Process for making puncture composite sensor for measuring pH and sensor therefor

A composite sensor and sensor technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of short service life, low precision and easy damage, and achieve the effects of long service life, fast response and stable electrode performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

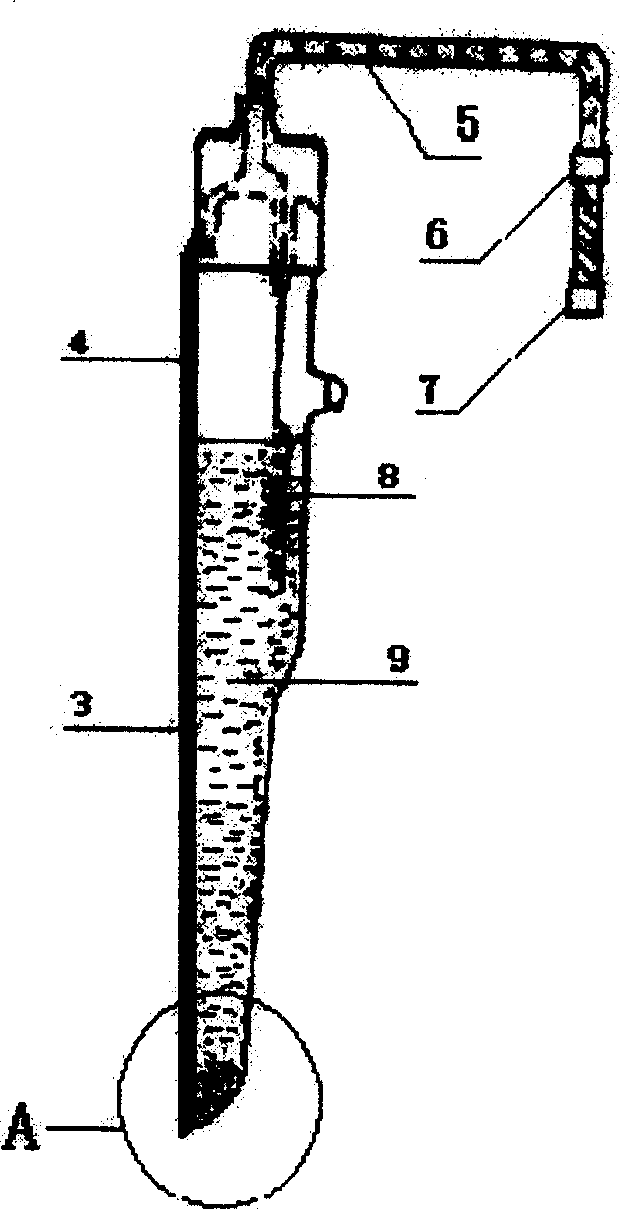

[0031] The preparation of inner liquid gel (9) is to add 4g agar powder into 100mL saturated potassium chloride KCl solution at a temperature of 25°C, and add 1g of silver chloride AgCl powder to make it precipitate, and stir evenly to prepare A liquid-filled gel (9) is formed; wherein saturated potassium chloride KCl, silver chloride AgCl and silver Ag form a reversible equilibrium system, and agar is the medium for forming the gel.

[0032] The filling liquid gel (9) prepared above is heated to 90 ℃, injects in the glass tube of sensor main body (4) at this temperature, then inserts the clean silver Ag wire into the filling liquid gel of the glass tube ( 9), when it is cooled to room temperature and is gelatinous, it is made into a solid exposed silver-silver chloride reference electrode (8); the pH indicating electrode (1) made above, exposed silver-silver The silver chloride reference electrode (8) and the inner liquid gel (9) are assembled together to form a piercing comp...

Embodiment

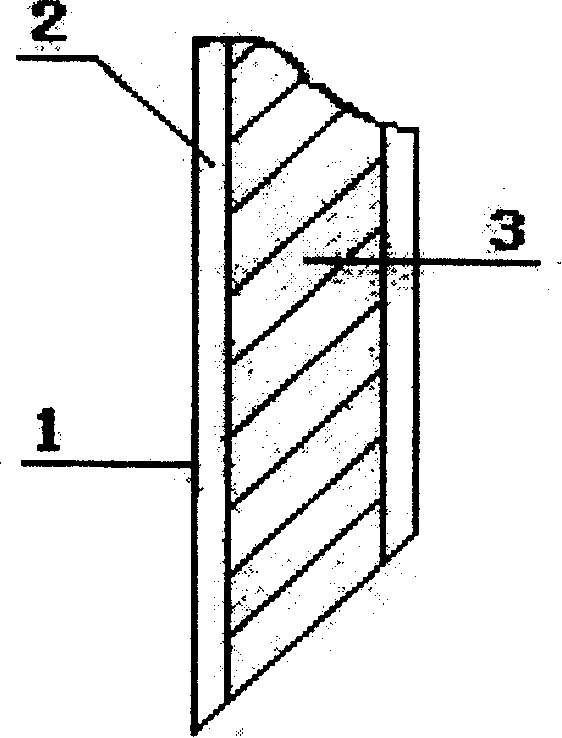

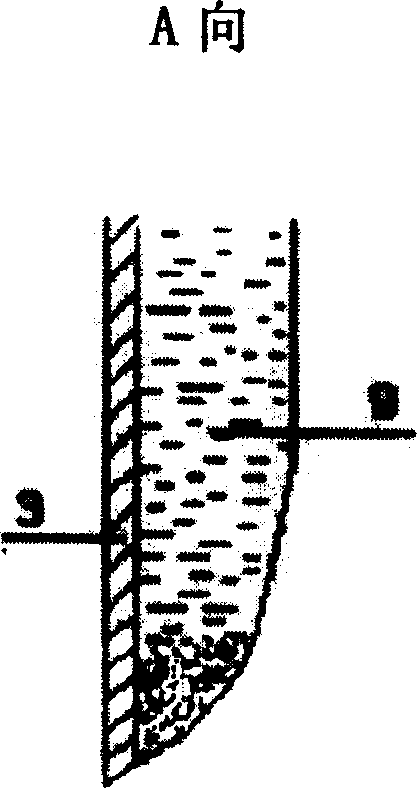

[0036]Take a section of 10cm glass tube containing ≤1% boron, which is used for blowing light bulbs, and fill it with 5 grains of antimony with a purity of ≥99.99%, heat the glass tube containing antimony grains and containing boron, and stretch it together with the glass tube When the diameter is Φ=2mm, when it is cooled, the antimony and the glass tube are combined into one, that is, the antimony-glass rod, which becomes the pH indicator electrode; the wall thickness of the glass tube is 0.5mm, and the inner diameter is 3mm;

[0037] Use silver wire with a diameter of 1mm and a purity of ≥99.9% to remove the oxide layer and oil stains, and then clean the surface with 1mol / L sodium hydroxide NaOH solution, 99% acetone solution, 99% ethanol solution and deionized water stand-by;

[0038] At 25°C, add 4g of agar powder and 1g of silver chloride AgCl powder to 100mL saturated potassium chloride KCl solution to make it precipitate, and stir evenly to make the filling liquid gel; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com