Motor with rotor balancer

A rotor balance and motor technology, applied in the field of motors, can solve the problems of easy structure loosening, noise generation, magnetic flux leakage, etc., and achieve the effect of improving rotation balance, improving floating height and vertical vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A rotor balancing device according to a preferred embodiment of the present invention will be described below with reference to related drawings. The same components will be represented by the same symbols.

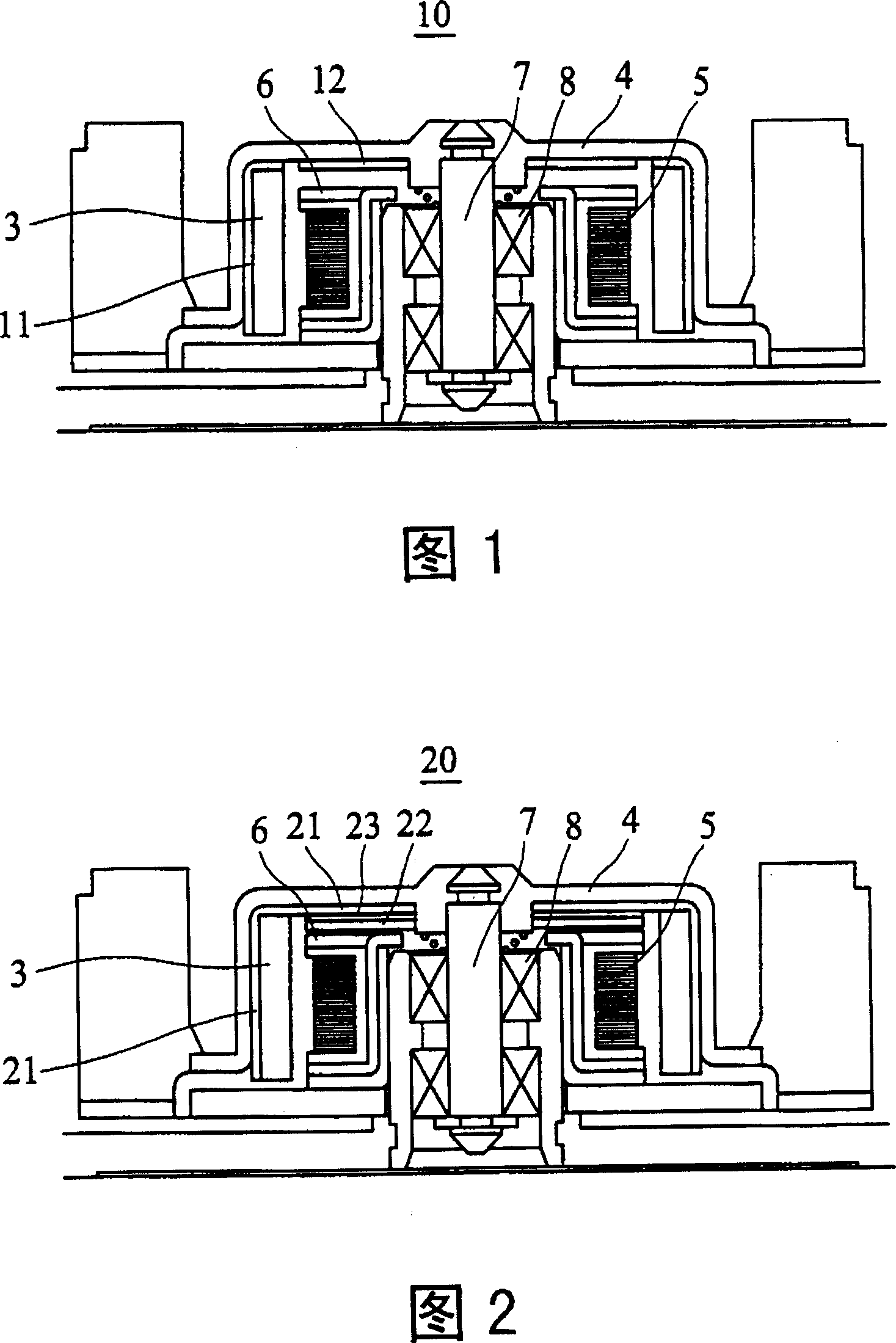

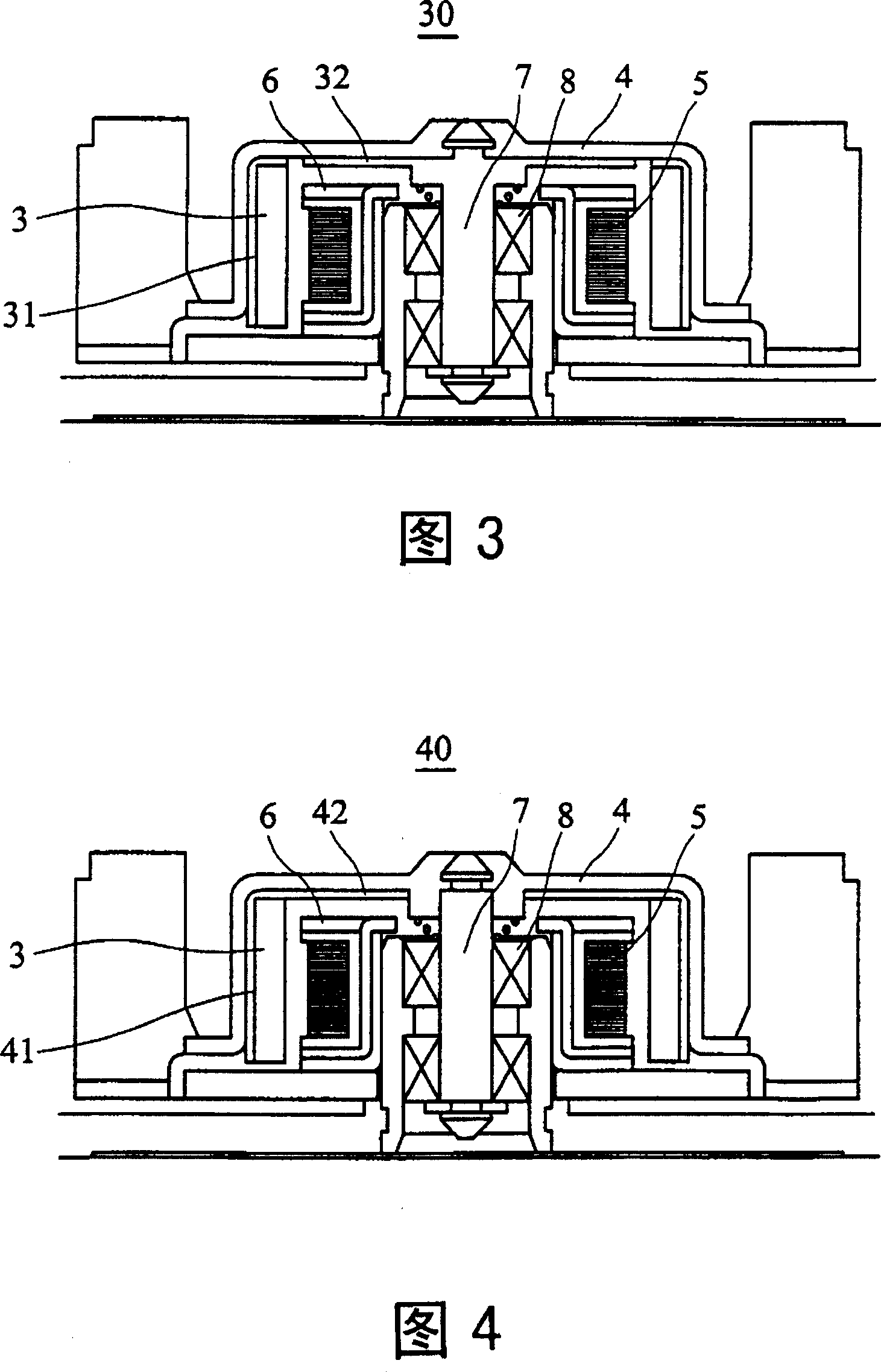

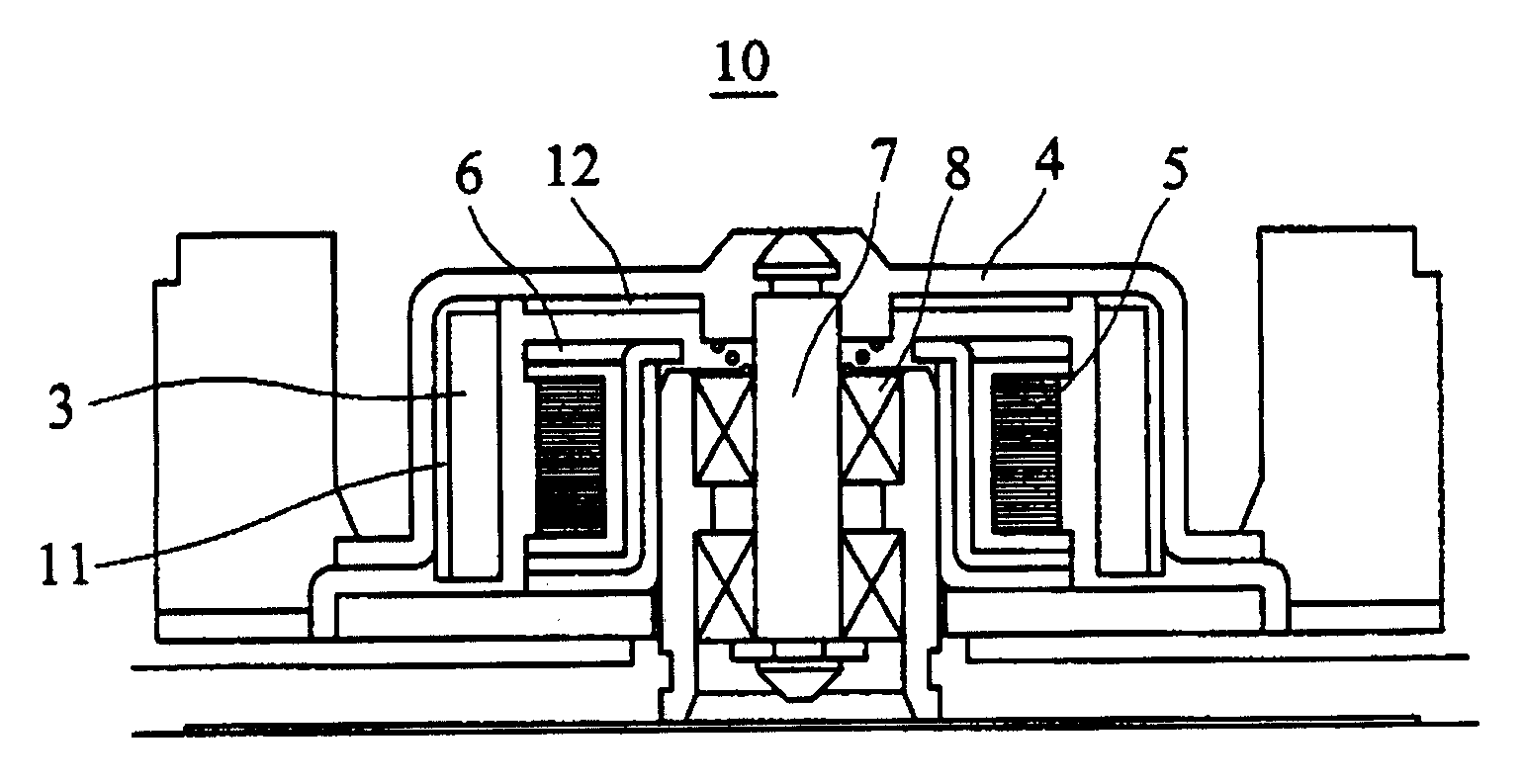

[0035] Referring to Fig. 1, the motor 10 with rotor balancing device of the present invention comprises an iron shell 11, a magnetically conductive sheet 12, a magnetic tape 3 and a fan blade housing 4, wherein the fan blade housing 4 is slightly cup-shaped, and the outer ring is provided with A plurality of fan blades; the iron shell 11 is a ring, installed on the inside of the fan blade shell 4, and extends slightly towards the center near the top of the fan blade shell 4; the magnetic tape 3 ring is located inside the iron shell 11; The magnetic sheet 22 is directly disposed on the inner top of the fan blade casing 4 and is not in contact with the iron casing 11 . The stator includes a coil 5 and a silicon steel sheet 6 . The rotor balancing device 10 cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com