Geotextile fabric and method for enhancing soil structure

A geotextile, fabric technology, applied in geotextiles, fabrics, perforated fabrics, etc., can solve problems such as labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

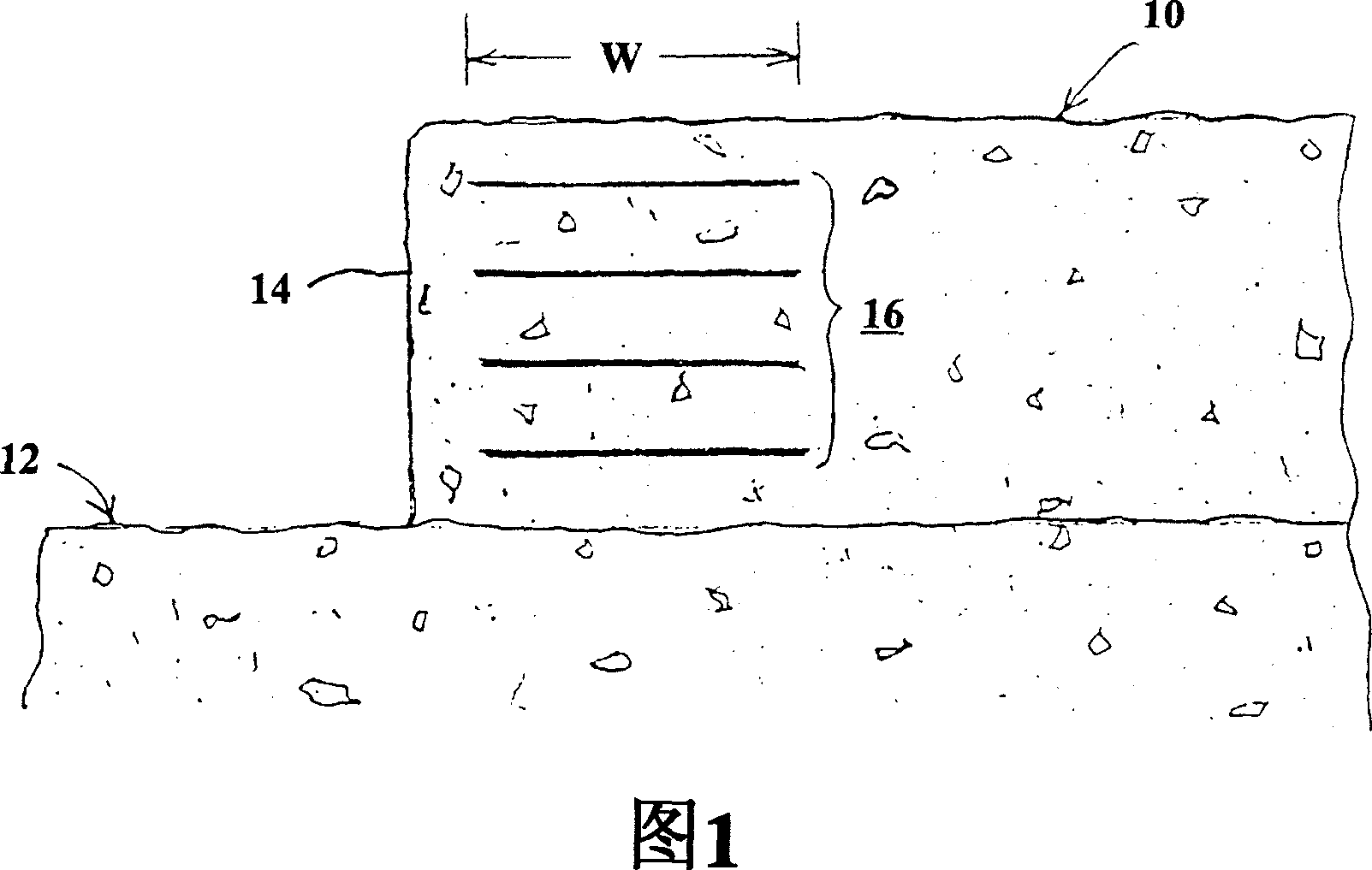

[0020] Referring to FIG. 1 , an earthen structure 10 is shown resting on a suitable natural or artificial foundation 12 . Surface 14 of structure 10 may form an angle with foundation 10 of about 60° to about 90° (as shown). The structure 10 may be of any height and includes one or more reinforcing layers 16 positioned substantially horizontally. The width W of reinforcement layer 16 is typically tens of centimeters (feet) and covers substantially the entire length of surface 14 of structure 10 . For example, a typical 3.0 meter (10 ft) high earth retaining wall structure may include about 2-4 layers of 1.5-1.8 m (5-6 ft) wide reinforcing layers 16 located a few centimeters ( inches) to tens of centimeters (feet).

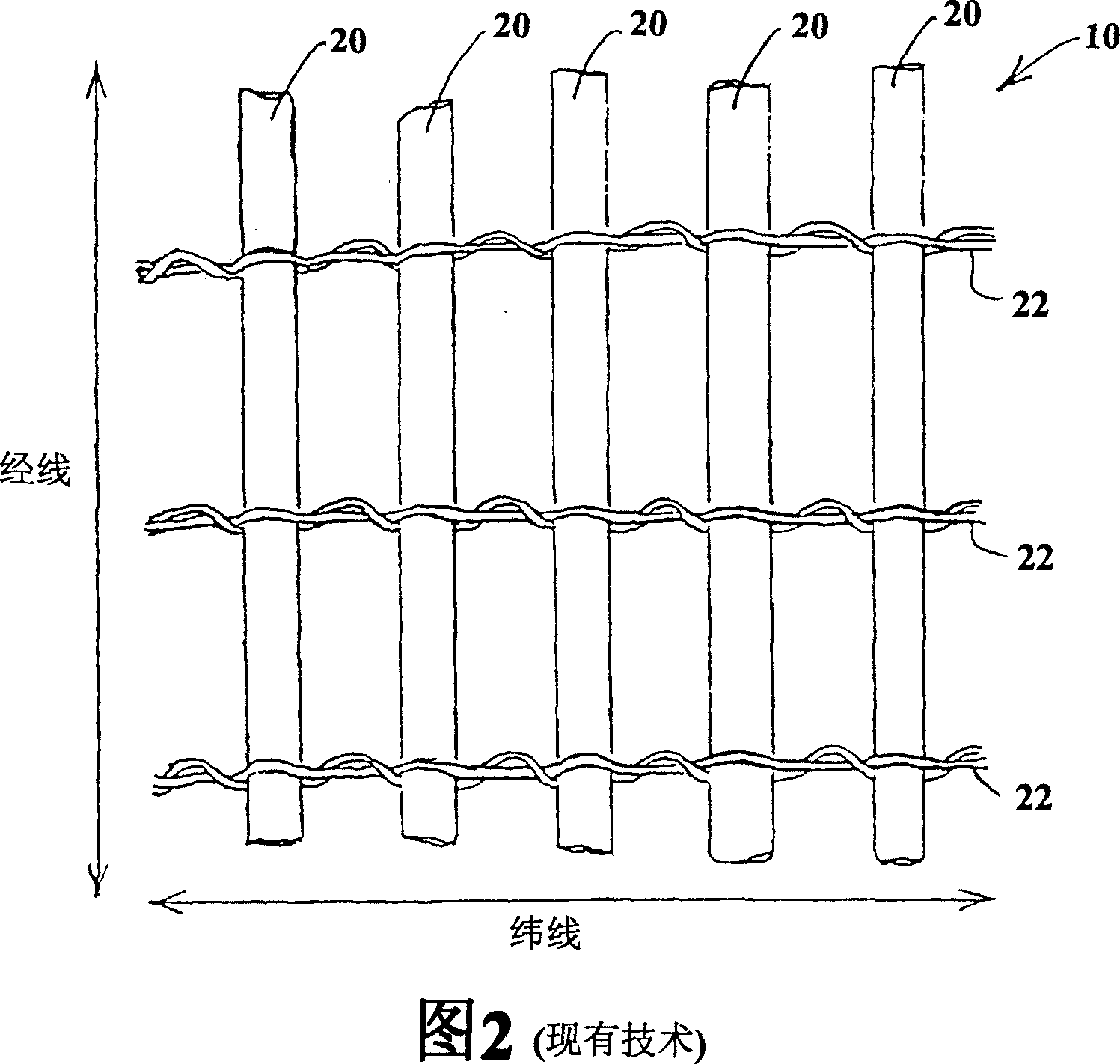

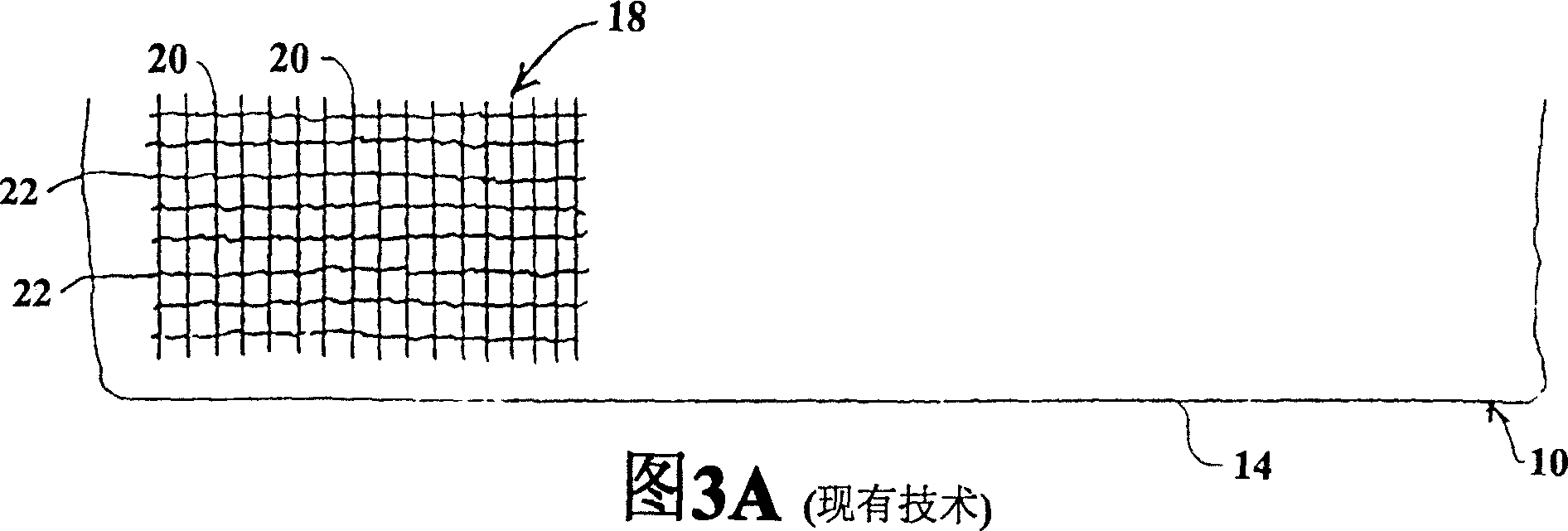

[0021] FIG. 2 shows a conventional configuration of a conventional geotextile fabric 18 suitable for use as a reinforcement layer in the earthen structure 10 of FIG. 1 . Fabric 18 is a unidirectional fabric. Herein, the term "unidirectional" can be interpreted a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Modulus of elasticity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com