A Handheld Electric Fiber Bundle Alignment Equipment and Production Method

A production method and technology of fiber bundles, which are applied in hand-held electric fiber bundle equipment and production fields, can solve the problems affecting the company's development stamina and grasp of development opportunities, low efficiency, high labor intensity, etc., and achieve good market application value, convenient and safe operation, and the effect of overcoming high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

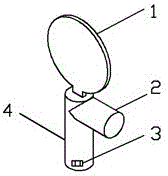

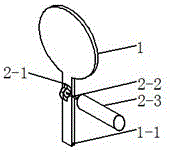

[0035] Such as figure 1 , figure 2 As shown, the embodiment of the present invention is that the hand-held electric equipment for aligning fiber bundles includes a clapper (1), a power system (2), a reset system, an adjustment device (3) and a handle (4), and the lower end of the clapper A positioning plate (1-1) is provided, and the clapper plate and the positioning plate are integrally formed. Further, the section of the clapper plate is circular, square, rectangular, trapezoidal or elliptical; the shape of the positioning plate is long Bar shape; further, the surface of the clapper is made of rough material. Or, the portion of the clapper plate in contact with the end surface of the fiber bundle is formed of a rough material; or, the portion of the clapper plate in contact with the end surface of the fiber bundle is pasted with an outer surface, and the outer surface is formed of a rough material.

[0036] An accommodating cavity is arranged in the handle, and an opening...

Embodiment 2

[0055] In this embodiment, the hand-held electric device for aligning fiber bundles is provided with components such as a clapper, a power system, an adjustment device, and a handle. The handle is kept stable, and one end of the clapper is positioned on the handle. The device completes the speed adjustment of the power system and the stroke adjustment of the reciprocating motion of the clapper, so that the reciprocating motion of the clapper can change the frequency and stroke. And beating the end face of the fiber bundle to complete the beating of the end face of the fiber bundle to obtain a relatively neat end face of the fiber bundle.

[0056] The handle, power system and adjustment device are relatively fixed, and the clapper positioning plate forms a hinge relationship with the handle, so that the handle can be kept stable and the clapper can be reset by a spring or a spring hinge. The power system is made up of cam, transmission shaft and motor, and the motor drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com