Camera provided with optical finder

A technology of optical viewfinder, camera, applied in the field of camera

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

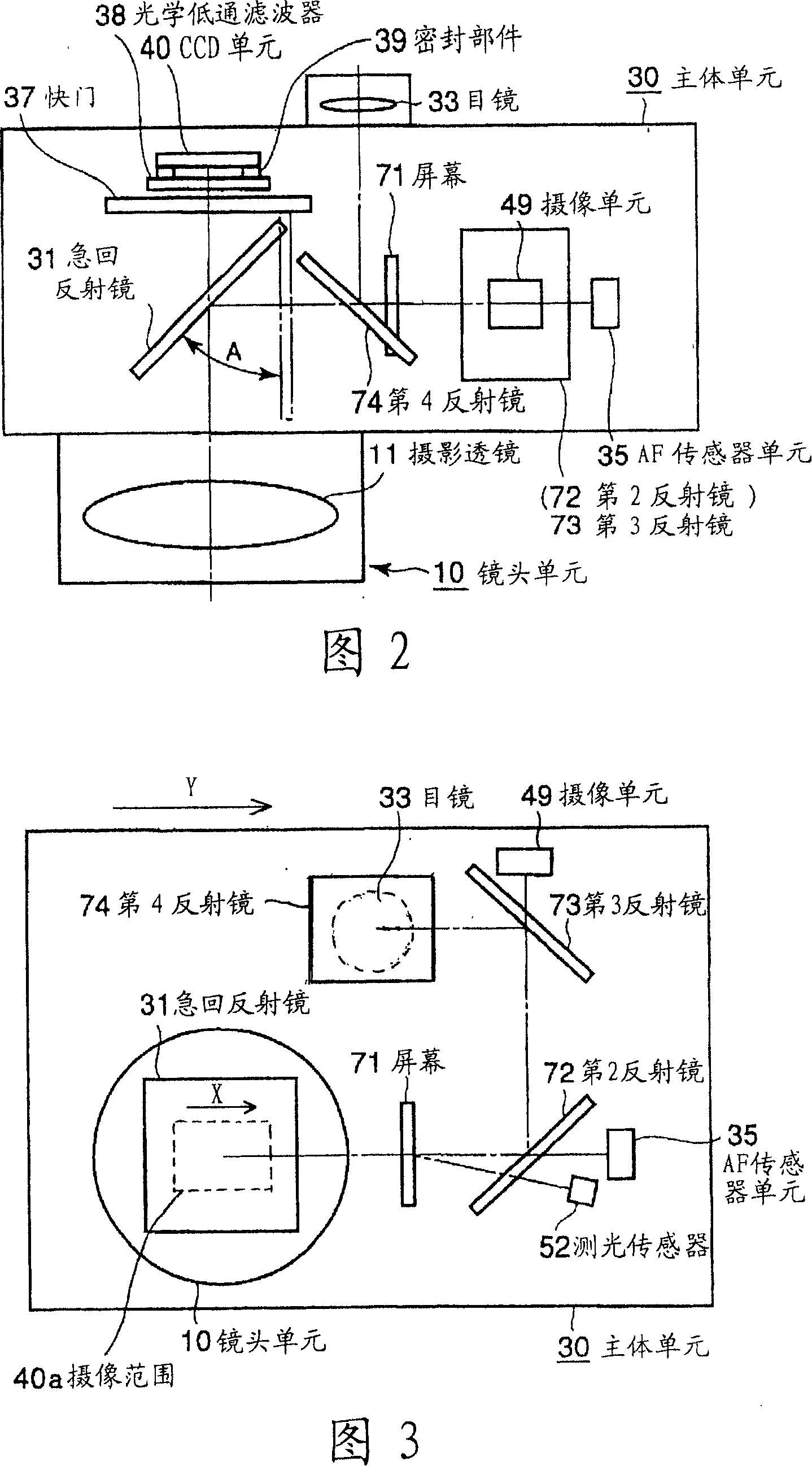

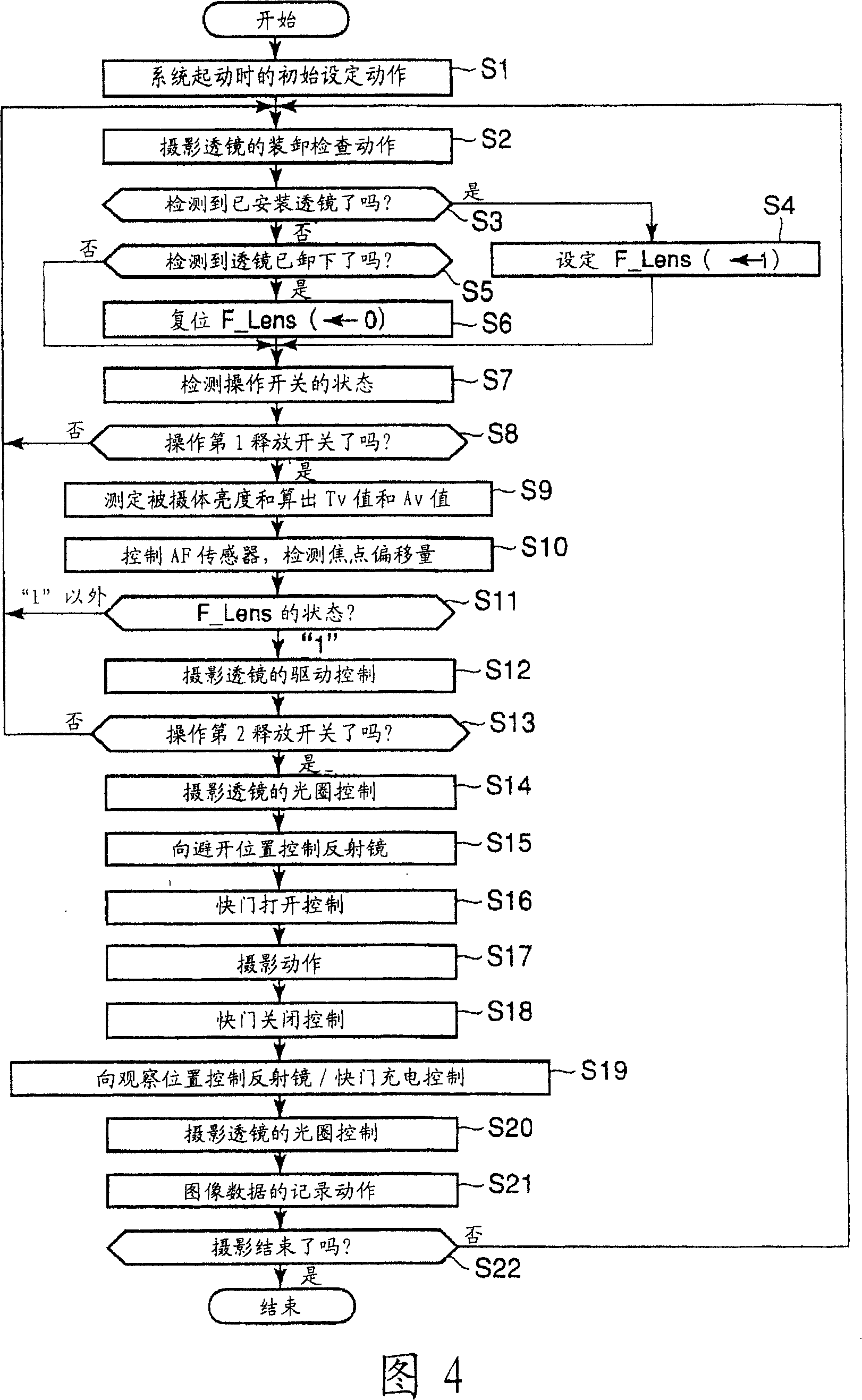

[0016] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

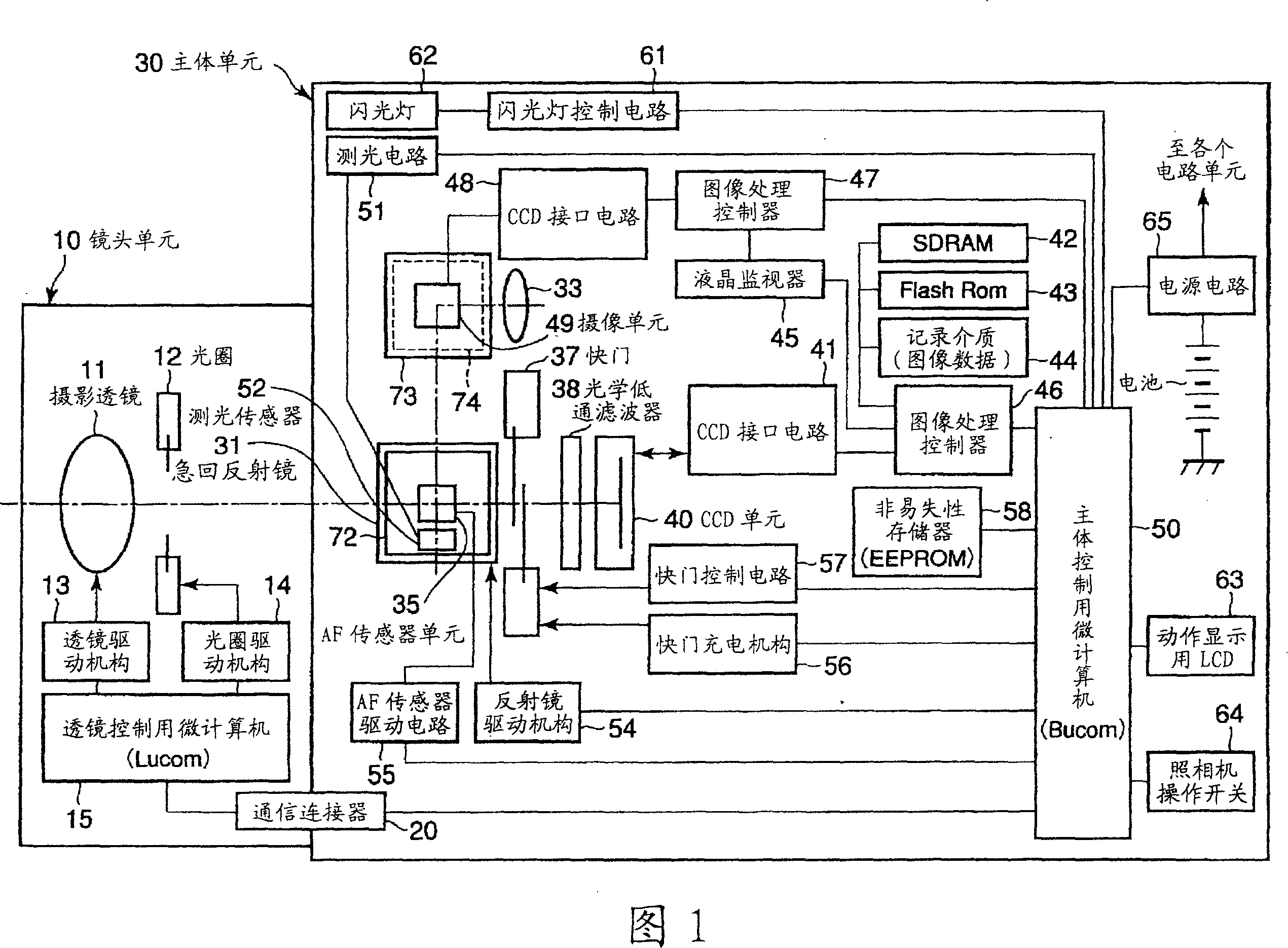

[0017] FIG. 1 is a block diagram showing a system configuration of a camera according to an embodiment of the present invention.

[0018] In FIG. 1 , the camera system is mainly composed of a lens unit 10 as an interchangeable lens and a main body unit 30 as a camera body, and a desired lens unit 10 is set to be detachable from the front of the main unit 30 .

[0019] The above-mentioned lens unit 10 can be freely attached and detached through an unillustrated lens mount provided on the front of the above-mentioned main body unit 30 . In addition, the lens unit 10 is composed of a photographic lens 11 , a diaphragm 12 , a lens driving mechanism 13 , a diaphragm driving mechanism 14 , and a microcomputer (hereinafter abbreviated as Lμcom) 15 for lens control.

[0020] The imaging lens 11 described above is driven in the optical axis direction by a DC motor (not shown) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com