Inflation tire and its producing method

一种充气轮胎、胎圈部的技术,应用在充气轮胎、特殊轮胎、轮胎零部件等方向,能够解决轮胎耐久性下降、龟裂、轮胎生产性降低等问题,达到耐久性优异、提高生产性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

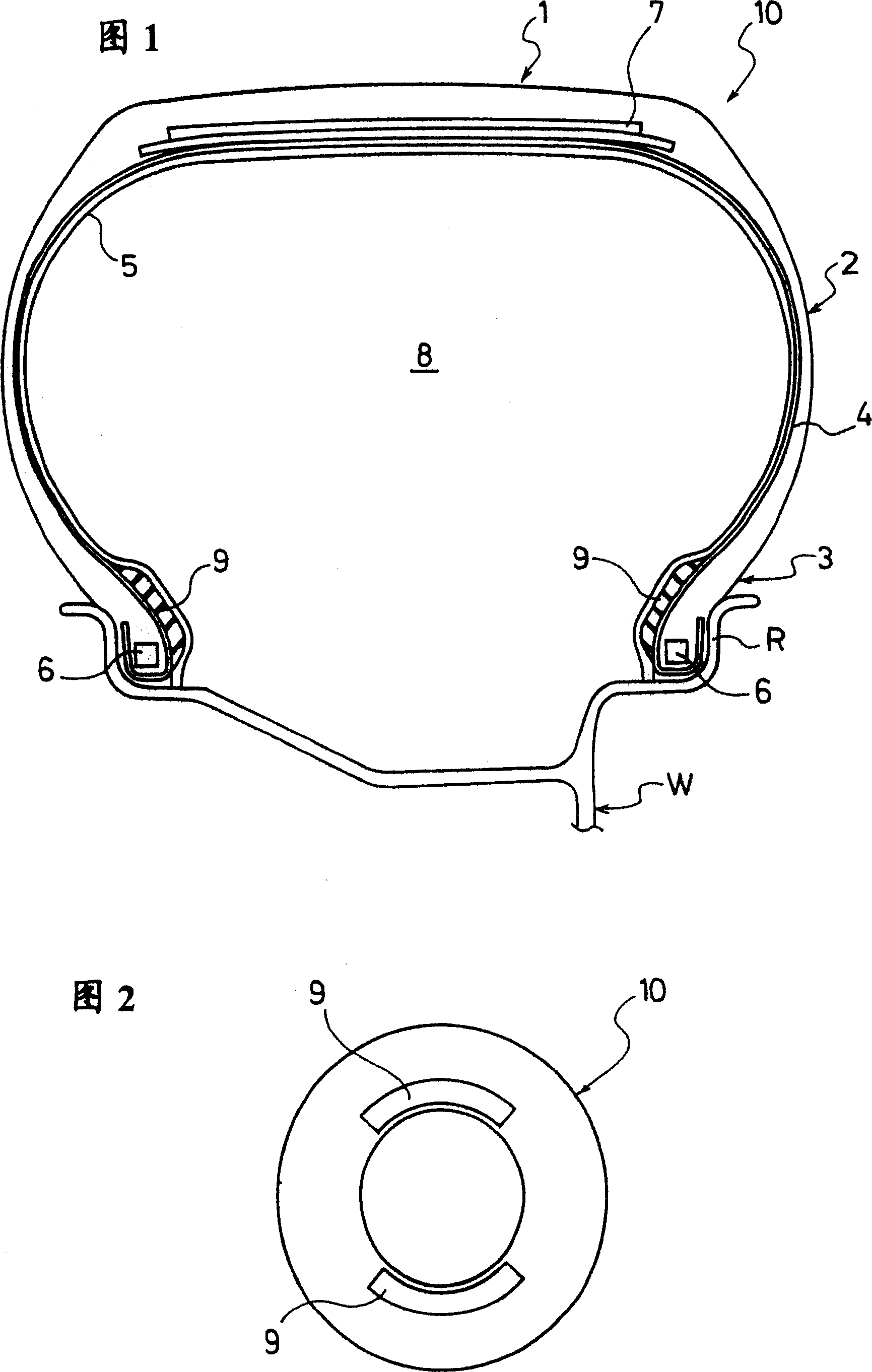

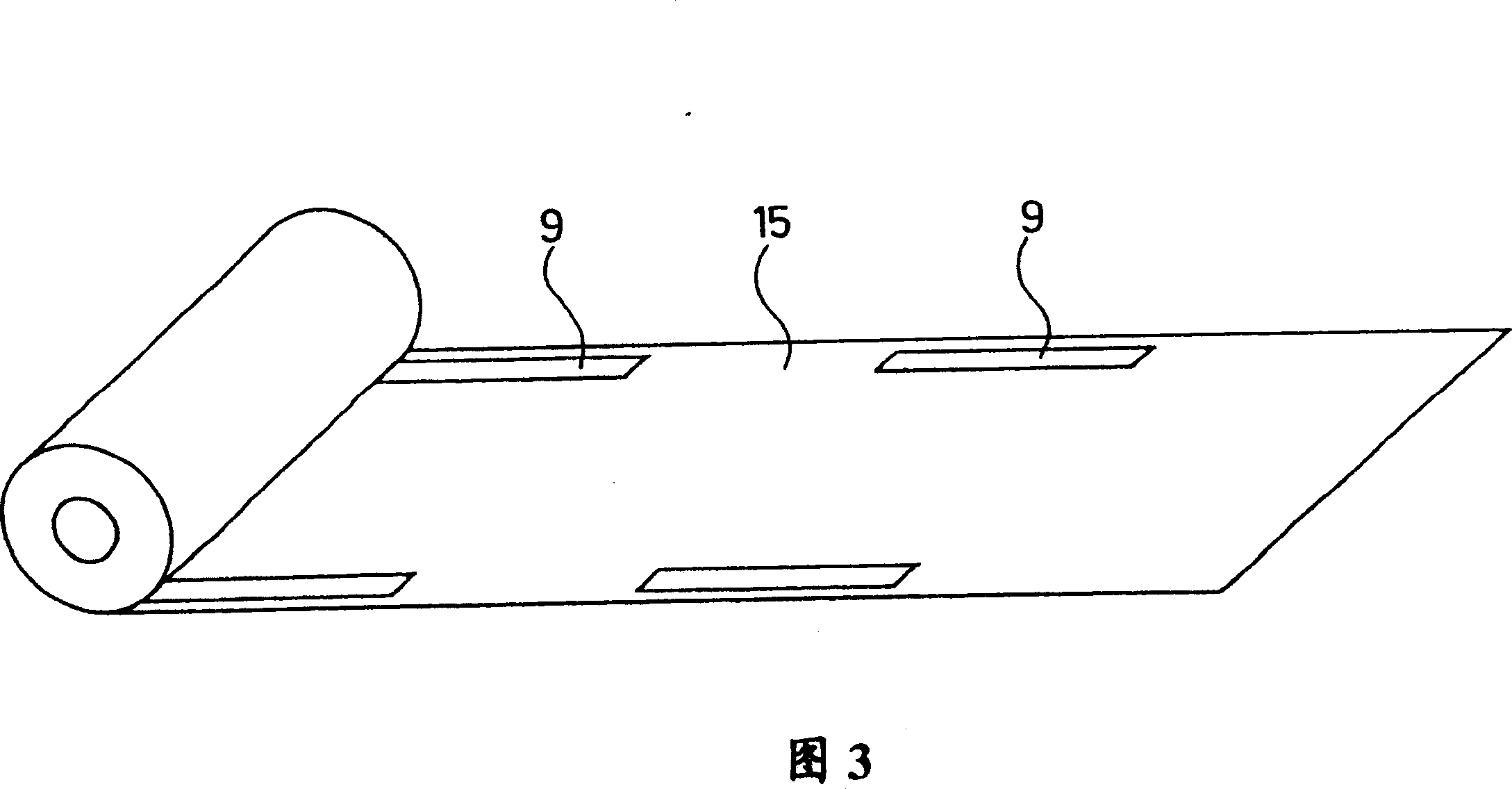

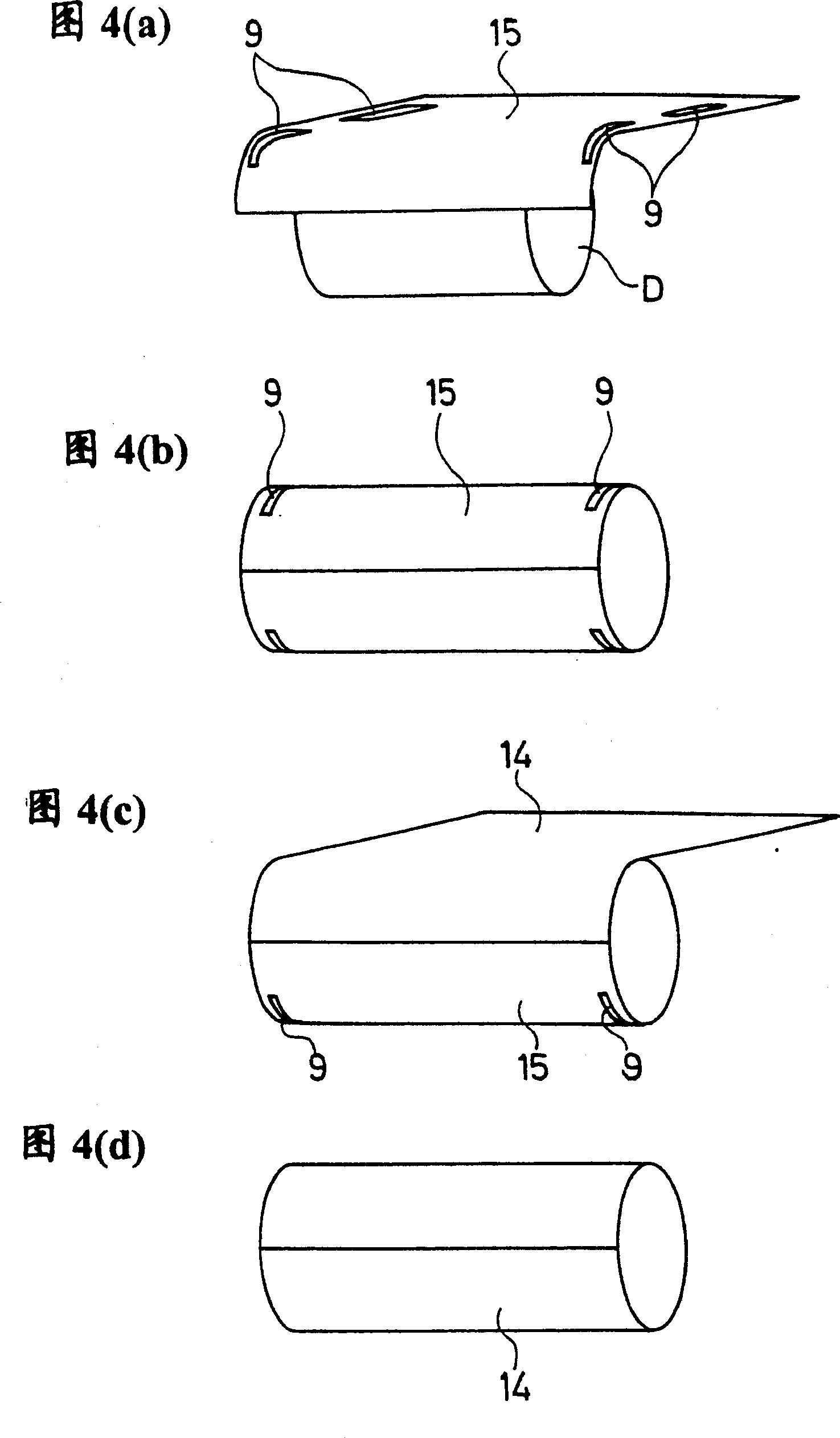

[0014] Hereinafter, the configuration of the present invention will be described in detail with reference to the drawings.

[0015] FIG. 1 shows a pneumatic tire according to an embodiment of the present invention, and FIG. 2 schematically shows an amount adjusting member arranged in a bead portion of the pneumatic tire from the side of the tire. As shown in FIG. 1 , a pneumatic tire 10 is composed of a tread portion 1 , sidewall portions 2 , and bead portions 3 . A skeleton layer 4 is spanned between the pair of left and right bead portions 3 , 3 , and an inner liner 5 is provided inside the skeleton layer 4 . End portions in the width direction of the skeleton layer 4 are rolled up from the inner side of the tire toward the outer side along the periphery of the bead core portion 6 at each bead portion 3 . In addition, a belt layer 7 is buried on the outer peripheral side of the skeleton layer 4 of the tread portion 1 . A pneumatic tire 10 is mounted on a rim (rim) R of a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com