Expanding temperature measuring head for buried pipeline

A technology of buried pipelines and temperature measuring heads, applied in thermometers, measuring devices, measuring heat, etc., can solve problems such as too late to deal with, safety, hidden dangers of economical operation, and unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

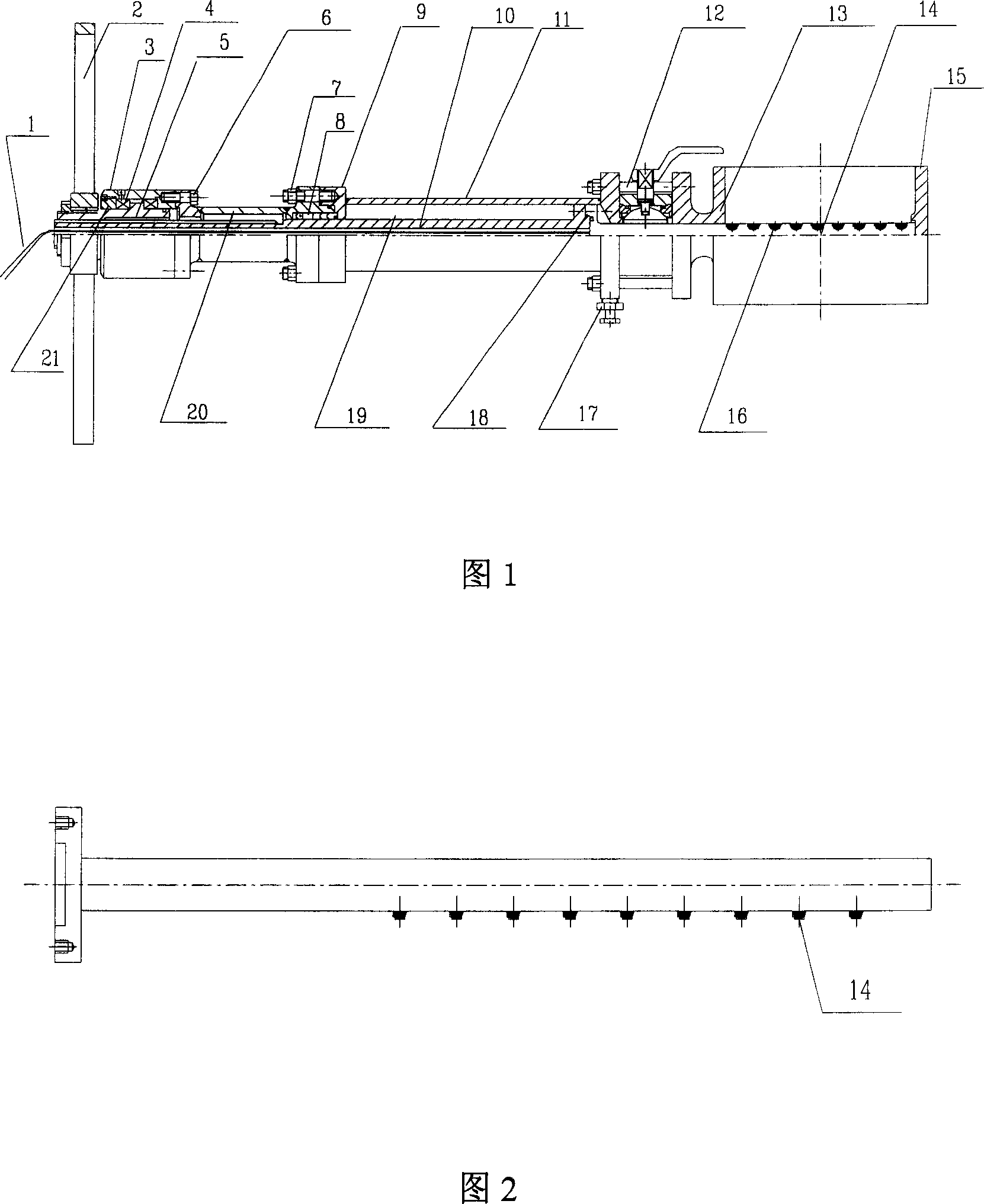

[0019] The invention will be further described below with a specific embodiment. The overall structure of this example is shown in Figure 1, which is a temperature measuring head for a φ325mm pipeline. Its main dimensions are that the total length of the temperature measuring head is 510mm, the diameter of the pipe is φ25mm, the front end has a 10mm plug, and the tail flange diameter is 75mm. A small hole; the isolation valve 12 is a ball valve with an inlet and outlet diameter of 25mm, the model is YQ71F-64DN25, and the total length of the temperature measuring head installation shell 13 is 200mm; the pressure relief valve 16 is selected as J11W-16P DN15; the connecting rod of the temperature measuring head is 10 φ30mm, length 1045mm, pipe wall thickness 5mm, and 350mm long external thread from the end to the front; casing 11 is a round steel pipe of φ80×408×5mm, and the rear end flange 9 is φ100×37mm; small casing 20 It is a φ60×100×5mm steel pipe, the rear end flange is φ1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com