Electromagnetic hand-holding patting plate and production method

A production method, electromagnetic technology, applied in the direction of textiles and papermaking, etc., can solve the problems of high labor intensity, low efficiency, affecting the stamina of the company's development and the grasp of development opportunities, etc., to overcome high labor intensity, convenient and safe operation, The effect of reducing the difficulty of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

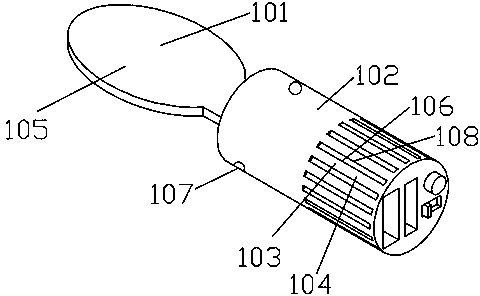

Image

Examples

Embodiment 1 ,,,。,,,,。 example ,2,2、1-3,0.5,0.5、10-20。 Embodiment 2

[0040]When in use: turn on the control switch, when the coil of the solenoid valve is energized, the valve core moves, so that the compressed air passes through the inlet of the solenoid valve, the outlet of the solenoid valve, and after entering the cylinder, the inlet pushes the cylinder rod under the action of air pressure; The air in the cylinder is discharged through the air inlet of the cylinder, the air outlet of the solenoid valve, and the exhaust port. When the solenoid valve coil is de-energized, the valve core moves, so that the compressed air enters the cylinder through the inlet of the solenoid valve, the outlet of the solenoid valve, and the air inlet pushes the cylinder rod under the action of air pressure; and the air in the cylinder enters through the cylinder. Air port, solenoid valve air outlet, exhaust port discharge. The cylinder push rod moves up and down to drive the handkerchief to move up and down, and the spring under the fixed rod makes it move up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com