Gravity type heat transfer device and preparation method thereof

A heat transfer, gravity-type technology, applied in the field of heat transfer, can solve the problems of reduced contact angle between the liquid working medium and the inner surface of the device, low frequency of gas-liquid phase change cycle, difficulty in the return of liquid working medium, etc., to achieve production The effect of low technical difficulty, light weight and high heat transfer density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

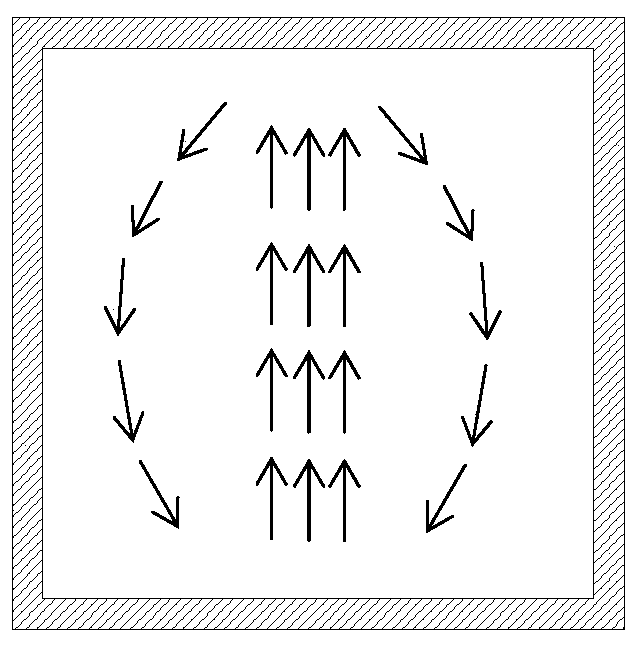

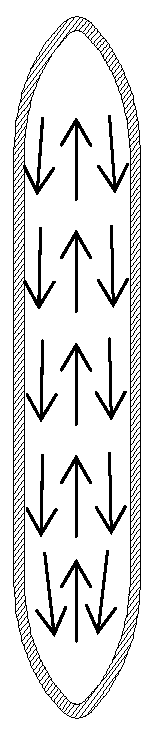

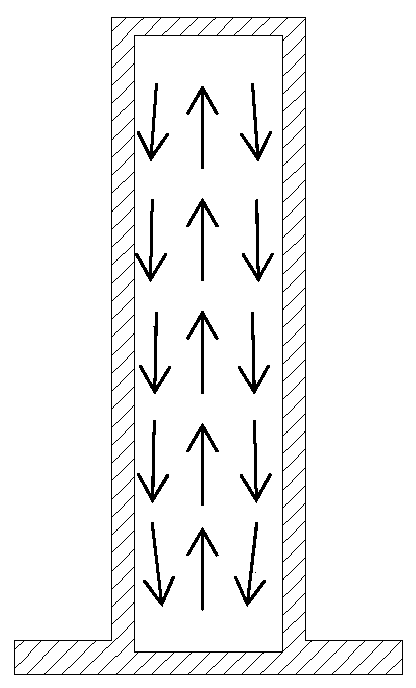

[0038] The gravity heat transfer device of the present embodiment, as Figure 4 Shown is a cross-sectional view of a gravity heat pipe as an example. The gravity heat transfer device includes a heat transfer body 1 and a liquid working medium 2. The heat transfer body 1 encloses a first cavity 13, and the first cavity 13 is A closed space, the liquid working medium 2 is located in the first cavity 13 , the heat transfer body 1 includes the heat transfer shell 11 and the separation layer 12 , the separation layer 12 covers the inner wall of the heat transfer shell 11 . Through the setting of the separation layer 12, the surface energy between the liquid working medium and the surface in contact with it is reduced, the contact angle is increased, and the effect of increasing the phase change cycle speed of the working medium and enhancing the heat transfer efficiency of the heat exchanger is achieved.

[0039] As a specific embodiment, the separation layer 12 is obtained by perf...

Embodiment 2

[0041] This embodiment provides a kind of preparation method of the gravity heat transfer device of embodiment 1, comprises the following steps:

[0042] S1: Manufacture the heat transfer shell, and the two ends of the heat transfer shell are open;

[0043] S2: Surface treatment is performed on the inner surface of the heat transfer shell by a plating process, and an isolation layer is formed that is isolated from the liquid working medium;

[0044] S3: The surface-treated heat transfer shell is edge-sealed by welding, and a liquid injection hole is reserved at any position of the heat transfer shell;

[0045] S4: inject the liquid working medium—HFC refrigerant into the first cavity through the liquid injection hole;

[0046] S5: pumping out the air in the first cavity to form a vacuum;

[0047] S6: closing the liquid injection hole.

[0048] The preparation method of the gravity heat transfer device in this embodiment has simple process steps and low production technical ...

Embodiment 3

[0050] This embodiment provides another preparation method of the gravity heat transfer device of embodiment 1, comprising the following steps:

[0051] S1: An aluminum hollow profile with a cavity structure is prepared by extrusion molding as a heat transfer shell, and the volume of the cavity is controlled by the design of the molding die;

[0052] S2: Surface treatment is carried out to the hollow aluminum profile through a dip coating process, and a separation layer is formed which is separated from the liquid working medium, so that the contact angle between the liquid working medium of the heat transfer device—ethanol and the surface of the separation layer is greater than 90° (such as Figure 5 As shown, the contact angle is the θ angle in the figure), the specific operation method is: when the contact angle is greater than 90°, proceed to the next step; when the contact angle is not greater than 90°, continue the surface treatment or adjust the surface treatment process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com