Device for sensing carload

A technology for sensing devices and automobiles, applied in the field of sensing devices, can solve problems such as reduced practicability, reduced practicability, and deformation of oil pipes, and achieves the effects of high reliability and strong maintenance-free performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

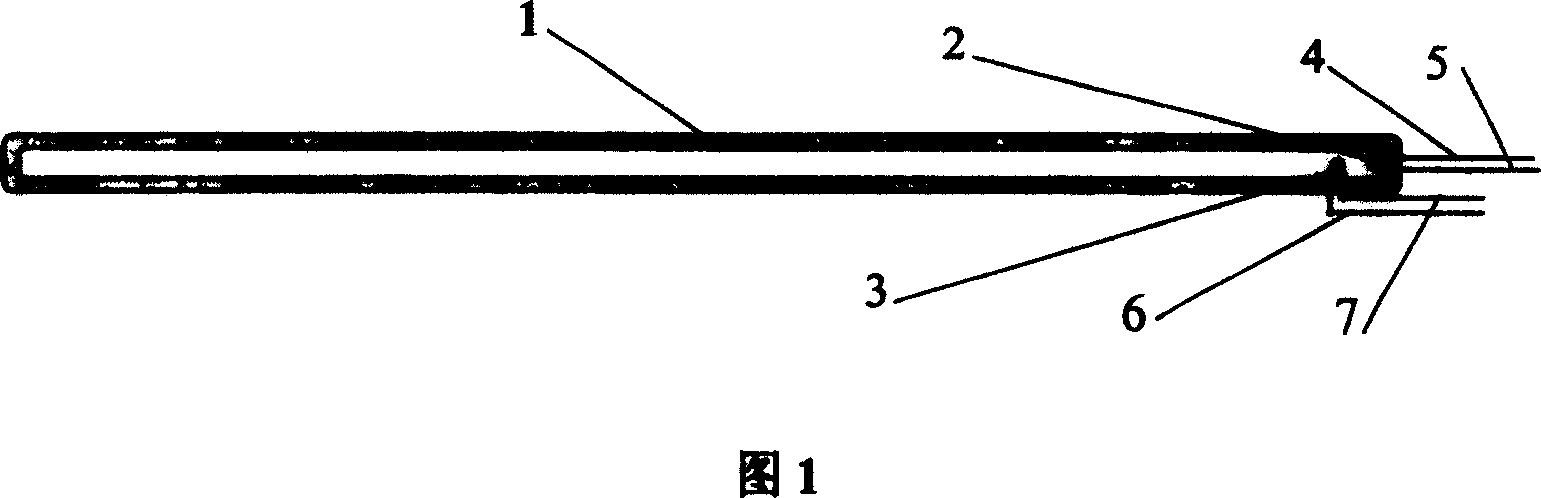

[0014] As shown in Figure 1, the present invention includes: a high pressure resistant rubber airbag 1, a main pressure sensor 2, a secondary pressure sensor 3, a first signal transmission cable 4, a first signal transmission redundant cable 5, a second signal transmission cable 6, a second signal transmission cable Two signal transmission redundant cables 7, the high pressure resistant rubber airbag 1 immediately transmits the pressure felt in the sealed cavity to the pressure sensor on the main pressure sensor 2 and the auxiliary pressure sensor 3, the main pressure sensor 2 and the auxiliary pressure sensor The output signals of 3 are respectively led out by the preset first signal transmission cable 4 and the second signal transmission cable 6, and the first signal transmission redundant cable 5 and the second signal transmission redundant cable 7 are the main pressure sensor 2 and the secondary pressure sensor respectively. Duplicate channel for sensor 3 output signal.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com