Small size universal petrol engine valve swing arm directional working mechanism

A general-purpose gasoline engine, valve rocker arm technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of valve push rod and bracket wear, affecting engine power, noise, etc., to eliminate friction wear and noise, ensure The effect of engine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

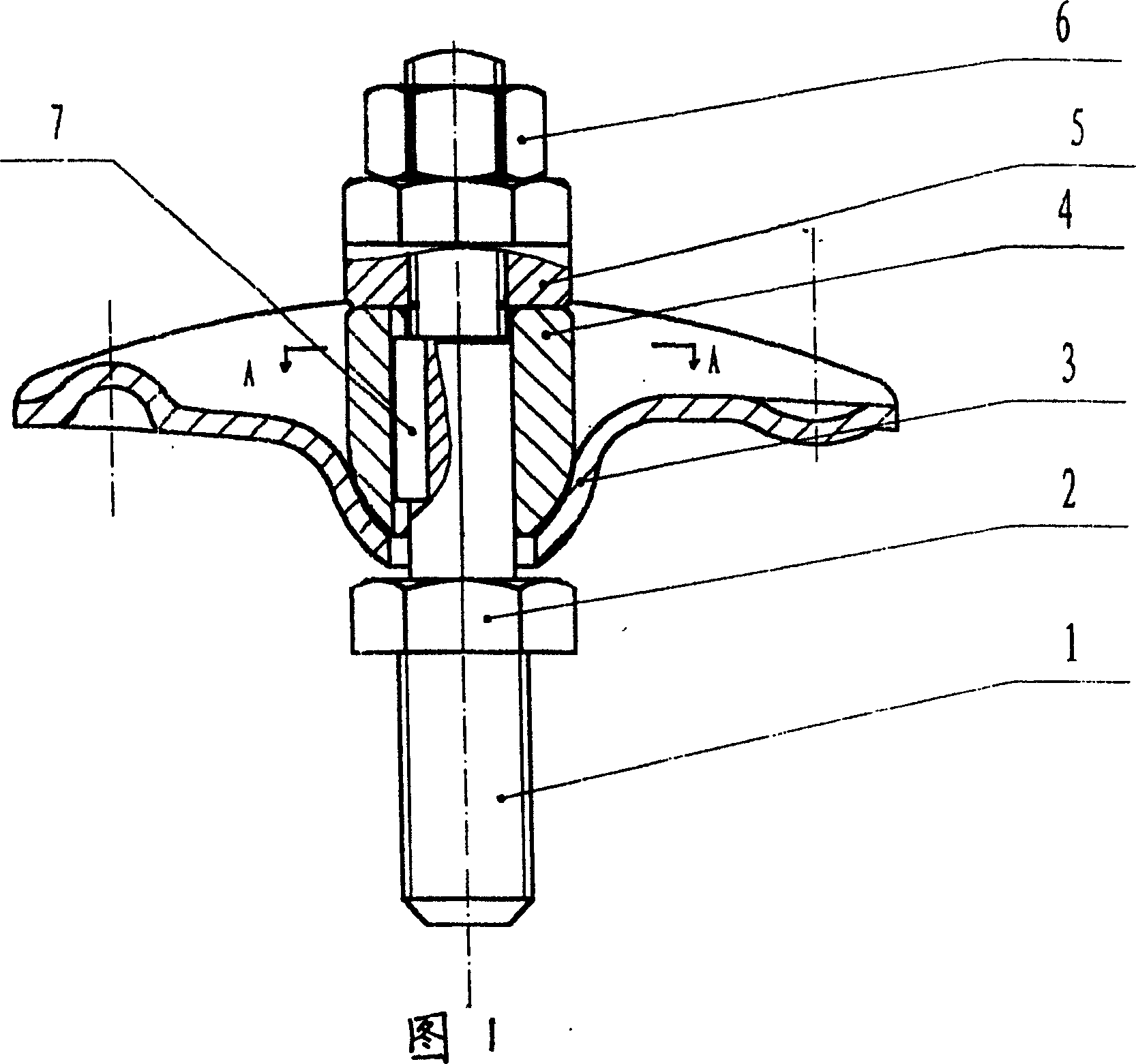

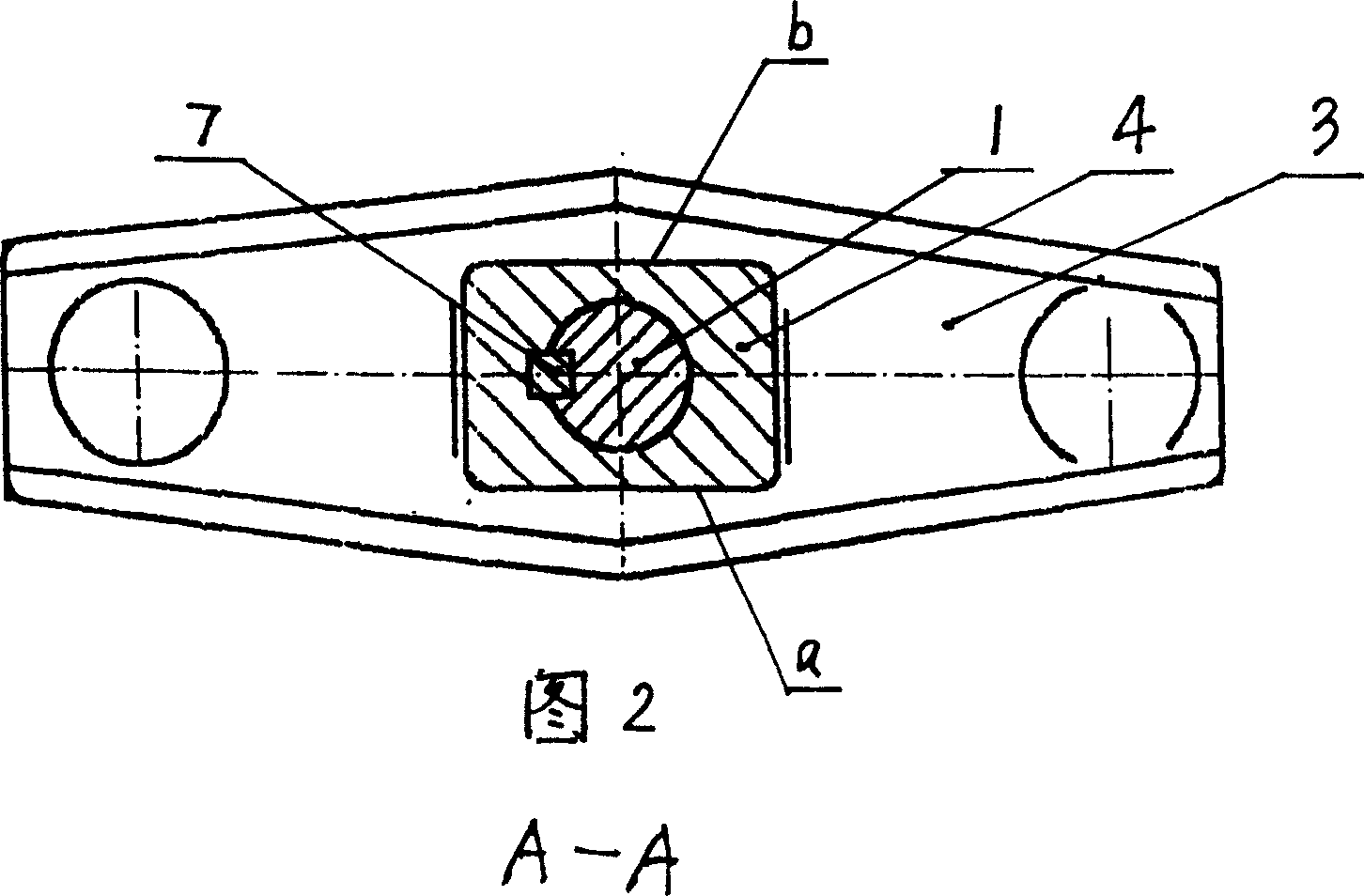

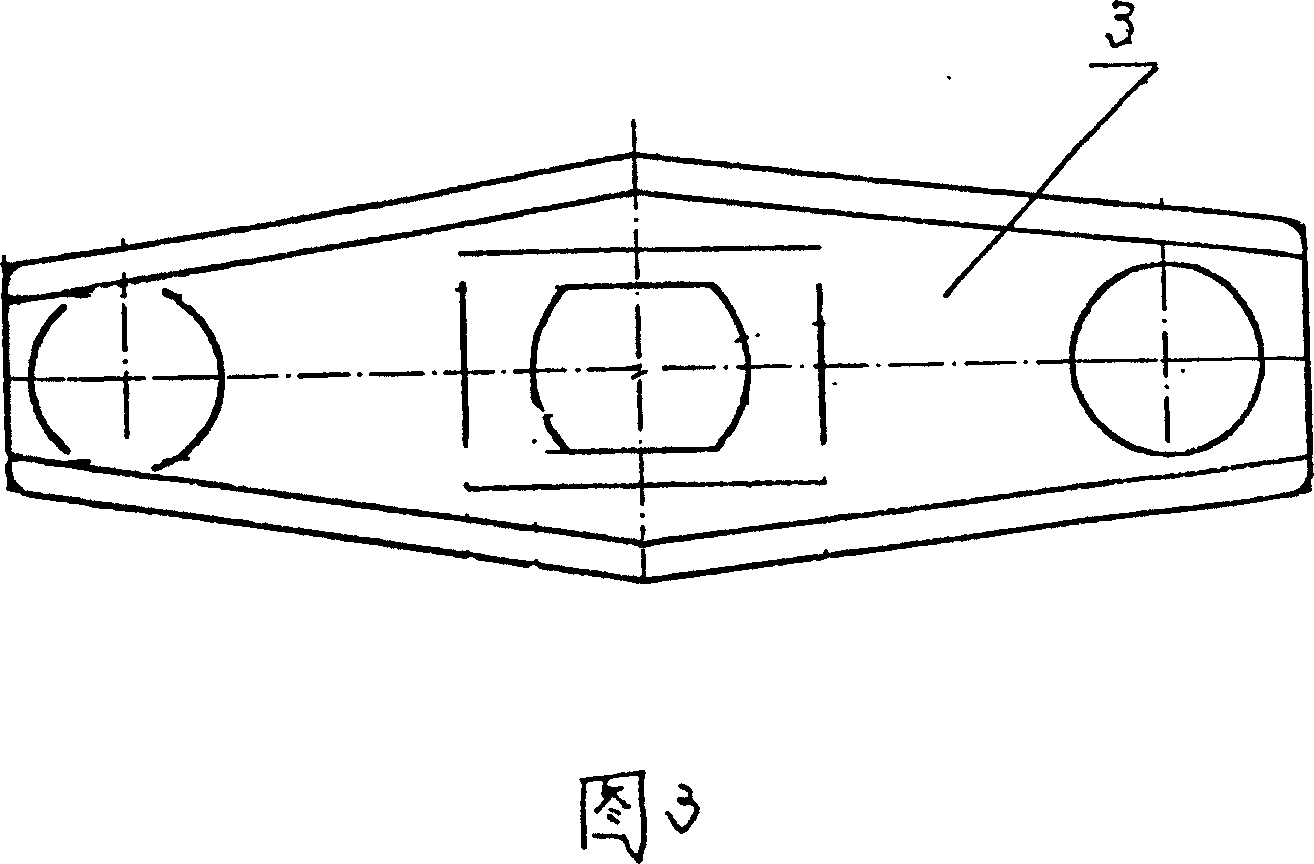

[0012] Please see Fig. 1 and Fig. 2, the present invention is mainly made up of adjusting screw rod 1, adjusting nut 2, valve rocker arm 3, guide block 4, valve clearance adjusting nut 5, lock nut 6, guide key 7, wherein adjusting screw rod 1 wears Through the valve rocker arm 3 with a groove at the bottom and dimples or convex hulls on both wings, the bottom surface of the valve rocker arm 3 is in contact with the adjustment nut 2 at the lower section of the adjustment screw 1, and a lock nut 6 is installed on the upper end of the adjustment screw 1. The invention gist of the invention is: A. a cuboid guide block 4 is installed in the middle of the adjusting screw rod 1, the bottom of the guide block 4 is inserted into the groove of the valve rocker arm 3, and the valve is set between the guide block 4 and the lock nut 6 Clearance adjustment nut 5; B. The bottom of the guide block 4 and the valve rocker arm 3 is an arc surface, the two sides of the arc surface are planes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com