Method for extracting lithium carbonate from sodium aluminate solution in alumina factory

A kind of technology of alumina plant and alumina, which is applied in the direction of lithium carbonate; The effect of easy quality control, simple process, and strong product market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

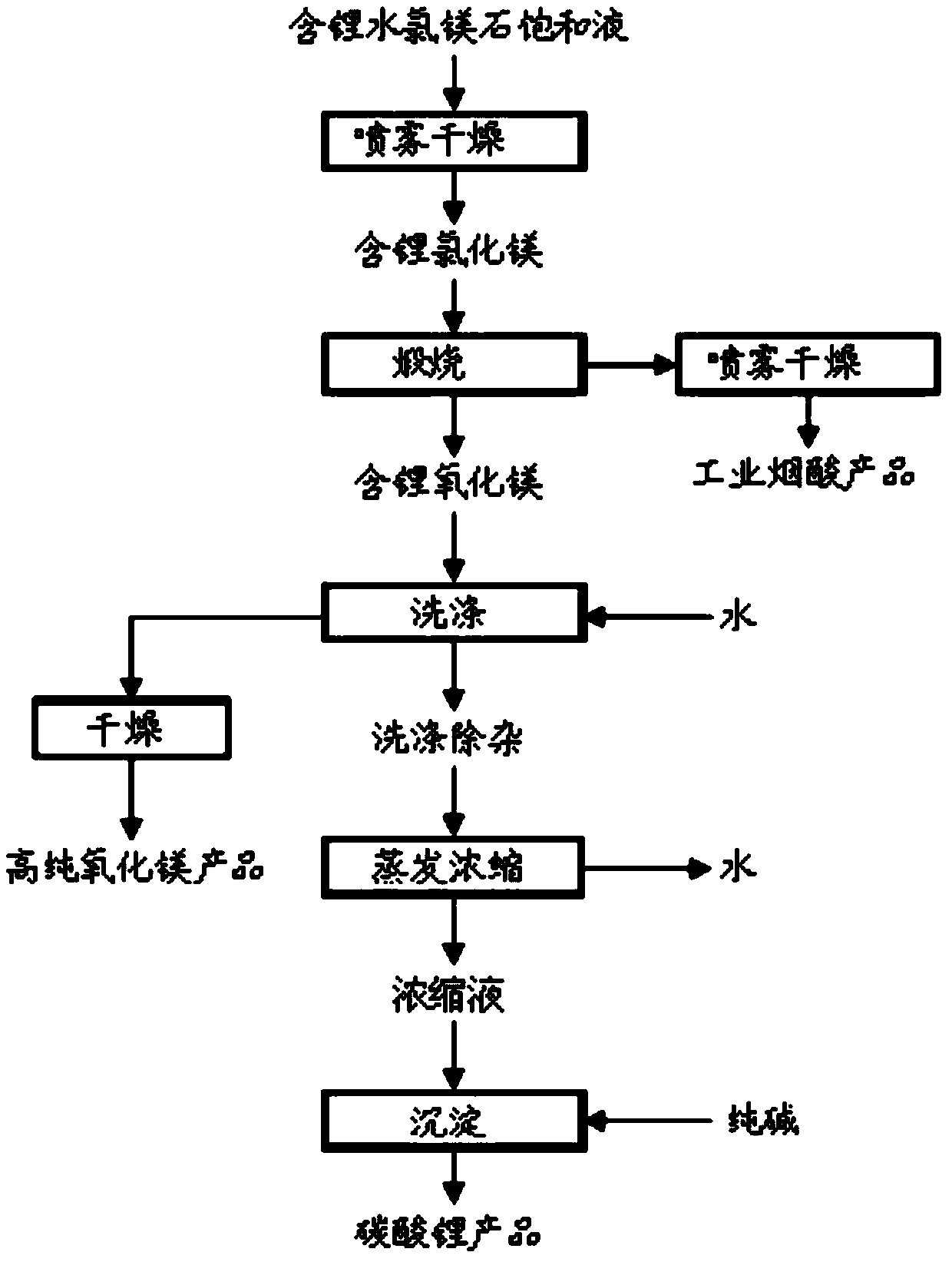

[0052] The method for extracting lithium carbonate from sodium aluminate solution in an alumina plant, the process flow chart is shown in 5, including:

[0053] 1. Use the semen of an alumina factory, the semen contains Nk=160g / L, Rp=1.08, Li + = 0.035g / L, temperature 75°C, add aluminum hydroxide seed crystal 2g / L, stir for 4 hours, separate aluminum hydroxide once, and return the semen to the Bayer factory. After testing, basically no Li can be detected in the semen after lithium precipitation + , indicating that the lithium precipitation reaction is relatively thorough.

[0054] 2. High-lithium primary aluminum hydrogen is washed twice in countercurrent with 2 times hot water. After washing, the aluminum hydrogen is beaten with 5 times hot water. It is soaked in a reactor at 200°C for 1 hour, and the slurry is separated after leaching.

[0055] 3. Redissolve hydrated alumina with Nk=242g / L, Rp=0.516 circulating mother liquor, temperature 220°C, time 30 minutes, RP=1.15 afte...

Embodiment 2

[0059] The method for extracting lithium carbonate from the sodium aluminate solution in an alumina plant, the process flow chart is shown in 6, including:

[0060] 1. Use the semen of an alumina factory, the semen contains Nk=160g / L, Rp=1.08, Li + = 0.035g / L, temperature 75°C, add aluminum hydroxide seed crystal 2g / L, stir for 4 hours, separate aluminum hydroxide once, and return the semen to the Bayer factory. After testing, basically no Li can be detected in the semen after lithium precipitation + , indicating that the lithium precipitation reaction is relatively thorough.

[0061] 2. Evaporate the mother liquor, containing Nk=175g / L, Rp=0.516, redissolve the aluminum hydrogen once, and make the ingredients according to the dissolved Rp=1.15, use the reactor to dissolve for 30 minutes at 220°C, adjust the dissolved semen to Nk=150g / L , lower the temperature to 75°C, add aluminum hydroxide seed crystal 2g / L, carry out a stage of decomposition, a period of decomposition time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com