Blazed grating light valve

A grating and projecting light technology, applied in the direction of diffraction grating, optics, optical components, etc., can solve the problems of difficult and expensive manufacturing of light modulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

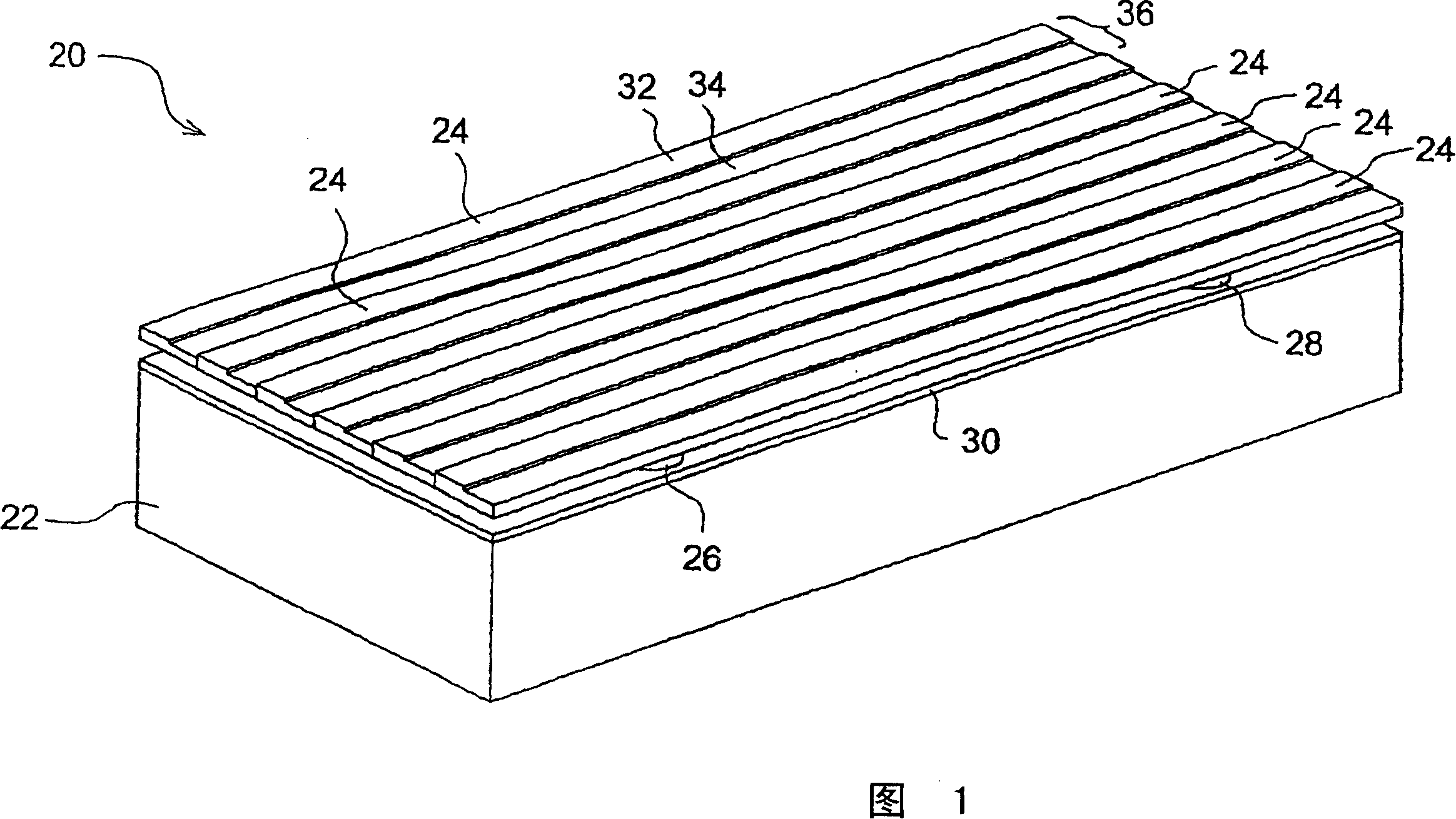

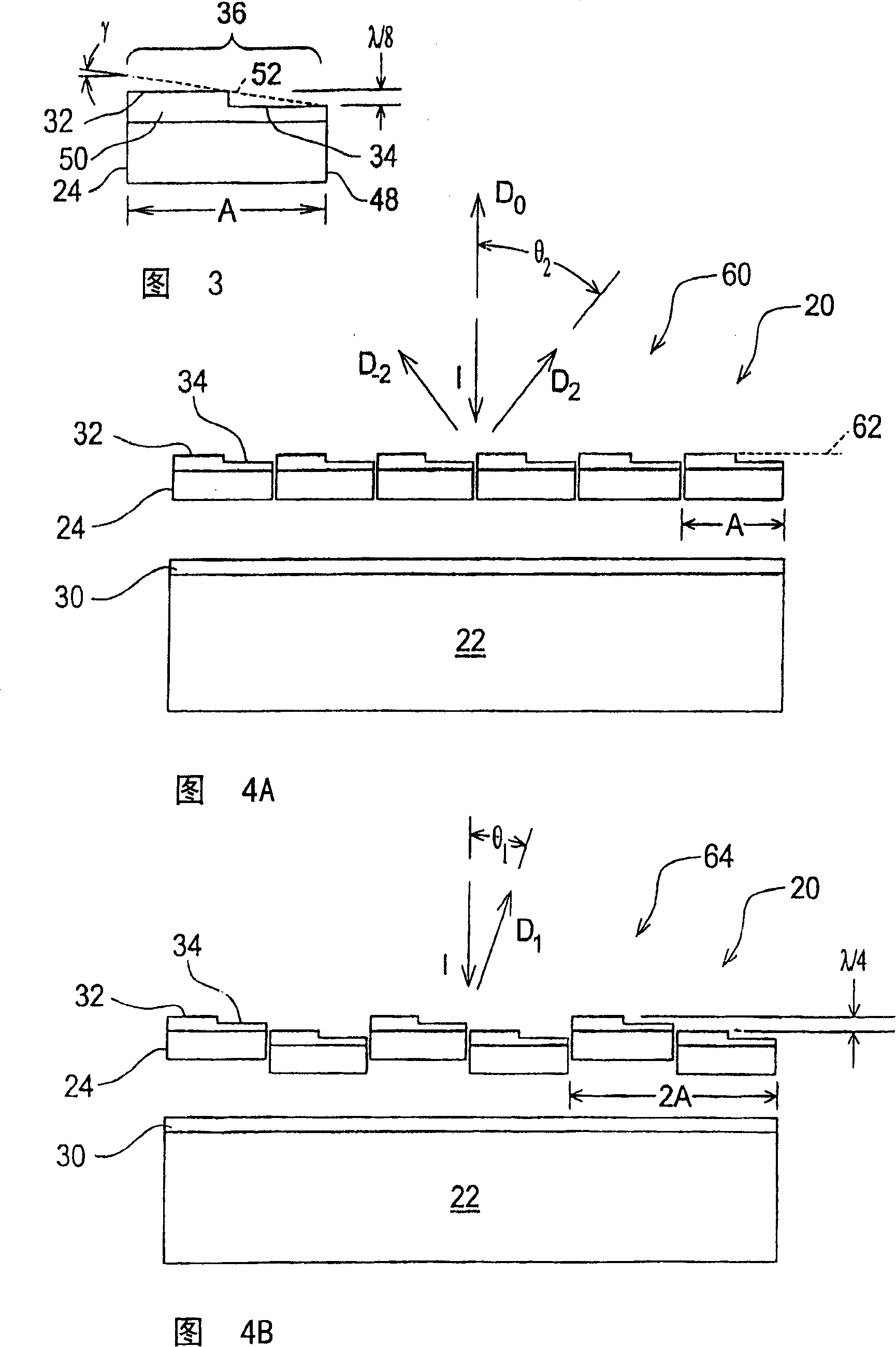

[0029] The preferred light-emitting grating light valve 20 shown in isometric projection in FIG. 1 includes a base 22, elongated members 24, first studs 26 (one shown) and second studs 28 (one shown). Substrate 22 includes a first conductor 30 . Preferably, each elongated member 24 includes a first surface 32 and a second surface 34, both of which reflect light and form a light emitting profile 36 for each elongated member 24. Each elongated member 24 is coupled to the base 22 with a first post cap 26 and a second post cap 28 . Each elongated member 24 is also preferably coupled to base 22 at its first and second ends (not shown).

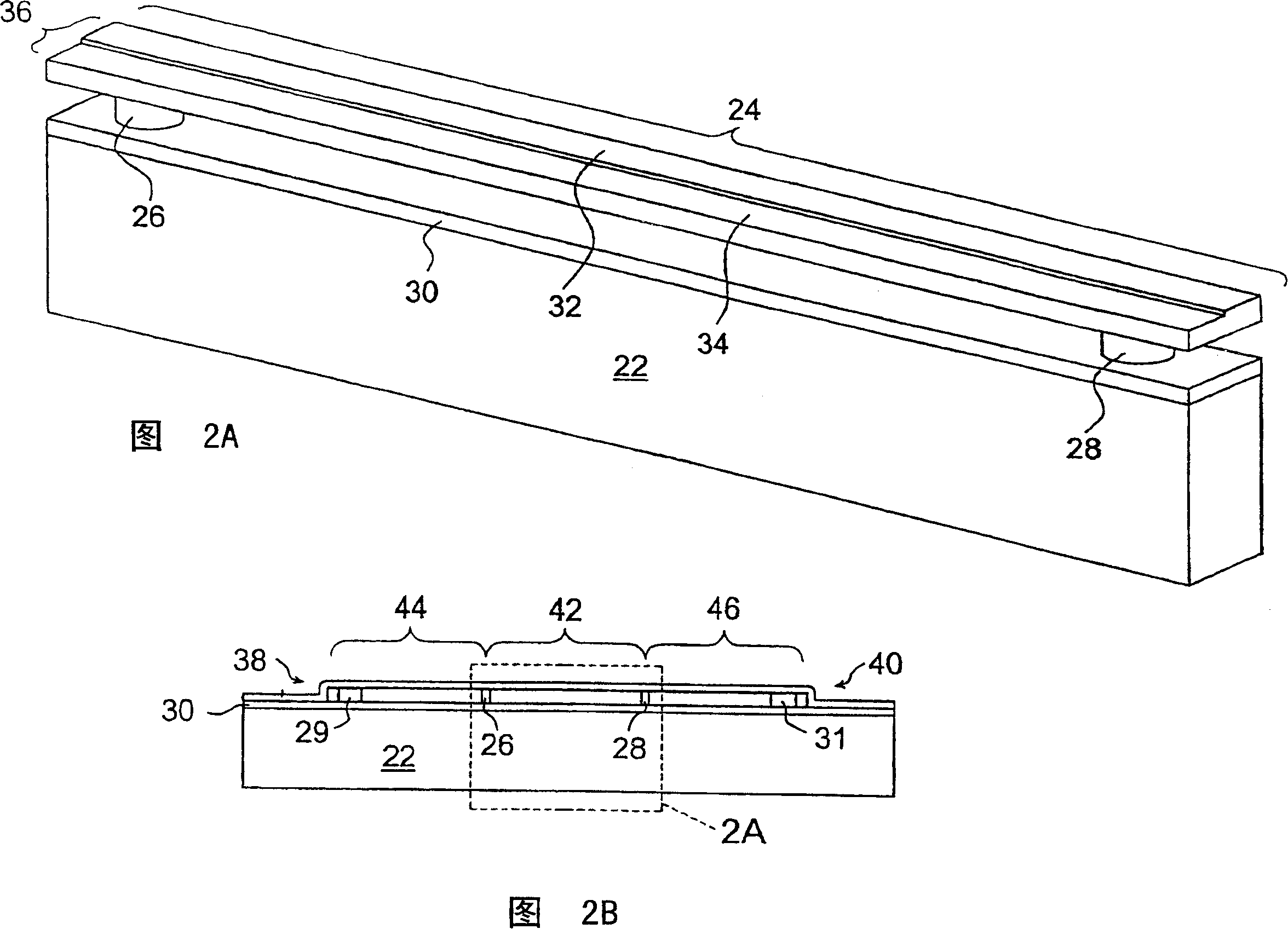

[0030] An elongate member 24 and a portion of base 22 are further shown in isometric projection in FIG. 2A. Elongated member 24 includes first and second surfaces 32 and 34 that both reflect light to form light emitting profile 36 . Elongated member 24 is coupled to the substrate by first and second studs 26 and 28 and is coupled at first and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com