Vibrating mechanism

A technology of vibration mechanism and main rocker arm, used in non-electric welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of impact, damage to the mechanical system of the equipment, and deterioration of the quality of the welding seam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

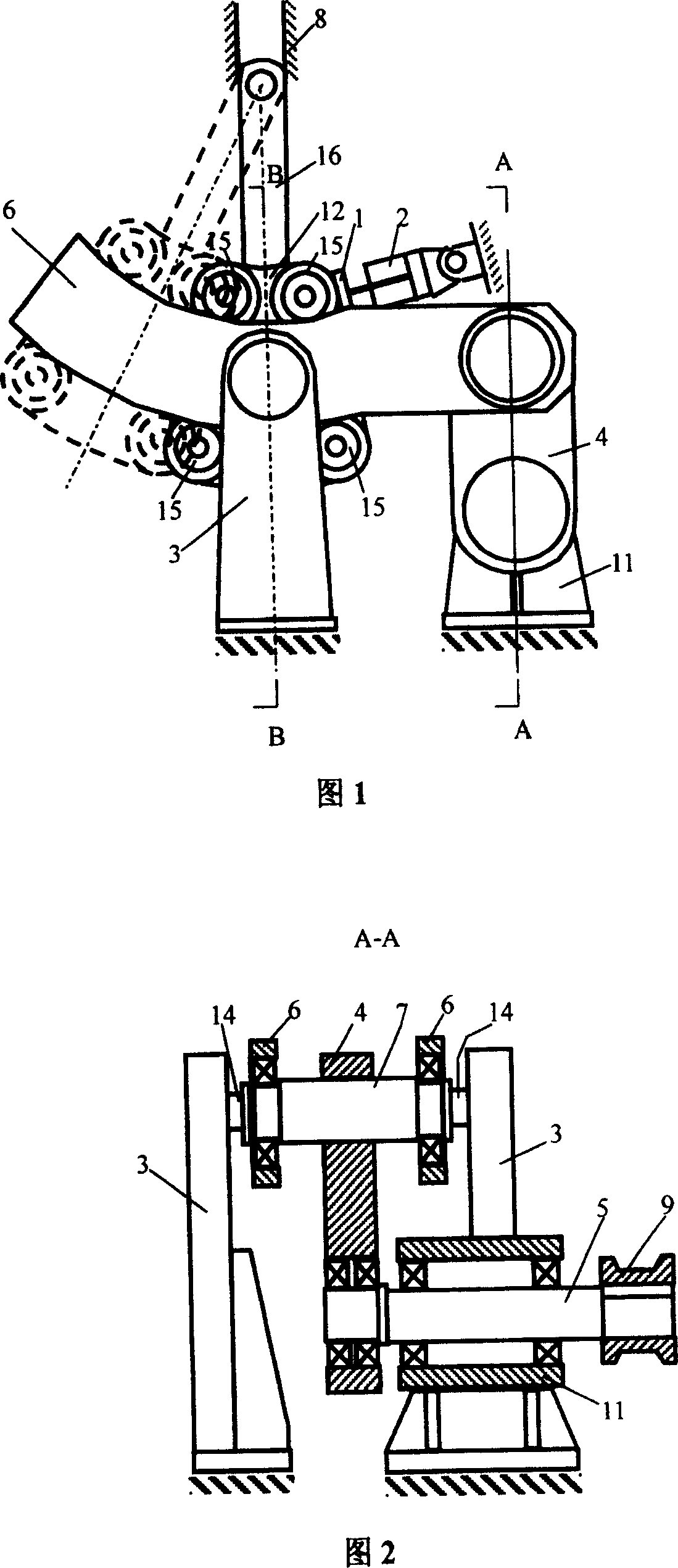

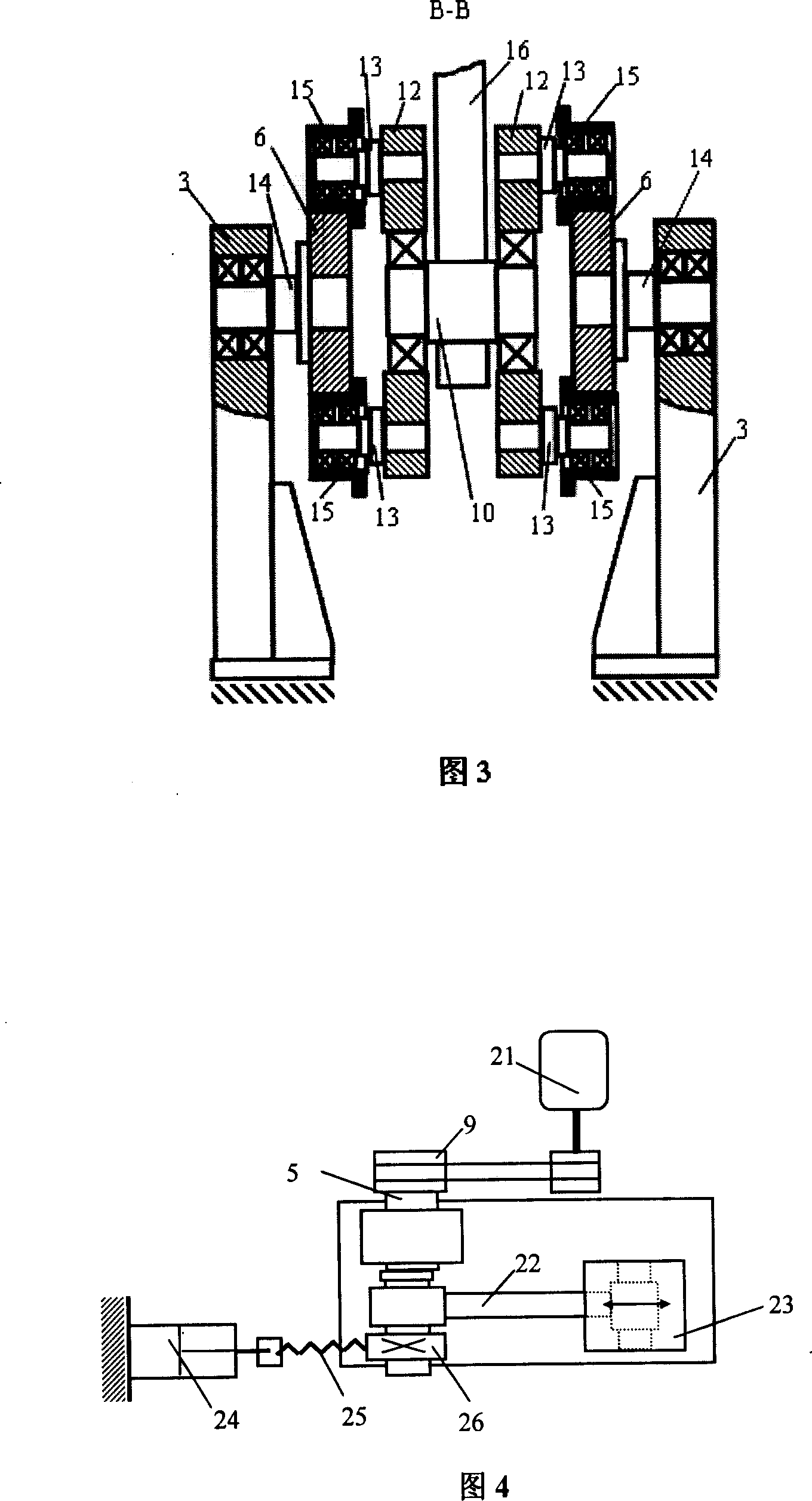

[0015] Referring to Figures 1 to 3, the eccentric shaft 5 is supported by the eccentric shaft support 11 through a pair of bearings, the pulley 9 is connected with the non-eccentric end of the eccentric shaft 5 through a flat key, and one end of the drive rod 4 is connected to the eccentric shaft 5 through a pair of bearings. The other end of the drive rod 4 is connected to the main rocker arms 6 on both sides through the main rocker arm connecting shaft 7, and the two ends of the main rocker arm connecting shaft 7 are respectively symmetrical to the main rocker arm 6 through a bearing. The two parts are connected. The pulley 9 is driven to rotate by the motor through the belt, and the eccentric shaft 5 drives the driving rod 4 to generate up and down reciprocating motion. The rotation center position of the main rocker arm 6 is respectively connected with two symmetrical parts of the main rocker arm support frame 3 through two main shafts 14 . Therefore, when the driving rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com