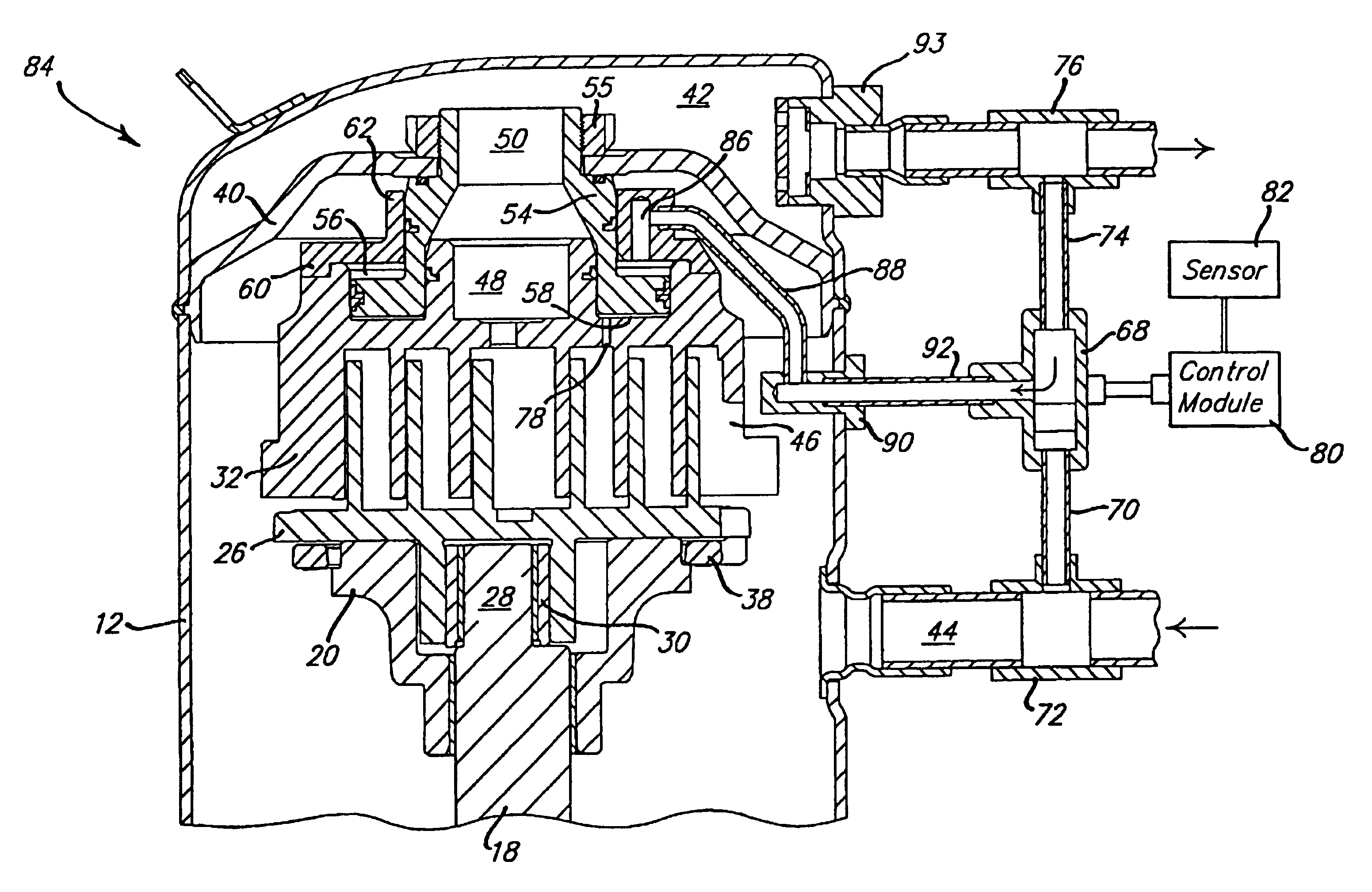

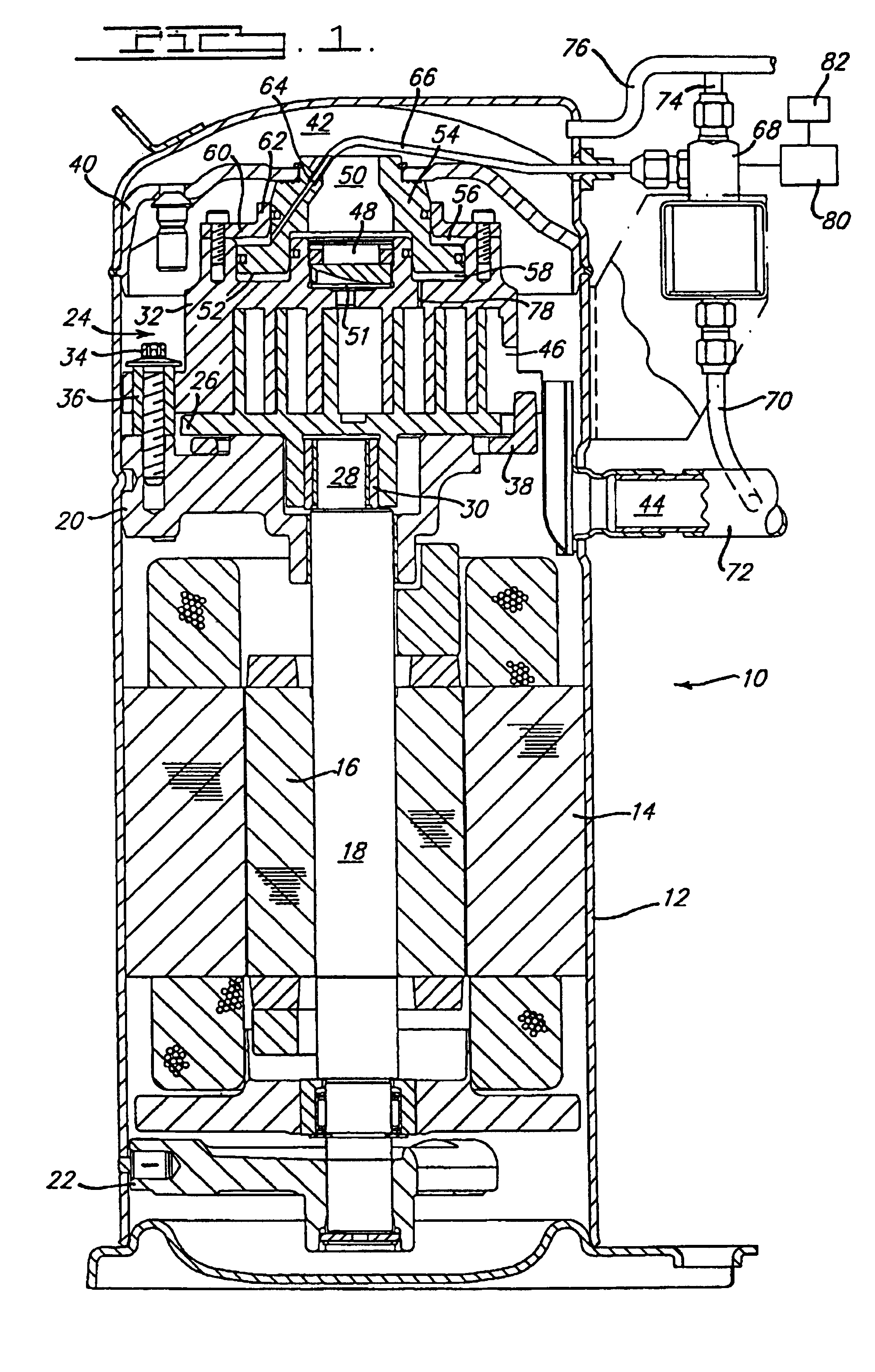

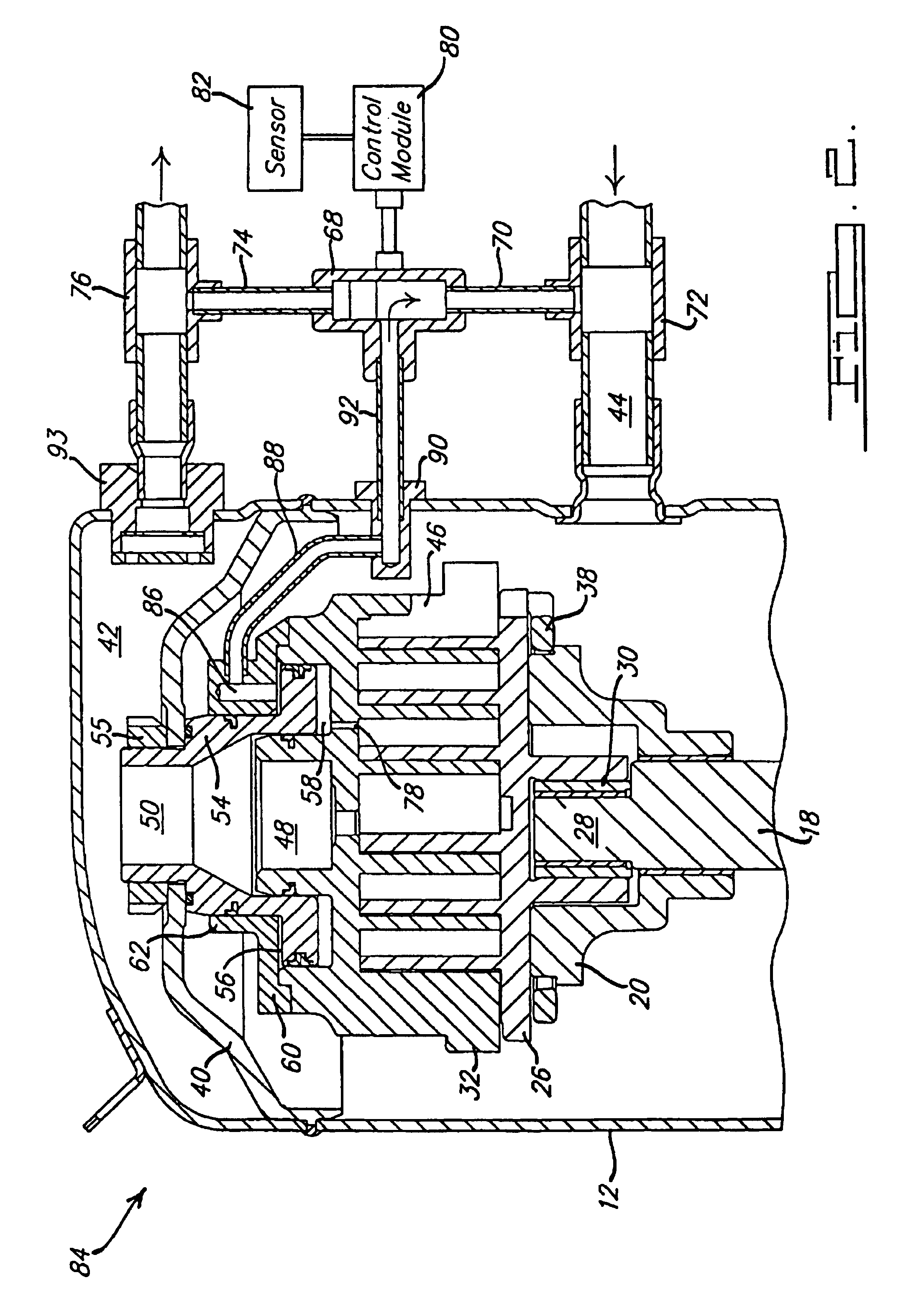

embodiment 94

[0045]FIGS. 4 and 5 show another embodiment 94 of the present invention in which axial unloading separating pressure fluid is provided directly from the discharge gas exiting the compressor. In this embodiment, a tubular member 96 is suitably secured to partition member 40 and includes a radially outwardly extending flange 98 which is positioned in and separates cylindrical recess into upper and lower chambers 56 and 58. Tubular member 96 also defines passage 50 for directing compressed discharge gas from port 48 to discharge chamber 42. An axial extending bore 100 is provided in tubular member which opens outwardly through the upper end thereof and is adapted to receive a fluid conduit 102. Fluid conduit 102 extends outwardly through the top of shell 12 and is connected to solenoid valve 68. Solenoid valve also has fluid conduits 70 and 74 connected to respective suction and discharge lines 72, 76 and is controlled by control module 80 in response to signals from appropriate sensor...

embodiment 208

[0057]The embodiment 208 of FIG. 12 represents a combination of the axial unloading arrangement of FIG. 11 and the orbiting scroll biasing arrangement of FIG. 9 both described above. Accordingly, elements corresponding to like elements shown in and described with reference to FIGS. 9 and 11 are indicated by the same reference numbers. In this embodiment, the intermediate pressure axial biasing chamber 148b for the orbiting scroll is completely separate from the unloading discharge pressure biasing chamber defined by recess 184 and annular piston 186.

embodiment 210

[0058]In like manner, the embodiment 210 of FIG. 13 represents a combination of the intermediate pressure biasing arrangement of FIG. 8 described above and the axial unloading pressure biasing arrangement of FIG. 11. Accordingly, corresponding elements have been indicated by the same reference numbers used in these respective figures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com