Receptacle-mounted cover plate

a technology for receptacles and covers, applied in the direction of electrical apparatus, casings/cabinets/drawers, casings/cabinets/drawers details, etc., can solve the problems of limited decorator designs, relatively expensive, and low cost per unit, so as to eliminate the concerns of socket and cover plate alignment, the effect of reducing the cost per uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

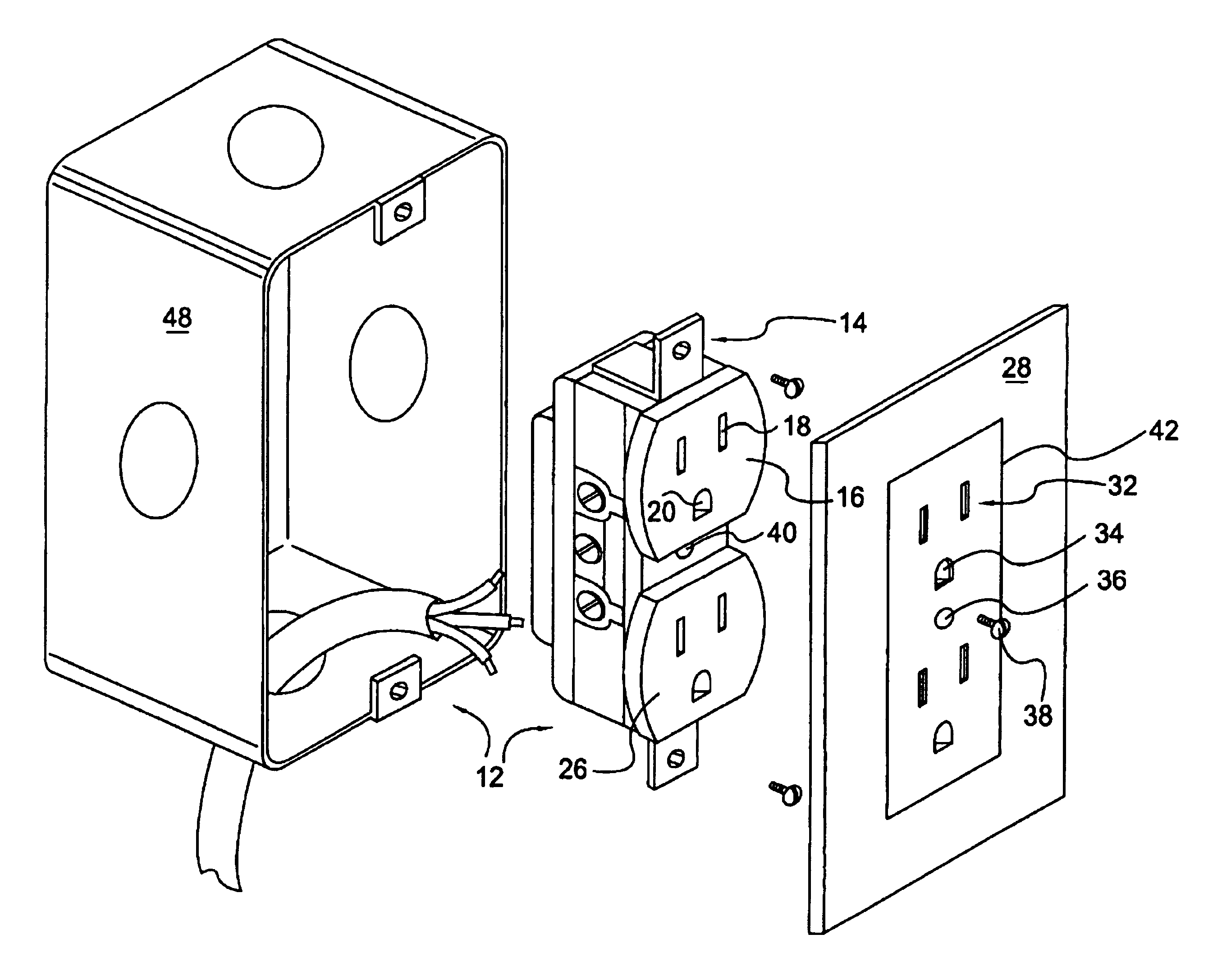

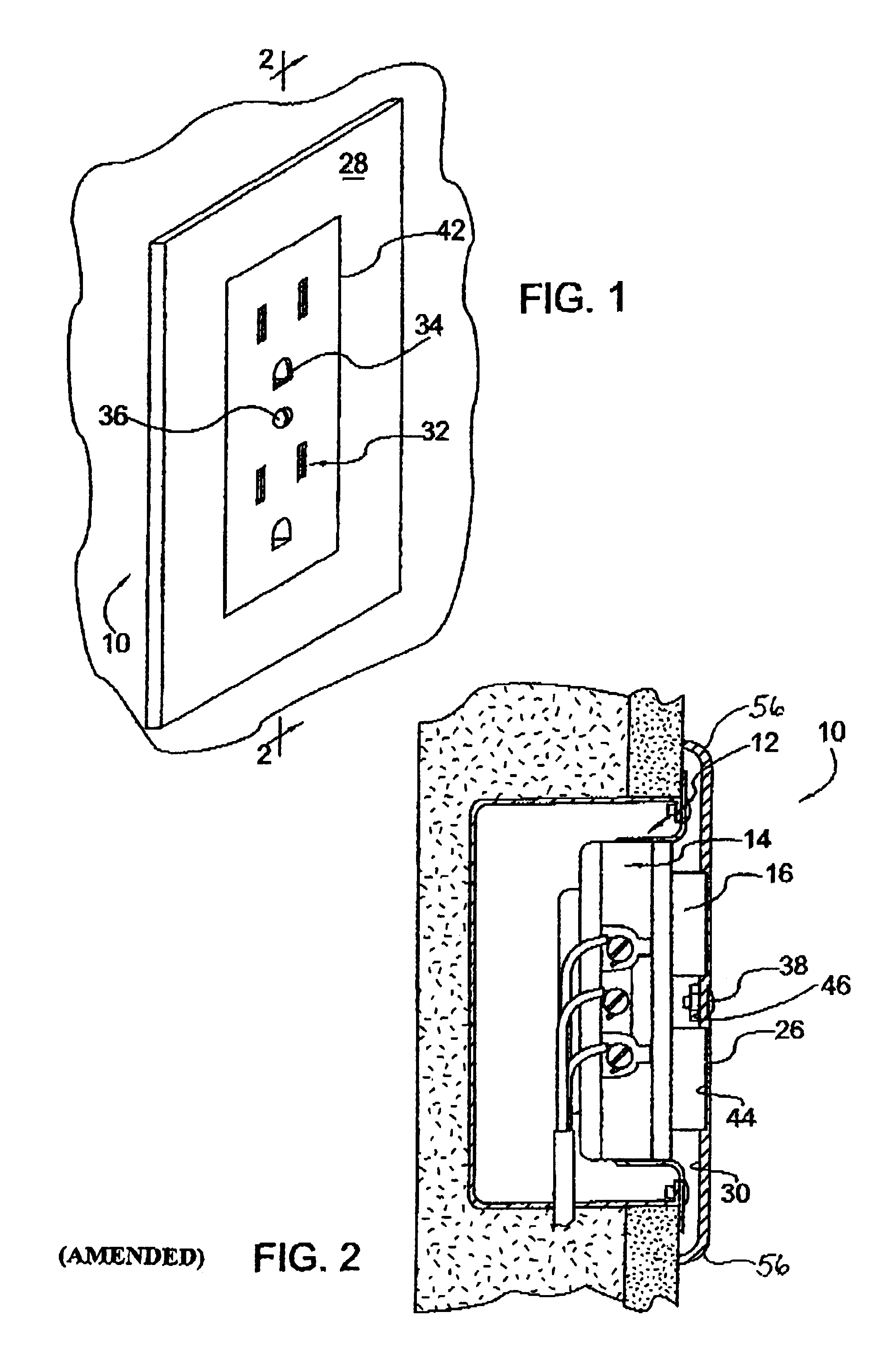

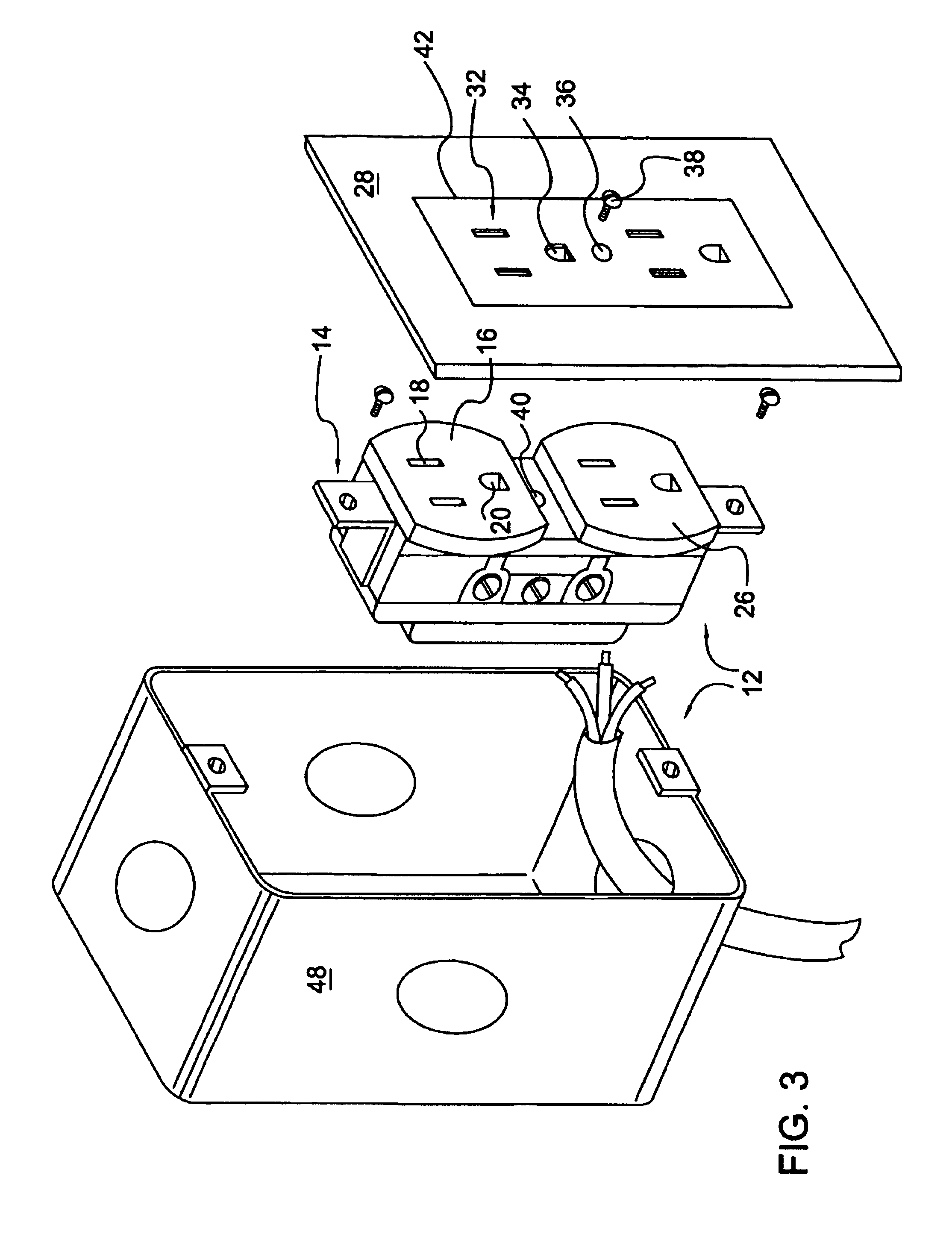

[0035]Reference will now be made in detail to the presently preferred embodiment of the invention as illustrated in the accompanying drawings, in which like reference characters designate like or corresponding parts throughout the drawings and the various embodiments.

[0036]In accordance with the invention, a cover plate is provided for covering an electrical outlet. Typical electrical outlets for which cover plates according to the invention are well suited would include a receptacle having at least one socket and, optionally, at least one securing aperture for receiving a securing device. Each of the at least one socket includes a face and a plurality of blade apertures for receiving plug blades. The portion of the receptacle corresponding to the socket face is referred to in this document as the socket face.

[0037]A cover plate 10 according to a presently preferred embodiment of the invention is shown in FIG. 1. Cover plate 10 is adapted to be attached to and cover an electrical ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com