Annular thermal superconducting pipeline phase change suppression heat sink and electronic product

A technology of thermal superconducting conduit and phase change suppression, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problem of high local temperature, achieve stable quality, solve welding problems, and high heat transfer effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

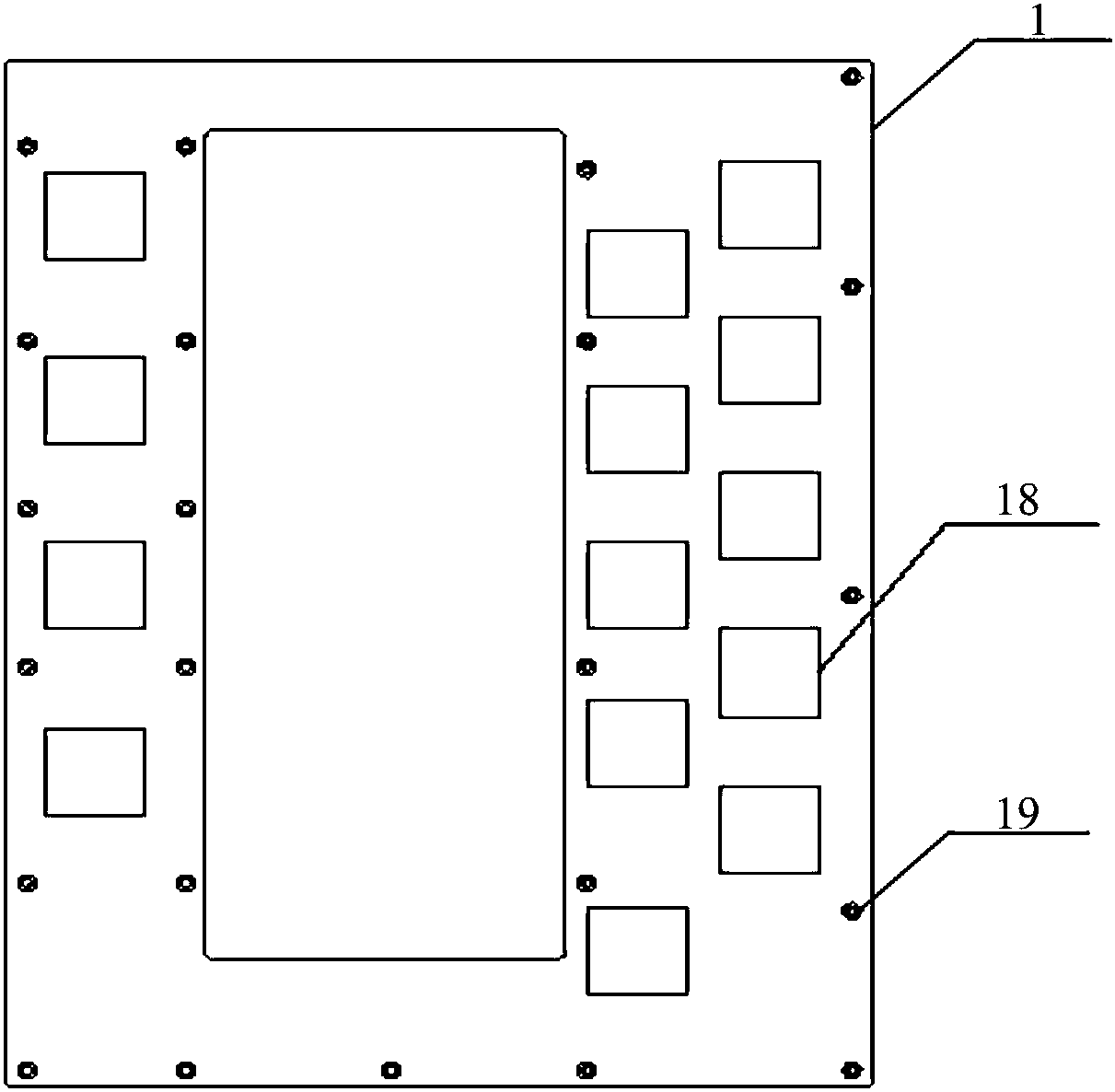

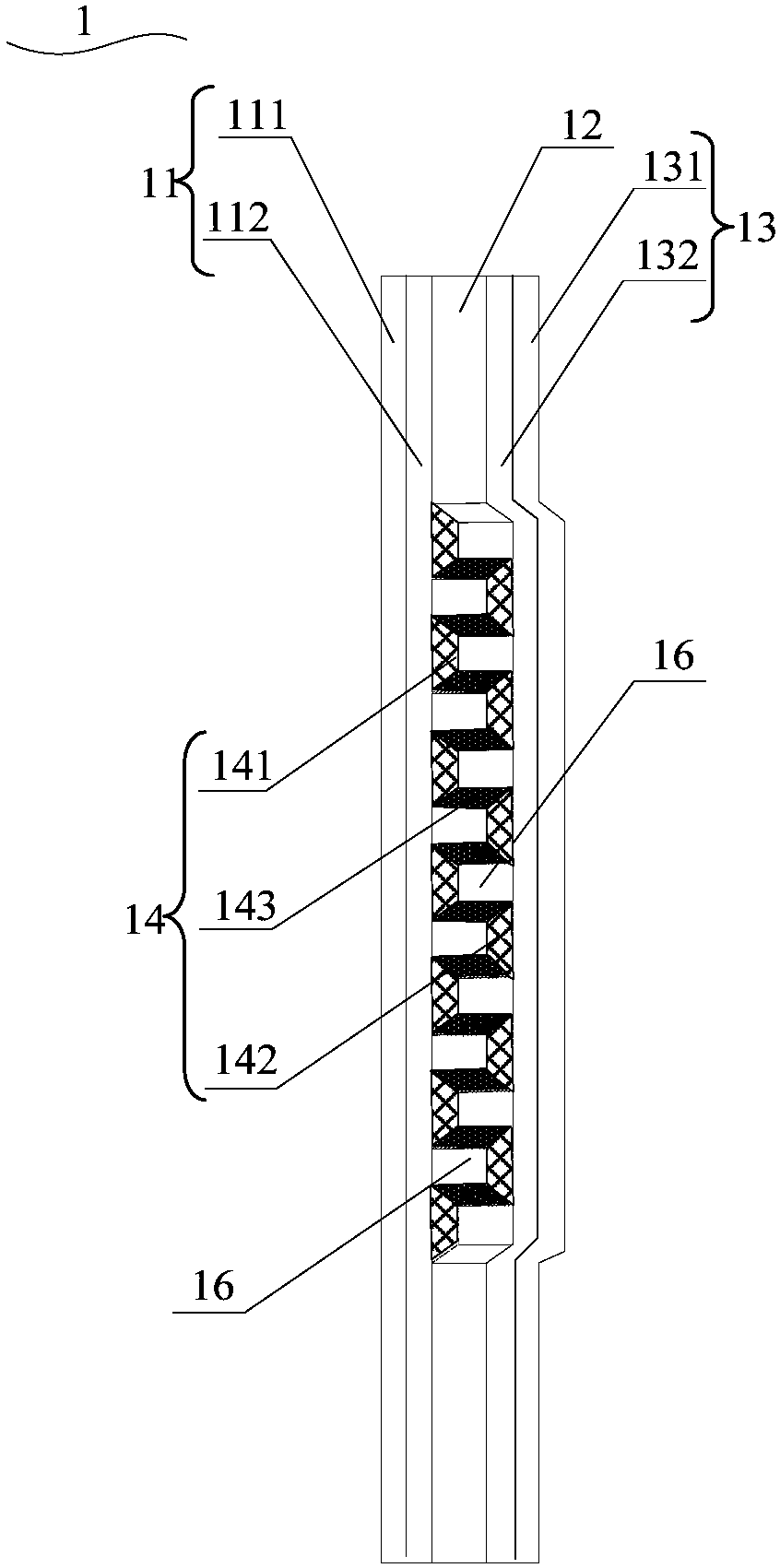

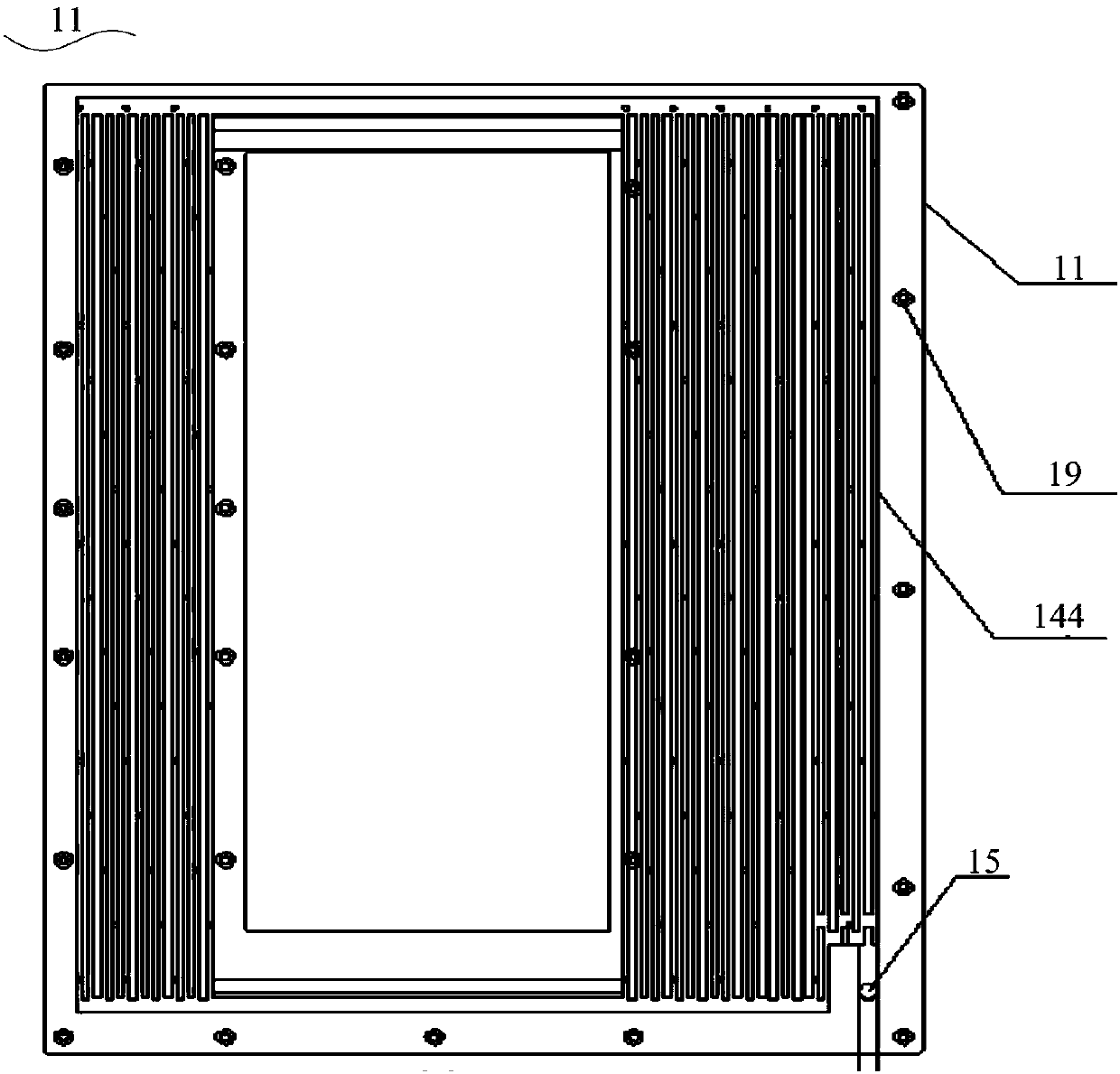

[0050] see Figure 1 to Figure 4, the present invention provides an annular thermal superconducting circuit phase change suppression cooling plate 1, the annular thermal superconducting circuit phase change suppression cooling plate 1 is a composite plate structure; the annular thermal superconducting circuit phase change suppression cooling plate 1 The surfaces are all flat, and the surface of the annular thermal superconducting circuit phase change suppression cooling plate 1 is provided with at least one heat source fixing area 18; the annular thermal superconducting circuit phase change suppression cooling plate 1 is internally formed with an annular thermal superconducting circuit 14 , the thermal superconducting circuit 14 is a closed circuit, and the thermal superconducting circuit 14 is filled with a heat transfer working medium. The annular thermal superconducting circuit phase change suppression cooling plate 1 of the present invention has the characteristics of high...

Embodiment 2

[0078] The present invention also provides an electronic product, which includes at least one heat source and the annular thermal superconducting circuit phase change suppression cooling plate 1 as described in Embodiment 1, and the heat source is fixed in the heat source fixing area 18 . For the specific structure of the annular thermal superconducting circuit phase change suppression cooling plate 1 , please refer to Embodiment 1, which will not be repeated here.

[0079] As an example, the electronic product may be a notebook computer, a desktop computer, or an ipad, and the like.

[0080] In summary, the present invention provides an annular thermal superconducting circuit phase change suppression cooling plate and electronic products, the annular thermal superconducting circuit phase change suppression cooling plate is a composite plate structure; the annular thermal superconducting circuit phase change The surfaces of the suppressing heat dissipation plates are all plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com