Motor vehicle heat exchanger system

A technology of heat transfer system and motor vehicle, applied in the field of motor vehicle heat transfer system, can solve problems such as pressure drop, and achieve the effect of high spontaneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

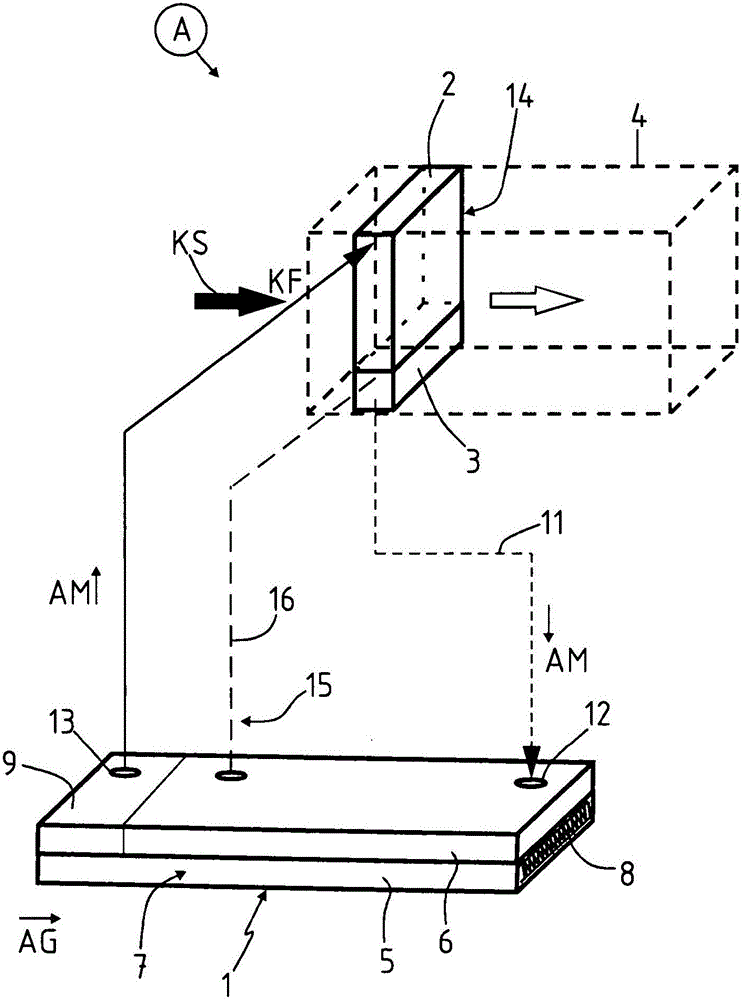

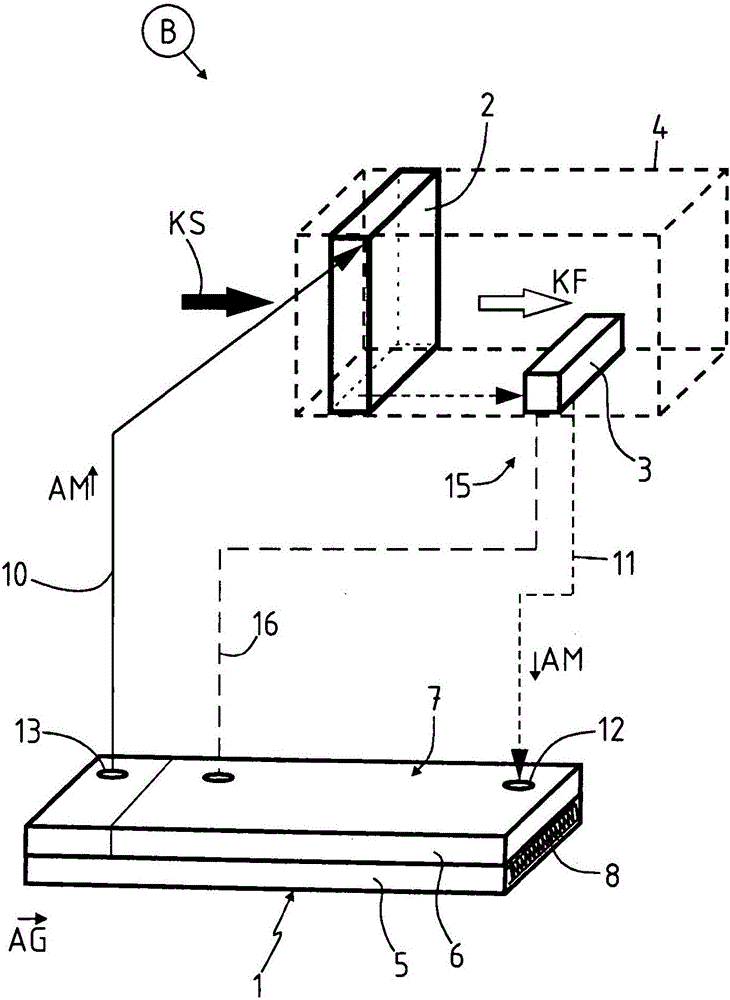

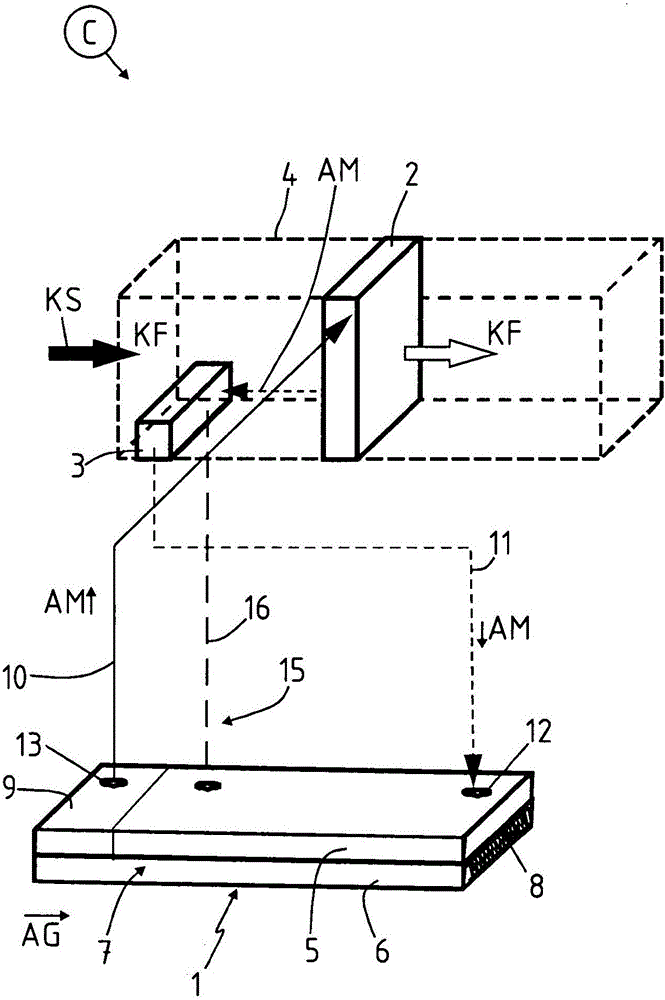

[0037] Corresponding components or system parts in the Figures 1 to 3 The same reference numerals are provided in .

[0038] Figures 1 to 3 A motor vehicle heat transfer system A, B, C is shown schematically and technically simplified in each case.

[0039]Each motor vehicle heat transfer system A, B, C has a closed circuit for the working medium AM and comprises an evaporator 1 for vaporizing the working medium AM and a condenser 2 for condensing the vaporous working medium AM. A compensation vessel 3 is provided between the condenser 2 and the evaporator 1 . The carburetor 1 is integrated into the exhaust gas flow AG of the internal combustion engine of the motor vehicle. Said condenser 2 is charged into the cooling fluid flow KS. The cooling fluid KF can be a gas, in particular air, or also a liquid, such as oil. The condenser 2 is impinged on the cooling fluid KF in the cooling fluid flow KS and the cooling fluid KF flows through it or flows around or through it. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com