Shaping processing product of synthetic resin board and its processing method

A technology of synthetic resin board and processing method, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of undisclosed shape shaping, the wall thickness of integrally formed products 76 becomes larger, and achieve the desired shape Excellent performance, excellent pattern appearance, and the effect of preventing breakage and resin leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

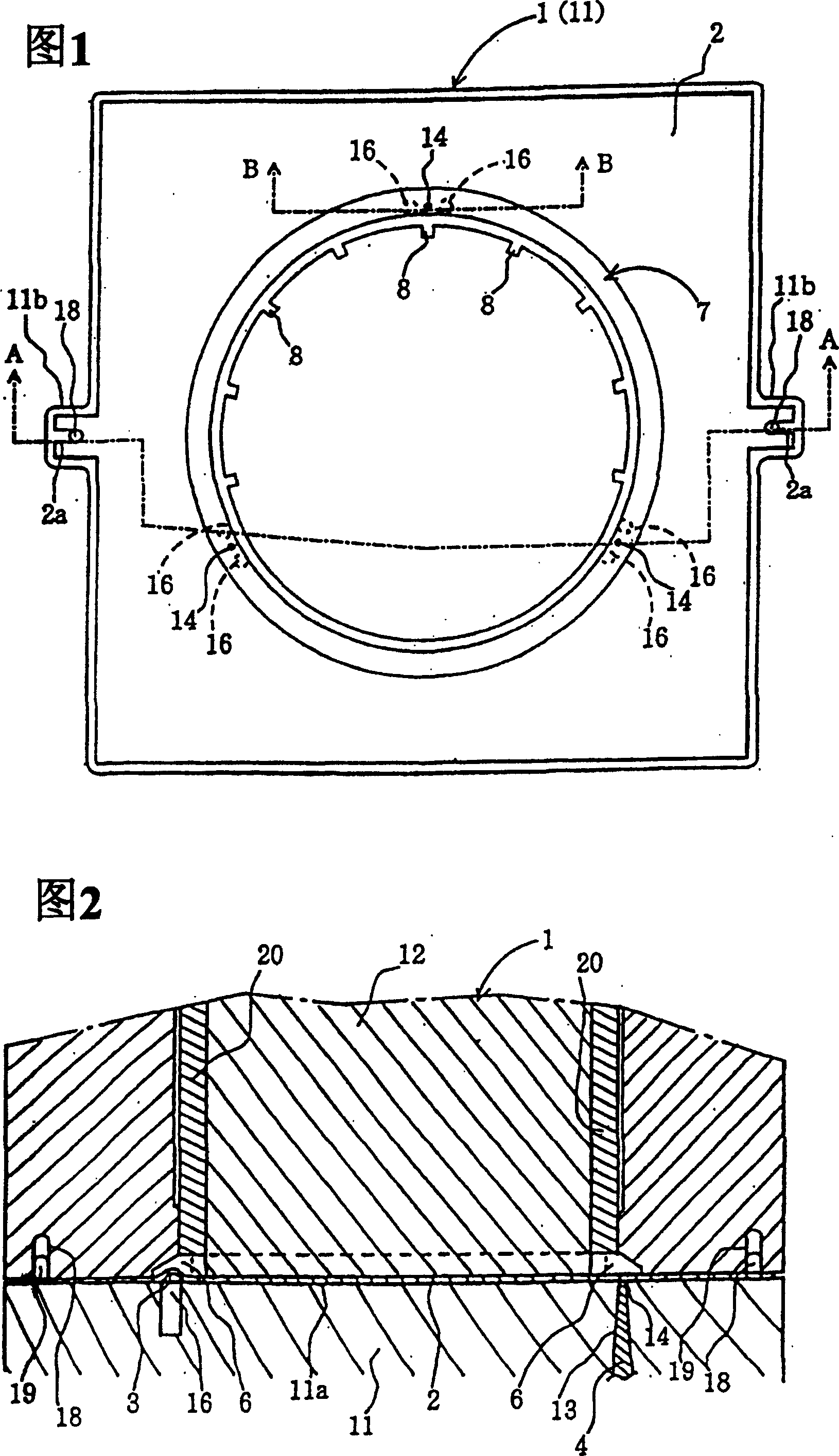

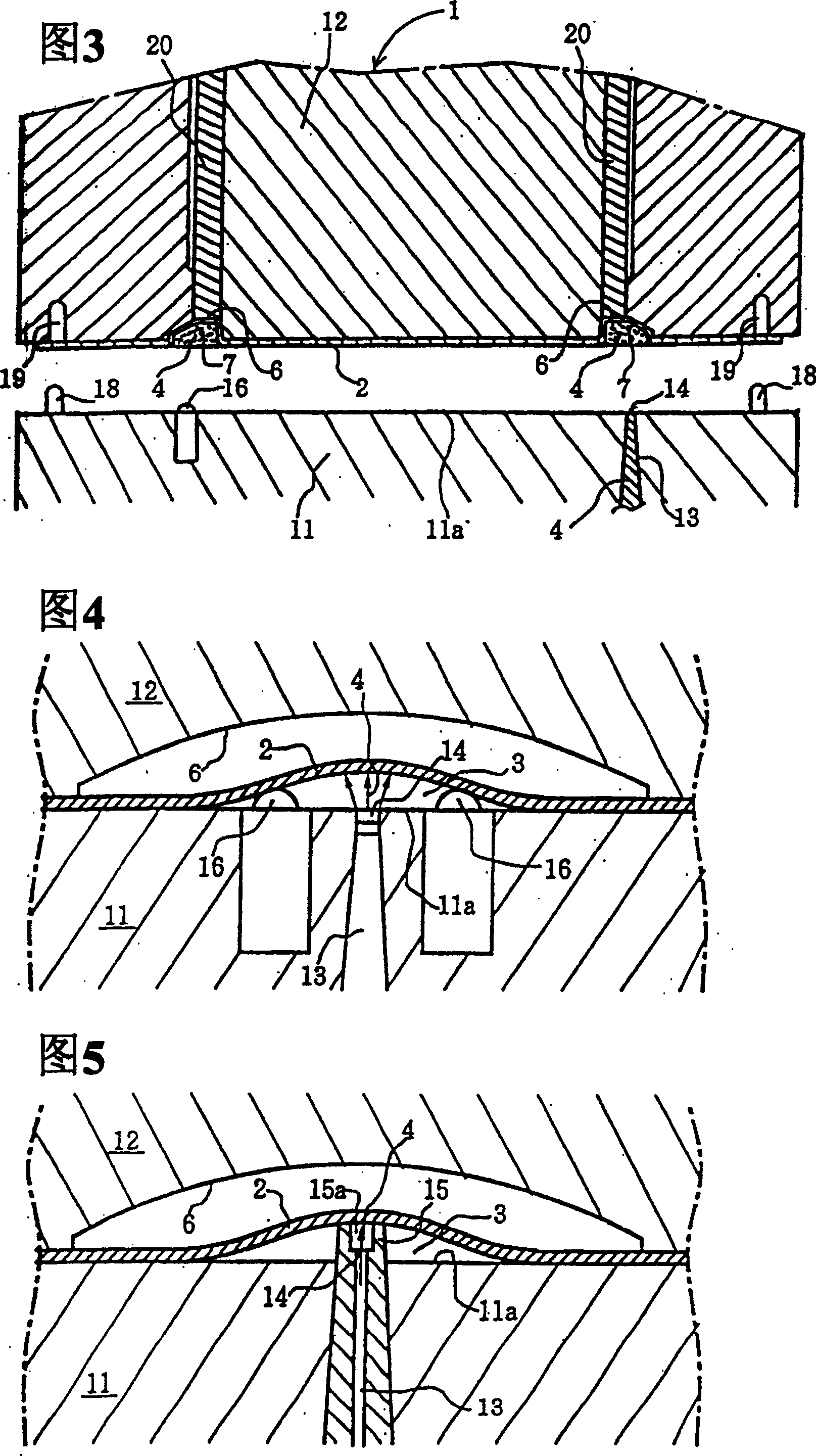

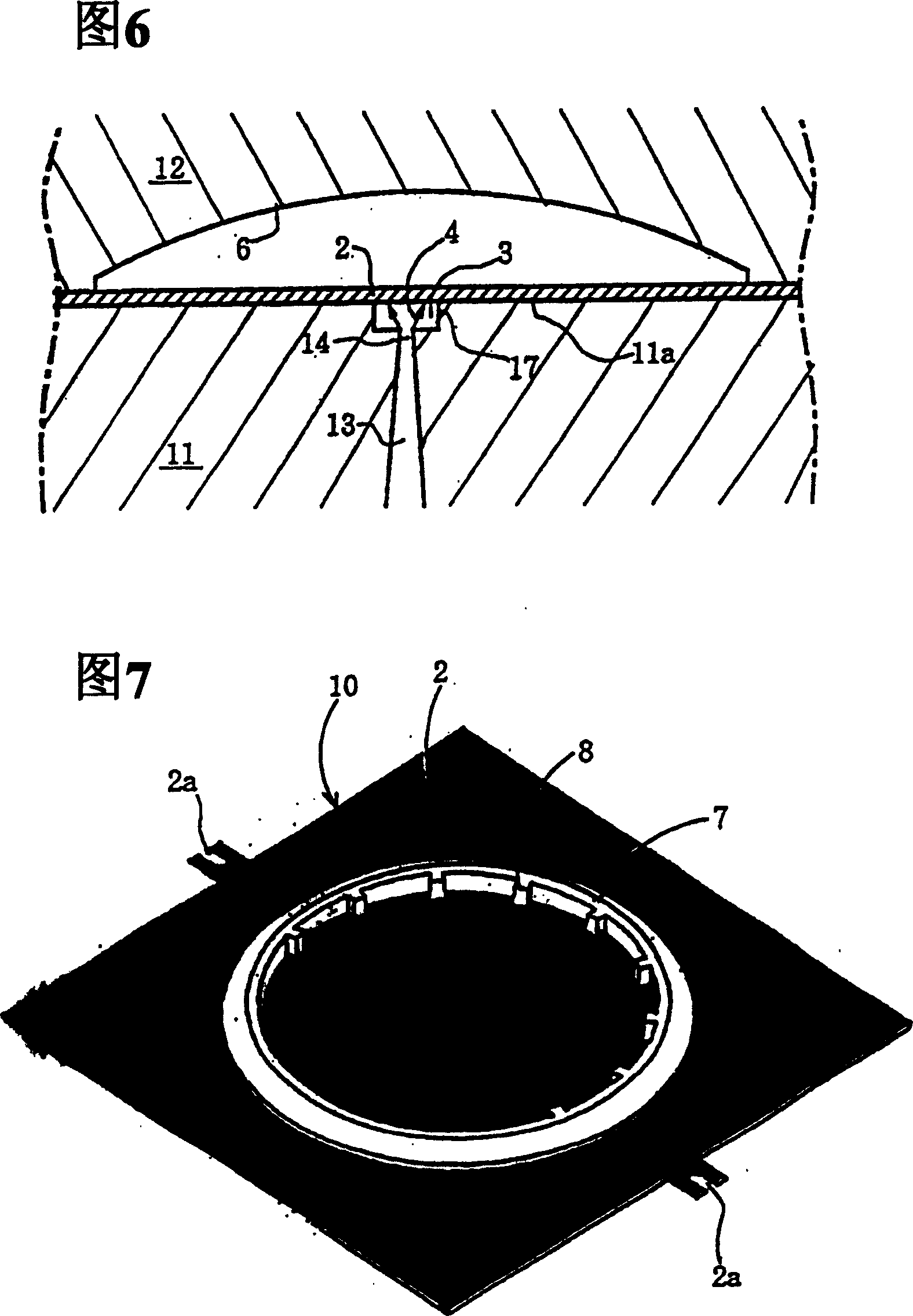

[0071] The shaped processed product 10 of this embodiment is the outer rings 24, 25 of an integrated (diagram) instrument panel equipped with three types of instruments such as a speedometer 21, a tachometer 22, and a fuel gauge 23 of an automobile as shown in FIG. The protruding portion 8 for the connected scale is shaped into the synthetic resin plate 2 on which the above-mentioned dial plate is printed as the protruding partial shape 7 . However, no convex portion for scale is formed on the outer ring 25 of the fuel gauge 23 , and the display of the water temperature gauge 27 is formed in the ring 25 in addition to the fuel gauge 23 .

[0072] The outer rings 24 and 25 of the instruments in the above-mentioned instrument panel 30 are shaped into a protruding shape with a metallic style appearance, and transparent polycarbonate is used as the synthetic resin plate 2, and metal is carried out at the outer ring positions of each instrument on the plate. printing.

[0073] In ...

Embodiment 2

[0078] In addition, in the dashboard 30 shown in FIG. 8 , instead of the metal rings (outer rings 24 , 24 , 25 ) of Example 1, the visible light transmittance is transferred to a transparent polycarbonate sheet as the synthetic resin sheet 2. 30% metal sheet such as aluminum, and then use the above-mentioned method to shape the ring shape of the protruding shape, so that the ring shape can be given a metallic appearance and can be backlit.

Embodiment 3

[0080] In addition, in the instrument panel 30 shown in FIG. 8 , when forming the characters and various warning symbols 28 in the instruments 21, 22, and 23 that can be backlit, transparent polycarbonate printed with black on the surface is used. The paint film thickness of the text part and pattern appearance part on the board is 5-7 μ for the single-color light-transmitting part, and 14.8 μ for the double-color overlapping light-shielding part. The warning symbols 28 and the like are made into outline characters or hollow shapes, whereby backlighting can be realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com