Flow passage sealing of turbine and streamline structure thereof

A turbine and flow channel technology, applied in the field of flow channel structure of steam turbines, can solve the problems of gas power loss, increase radial intrusion flow, increase leakage flow rotor suction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

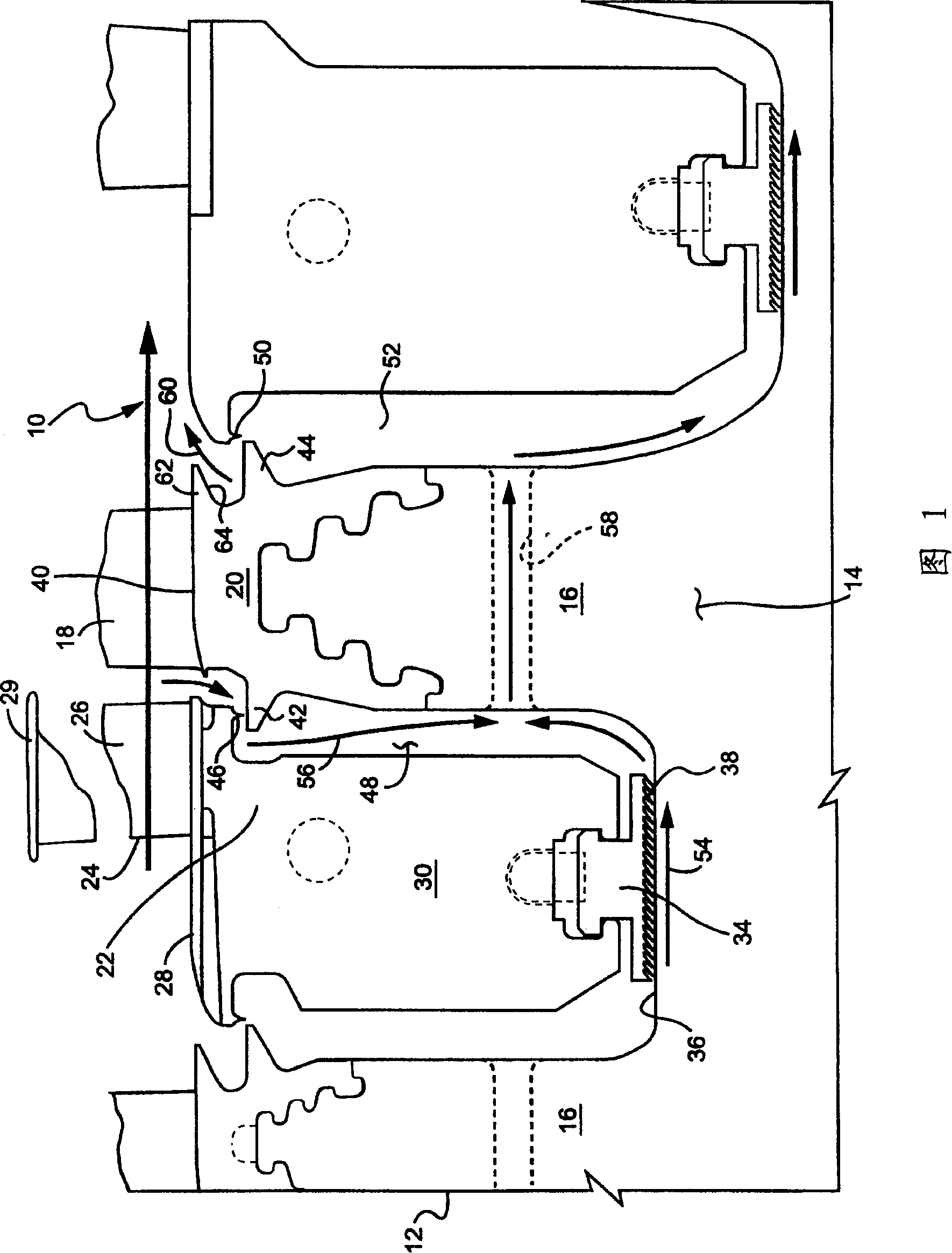

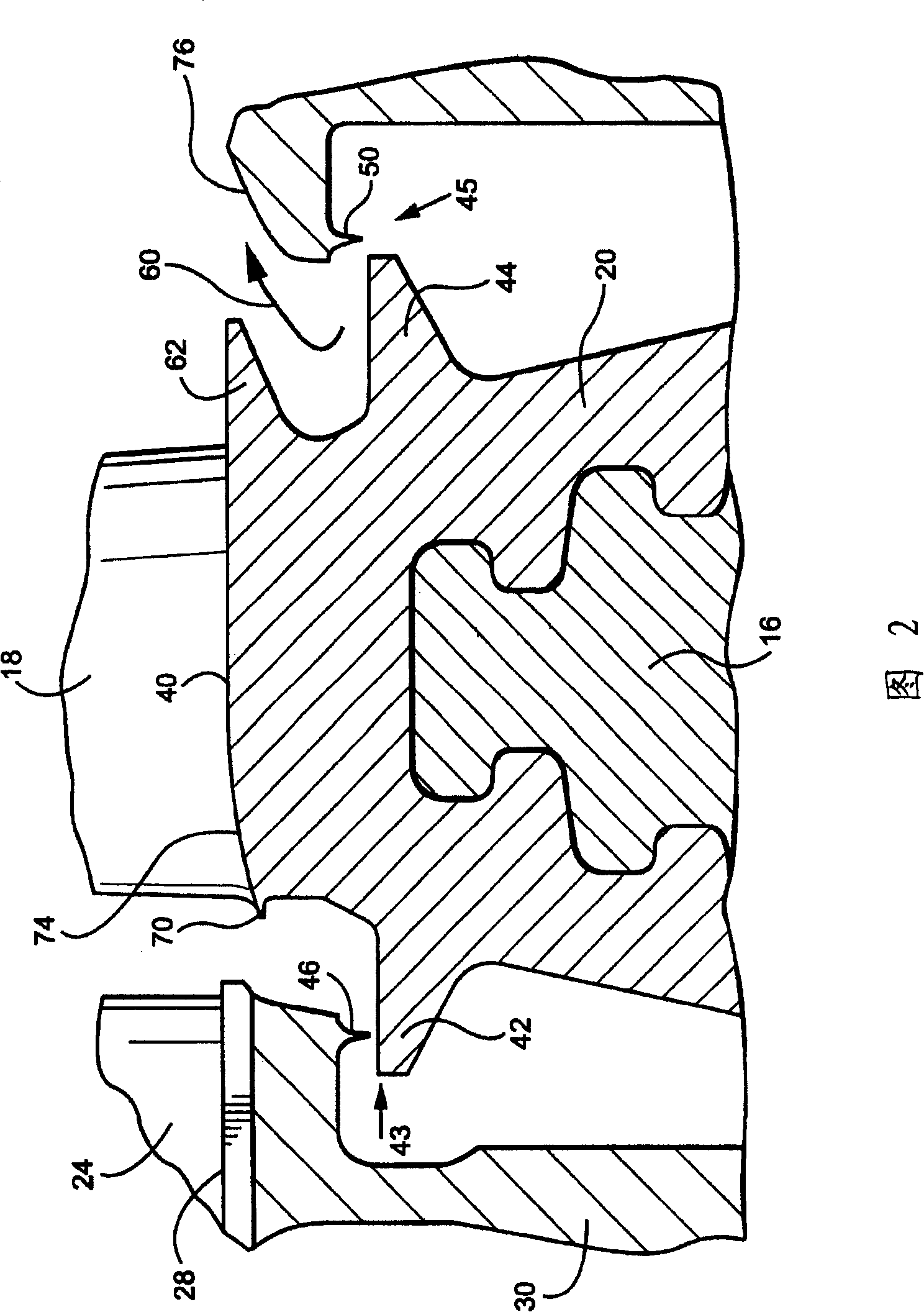

[0012] Referring now to the drawings, and in particular to FIG. 1 , there is shown an interior or root region of the flow path of a turbine 12 , indicated by arrows and generally identified by the reference numeral 10 . An energetic fluid, such as steam, flows along the channel 10 and in the direction of the arrow. The turbine 12 includes a rotor 14 rotatable about a horizontal axis and a plurality of axially spaced rotor wheels 16 each carrying a plurality of circumferentially spaced blades 18 mounted to dovetails at the blade bases. The tail tenon 20 is used to form a tenon connection with the rotor impeller 16 . Also shown in FIG. 1 is a stationary part 22 of the turbomachine comprising an array of axially spaced nozzles 24 . Each array of nozzles 24 has circumferentially spaced stationary airfoils 26 mounted between an inner rim or ring 28 and an outer rim or ring 29 . The nozzle also has an inner web 30 between the rotor wheel and the dovetail 20 of the axially adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com