Vacuum cleaner with preseparating structure

A vacuum cleaner and pre-separation technology, applied in vacuum cleaners, suction filters, household appliances, etc., can solve the problems of high dust collection efficiency and low energy consumption, and achieve the effects of small system resistance, load reduction, and overload suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

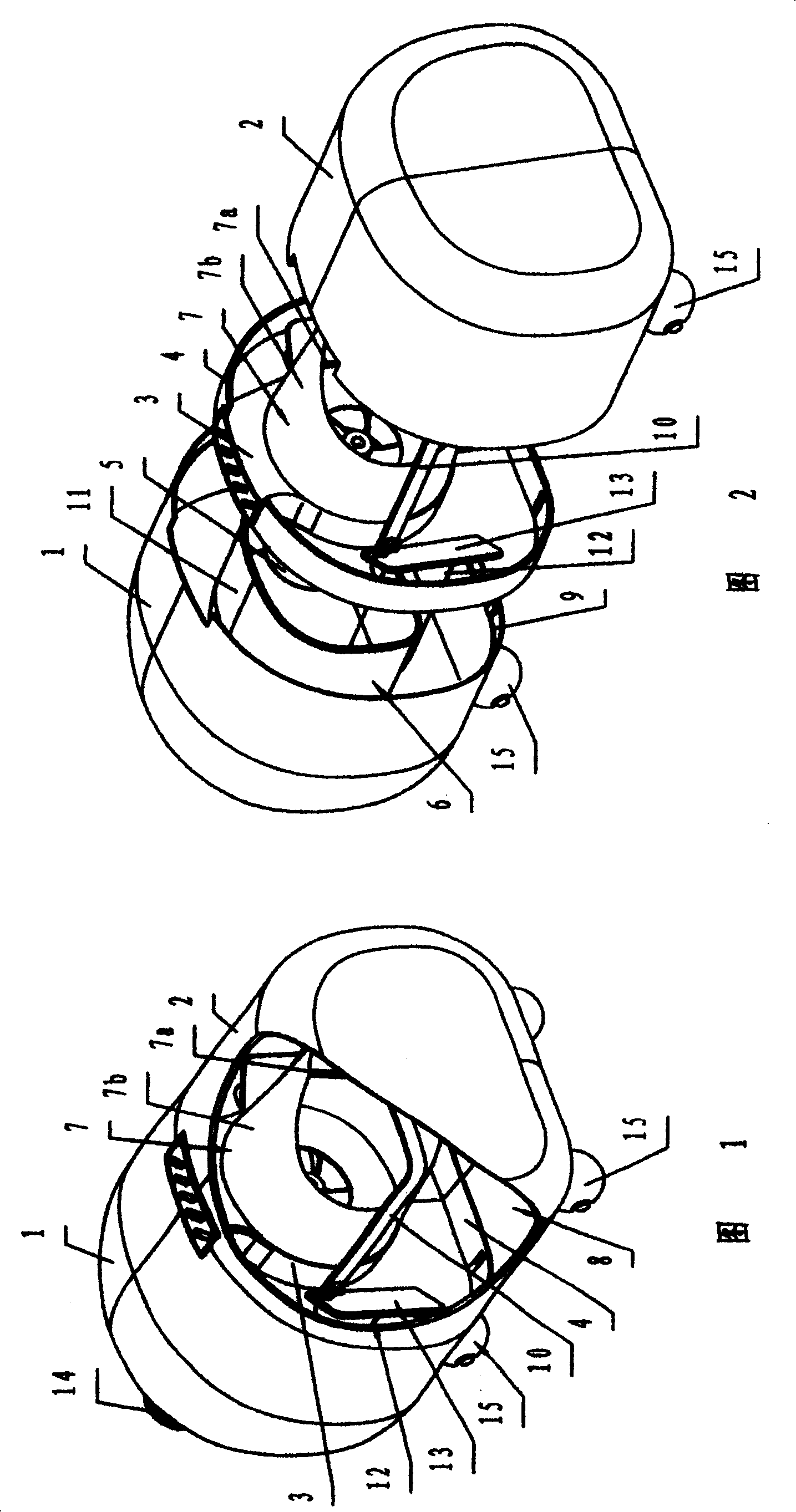

[0016] Referring to Fig. 1 or Fig. 2, this embodiment is a horizontal structure main body.

[0017] Referring to Figure 1 or Figure 2, the body 1 and the card cover 2 that constitute the main body are respectively provided with positioning steps 9, the body 1 and the card cover 2 are respectively fitted from the two ends of the support seat 4, and the support seat 4 is clamped between them . The space in the housing is divided into two laterally by the support base 4 , where the motor 5 is located at one end is the air intake passage 6 , and the filter 7 is located at the end where the dust collection chamber 8 is located. The filter 7 is a bag filter, which is composed of a filter bag 7b and a disc-shaped frame 7a arranged at the bottom of the filter bag 7b. On the U-shaped bracket 10, the U-shaped bracket 10 is fixed on the casing side of the blower fan 3.

[0018] Referring to FIG. 2 , the motor 5 is provided with a crown casing 11 , and the root of the casing 11 is fixed...

example 2

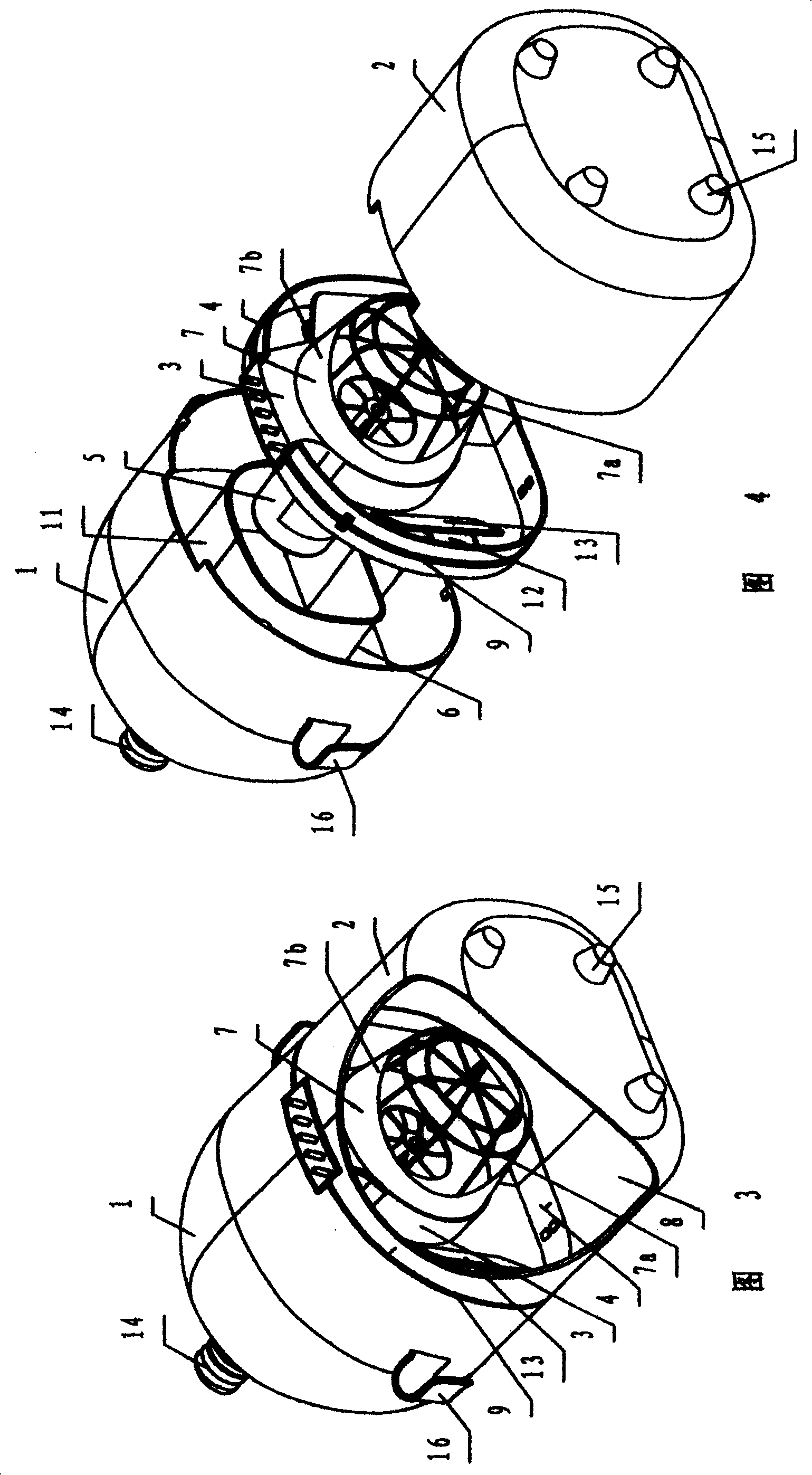

[0023] Referring to Fig. 3 or Fig. 4, this embodiment is a main body of a portable vacuum cleaner that can be used on the back.

[0024] Referring to Fig. 3 or Fig. 4, the fan 3 is installed on a disc-shaped supporting base 4, and the surface of the supporting base 4 is provided with an annular positioning boss 9, and the body 1 and the card cover 2 constituting the main body are respectively fitted from both ends, and the supporting base 4 is sandwiched between the two.

[0025] Referring to Fig. 3 or Fig. 4, the filter 7 is formed by setting a cloth bag 7b on the outer surface of a crown grille cover 7a, and is fixed on the inlet of the blower fan 3 through the crown grille cover 7a.

[0026] Referring to FIG. 3 or FIG. 4 , the two sides of the body 1 and the card cover 2 are provided with straps 16 , and the bottom surface of the card cover 2 is provided with supporting feet 15 .

[0027] The implementation method of this embodiment other than the above is the same as that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com