Low-temperature phase-change cold storage material suitable for medical cold-chain transportation and preparation method of low-temperature phase-change cold storage material

A low-temperature phase change and cold storage material technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of insufficient product quality assurance, large subcooling degree and poor stability of cold storage materials, and achieves high latent heat. , Long holding time and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

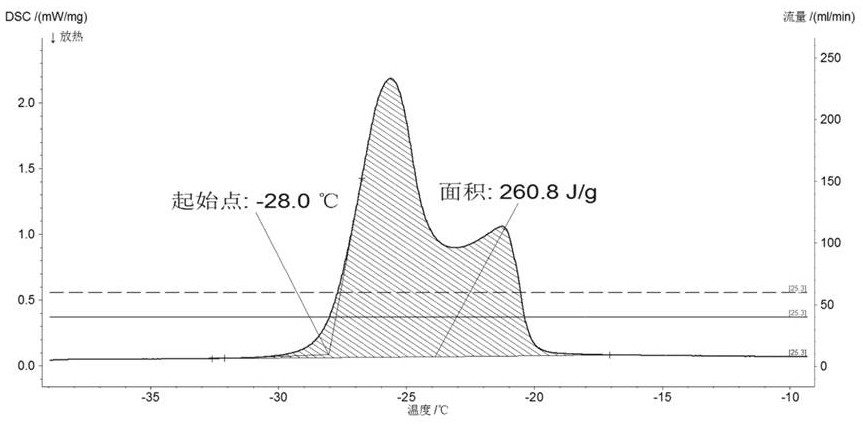

Embodiment 1

[0030] A method for preparing a low-temperature phase-change cold storage material suitable for medical cold chain transportation, comprising the following steps:

[0031] (1) In terms of mass percentage, add 19.45% sodium formate to 69.85% 35°C constant temperature ultrapure water, use inclined blades to open the turbine stirrer, and stir at a rate of 1300rpm for 5min;

[0032] (2) Add 6.2% ammonium chloride into the constant temperature salt solution at 35°C obtained in step (1), and turn on the turbine stirrer with inclined blades, the stirring rate is 800rpm, and the time is 5min;

[0033] (3) Add 1.5% trimethylolpropane to the constant temperature solution at 35°C obtained in step (2), and turn on the turbine stirrer with inclined blades at a stirring rate of 900 rpm for 7 minutes;

[0034] (4) Add 2% sodium polyacrylate to the constant-temperature mixed salt solution obtained in step (3), use the inclined blade to open the turbine agitator, the stirring rate is 6500rpm, ...

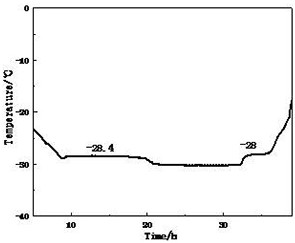

Embodiment 2

[0038] A method for preparing a low-temperature phase-change cold storage material suitable for medical cold chain transportation, comprising the following steps:

[0039] (1) In terms of mass percentage, add 21.5% sodium formate to 69.4% 35°C constant temperature ultrapure water, use inclined blades to open the turbine stirrer, and stir at 1500rpm for 6 minutes;

[0040] (2) Add 5.1% ammonium chloride into the 35°C constant-temperature salt solution obtained in step (1), and turn on the turbine stirrer with inclined blades at a stirring rate of 900 rpm for 7 minutes;

[0041] (3) Add 1% trimethylolpropane to the 35°C constant temperature solution obtained in step (2), and turn on the turbine stirrer with inclined blades, the stirring rate is 1100rpm, and the time is 8min;

[0042] (4) Add 1.5% sodium polyacrylate into the constant temperature mixed salt solution obtained in step (3), use the inclined blade to open the turbine agitator, the stirring rate is 5700rpm, the time i...

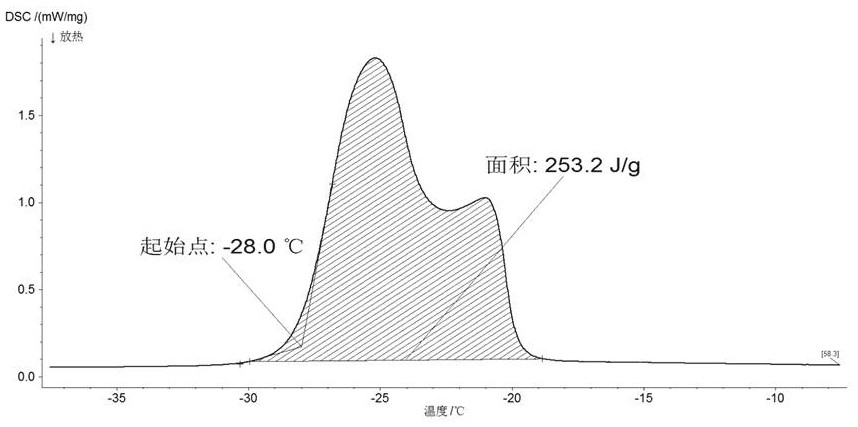

Embodiment 3

[0046] A method for preparing a low-temperature phase-change cold storage material suitable for medical cold chain transportation, comprising the following steps:

[0047](1) In terms of mass percentage, add 18.05% sodium formate to 75.25% 35°C constant temperature ultrapure water, use inclined blades to turn on the turbine stirrer, stir at 1000rpm for 4min;

[0048] (2) Add 4.4% ammonium chloride into the 35°C constant temperature salt solution obtained in step (1), and turn on the turbine stirrer with inclined blades, the stirring rate is 600rpm, and the time is 4min;

[0049] (3) Add 0.8% trimethylolpropane to the 35°C constant temperature solution obtained in step (2), and turn on the turbine stirrer with inclined blades, the stirring rate is 500rpm, and the time is 4min;

[0050] (4) Add 1% sodium polyacrylate to the constant temperature mixed salt solution obtained in step (3), use the inclined blade to open the turbine agitator, the stirring rate is 4800rpm, the time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com