AC high-voltage high-power electric tool motor

A power tool, high-power technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of general insulation effect and balance performance, general rotor balance, poor high-voltage test effect, etc., to achieve remarkable insulation effect and insulation. The effect and the balance effect are good, and the copper loss of the rotor is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

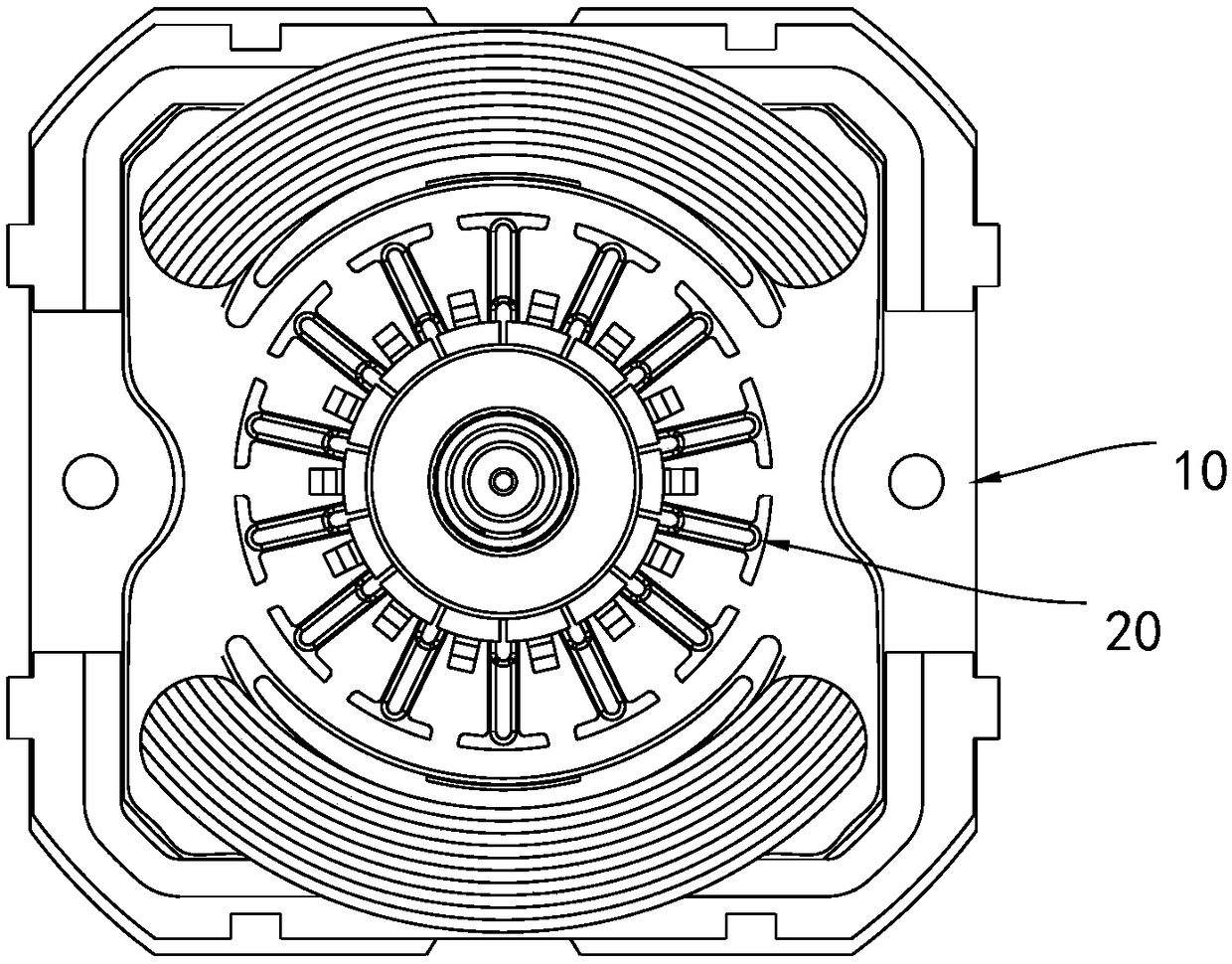

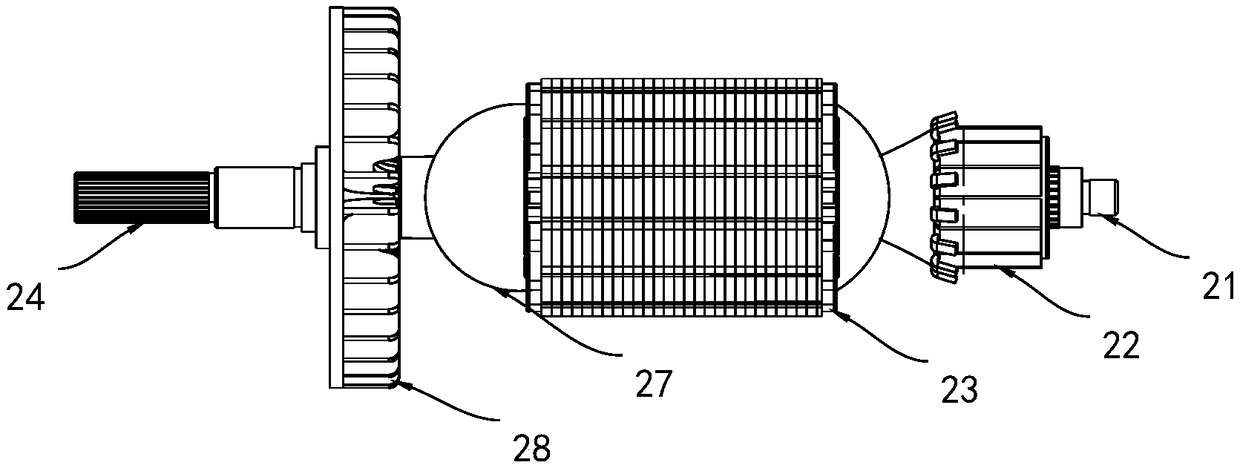

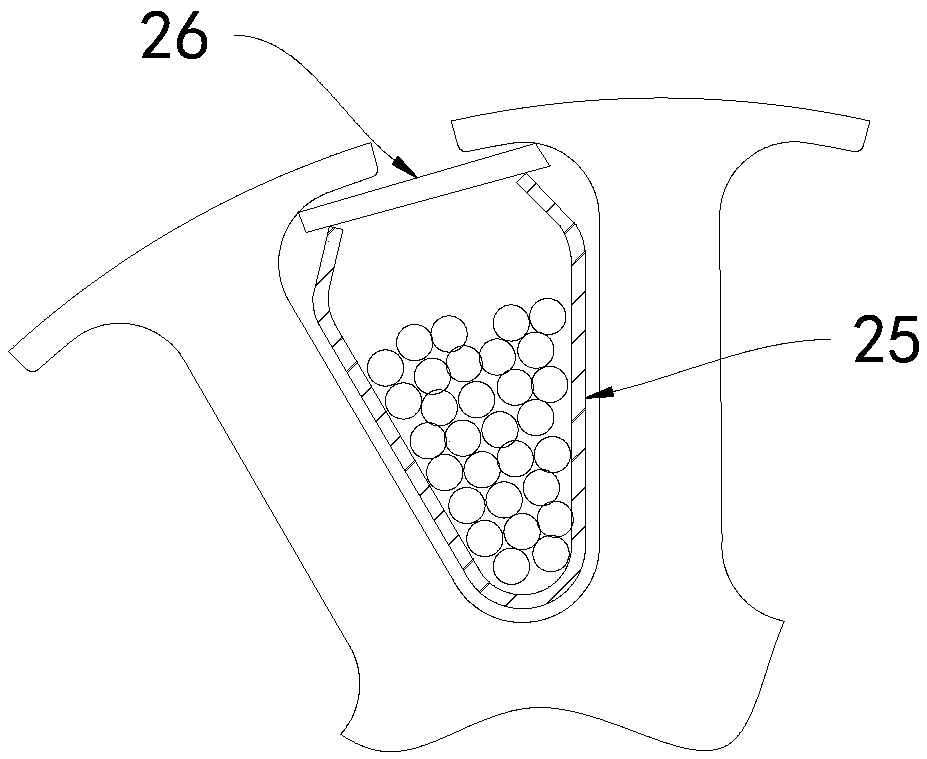

[0022] Embodiment: An AC high-voltage high-power electric tool motor includes a stator 10 and a rotor 20; the rotor 20 includes a rotor shaft 21, and the rotor shaft 21 is provided with a commutator 22, a rotor chip 23 and an output shaft 24 in sequence, The number of slots of the rotor chip 23 is 14, the inner wall of the slot is provided with insulating paper 25, the insulating paper 25 is provided with an enameled wire, and the notch is provided with a baffle 26 matched with the insulating paper 25; the stator 10 includes a The stator core 11 is matched with the rotor core 23 . The stator core 11 is formed by stacking square steel sheets with holes one by one. The output shaft 24 is a spline shaft.

[0023] The insulating paper 25 is V-shaped, and the two ends of the insulating paper 25 are folded inwardly.

[0024] The inner wall of the hole of the stator chip 11 is provided with a skeleton 12, the inner side of the skeleton 12 is provided with an end plate 13 surroundin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com