Antiback component of exhaust duct

An air exhaust duct and anti-backflow technology, which is applied in vertical pipes, building components, buildings, etc., can solve the problems of unsatisfactory air flow velocity at the outlet, affecting the negative pressure effect of the air duct, and deficiencies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

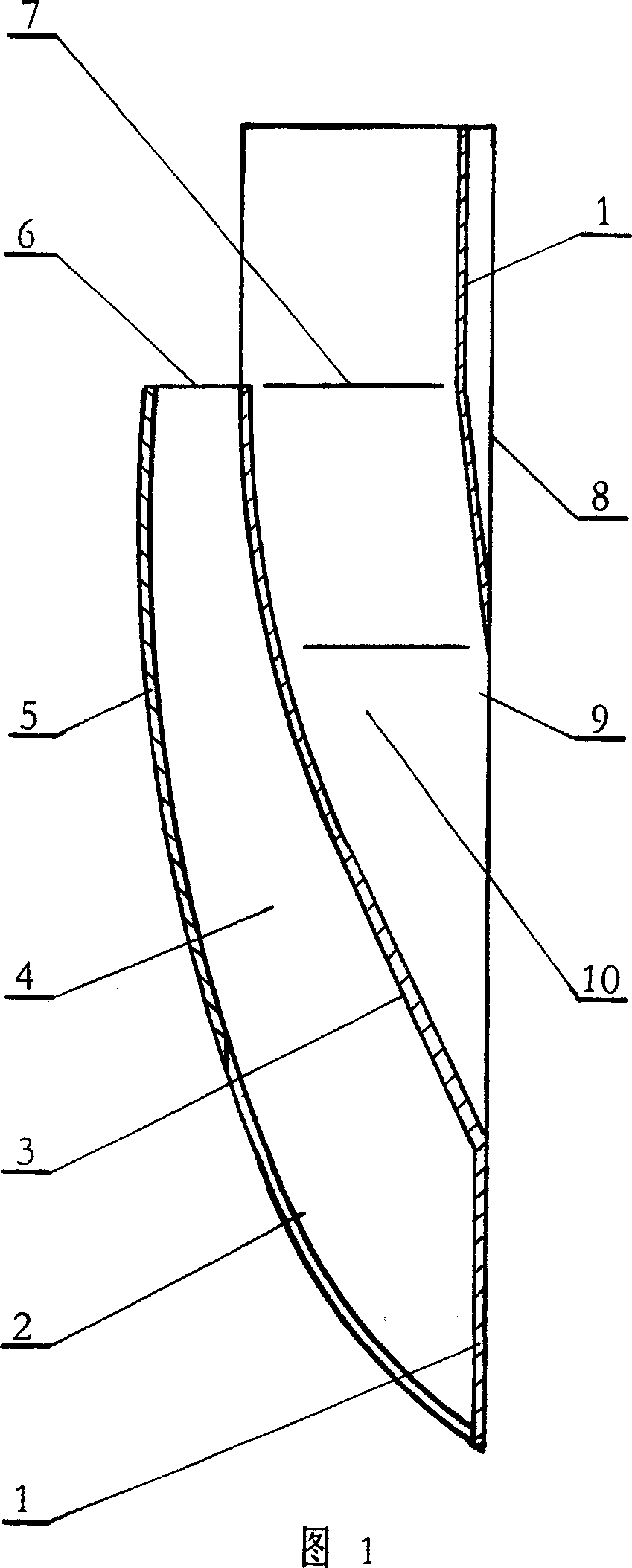

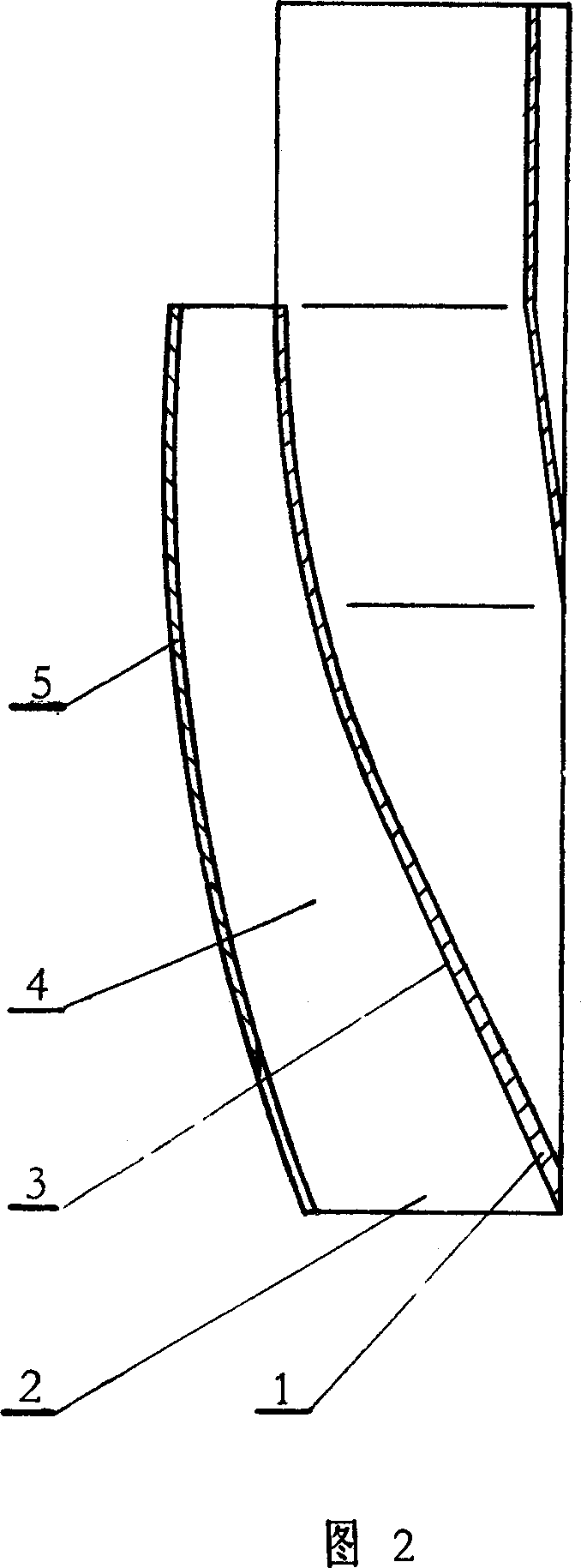

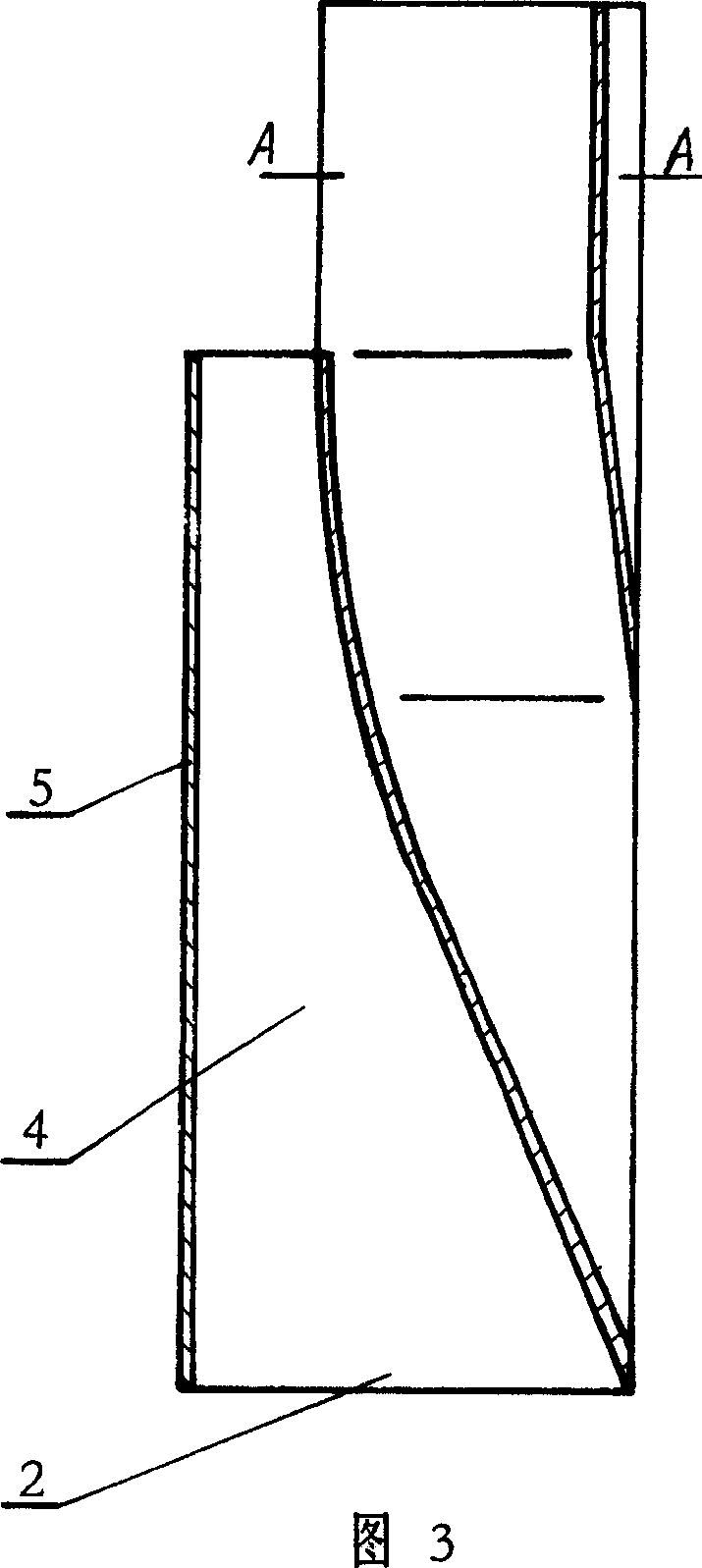

[0017] As shown in Figures 1, 2, 3, 4, 5, and 6, the present invention includes a housing 1 and a speed change plate 5 arranged on the outside of the housing. The outer shape of the housing 1 is a cone with a thin bottom and a thick top. The body 1 includes an air inlet side 8 and a shift side 3, and an air induction channel 10 is arranged in the casing 1. The shift plate 5 is a thin plate and is arranged on the outside of the shift side 3 of the casing 1. The shift plate 5 and the shift side 3 Constitute an air inlet 2 big between, the speed change hole 4 that air outlet 6 is little, housing 1 and speed change plate 5 are packed in the exhaust duct, and the outside of speed change plate 5 is the air passage in the exhaust duct. The air inlet 9 of the air induction passage 10 is arranged on the air inlet side 8, and the section from the air inlet 9 to the upward air outlet 7 gradually decreases until the air outlet 7 has the smallest section, and the section above the air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com