Vacuum mechanical-arm

A vacuum manipulator and arm technology, applied in the direction of manipulators, program control manipulators, conveyor objects, etc., can solve the bottleneck of vacuum manipulator transmission capacity and other issues, achieve the effect of improving transmission efficiency, optimizing motion path, and achieving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

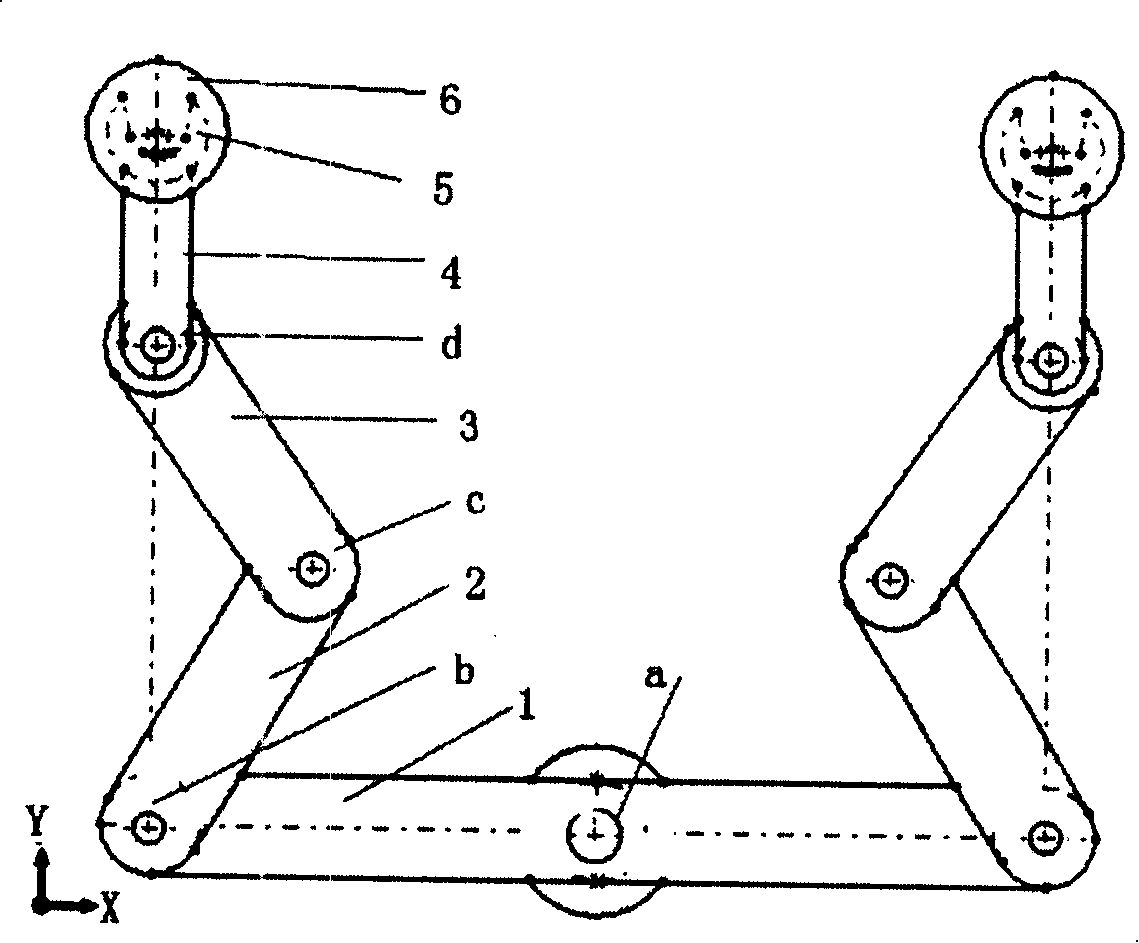

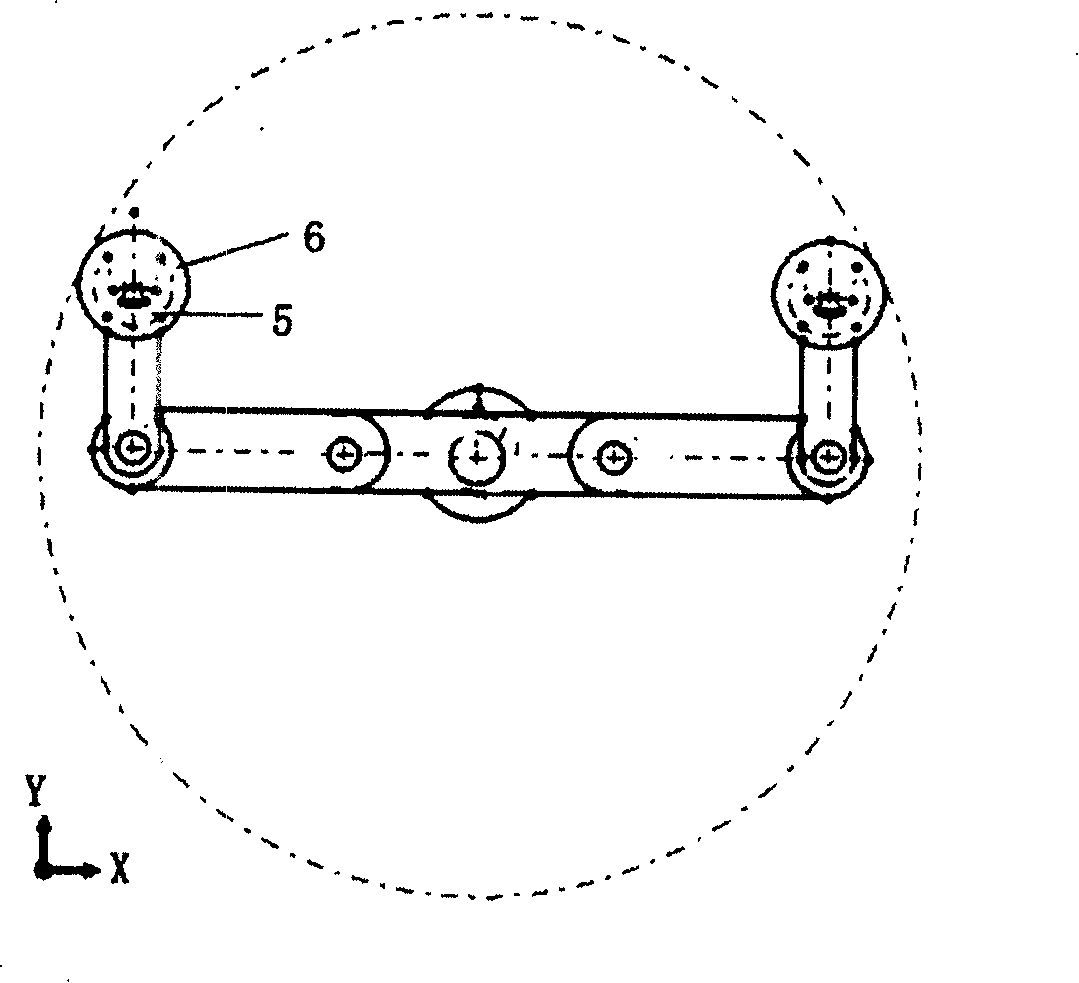

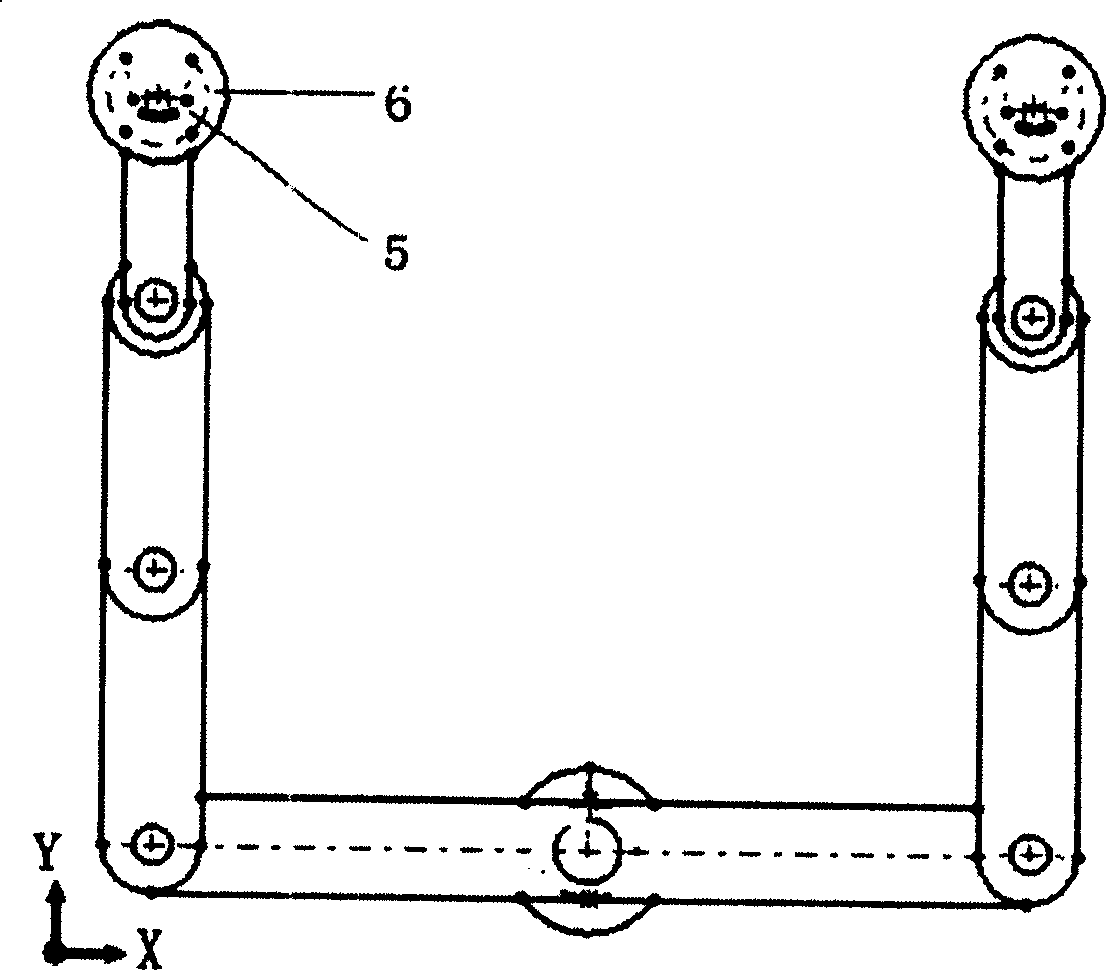

[0027] see figure 1 , the vacuum manipulator of the present invention includes a fixed arm 1 (this arm can also be referred to as the first arm), the fixed arm is fixed on the drive shaft of the motor through a hinge structure, and is located at the center of the vacuum transfer chamber. The two ends of the arm 1 are symmetrically arranged with the second arm 2, the third arm 3 and the fourth arm 4. The arms are connected by a hinge structure, and the free end of the fourth arm 4 is provided with a terminal receiving device for supporting wafers. Actuator 5, the end effector is fixed on the fourth arm 4 through threaded connection, so the compatibility of 200mm wafer and 300mm wafer 6 can be realized by replacing the end effector at the threaded connection according to the process requirements; Software control always makes the center of the end effector 5 move on the line perpendicular to the center of the chamber and the center of the motor drive shaft. Therefore, no matter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com