Ball shape rotary engine

A rotary engine, spherical technology, applied in the direction of rotary piston engines, rotary or swinging piston engines, engine components, etc., can solve the problems of high requirements for sealing and lubrication conditions, complex parts of the motion mechanism, and not being widely used. Achieve the effect of light weight, compact structure and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

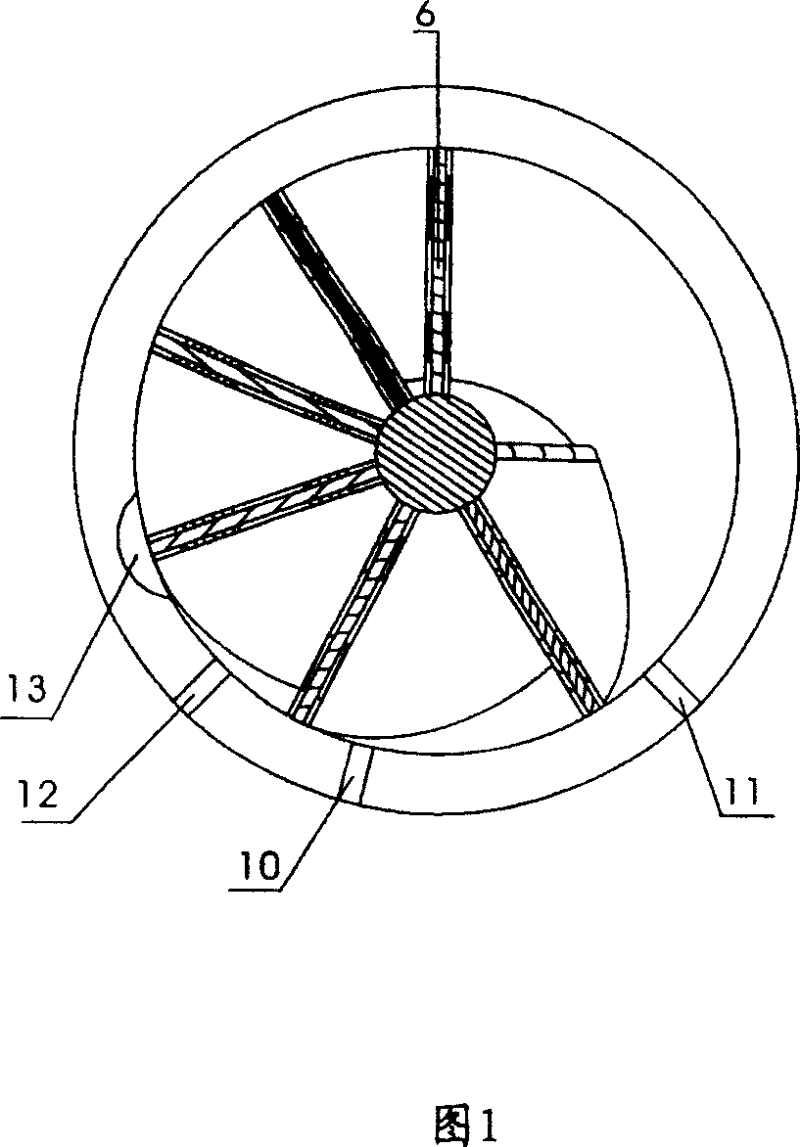

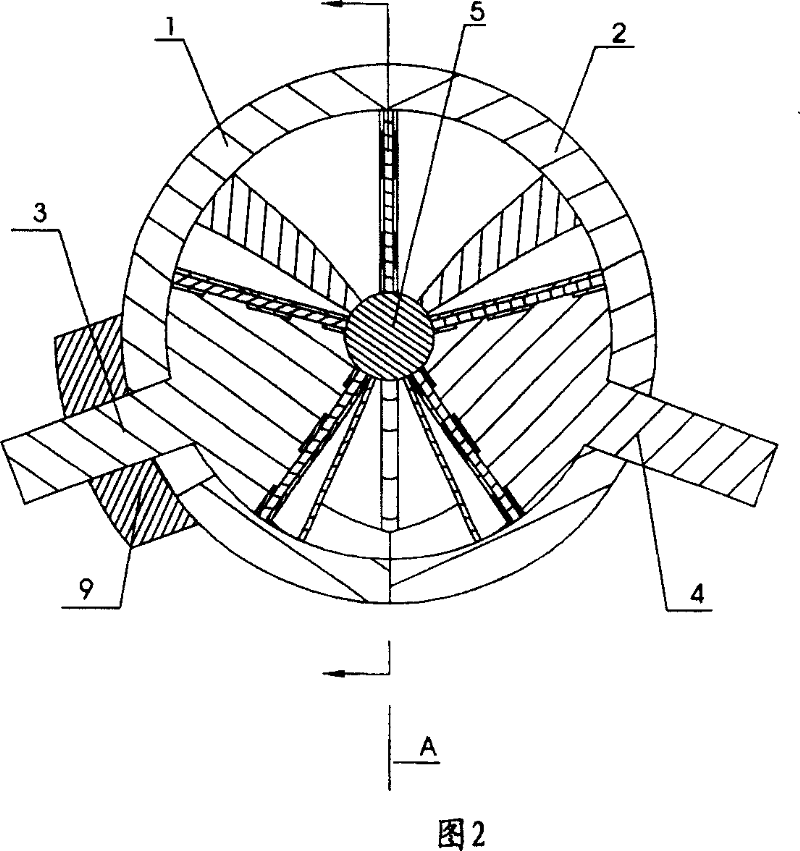

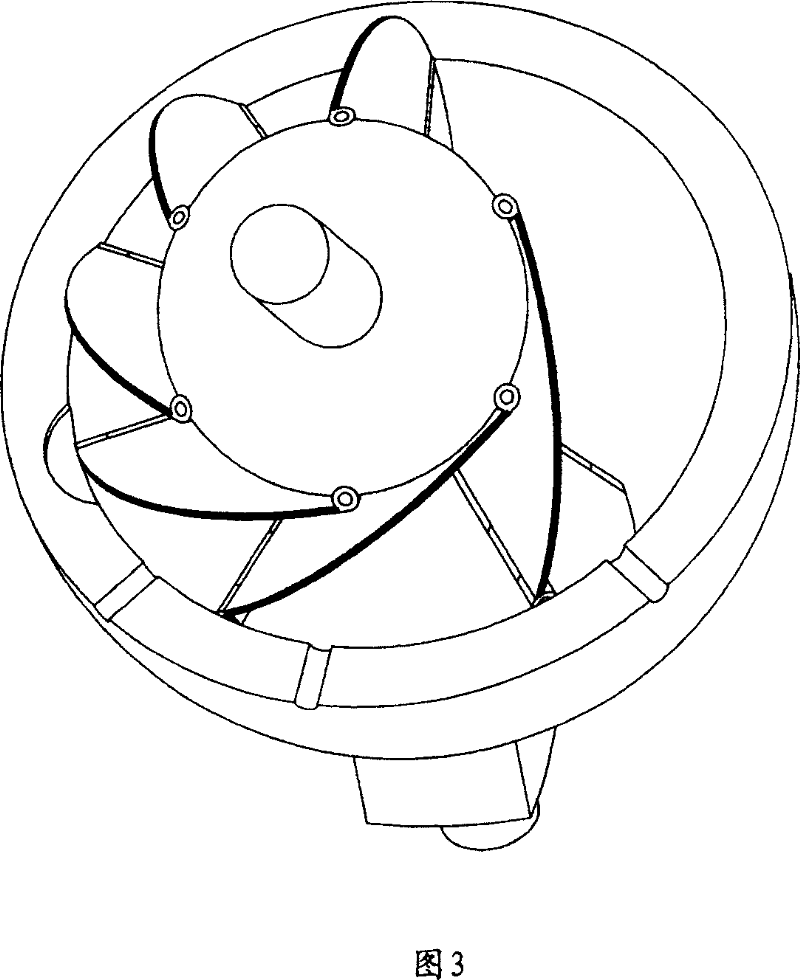

[0029] Please refer to Fig. 1 to Fig. 21, the cylinder block of the present invention is made up of half-cylinder body 1, half-cylinder body 2, and the present invention also includes left shaft 3, right shaft 4, small ball 5, connecting pin 6, left piston piece 7, The right piston plate 8, the rotating shaft angle adjustment device 9 etc. are formed, and the air intake hole 10, the exhaust hole 11, the ignition hole 12 and the automatic tempering groove 13 are processed on the cylinder block simultaneously. Half cylinders 1 and 2 are provided with two holes, the centerlines of the two holes pass through the center of the sphere, and the angle between the two is less than 180°. The two holes are used to locate the rotating shaft to ensure that the centerline of the rotating shaft passes through the center of the sphere after the rotating shaft is installed, and Ensure that the shaft can only rotate around its own centerline. The top of the left piston plate and the right pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com