Compressor

A compressor and exhaust gas technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as power consumption of fans and unsatisfactory energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

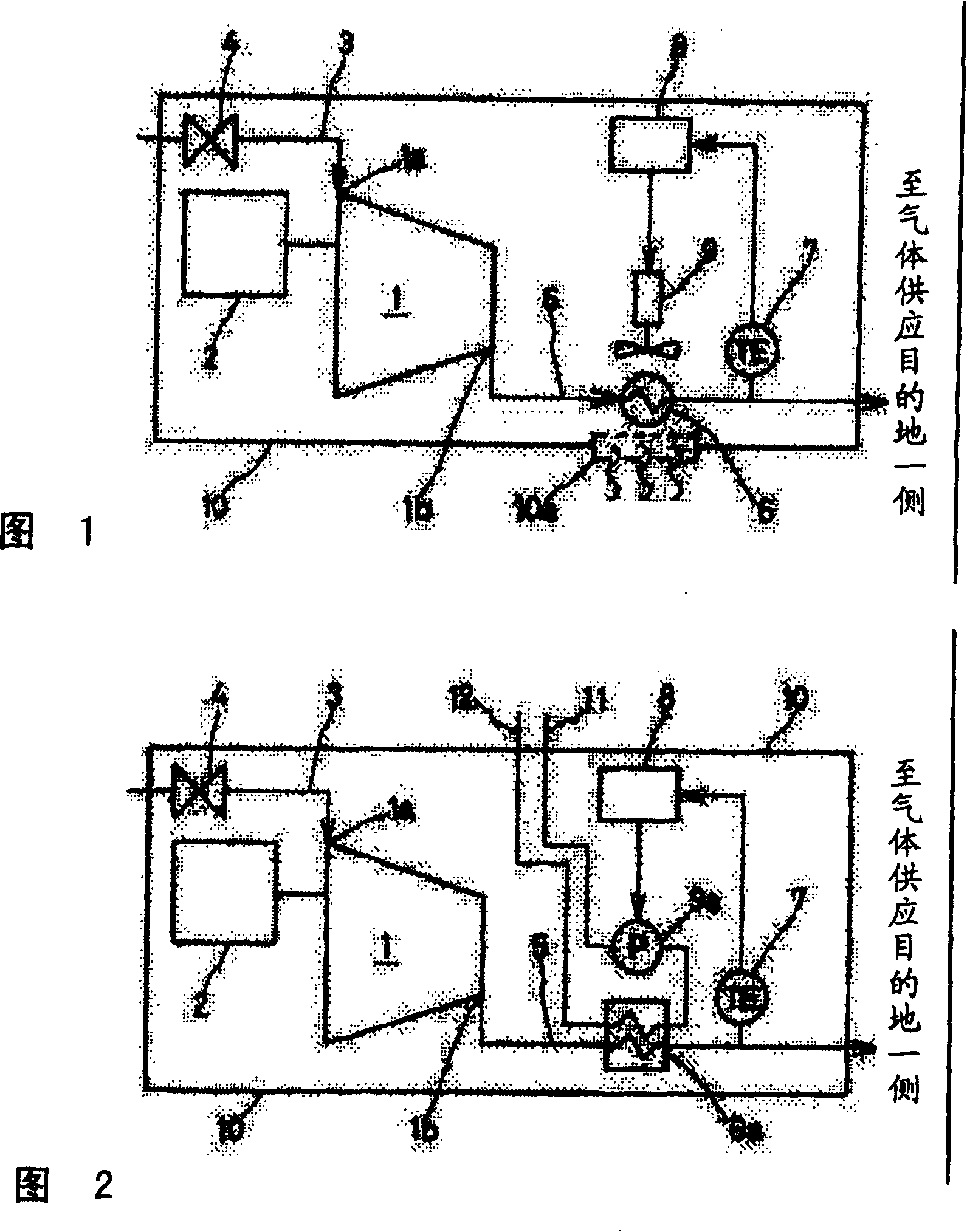

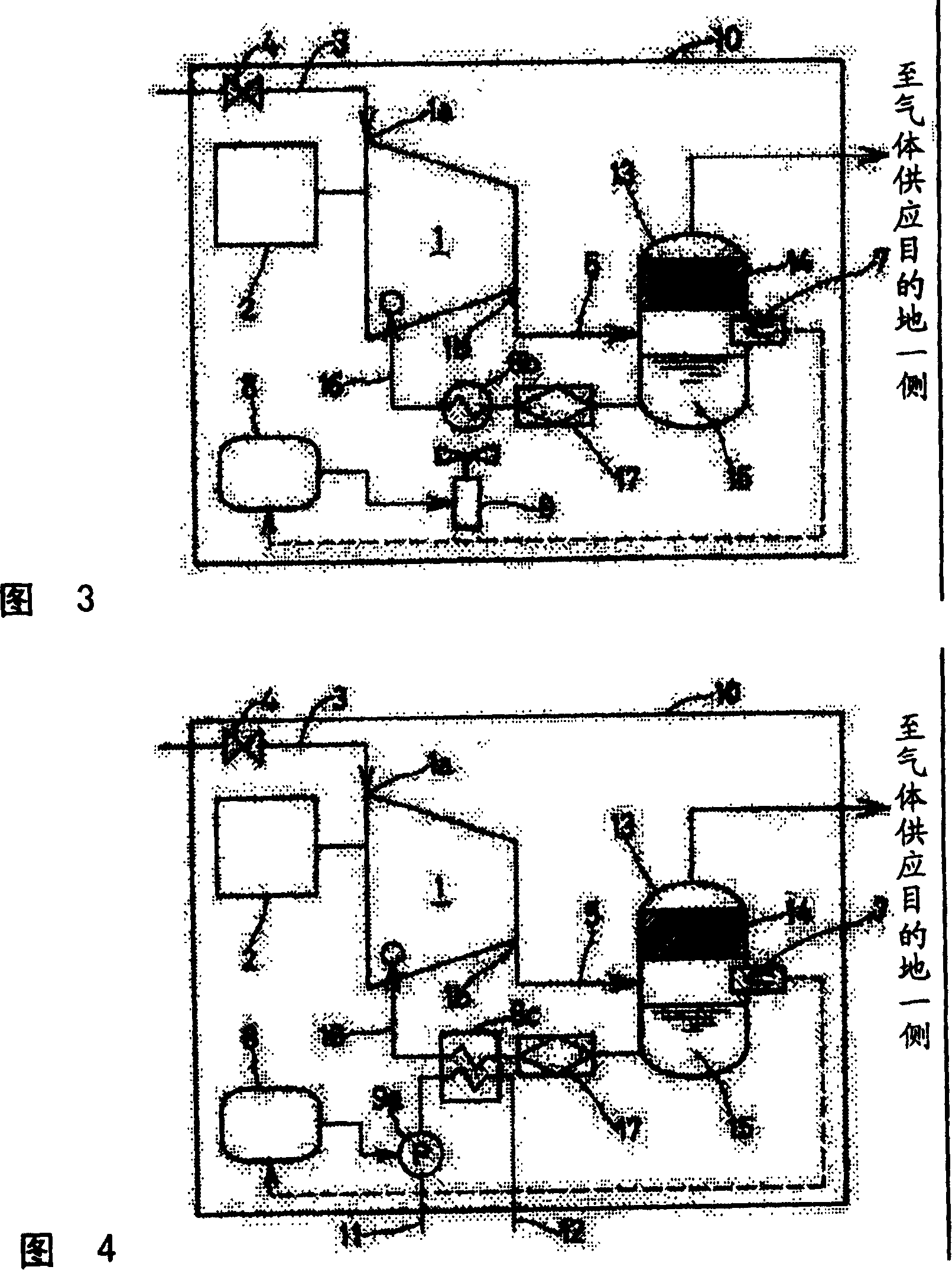

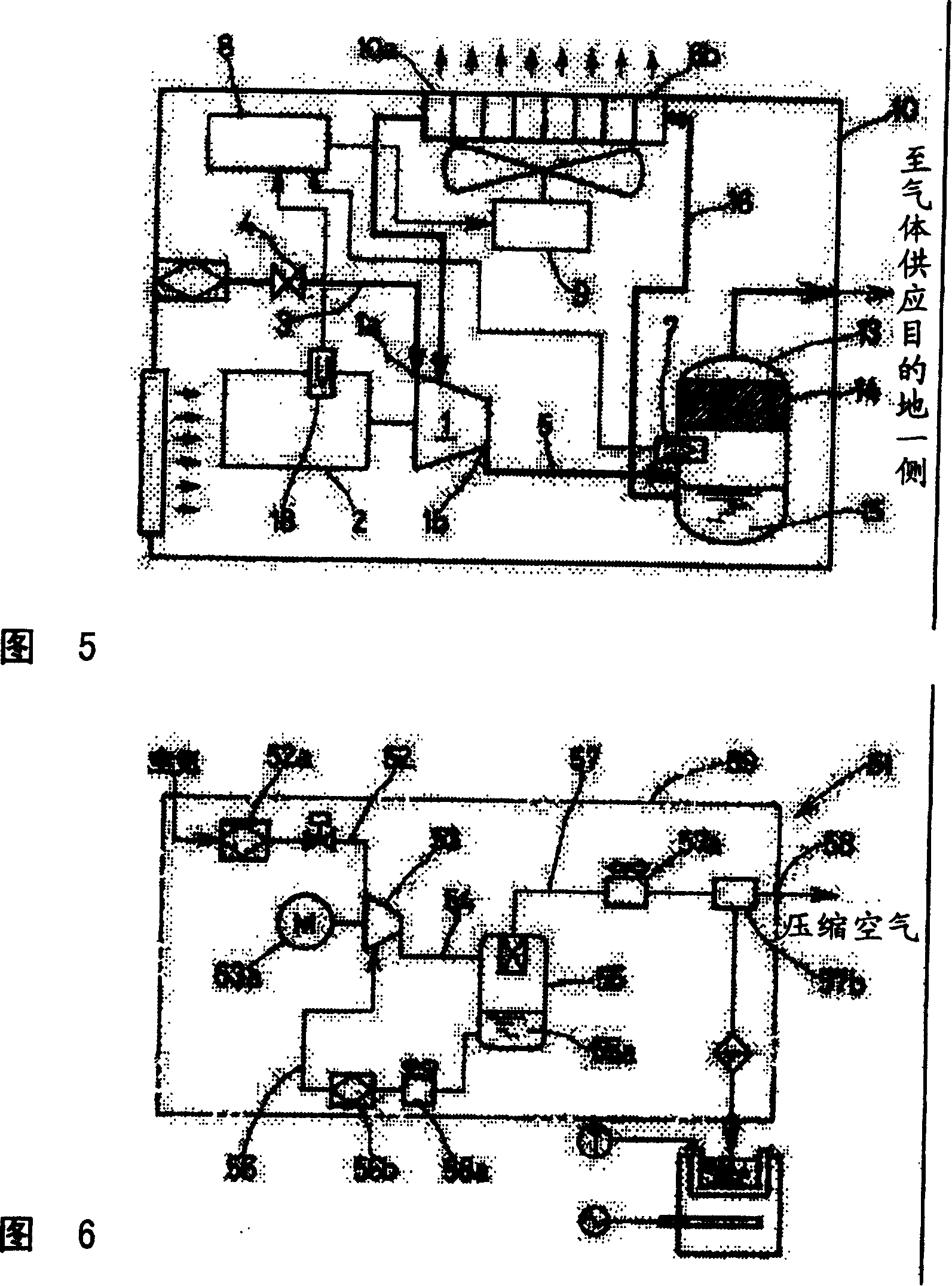

[0031] The compressor according to Embodiment 1 of the present invention will be described as an example in which the compressor is a self-contained compressor and the gas to be compressed is air. FIG. 1 is a schematic system diagram of a self-contained compressor according to Embodiment 1 of the present invention.

[0032] Symbol 1 shown in FIG. 1 is a compressor main body driven by a motor 2, and a suction flow path 3 formed by adding a flow regulating valve 4 to adjust the flow rate of suction air communicates with the suction port 1a of the compressor main body 1. . Furthermore, from the discharge port 1b of the compressor main body 1 to the supply destination side of the compressed and discharged discharge air (discharge gas) not shown in the figure, there is connected a discharge discharge system formed by adding an air-cooled heat exchanger 6 for cooling the discharge air. Flow path 5. On the downstream side of the heat exchanger 6 of the discharge flow path 5, a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com