Closed blade stirring sludge drying system

A sludge drying and paddle technology, which is applied in the direction of non-progressive dryers, dry solid materials, and dry cargo processing, can solve the problems of high processing cost and general processing effect, achieve high heat transfer density, and reduce harmful gases Discharge, increase the effect of stirring intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

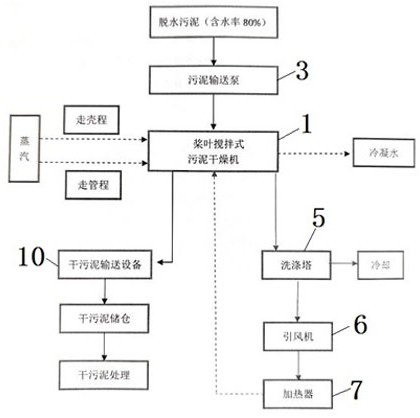

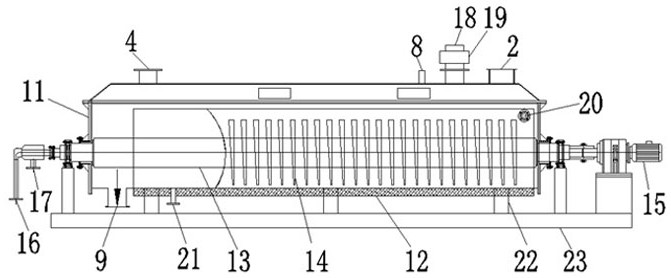

[0023] Such as figure 1 and figure 2 As shown, the closed paddle agitation sludge drying system of the present invention includes a paddle agitation sludge dryer 1, and the mud inlet 2 of the paddle agitation sludge dryer 1 is connected to the sludge conveying The pump 3 is connected, and the carrier gas outlet 4 of the paddle-stirred sludge dryer 1 is connected with the scrubber 5, and the gas outlet of the scrubber 5 is connected with the paddle-stirred sludge through the induced draft fan 6 and the heater 7 in turn. The reuse port 8 of the dryer 1 is connected, the sludge discharge port 9 of the paddle agitation sludge dryer 1 is connected with the dry sludge conveying equipment 10, and the paddle agitation sludge dryer 1 includes a cylinder body 11, a steam jacket 12 is provided in the cylinder 11, two or four horizontal hollow paddle shafts 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com