Lining method for fragile material base plate and apparatus therefor

A brittle material substrate, brittle material technology, applied in fine working devices, glass cutting devices, stone processing equipment, etc., can solve problems such as affecting product quality and reducing the yield of FPD substrate manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, a scribing method and an apparatus for a brittle material substrate according to an embodiment of the present invention will be described with reference to the accompanying drawings.

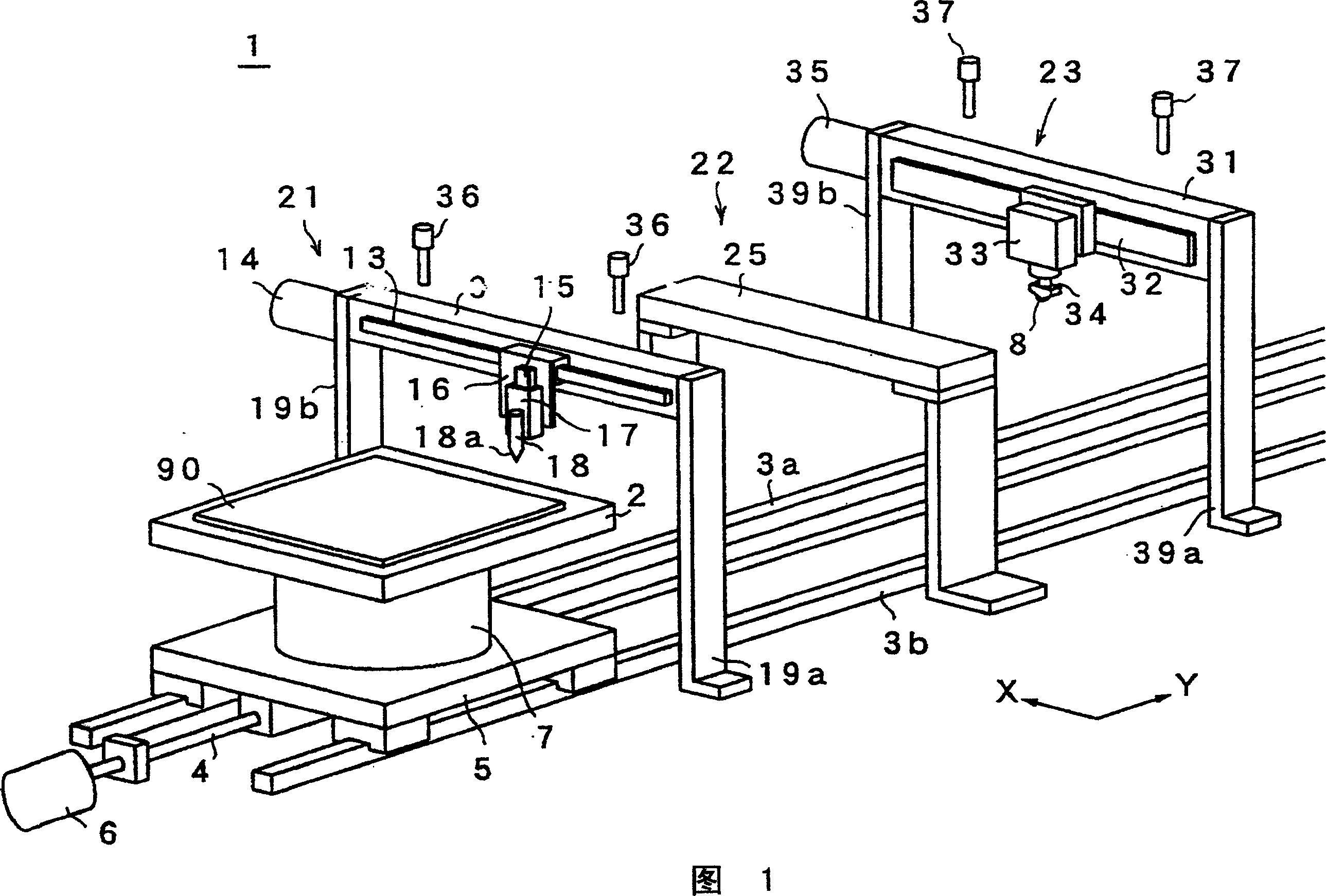

[0049] FIG. 1 is a schematic perspective view showing a scribing device in an embodiment of the present invention. The structure of this scribing device 1 includes a moving body 5 , a coating unit 21 , a drying unit 22 , and a scribing unit 23 . The moving body 5 can be driven in the y-axis direction by the ball screw 4 and the electric motor (motor) 6 along the pair of guide rails 3a, 3b, and can be positioned at a predetermined position. The brittle material substrate 90 is positioned and held on the workbench 2 by a positioning assembly (not shown in the figure). The brittle material substrate 90 held on the stage 2 is sequentially processed by the coating unit 21 , the drying unit 22 , and the scribing unit 23 , and moved to complete scribing.

[0050] The brittle mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com