Electric device and method for spinning generation and collection

A collection device and electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of small collection range and poor fiber orientation, achieve broad application prospects and expand the flexibility of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

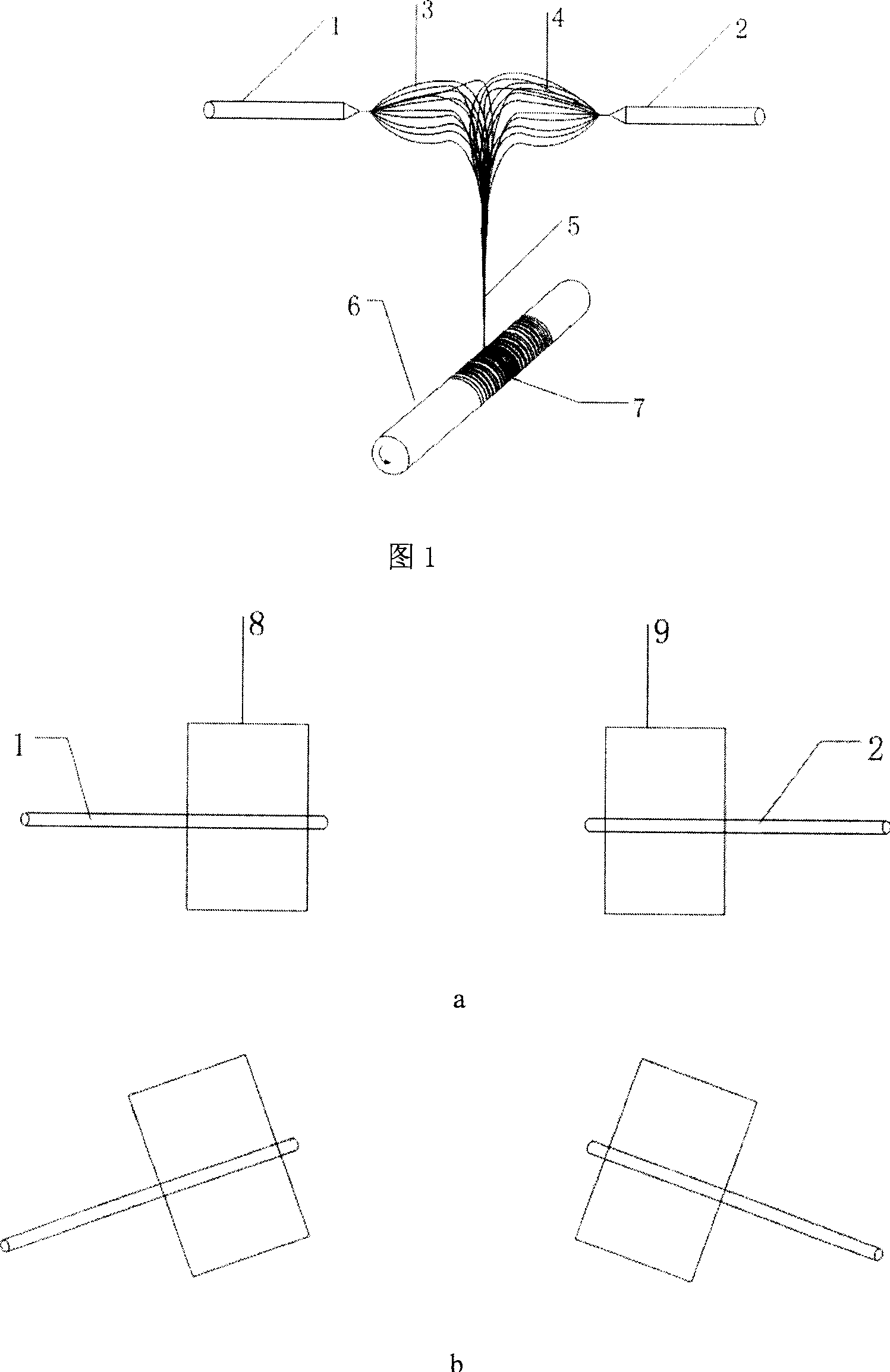

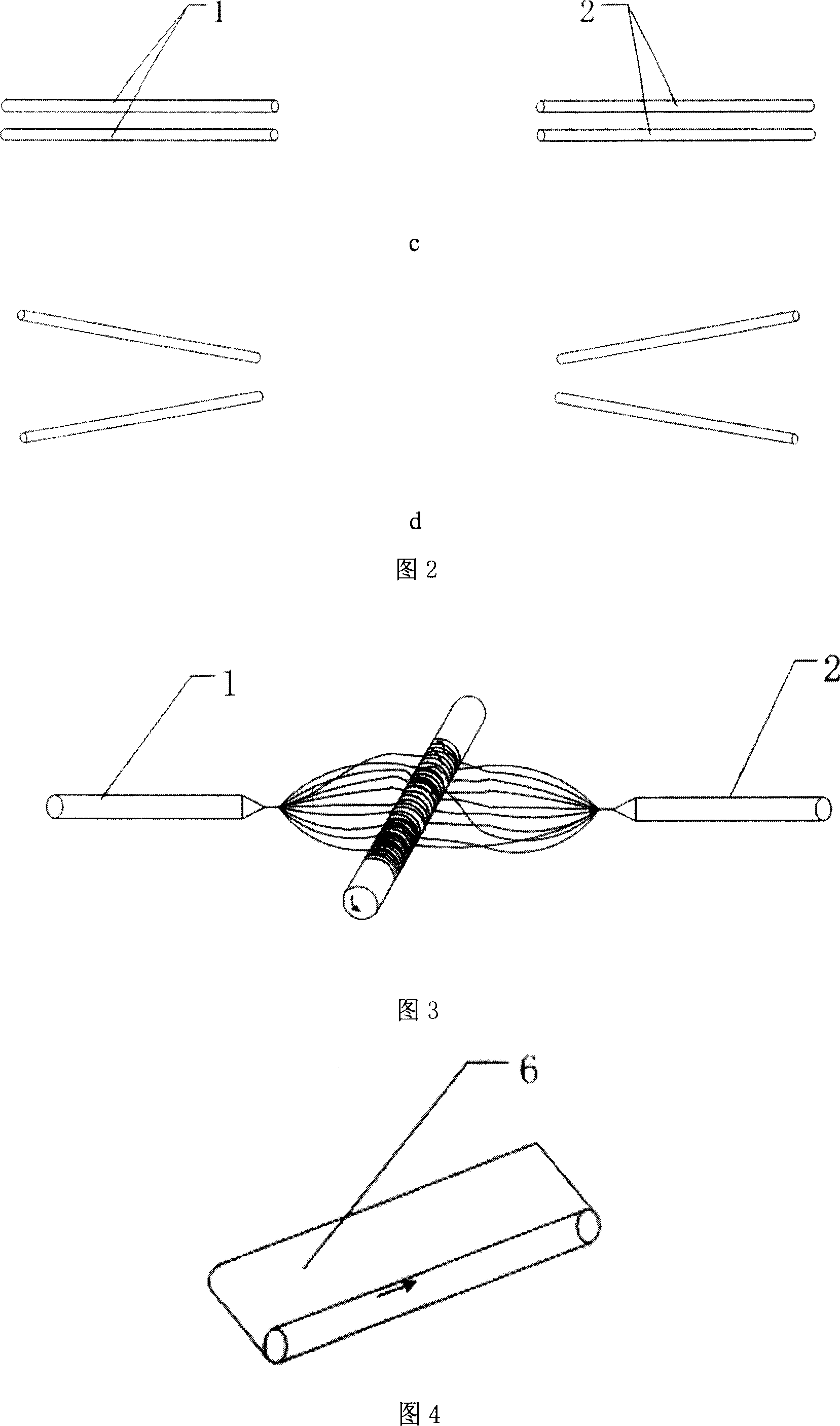

example 1

[0049] 1. Use the PVA aqueous solution with a mass percentage of 7% as the working liquid, put it into the air pressure liquid supply device and connect it with two nozzles;

[0050] 2. Adjust the supply flow rate of the two nozzles to 0.1μl / min;

[0051] 3. Make the two nozzles face each other, and adjust the distance between them to 30cm;

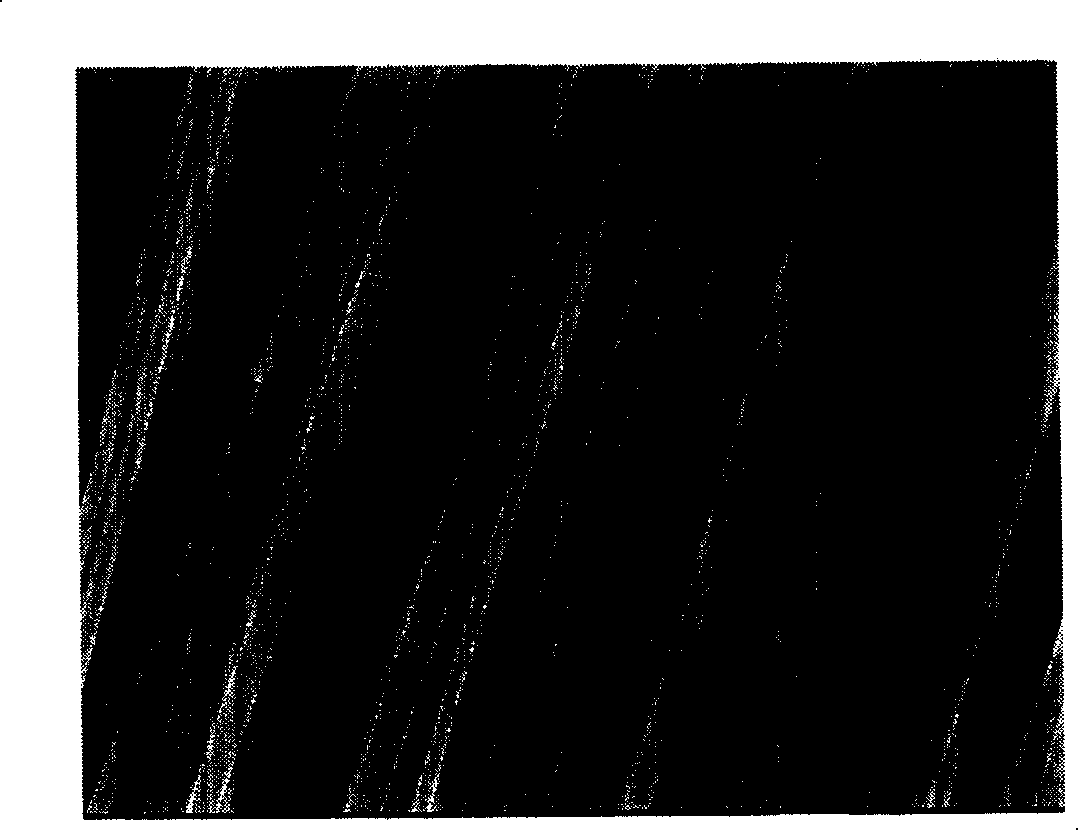

[0052] 4. Use a polytetrafluoroethylene tube with a diameter of 6mm as the collection device, and adjust the vertical distance between it and the two nozzles to be 5cm.

[0053] 5. Adjust the rotating speed of the cylinder to 3000rpm;

[0054] 6. Turn on the positive and negative high-voltage power supplies, and adjust the voltages to 7kV and -7kV respectively. Use an insulating rod to draw the ejected fiber bundle to the surface of the Teflon tube and start collecting and spinning.

example 2

[0056] 1. Take 10% PVA aqueous solution as the working liquid, put it into a dual-channel syringe pump and connect it with two nozzles;

[0057] 2. Adjust the supply flow rate of the two nozzles to be 3μl / min;

[0058] 3. Make the two nozzles face each other, and adjust the distance between them to 2cm;

[0059] 4. Use a metal cylinder with a diameter of 40mm as the collection device, and adjust the vertical distance between it and the two nozzles to be 15cm.

[0060] 5. Adjust the rotation speed of the cylinder to 1000rpm;

[0061] 6. Turn on the positive and negative high-voltage power supplies, and adjust the voltages to 2kV and -2kV respectively. The ejected fiber bundles are drawn to the surface of the metal cylinder using insulating rods to start collecting and spinning.

example 3

[0063] 1. Use 10% PVA aqueous solution as the working liquid, put it into a dual-channel syringe pump and communicate with two nozzles;

[0064] 2. Adjust the flow rates of the positive and negative nozzles to 2μl / min and 7μl / min respectively;

[0065] 3. Make the two nozzles face each other, and adjust the distance between them to 20cm;

[0066] 4. Use a metal cylinder with a diameter of 40mm as the collection device, and adjust the vertical distance between it and the two nozzles to be 20cm.

[0067] 5. Adjust the rotation speed of the cylinder to 1000rpm;

[0068] 6. Turn on the positive and negative high-voltage power supplies, and adjust the voltages to 7kV and -7kV respectively. The ejected fiber bundle is drawn to the surface of the metal cylinder by means of airflow control, and the collection and spinning are started.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com