Substrate supporting apparatus

a technology for supporting apparatus and substrates, applied in mechanical apparatus, vacuum evaporation coating, coatings, etc., can solve the problems of reducing the quality of semiconductors, brittle and structural solidity problems of conventional substrate supporting apparatus, so as to prevent slipping or breakage of spacer members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Substrate supporting apparatuses according to embodiments of the present invention will now be described with reference to FIGS. 1 to 9.

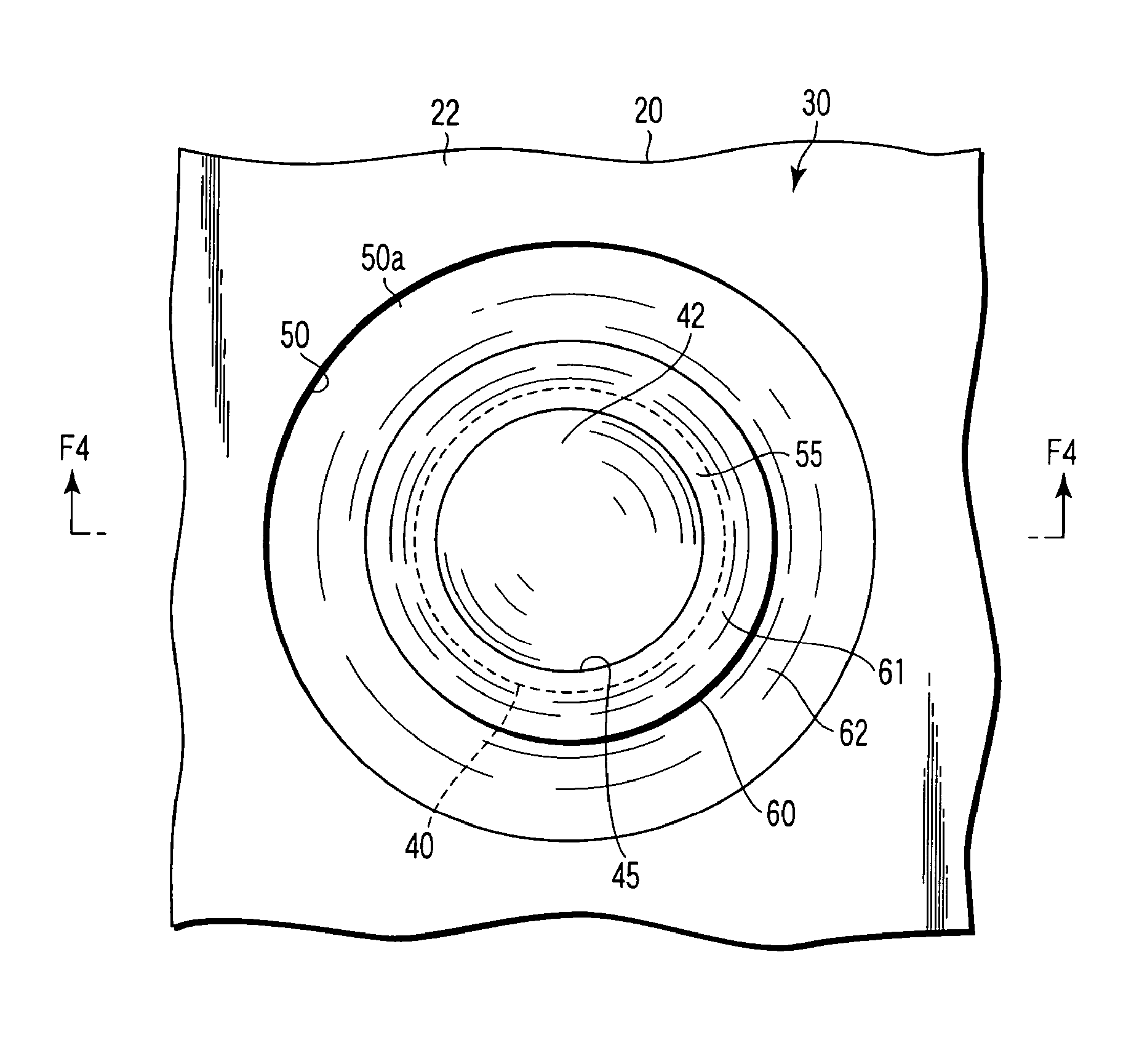

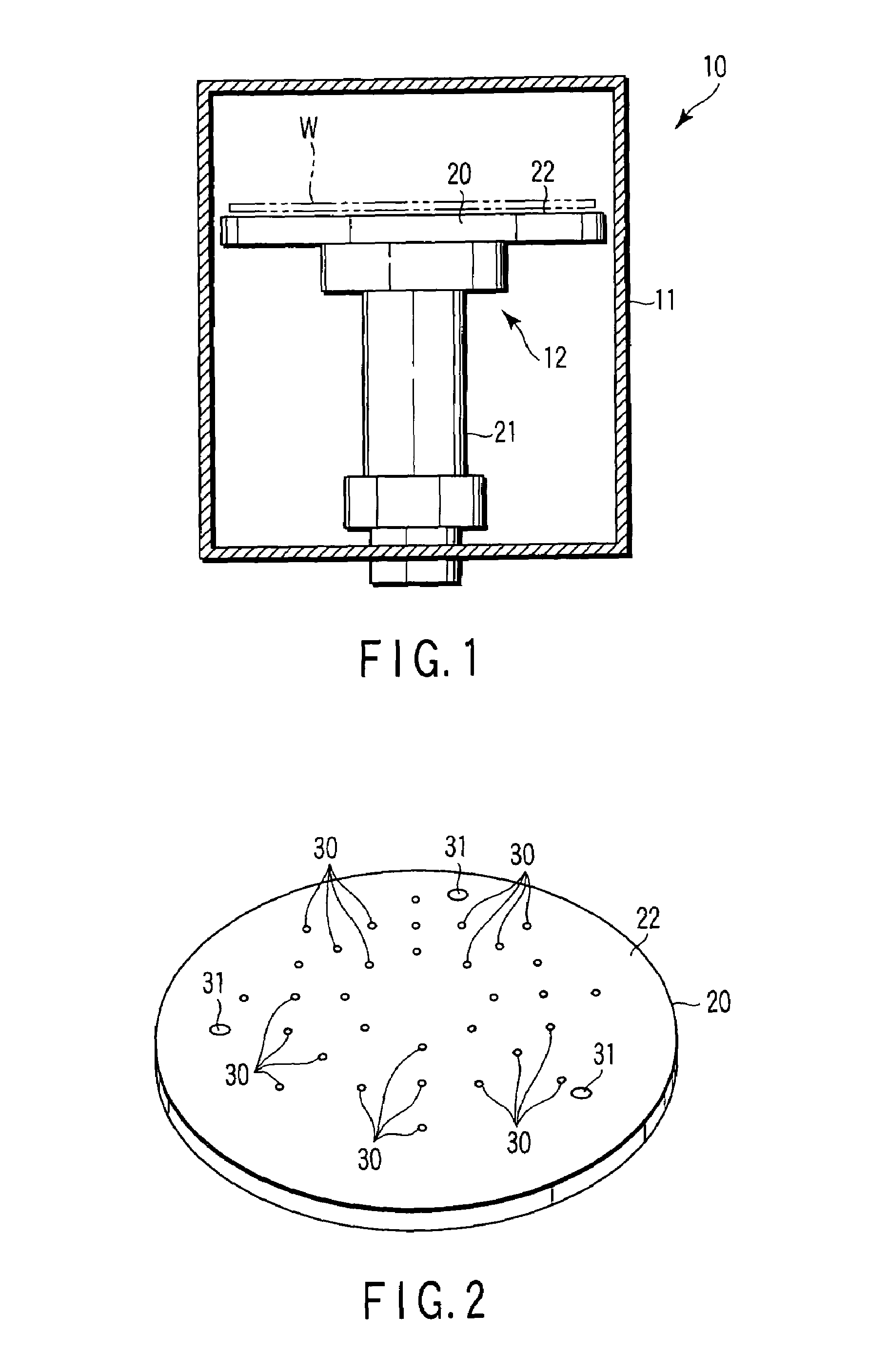

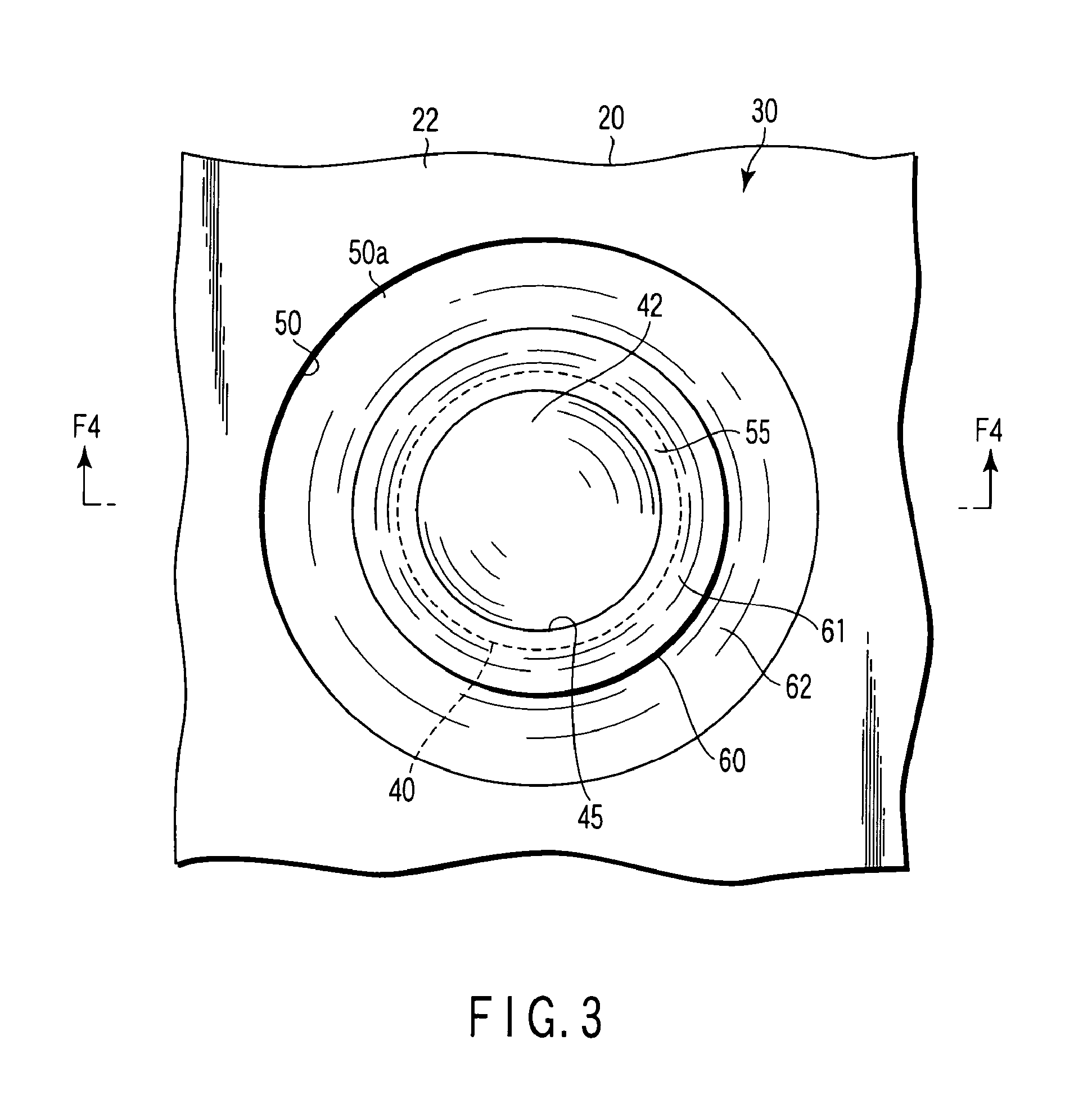

[0028]FIG. 1 shows a wafer processor 10 that is used in, for example, semiconductor manufacturing processes. The wafer processor 10 is used in processes such as chemical vapor deposition (CVD), plasma vapor deposition (PVD), etching, etc. The processor 10 comprises a sealed case 11 and a substrate supporting apparatus 12 that is arranged in the case 11.

[0029]The substrate supporting apparatus 12 includes a disc-shaped plate member 20 of a metal, such as an aluminum alloy, a post member 21 that supports the plate member 20 from the underside, and the like. The plate member 20 contains a heater unit (not shown). The heater unit heats the plate member 20 to a predetermined temperature. A substrate W, such as a wafer as an example of a supported object (workpiece), is placed on an upper surface 22 of the plate member 20.

[0030]FIG. 2 is a perspecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter D1 | aaaaa | aaaaa |

| thermal expansion coefficient | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com