Energy-saving air-drawing coal-fired range

A coal-fired, wind-type technology, applied in the field of coal-fired stoves, to achieve safety performance assurance, clean stove surface, and reduce the difficulty of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

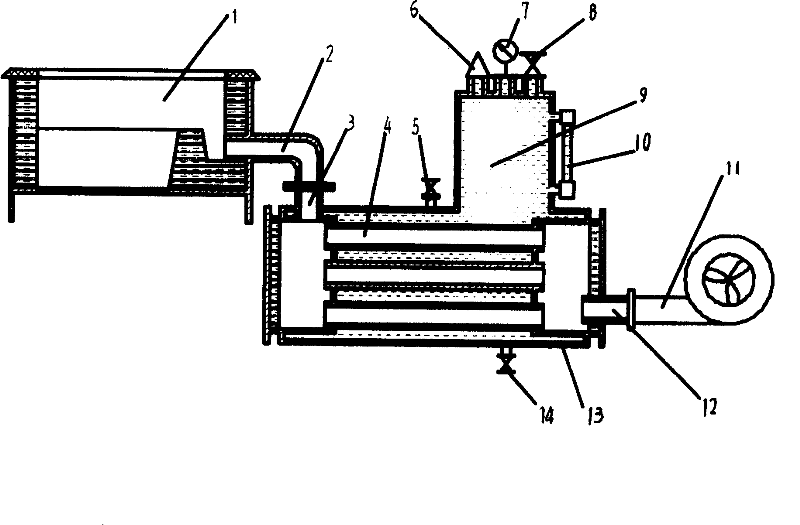

[0008] The energy-saving draft-drawing coal-fired stove is composed of a coal-fired stove (1), an induced draft pipe (2), a waste heat boiler (9) and a draft fan (11) connected in series. One end of the air induction pipe (2) is sealed to it, the other end is sealed to the air inlet (3) of the waste heat boiler (9), and the air outlet (12) of the waste heat boiler (9) is connected to the air outlet of the exhaust fan (11) Sealed connection. The coal-burning stove (1) can be selected as a single-eye stove, or a multi-eye stove with tuyere outlets connected in series or in parallel. The waste heat boiler (9) should at least include a casing (13), an air inlet (3), an air outlet (12), an air passage (4), a water inlet (5), a sewage outlet (14), a safety valve (6), Pressure gauge (7), steam switch (8), water level gauge (10), air inlet (3), air outlet (12), water inlet (5), sewage outlet (14), safety valve (6), pressure gauge (7), steam switch (8), water level gauge (10) are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com