High actuating torque low operating power three phase capacitane type bisquirrel motor

A technology of starting torque and operating power, applied in the field of electric motors, can solve the problems of large horse-drawn trolleys, low power factor, high price, etc., and achieve the effect of solving the phenomenon of large-drawn trolleys, high starting quality factor, and high power factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

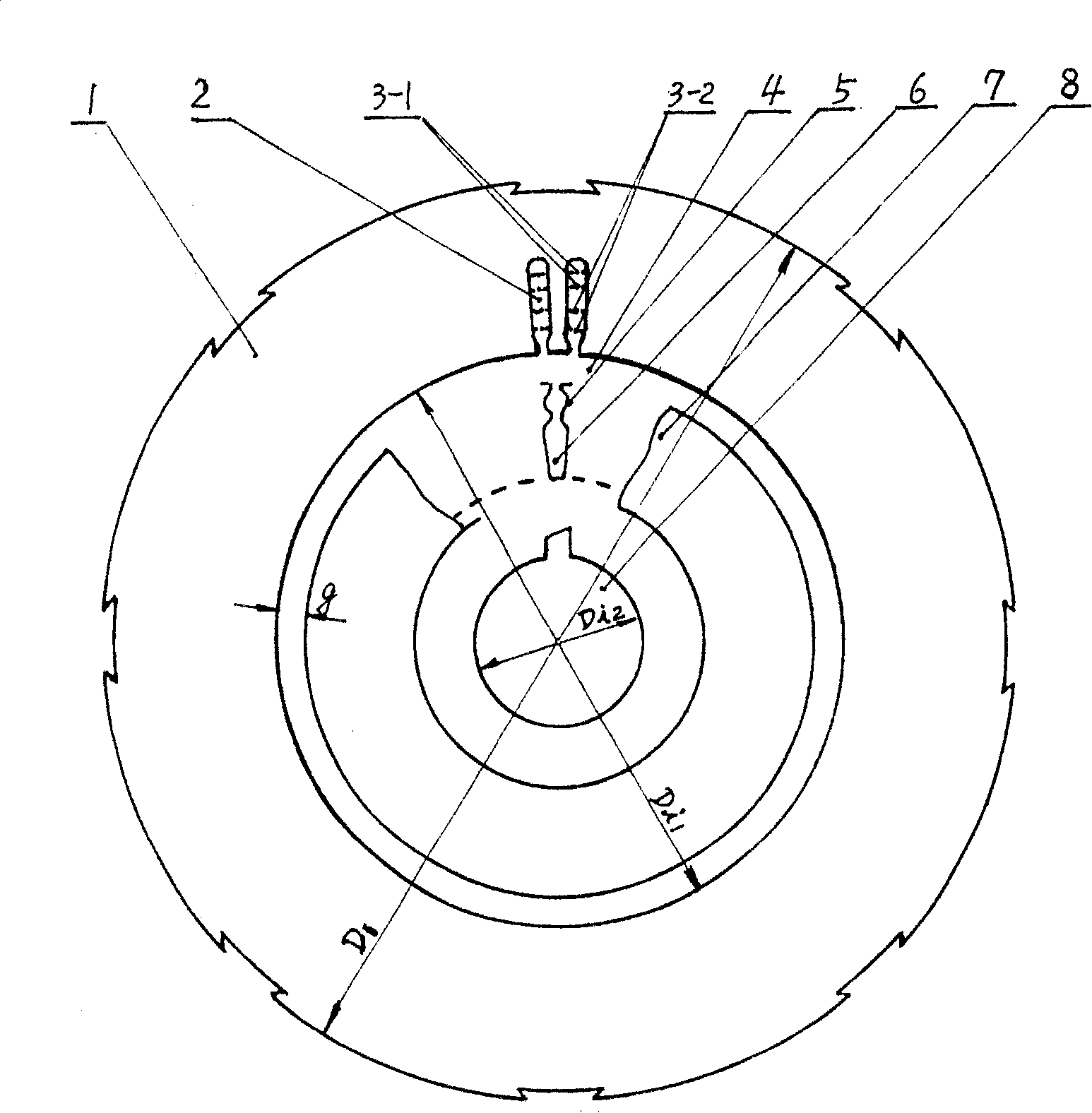

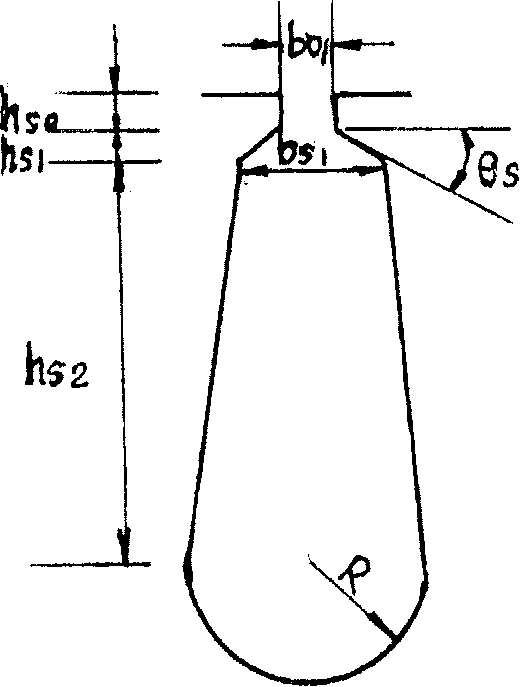

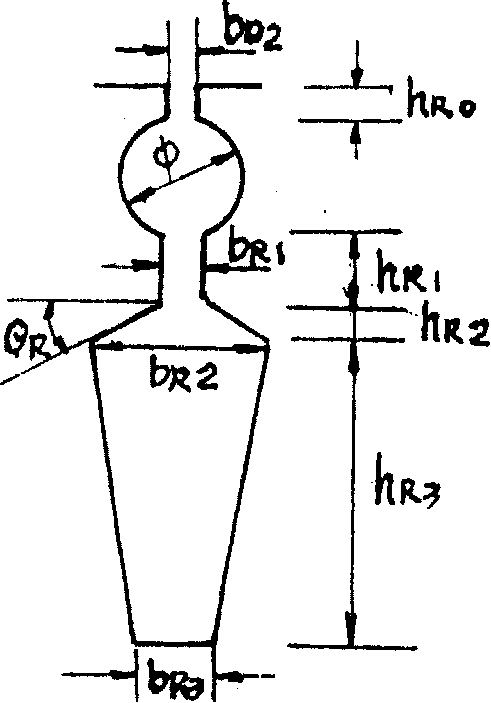

[0016] Refer to attached figure 1 , the motor is composed of stator 1, rotor 4 (rotor guide bar 6, rotor end ring 7) and shaft 8, and its characteristic is that two sets of low-harmonic concentric three-phase symmetrical phase-shift double-layer are embedded in the motor stator slot 2 Windings 3-1 and 3-2, one set of compensation winding 3-1 is a low-harmonic concentric three-phase symmetrical phase-shift double-layer winding, each phase is connected in series with a capacitor C, and the capacitor C=70μF, and the compensation winding 3-1 is embedded At the bottom of the stator slot 2 in the lower part of the stator slot 2, the working winding 3-2 is a low-harmonic concentric three-phase symmetrical phase-shifting double-layer winding, and the working winding 3-2 is embedded in the upper part of the stator slot 2. At the notch; the outer diameter of the iron core of the stator 1 D 1 =400mm, inner diameter D i1 =285mm, stator core length L=225mm, rotor 4 core inner diameter D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com