Overcompression prevention device for tubine compressor

A scroll compressor and overcompression technology, applied in the direction of machines/engines, etc., to achieve the effects of improving efficiency, reducing volume, improving combination and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

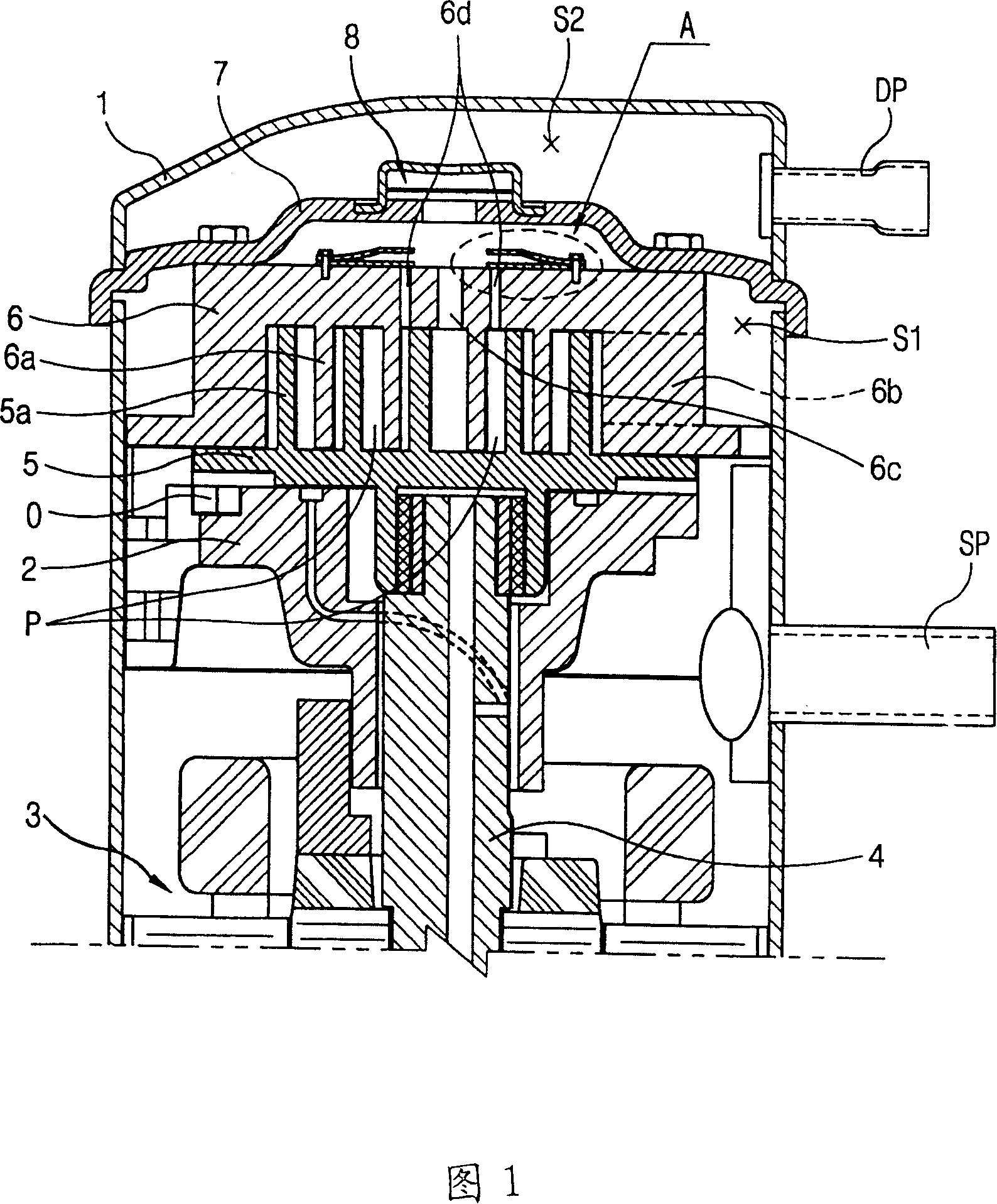

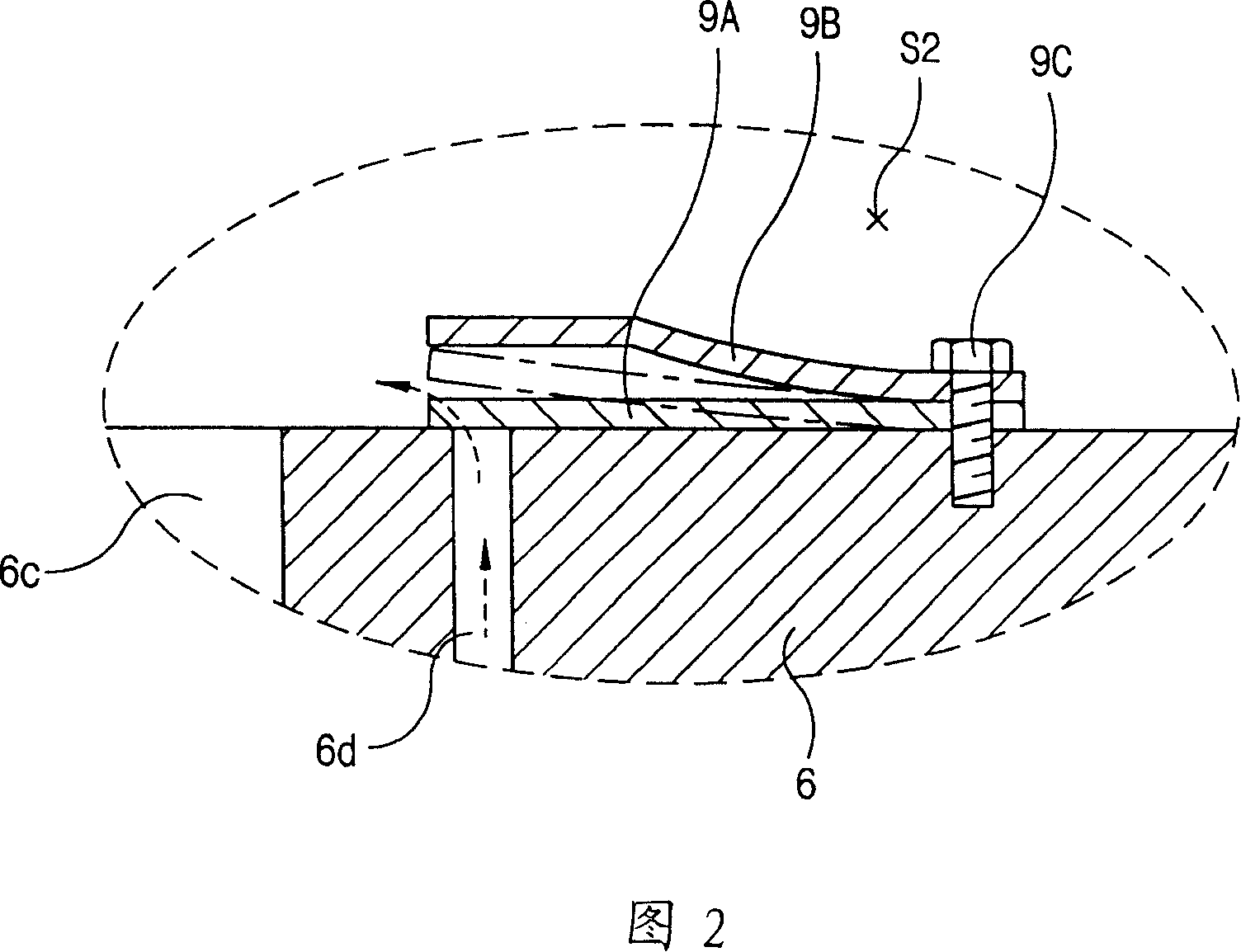

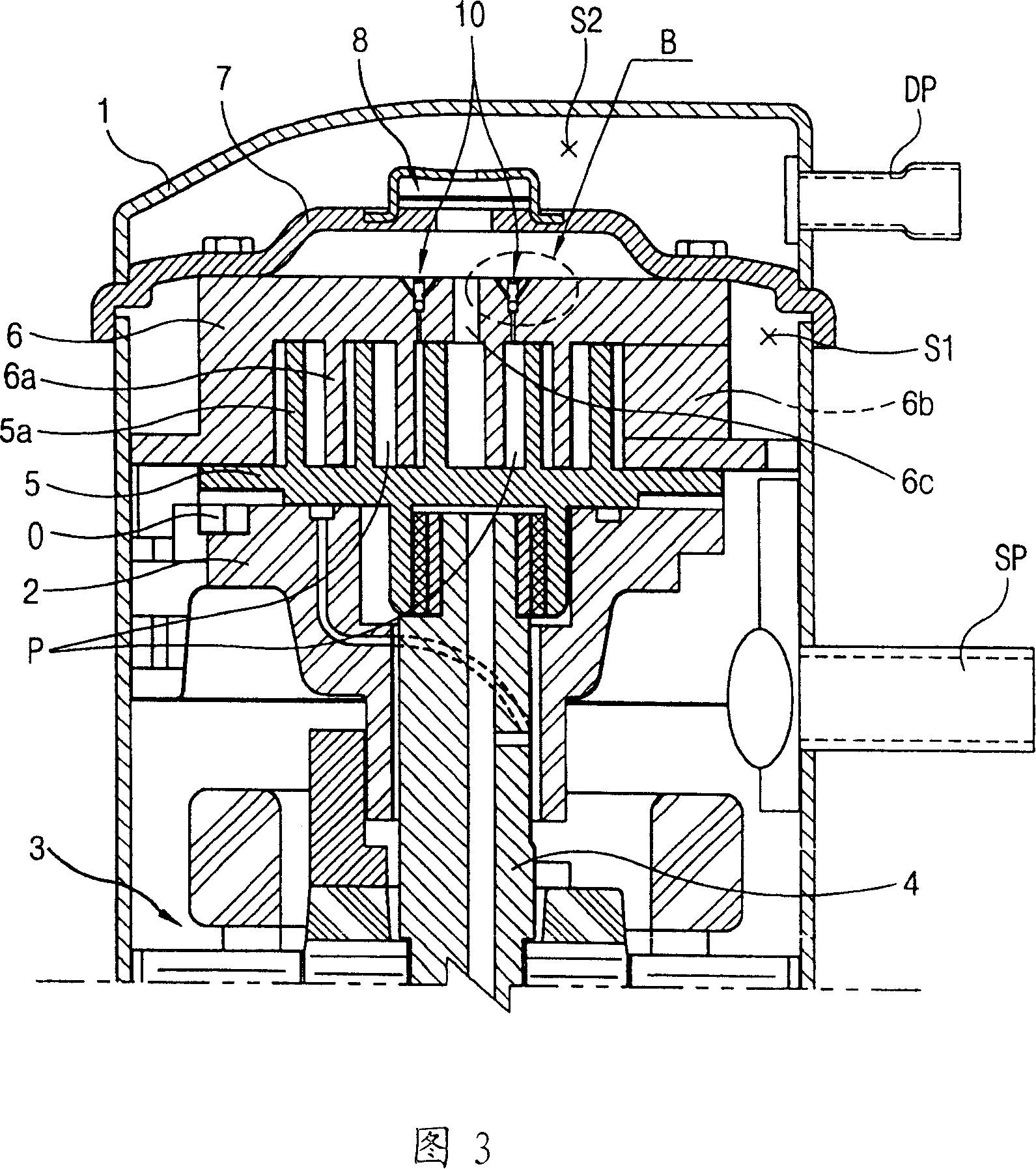

[0058] The specific implementation, structure, features and effects of the anti-overcompression device for a scroll compressor according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0059] Please refer to Fig. 3, Fig. 4, Fig. 5, Fig. 6, and Fig. 7. Fig. 3 is a partial cross-sectional view of the scroll compressor of the present invention, and Fig. 4 is part "B" of Fig. 3, that is, the row of the present invention. As for the sectional view of the gas valve device, Fig. 5 is a three-dimensional exploded view of the exhaust valve device of the present invention, and Fig. 6 and Fig. 7 are sectional views of the working states of each part of the exhaust valve device of the present invention. The anti-overcompression device of the scroll compressor of the present invention mainly includes: a casing 1 having a gas suction pipe SP and a gas discharge pipe DP; Illustrated); the driving motor 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com