Vertical dryer

A vertical dryer and material elevator technology, applied in dryers, drying, heating devices and other directions, can solve problems such as drying failure, material adhesion and loss in the machine, and achieve effective control of dust and production quality. The effect of stable and high output per hour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

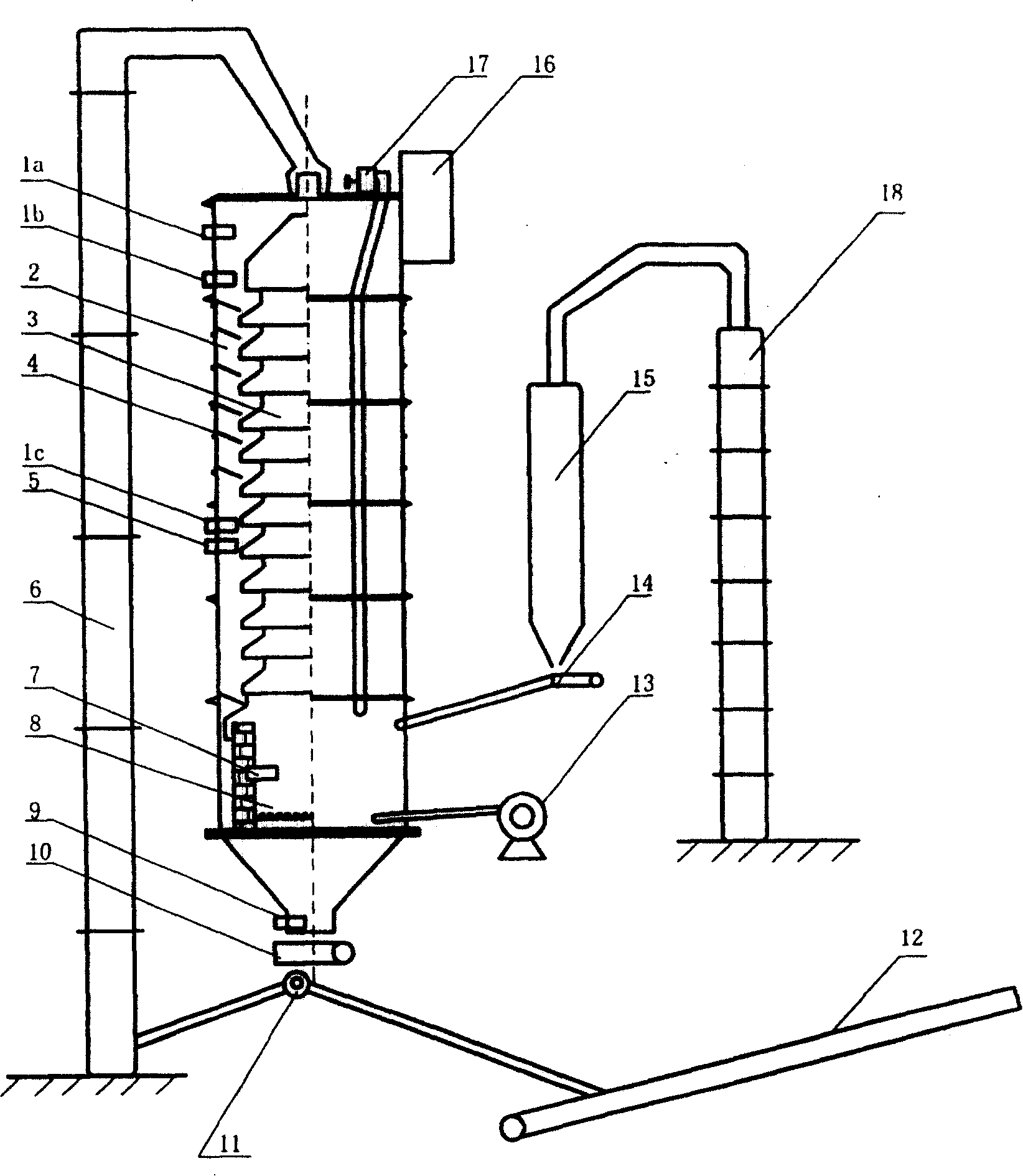

[0020] Main structure of the present invention sees figure 1 . The vertical drying furnace is composed of a cylinder body, a heat source placed in the cylinder body and a material hoist, etc. The material hoist 6 is connected to the material inlet on the upper part of the cylinder body 2 through a conveying device, and the heat source 8 placed in the cylinder body 2 is Fluidized furnace and the furnace is located in the middle of the cylinder bottom.

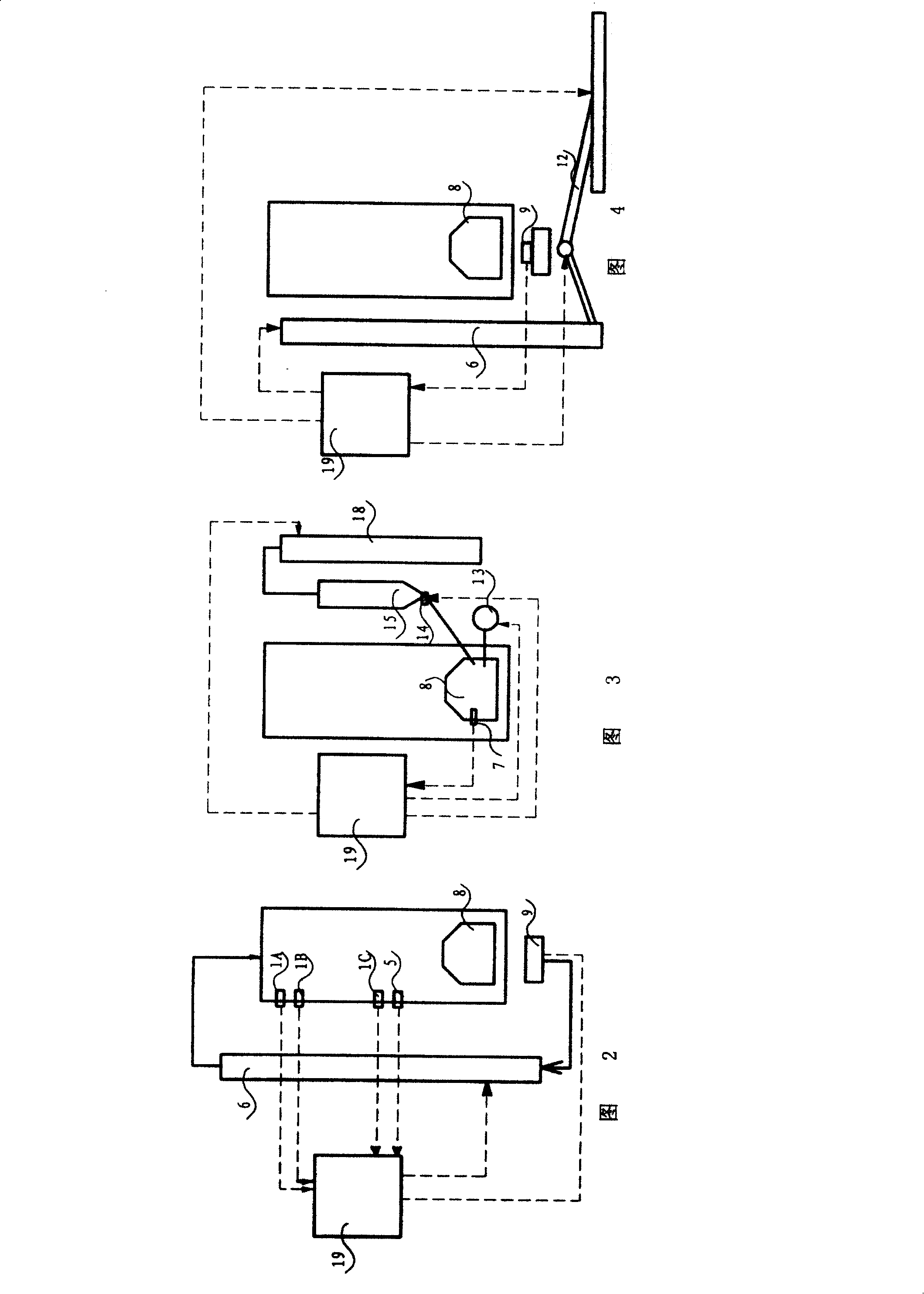

[0021] The drying equipment further includes an automatic control device 19, and several level gauges 1A, 1B, 1C and temperature measuring instruments 5, material hoists 6, material level gauges 1A, 1B, 1C and measuring instruments are arranged on the cylinder wall. The thermometer 5 is electrically connected with the automatic control device 19 . This part can be seen in Figure 2. The working principle is: if the material is already at the position of the material level indicator 1A, it will indicate that the material in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap